The Art of Owning & Operating Rubber Calenders

Choosing the right Rubber Calender is important; learning to operate it smartly is equally key for your success with this machine. This edition covers all these aspects in a descriptive manner.

Choosing the right Rubber Calender is important; learning to operate it smartly is equally key for your success with this machine. This edition covers all these aspects in a descriptive manner.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

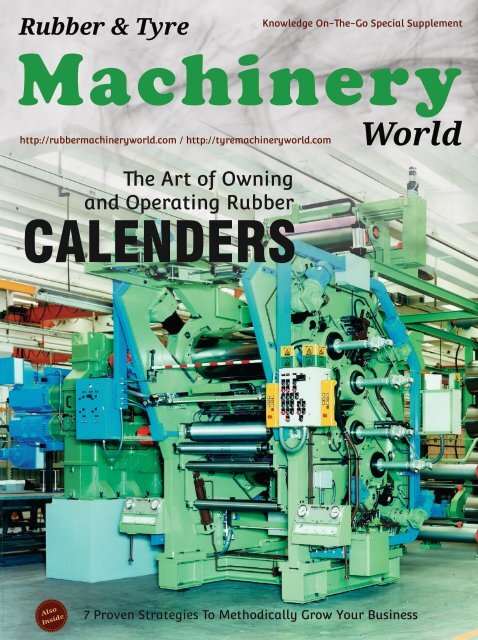

<strong>Rubber</strong> & Tyre<br />

Knowledge On-<strong>The</strong>-Go Special Supplement<br />

Machinery<br />

http://rubbermachineryworld.com / http://tyremachineryworld.com<br />

World<br />

<strong>The</strong> <strong>Art</strong> <strong>of</strong> <strong>Owning</strong><br />

and <strong>Operating</strong> <strong>Rubber</strong><br />

CALENDERS<br />

Also<br />

Inside<br />

7 Proven Strategies To Methodically Grow Your Business

Contents<br />

<strong>Rubber</strong> & Tyre<br />

Machinery<br />

http://rubbermachineryworld.com / http://tyremachineryworld.com<br />

Knowledge On-<strong>The</strong>-Go Special Supplement<br />

World<br />

July 2016<br />

8COVER STORY<br />

<strong>The</strong> <strong>Art</strong> <strong>of</strong> <strong>Owning</strong><br />

and <strong>Operating</strong><br />

<strong>Rubber</strong> <strong>Calenders</strong><br />

A cover story that you will like for all the right<br />

reasons as it covers the different facets <strong>of</strong><br />

rubber calenders.<br />

5<br />

37<br />

INSIGHT<br />

7 Proven Strategies To Methodically<br />

Grow Your Business<br />

RUBBER&TYREMACHINERYWORLD<br />

INFORMATIONONEQUIPMENT,TECHNOLOGY,INNOVATION&SUPPLIERS<br />

KNOWLEDGE-ON-THE-GO<br />

Through A Gadget Of Your Choice<br />

<br />

INFORMATION PORTAL | E-MAGAZINES | INTERVIEWS | KNOWLEDGE PARTNERS | DOWNLOADS<br />

........... And More

| Editor’s Note |<br />

<strong>The</strong> <strong>Art</strong> <strong>of</strong> <strong>Owning</strong> & <strong>Operating</strong> <strong>Rubber</strong><br />

<strong>Calenders</strong><br />

Calendering is one <strong>of</strong> the oldest rubber processing<br />

technologies. This is a mechanical process by which rubber<br />

is pressed into textiles (cloth, fabric, tire cord) forming<br />

composite sheets.<br />

<strong>Rubber</strong> Calendering is classified into two based on what you<br />

are calendering. Your guiding principle for calender line<br />

operation should be consistency and continuity.<br />

<strong>The</strong> machinery that helps you do rubber calendering is<br />

known as a <strong>Rubber</strong> Calender and it performs various<br />

functions. This is a heavy-duty machinery consisting <strong>of</strong><br />

two or more rolls that revolve in opposite directions.<br />

Today, you have a wide range <strong>of</strong> new and used calender<br />

purchase options.<br />

Choosing the right <strong>Rubber</strong> Calender is important; learning<br />

to operate it smartly is equally key for your success with<br />

this machine. This edition covers all these aspects in a<br />

descriptive manner.<br />

In addition, we have the ‘Insight’ section that is an<br />

infographic on ‘7 Proven Strategies To Methodically Grow<br />

Your Business’. I hope you enjoy this issue.<br />

Choosing the right<br />

<strong>Rubber</strong> Calender<br />

is important;<br />

learning to operate<br />

it smartly is equally<br />

key for your<br />

success with this<br />

machine.<br />

7<br />

As always, I welcome your feedback on<br />

rubbermachineryworld@gmail.com.<br />

Best Regards<br />

Prasanth Warrier<br />

rubbermachineri<br />

rubbermachineryworld<br />

+<strong>Rubber</strong>machineryworld1<br />

grp/home?gid=8252803<br />

rubbermachineri<br />

(Disclaimer: <strong>The</strong> pictures and statements in our special supplements are shared by the respective companies and/or sources mentioned.<br />

<strong>Rubber</strong> & Tyre Machinery World does not verify/vouch for their genuineness, hence will not be liable for any misrepresented data)<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

8<br />

Image: Rodolfo Comerio<br />

<strong>The</strong> <strong>Art</strong> <strong>of</strong> <strong>Owning</strong> and <strong>Operating</strong><br />

<strong>Rubber</strong> <strong>Calenders</strong><br />

Prasanth Warrier<br />

Calendering is one <strong>of</strong> the oldest rubber<br />

processing technologies. This is a<br />

mechanical process by which rubber is<br />

pressed into textiles (cloth, fabric, tire<br />

cord) forming composite sheets.<br />

<strong>The</strong> machinery that helps you do rubber<br />

calendering is known as a <strong>Rubber</strong><br />

Calender. <strong>The</strong> word 'calender' itself is a<br />

derivation <strong>of</strong> the word kylindros – the<br />

Greek word that is also the source <strong>of</strong> the<br />

word 'cylinder'.<br />

Despite its development in 1836,<br />

calendering as a process became<br />

popular only after the 1930's<br />

(almost 200 years later)!<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

Delayed rise to popularity<br />

In 1836 Edwin M. Chaffee, <strong>of</strong> the Roxbury<br />

India <strong>Rubber</strong> Company, patented a fourroll<br />

calender to make rubber sheet. He<br />

worked with Charles Goodyear with the<br />

intention to 'produce a sheet <strong>of</strong> rubber<br />

laminated to a fabric base'.<br />

Despite this development, calendering as a<br />

process became popular only after the<br />

1930's because it was difficult to adjust the<br />

desired gap between rolls. Consequently, it<br />

was difficult to get an accurate rubber<br />

sheet thickness.<br />

Since the calender machines became easier<br />

to adjust, features have evolved. Modern<br />

calenders' can achieve tolerances around<br />

±0.005mm and their lines are adaptive for<br />

most sophisticated precision requirements<br />

<strong>of</strong> your product.<br />

Purpose <strong>of</strong> <strong>Rubber</strong> Calendering<br />

In calendering process, you pass pre-selected<br />

fabric and rubber through a series <strong>of</strong> rolls to<br />

flatten, smoothen and sandwich the<br />

materials.<br />

- On the other hand, a 'supported' sheet has<br />

textile fabric or steel cord coated with a<br />

film <strong>of</strong> rubber (also known as 'skim stock<br />

rubber') on both sides and into the material.<br />

Supported rubber sheets give you higher<br />

strength or tear resistance.<br />

<strong>The</strong> adhesion <strong>of</strong> rubber to the fabric or steel<br />

cord is critical to final performance. And the<br />

rubber compound that you coat the fabric is<br />

different from the one used to make the<br />

tread or that which coats the cords.<br />

Coating <strong>of</strong> fabrics has been done for almost<br />

200 years. Steel cord and fabric cord topping<br />

is a process in your tire manufacturing.<br />

Specifications and tolerances for calendered<br />

cords are tough. So you will find it difficult<br />

to fulfill the thickness variation across the<br />

calendered ply and the cord density.<br />

For example, you use calendared textiles for<br />

casing, cap plies and chafers in tyre industry.<br />

And you use calendered steel cord for belts.<br />

Calendering process is also well adopted in<br />

plastic industry (say, PVC sheeting).<br />

Image: JM Machinery<br />

9<br />

Depending on your end-use, the calendered<br />

sheets could have multiple layers<br />

'sandwiched' together.<br />

A <strong>Rubber</strong> Calender can help you get either<br />

'supported' or 'unsupported' calendered<br />

sheets.<br />

- Unsupported' sheets contain only layers <strong>of</strong><br />

rubber that has been joined together.<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

Image: Maxxis Canada<br />

10<br />

Types <strong>of</strong> <strong>Rubber</strong> Calendering<br />

<strong>Rubber</strong> Calendering is classified based on<br />

what you are calendering, (A) Fabric<br />

calendering and (B) Steel cord calendering.<br />

Each <strong>of</strong> these is different yet similar in<br />

operations and sensitive to environment<br />

influence for your high quality product.<br />

This textile is arranged in a flat and parallel<br />

manner. Under proper tension they are<br />

continually pressed through two rolls.<br />

Simultaneously, you add the rubber<br />

compound to the opening area or nip<br />

between the rolls. As a result, a thin layer <strong>of</strong><br />

rubber is applied into top <strong>of</strong> and the bottom<br />

layers <strong>of</strong> the fabric.<br />

A. Fabric Calendering<br />

<strong>The</strong> materials that go into your fabric<br />

calendering are your s<strong>of</strong>tened rubber<br />

compound (from mills) and Nylon or<br />

Polyester from the Dip Unit.<br />

In this process, the tension, temperature<br />

and humidity are critical parameters <strong>of</strong><br />

your fabric cords before they are<br />

calendared with the rubber compound.<br />

And hence is the reason you will observe<br />

that the fabric cord is kept in a room<br />

(where temperature and humidity are<br />

controlled well) once this raw material<br />

arrives in your shop floor.<br />

<strong>The</strong>n you make this continuous sheet <strong>of</strong><br />

fabric and rubber go through many<br />

additional rolls to ensure that rubber is<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

12<br />

penetrated properly between the cords<br />

achieving the desired adhesion between<br />

rubber and the fabric.<br />

<strong>The</strong> sheets are cut at required angles so that<br />

the cords are set at predetermined angles<br />

across the sheet.<br />

Even inner liners for tyre manufacturing are<br />

calendered the same way into sheets <strong>of</strong><br />

required thickness and then cut into<br />

appropriate widths for use in tire<br />

construction.<br />

Finally, your calendered fabric sheets are<br />

wound into rolls with layers <strong>of</strong> woven fabric<br />

liner to prevent the surfaces <strong>of</strong> sheets from<br />

sticking together.<br />

B. Steel Cord Calendering<br />

In the tire industry, steel cord calendering is<br />

for the radial tires.<br />

Here, the body plies and reinforcing strips<br />

incorporate polyester cord that is coated in<br />

an adhesive liquid. This cord is passed<br />

between large, heated rolls <strong>of</strong> a rubber<br />

calender machine. Woven fabric is similarly<br />

prepared and calendered for the anti-chafing<br />

strips.<br />

Since your rubber compound will not adhere<br />

to bare steel, the steel cord wires for the steel<br />

belts are coated with a very thin layer <strong>of</strong><br />

brass. <strong>The</strong>se high-tensile brass-coated<br />

rubber-encased steel cords (multi-strand<br />

cables) become the steel belts.<br />

You pass preset number <strong>of</strong> steel<br />

cords under proper tension from<br />

the creel room on rolls through<br />

aligning combs into the calender<br />

where the wires are coated with<br />

a thin sheet <strong>of</strong> skim stock rubber.<br />

You may note that the steel cords come in<br />

various arrangements like cross-section <strong>of</strong><br />

pairs, triplets and so on.<br />

<strong>The</strong> brass-coated steel wires used in the<br />

manufacture <strong>of</strong> tire components are also<br />

extremely moisture sensitive. Hence, they<br />

must be protected in a temperature and<br />

humidity controlled environment – right<br />

from procurement, to during shipment<br />

and at the tire plant location. More<br />

importantly, any exposure to moisture can<br />

result in corrosion and a breakdown in<br />

rubber adhesion when calendered.<br />

At your plant, these wires are stored in an<br />

environmentally controlled 'Creel Room'<br />

until it is processed in your rubber calender.<br />

You pass a preset number <strong>of</strong> steel cords<br />

under proper tension from the creel room<br />

on rolls through aligning combs into the<br />

calender where the wires are coated with a<br />

thin sheet <strong>of</strong> skim stock rubber. For<br />

maximum adhesion, the rubber should also<br />

penetrate these steel cords. Maximum<br />

adhesion also means least rusting.<br />

<strong>The</strong>se steel cords are cut at specified angles<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

and widths for use in tire building process.<br />

In ground reality, the distance between the<br />

creel room and your rubber calender<br />

(varying between 20 – 60 feet depending on<br />

your layout) is usually not environmentally<br />

controlled and, hence the wire may be<br />

exposed to moisture prior to its being<br />

encapsulated in rubber.<br />

This problem is worsened by slowdowns,<br />

temporary shutdowns, humidity spikes and<br />

failure to adequately control temperature<br />

and humidity within the creel room. Once<br />

the belt wire becomes contaminated with<br />

moisture, it becomes more difficult to<br />

obtain proper adhesion <strong>of</strong> the rubber to the<br />

brass-coated wire.<br />

<strong>The</strong> strongest possible bond between the<br />

rubber and the belt wire is critical in the<br />

construction <strong>of</strong> your steel belted radial<br />

tyres.<br />

Judging Quality<br />

So, how do you judge the quality <strong>of</strong> a<br />

calendered sheet?<br />

Well, you could quantify the quality <strong>of</strong> your<br />

fabric calendered sheet in terms <strong>of</strong> your<br />

pre-desired<br />

- Thickness <strong>of</strong> the sheet<br />

- Spacing between cords<br />

- Number <strong>of</strong> cords and<br />

- Penetration <strong>of</strong> rubber into the space in<br />

between cords.<br />

Recently, an industry friend confided that<br />

many rubber good manufacturers look at a<br />

<strong>Rubber</strong> Calender as a 'mysterious rubber<br />

machinery'. Is it because <strong>of</strong> all this nuances,<br />

I wonder?<br />

Image: Cross-section <strong>of</strong> Radial Tyre<br />

13<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

14<br />

Image: Rodolfo Comerio<br />

Functions <strong>of</strong> <strong>Rubber</strong> Calendering<br />

1. Skim Coating or Topping: Here, rubber<br />

is coated on both sides <strong>of</strong> the substrate (i.e<br />

your fabric or steel cords). This operation<br />

strengthens the adhesion between rubber<br />

and the substrate. Your process decides<br />

whether you use a 3-Roll Calender or a<br />

4-Roll Calender.<br />

2. Frictioning: Here, you use calendering<br />

process to force rubber into the fabric<br />

weave. Frictioning imparts good<br />

adhesiveness. You deploy 3-Roll Calender,<br />

where the top and bottom rolls have a<br />

lower speed than the middle roll. 4-Roll<br />

<strong>Calenders</strong> cannot be used for Frictioning,<br />

because obtaining a speed difference<br />

between fabric and compound is difficult.<br />

3. Rolling: Here, you just allow hot rubber<br />

compound to pass through a 2-Roll Calender<br />

and get a continuous sheet <strong>of</strong> rubber <strong>of</strong><br />

thickness 3-4 mm.<br />

4. Embossing and Pr<strong>of</strong>ile Calendering: If<br />

you produce tread sections <strong>of</strong> cycle tires or<br />

involved in hand building <strong>of</strong> foot wear, you<br />

may choose a Calender with “patterns” on<br />

the rolls to produce pr<strong>of</strong>iled treads or<br />

patterned sheets. A step forward <strong>of</strong> Rolling,<br />

here you press a heavy engraved roll<br />

against hot rubber compound. You would<br />

consider this if your sheet needs a 'design'<br />

look. <strong>The</strong> engraved design <strong>of</strong> the rolls is<br />

transferred to your rubber sheets.<br />

Calendering operations need critical checks<br />

to ensure you get high quality products.<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

2-RollCalender<br />

Types <strong>of</strong> <strong>Rubber</strong> <strong>Calenders</strong><br />

A calendar is heavy-duty rubber machinery<br />

consisting <strong>of</strong> two or more rolls that revolve<br />

in opposite directions. <strong>The</strong> classification <strong>of</strong><br />

<strong>Rubber</strong> <strong>Calenders</strong> is based on<br />

1. <strong>The</strong> Number <strong>of</strong> rolls<br />

2. <strong>The</strong> Position or Orientation <strong>of</strong> the rolls<br />

4-RollCalender<br />

VerticalTypeCalender<br />

InclinedorTiltedTypeCalender<br />

VerticalStackor<br />

ʻIʼTypeCalender<br />

3-RollCalender<br />

» Also known as the “Universal<br />

Calender”.<br />

» Highly Flexible in usage.<br />

» Used for Frictioning and<br />

Skim Coating.<br />

» ‘I’ Type is the oldest & most<br />

common configuration.<br />

» Also known as the “Modern<br />

Calender”.<br />

» Different Configurations.<br />

» Used for Skim Coating.<br />

InvertedʻLʼTypeOffsetStackCalender<br />

OffsetStackTypeCalender<br />

16<br />

ʻIʼTypeorVertical<br />

StackCalender<br />

ʻZʼTypeOffset<br />

StackCalender<br />

Images from different sources only for representation purposes.<br />

Various rubber calender manufacturers<br />

<strong>of</strong>fer you different types. Today, you have<br />

a wide range <strong>of</strong> new and used calender<br />

purchase options (see box below) for your<br />

budget albeit <strong>of</strong> varying nature <strong>of</strong> quality,<br />

features and durability.<br />

Box: Excerpts from ‘Know Your Supplier’ Editions<br />

“Pelmar is there to <strong>of</strong>fer a total<br />

solution. Calendering lines sold<br />

as is or refurbished, along with<br />

mixing lines are amongst our<br />

largest sales chunk”<br />

Jacob Peled<br />

Executive Chairman<br />

Pelmar Engineering Ltd.<br />

“<strong>The</strong> wide range <strong>of</strong> quality new<br />

machinery made by Bharaj is wellaccepted<br />

worldwide. We <strong>of</strong>fer<br />

complete solutions.. I would say that<br />

our <strong>Calenders</strong> are high in demand.”<br />

Amardeep Singh Bharaj<br />

Director - Sales & Projects<br />

Bharaj Machineries Pvt. Ltd.<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

Information On Equipment, Technology, Innovation & Suppliers<br />

ReachMachineryBuyersFast.Anytime.Anywhere.<br />

On-<strong>The</strong>-Go With Your Info<br />

InfoPortal|DigitalMagazines|SocialMarketing<br />

ADVERTISE On<br />

RUBBER&TYREMACHINERYWORLD<br />

INFORMATIONONEQUIPMENT,TECHNOLOGY,INNOVATION&SUPPLIERS<br />

<br />

<strong>Rubber</strong> & Tyre Know A<br />

Machinery<br />

World<br />

<strong>Rubber</strong> & Tyre<br />

LEADER<br />

In 10 Questions<br />

Know Your<br />

Supplier<br />

rubbermachineryworld.com / tyremachineryworld.com<br />

<strong>Rubber</strong> & Tyre Equipment - Accessories<br />

Technology & Innovation<br />

Special Edition<br />

<strong>Rubber</strong> & Tyre<br />

Machinery<br />

World<br />

Because we publish digitally on our portal and promote on social<br />

media differently, Buyers get all information <strong>of</strong> Your Products &<br />

Solution anytime and anywhere - on any smart gadgets they<br />

use (Phone, Tab, Laptop or Desktop).<br />

1.DISPLAYYourProductsRegularlytoBuyers.<br />

2.COMMUNICATEYourCompetenciesDifferently.<br />

3.ATTRACTMoreBuyerstoYourBrandInformatively.<br />

For more details and your customized advertising, please email us<br />

at engage@rubbermachineryworld.com<br />

OptimizedRoIOfYourEquipmentMarketingFor<strong>Rubber</strong>&TyreIndustry

| CALENDERS |<br />

Choose Wisely. Operate Smartly<br />

8 Common Defects in <strong>Rubber</strong> Calendering<br />

And <strong>The</strong>ir Causes<br />

» Incorrect crowning <strong>of</strong> calender rolls<br />

» Excessive wearing <strong>of</strong> bearings<br />

» Improper operation <strong>of</strong> roll bending/zero clearance devices<br />

A more significant aspect <strong>of</strong> rubber<br />

calendering is operating this rubber<br />

machinery itself.<br />

» Roll temperature too high<br />

» High feed bank on to the rolls<br />

» Compound Stock warmed up for longer duration<br />

You could have chosen your rubber calender<br />

wisely but if you do not operate it smartly,<br />

you are likely to have defects in the<br />

calendered sheet.<br />

And when you know the causes leading to the<br />

defect (refer adjacent box), it becomes easy for<br />

you to investigate them deeper, resolve and<br />

continue production.<br />

» Insufficient break-down <strong>of</strong> your compound<br />

» Inadequate temperature control<br />

» Insufficient compound feed in the banks<br />

» Roll temperature too high<br />

» Large nip opening<br />

» Stock warm up for long time<br />

» High Compound in the nips<br />

» Insufficient nip opening between rolls<br />

» Excess compound in the nip<br />

» Improper roll crown<br />

» High compound viscosity<br />

18<br />

Image <strong>of</strong> A 3-Roll Vertical Calender from<br />

Bharaj Machineries Pvt. Ltd.<br />

» Improper Roll temperature<br />

» Improper running speed<br />

» Low compound viscosity<br />

» Improper warming <strong>of</strong> the compound<br />

» High viscosity compound<br />

» Improper warm up, high bank<br />

» Non uniformity <strong>of</strong> warm up<br />

» Lower roll temperature<br />

» Lower temperature in one <strong>of</strong> the rolls<br />

» High friction ratio<br />

» High calendering speed<br />

» Use <strong>of</strong> anisotropic fillers<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

7 Do's (And Don'ts) In Calendering<br />

Choosing the right rubber calender is<br />

important, learning to operate it smartly is<br />

equally key for your success with this<br />

machine. (Refer adjacent box)<br />

» Use lab approved fabric and compound only.<br />

» Clean the mill and calender guides including the<br />

equipment surrounding area before starting unit.<br />

» Load single strip <strong>of</strong> compound to both the cracker<br />

mills. <strong>The</strong>n feed these compound to your holding mill.<br />

» Always keep minimum compound in calender nips<br />

and mills.<br />

» Apply correct bleeder yarn.<br />

» Put identification tags before storing your calendered<br />

fabric in racks.<br />

» Close cooling water lines to mills when mills are not<br />

running<br />

Image: Reconditioned Calender<br />

(JM Machinery)<br />

» Do not over load your two-roll mills and calender nips.<br />

» Do not use held up compounds and dipped fabric.<br />

» Do not stop unit with fabric in the line.<br />

» Do not throw sheeted-out compound on the floor.<br />

» Do not store calendered fabric on floor.<br />

» Do not use damaged liner / baggy liner.<br />

» Do not run mills with cooling water lines closed.<br />

Solving issues with Calender Gauge<br />

Control<br />

Calender control issues directly affect your<br />

ability to properly control the rubber gauge<br />

or to produce a rubber sheet <strong>of</strong> consistent<br />

thickness.<br />

While these sources are closely related, for<br />

quicker understanding, you may visualize<br />

and attribute the two main sources <strong>of</strong><br />

variations in calendered gauge (or<br />

thickness) as,<br />

A. Mechanical Induced – variations when<br />

your calender is not operating under<br />

any load and are at ambient conditions.<br />

B. Force Induced – variations when your<br />

calender is in operation or is<br />

programmed to follow a set-process for<br />

your product under manufacturing.<br />

A. Mechanical Induced Variations<br />

Mechanically induced Calender Gauge<br />

variations relate directly to your rubber<br />

calender's mechanical condition. Thus it's<br />

basically a maintenance issue.<br />

While there are many maintenance issues<br />

that could affect your calender<br />

performance, the following five directly<br />

affect your rubber sheet's calendered gauge<br />

1. Grind Pr<strong>of</strong>ile <strong>of</strong> Calender Roll (Roll<br />

Crowning)<br />

You must periodically grind the calender<br />

rolls to establish the proper pr<strong>of</strong>ile. Your<br />

selected crown pr<strong>of</strong>iles is based on the range<br />

<strong>of</strong> your rubber compound hardness, type <strong>of</strong><br />

center compensation such as cross-axis or<br />

rolls bending, and roll width.<br />

19<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

a) No Crown - No Load b) No Crown - Uniform Load<br />

c) Uniform Load - Correct Crown d) Uniform Load - Correct Crown<br />

by bending roll to frame<br />

20<br />

e) Uniform Load - Correct Crown<br />

by bending reaction roll pair<br />

Source: GEA<br />

f) Roll Crossing<br />

<strong>The</strong> forces that separate the rubber calender<br />

rolls to bend apart in the center are partially<br />

compensated for, by grinding the center to a<br />

larger diameter. When the grind pr<strong>of</strong>ile is<br />

incorrect it will be difficult or even<br />

impossible for you to achieve a consistently<br />

flat-calendered rubber sheet.<br />

2. Eccentricity <strong>of</strong> Calender Roll or Run-out<br />

at Ambient Temperature<br />

Your calender rolls must be round and free<br />

<strong>of</strong> run-out at ambient temperature. Any run<br />

-out <strong>of</strong> the individual calender rolls will be<br />

amplified as the high spots and low spots<br />

periodically match up between the roll<br />

pairs. You can easily check this with dial<br />

indicators when the calender is running<br />

without rubber and with a small nip gap<br />

between the pairing rolls.<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

IKATAN TEKUN SDN. BHD.<br />

Your Partner in MALAYSIA for <strong>Rubber</strong> & Processing Machinery<br />

“Complete your Plant<br />

with your desired<br />

technology to your<br />

complete satisfaction<br />

on-time through us.”<br />

For your green-field and brown-field expansion<br />

or research projects in raw rubber and other<br />

technical rubber goods, we can source for you<br />

the right machinery to meet your technology<br />

requirements, and be your single-window<br />

support for after-sales service communication<br />

and training in Malaysia.<br />

For crucial projects, we train our personnel on<br />

the machinery we supply, to give you quick<br />

support.<br />

In addition, we are established and licenced<br />

contractors in Mechanical, Telecommunications,<br />

Electrical and Civil Works. Hence, we <strong>of</strong>fer you<br />

on turnkey basis - from equipment supply,<br />

material handling at site, equipment relocation,<br />

erection and installation, services and utilities<br />

to equipment commissioning.<br />

Contact me today to know more on our<br />

team, the equipment brands we partner<br />

with, our esteemed clients and full range<br />

<strong>of</strong> services for your rubber related projects.<br />

IKATAN TEKUN SDN. BHD.<br />

1st, Floor, Bangunan Sapura,Lot 2,<br />

Jalan Enggang, Kawasan Perindustrian PKNS,<br />

Hulu Kelang, 54200, Kuala Lumpur, Malaysia.<br />

Tel: (+6) 03 - 425.6 5.589 | Fax: (+6) 03 - 425.7 5.589<br />

AUTUS CONSULTING @2016<br />

Ahmad Fezal Bin Zakaria<br />

Sales & Project Manager<br />

* fezal@ikatantekun.com<br />

) (+6) 017-362.79.71

| CALENDERS |<br />

3. Condition <strong>of</strong> Calender Roll's Bearings<br />

You must ensure that your <strong>Rubber</strong> Calender<br />

roll bearings does not have excessive runout.<br />

Modern calenders employ precision anti<br />

-friction bearings with very small radial<br />

clearances. Excessive bearing clearance will<br />

result in the roll shifting during operation<br />

because the roll separating forces vary. This<br />

could appear as calender roll surface runout<br />

and will adversely affect your ability to<br />

control calendered gauge.<br />

4. Condition <strong>of</strong> Calender Roll's Water<br />

Passage<br />

Most modern calenders have drilled rolls.<br />

A drilled roll has water passages across the<br />

roll face beneath their surface. <strong>The</strong>se water<br />

passages effectively forms a radiator-like<br />

heat exchanger around the periphery <strong>of</strong><br />

your calender rolls.<br />

In an event when these passages become<br />

plugged, then non-uniform heat transfer<br />

will occur. And this result in a thermal 'out<strong>of</strong>-round'<br />

condition for your calender roll<br />

which subsequently has has the same effect<br />

as if the rolls were machined 'out-<strong>of</strong>-round'.<br />

You may avoid this situation by using only<br />

treated water and ensuring that the rolls<br />

are periodically flushed. You could also<br />

check this condition by comparing the roll<br />

run-out or eccentricity at ambient<br />

temperature with that at normal operating<br />

temperatures <strong>of</strong> your Calender.<br />

5. Condition <strong>of</strong> Calender Roll's End<br />

Actuator<br />

Of the different variants - manual, motordriven<br />

and hydraulic nip gap adjustments<br />

- electric screw actuators are the most<br />

common type <strong>of</strong> calender roll endpositioning-system.<br />

<strong>The</strong> screw and nut<br />

operate under very high loads and thus,<br />

you will observe, that they experience<br />

significant wear even with proper<br />

lubrication. As these actuators wear,<br />

backlash develops.<br />

When the backlash increases, the response<br />

to small changes or corrections deteriorate.<br />

Further with increased backlash the<br />

number <strong>of</strong> corrections required would<br />

increase, which in turn causes additional<br />

wear.<br />

23<br />

Image: Three-Roll Calender (Left) and Spare Calender Rolls With Bearings (Right)<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

Image: From Web<br />

24<br />

<strong>Rubber</strong> calenders that have fixed speed<br />

electric motors with mechanical brakes<br />

require periodic maintenance, particularly<br />

the brakes. Because sticky brakes will<br />

adversely affect your gauge control results.<br />

Thus, proper maintenance <strong>of</strong> all the above<br />

systems is crucial to your rubber calender<br />

performance and solves issues with<br />

gauge control that are mechanically<br />

induced.<br />

Proper maintenance <strong>of</strong> all the<br />

above systems is crucial to your<br />

rubber calender performance<br />

and solves issues with gauge<br />

control that are mechanically<br />

induced.<br />

B. Force Induced Variations<br />

Force induced variations result from the<br />

way your calender is operated. This is also<br />

an outcome from previous process steps<br />

such as your feed mill operation and<br />

compound consistency from rubber mixing.<br />

<strong>The</strong> separating forces generated during<br />

calendering are quite high! For example, if<br />

you have a 66 inch calender roll and<br />

producing 60 inch wide rubber sheet, the<br />

separating forces are in the range <strong>of</strong> 72,575<br />

Kg (approx. 160,000 lbs) to 136,000 Kg<br />

(approx. 300,000 lbs) at each actuator.<br />

Such high forces literally stretch your<br />

calender frame. Variations in these forces<br />

will therefore vary the amount <strong>of</strong> frame<br />

stretch and thus vary roll position and<br />

calendered gauge <strong>of</strong> your rubber sheet.<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

Here are five tips on how you could solve<br />

issues <strong>of</strong> calender gauge control from force<br />

induced variations.<br />

1. Keep the rubber calender running.<br />

that are open is higher. This differential<br />

heat transfer leads to different<br />

temperatures on your calender rolls. And<br />

therefore different degrees <strong>of</strong> calender<br />

roll expansion.<br />

Because stoppages cause your calender<br />

rolls to become egg-shaped, that in turn<br />

introduce significant gauge thickness<br />

variation.<br />

When you stop the rubber calender, the<br />

heat loss from the rolls is not uniform<br />

around their surface. Heat loss along the<br />

face <strong>of</strong> the rolls near adjacent rolls is<br />

minimal, while heat loss in other areas<br />

If you have a calender with rolls that is<br />

24 -30 inches in diameter, even a few<br />

degrees <strong>of</strong> expansion will result in<br />

‘out-<strong>of</strong>-roundness’ <strong>of</strong> each roll that you can<br />

measure. This is true when the calender<br />

is empty but even more so when there is a<br />

hot bank <strong>of</strong> rubber between the rolls. If<br />

you stop the calender for longer period,<br />

this condition worsens further.<br />

26<br />

Image: India’s first fully Automatic Tyre<br />

Cord Calender Line from Bharaj Machineries<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

Image Source: Web<br />

Your calender rolls run at different speeds.<br />

This means that periodically the high and<br />

low spots on the rolls match up. When high<br />

spots <strong>of</strong> adjacent rolls match up, you get<br />

thin gauge spots on your calendered sheet.<br />

When the low spots match up a thick spot is<br />

observed. So calender stops induced<br />

variation results in an effective doubling <strong>of</strong><br />

any roll “out-<strong>of</strong>-round” or run-out error.<br />

Typical short-term thermal out-<strong>of</strong>-round<br />

gauge variations are ± 0.0005 to .002 inches.<br />

Though thermal run-out is gradually<br />

reduced as the calender runs, it takes 15 to<br />

25 minutes for variations to be eliminated.<br />

Experts recommend you to adopt the<br />

following steps to minimize ‘thermal<br />

run-out’ <strong>of</strong> rubber calender,<br />

- Keep the calender running during warmup.<br />

If not done, severe thermal run-out can<br />

be introduced. You need to remember that<br />

the calender nip gap between adjacent rolls<br />

will be reduced as the rolls enlarge with<br />

their temperature increases. So, a good<br />

practice is to open your rubber calender at<br />

least 0.10 inches (2.54 mm) before starting<br />

to increase the roll temperature above<br />

ambient. Keeping the calender rolls turning<br />

during warm-up and cool-down also<br />

eliminates the possibility <strong>of</strong> warping the<br />

rolls.<br />

- Minimize calender stops.<br />

- When you stop the calender for longer<br />

time, remove the rubber from the banks.<br />

This is a good operating practice for the<br />

rubber compound as well.<br />

- When leader is going thru the calender,<br />

dropping <strong>of</strong>f tension and allowing the<br />

uncoated fabric or leader to go slack will<br />

permit running the calender during delays<br />

and personnel breaks. This will<br />

dramatically reduce thermal run-out.<br />

27<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

2. Increase the temperature by 5 degrees<br />

Celsius when you stop the rolls.<br />

loop. In this condition the roll surface<br />

temperature is below the water temperature.<br />

28<br />

Because this helps to maintain a more<br />

uniform roll surface temperature.<br />

You need to realize that the TCU<br />

(Temperature Control Unit) <strong>of</strong> your rubber<br />

calender controls the temperature <strong>of</strong> the<br />

water exiting the rolls and not the 'roll<br />

surface temperature'. This is an important<br />

distinction.<br />

Visualize these two scenarios –<br />

Scenario 1 – When the calender is not<br />

processing rubber (i.e. during warm-up and<br />

when the calender is stopped), the roll<br />

surface is losing heat to the atmosphere.<br />

Here, the TCU is actively heating the water<br />

Scenario 2 – When the calender is running<br />

and processing rubber, heat is being<br />

generated. Here, the TCU is cooling the water<br />

loop. In this condition the roll surface<br />

temperature is above the water temperature.<br />

From the above, you will realize that for a<br />

constant water circuit temperature, the roll<br />

surface temperature swings (above & below<br />

the water temperature) between the<br />

calender normal running condition and<br />

when the calender is stopped. This<br />

difference in roll surface temperature<br />

means that your rubber compound is being<br />

processed under varying conditions.<br />

Shrinkage and other properties <strong>of</strong> your<br />

processed compound will therefore vary.<br />

Image Source: Pelmar Engineering Ltd.<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

To minimize the differences from such<br />

processing condition variations, the roll<br />

temperatures should be increased whenever<br />

the calender stops. <strong>The</strong> temperature<br />

increase should be gradual. Your specific<br />

value should be experimentally determined<br />

by comparing roll surface temperatures in<br />

normal operation and after the calender has<br />

been stopped for 20 minutes.<br />

3. Limit the temperature rate <strong>of</strong> change at<br />

all times to a maximum <strong>of</strong> 3 degrees per<br />

minute.<br />

Because faster rates can damage or warp the<br />

rolls.<br />

the TCU circulation pumps before the<br />

calender reaches ambient is not considered<br />

good practice.<br />

If the temperature control system has rate<br />

<strong>of</strong> change limits properly set, cooling down<br />

is easy, since all the operator must do is to<br />

lower the temperature set points to ambient<br />

and then 60 to 90 minutes later return back<br />

to the operator console to turn <strong>of</strong>f the TCU.<br />

4. Minimize speed changes.<br />

Because changes in your calender speed<br />

result in gum wall gauge thickness<br />

variations that are undesirable.<br />

30<br />

<strong>The</strong> control system on the TCU should be<br />

designed and operated to limit the rate <strong>of</strong><br />

temperature change for each calender roll<br />

water circuit to 3 degrees per minute. Faster<br />

rates <strong>of</strong> change do not allow for equalization<br />

<strong>of</strong> mechanical expansion throughout the<br />

rolls, bearings, and calender frames.<br />

Differential expansion can stress various<br />

components <strong>of</strong> your calender. In extreme<br />

cases, they can actually crack or warp the<br />

rolls, or even damage the bearings.<br />

Heating usually is limited by the available<br />

heating capacity but the cooling system<br />

frequently has the capacity to rapidly cool<br />

the rolls and therefore also has the potential<br />

to cause damage if not limited to 3 degrees<br />

per minute.<br />

Again, it is important to keep the calender<br />

running during warm-up and during cool<br />

down. Stopping the calender and turning <strong>of</strong>f<br />

When the calender is running there are<br />

forces generated that try to separate the<br />

rolls, as explained earlier. And these<br />

separating forces are proportional to<br />

calender speed (although the relationship<br />

is not linear).<br />

<strong>The</strong> hardness <strong>of</strong> your rubber stock and<br />

bank temperature determines the<br />

magnitude <strong>of</strong> separating forces. <strong>The</strong><br />

thickness <strong>of</strong> the gum wall being calendered<br />

also affects the separating force – thinner<br />

gum walls generate higher separating<br />

forces. Separating forces <strong>of</strong> 160,000 to<br />

300,000 lbs at each actuator literally<br />

stretches the calender frame. When the<br />

forces vary, the amount <strong>of</strong> stretch varies.<br />

This further results in the roll-gap varying<br />

that in turn causes the gum wall gauge to<br />

vary.<br />

Hence, speed changes should be avoided<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

AMCL MACHINERY LIMITED<br />

SERVICE TO THE NATION FOR FOUR DECADES<br />

Product Range<br />

• <strong>Rubber</strong> Mixer – 76" liter and 270 liter.<br />

• Mixing Mills – 16", 22", 26" and special sizes<br />

• Hot feed extruders – 6" and 8"<br />

• <strong>Rubber</strong> <strong>Calenders</strong> – 2/3 rolls.<br />

• Bias Tyre Building machine – RB1/RB3<br />

• Automatic LCV Tyre Building Machine – RB1619<br />

• Automatic Truck Tyre Building Machine-RB2022<br />

• Mechanical Tyre Curing Presses – Scooter to Truck size<br />

• Bladder Curing Presses<br />

• Tube Splicers<br />

For all your enquiries please contact:<br />

AMCL MACHINERY LIMITED<br />

Works: Plot No.A1/1, MIDC, Butirobi-441122, Nagpur<br />

Mumbai <strong>of</strong>fice: 202, Ackruti Centre Point, MIDC Central Road, Andheri (East), Mumbai-400 093.<br />

Contact person: Mr. S.H. Mehta<br />

Mobile No. +91-9004697430. Email: shmehta@amcl.in Website: www.amcl.in

| CALENDERS |<br />

Image Source: Pelmar Engineering Ltd.<br />

32<br />

to the extent practical. A speed reduction<br />

from 45 mpm (meters per minute) to 9 mpm<br />

can result in a gauge decrease <strong>of</strong> approx.<br />

0.002 inches. Similarly, the vice-versa holds<br />

for a gauge increase with roll speed increase.<br />

<strong>Calenders</strong> are <strong>of</strong> different types. And<br />

different calendars have different degrees<br />

<strong>of</strong> frame stiffness so the quantum <strong>of</strong> the<br />

gauge change for a given speed change will<br />

vary accordingly.<br />

5. Mill management<br />

Maintain consistency.<br />

You can substantially reduce gauge<br />

variations by feeding the calender<br />

consistently.<br />

A consistent, uniform, dwell times on the<br />

cracker and feed mills, as well as consistent<br />

bank size, will give consistent rubber stock<br />

temperatures and work history. <strong>The</strong> stock<br />

temperatures, bank sizes, and work history<br />

directly influence calender roll-separating<br />

forces.<br />

When you minimize variations in these 3<br />

important process parameters, you will<br />

minimize variations in roll separating<br />

forces, and this in turn will minimize gauge<br />

variations <strong>of</strong> your calendered sheet.<br />

Further, good mill and bank control<br />

practices also give improved uniformity for<br />

other final calendered gum and/or fabric<br />

properties.<br />

When you feed to the calender, you must<br />

also ensure that the rubber bank does not<br />

have areas that could stagnate. Because if<br />

rubber remains in the bank on the calender<br />

for an excessive amount <strong>of</strong> time, it will<br />

partially cure and become much harder.<br />

Edge trim process that returns to the bank<br />

and stagnates is a common source <strong>of</strong> this<br />

problem.<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

| CALENDERS |<br />

Such cured and hardened compound will<br />

introduce gauge variations as well as<br />

negatively influence other properties <strong>of</strong><br />

your calendered material. In extreme<br />

cases, burnt lumps will appear in the<br />

calendered gum.<br />

Presence <strong>of</strong> hard stock makes it difficult<br />

to properly penetrate the cord and may<br />

cause cord disturbance and improper<br />

cord distribution.<br />

In such cases the cushion force causes<br />

lateral movement in the nip and this<br />

further results in cord displacement that<br />

is visible. Paired cords are <strong>of</strong>ten the first<br />

indicator. You will observe that the<br />

calendered thickness will be heavy and<br />

there will be cord displacement or<br />

irregularities. However, the weight <strong>of</strong> test<br />

samples will not be significantly affected.<br />

Localized cord disturbance in cord<br />

distribution does not usually affect fabric<br />

weight, whereas redistribution <strong>of</strong> the cord<br />

does. Overall cord distribution problems<br />

can affect fabric weight in the case <strong>of</strong> fabric<br />

calenders.<br />

For example, incorrect cord distribution<br />

may reduce the average EPI (Ends Per Inch)<br />

in the center <strong>of</strong> the fabric and increase the<br />

EPI (Ends Per Inch) on the outer edges. This<br />

will affect fabric weight and thickness – the<br />

weight <strong>of</strong> the center would be light, while<br />

the outer edges would be heavy.<br />

In steel cord calendering, visible cord<br />

33<br />

A) Uniform Cord Spacing - Uniform Top and Bottom <strong>Rubber</strong> Coat.<br />

Image Source: GEA<br />

B) Cords spread at the edge <strong>of</strong> the sheet.<br />

C) Cords paired. Top or Bottom <strong>Rubber</strong> Coat is heavy in the center.<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

Information On Equipment, Technology, Innovation & Suppliers<br />

| CALENDERS |<br />

Image: Bharaj Machineries Pvt. Ltd.<br />

34<br />

displacement and cord pairing after the<br />

cushion nip is to be expected in the areas<br />

where the cord EPI count is excessive.<br />

Training<br />

Your guiding principle for calender line<br />

operation should be consistency and<br />

continuity. If all the inputs to your<br />

calendering process are constant, and your<br />

installed machinery is functioning correctly,<br />

you can produce quality goods meeting tight<br />

specification tolerances. Your operators need<br />

to acquire knowledge on how the rubber<br />

calender works, how changes in process<br />

variables affect outcomes, and how changes<br />

in machine and/or process conditions can<br />

beat those changes. Training them to run the<br />

calender under complete manual control<br />

Your guiding principle for<br />

calender line operation should<br />

be consistency and continuity.<br />

will make them know enough to understand<br />

the importance <strong>of</strong> maintaining as close to<br />

steady-state operation as possible. Further,<br />

this knowledge will also help them to<br />

operate the line without the gauge or the<br />

automatic set-up, if they ever need to do so.<br />

Summarizing, the nuances in the world <strong>of</strong><br />

rubber calenders is an interesting subject<br />

and as you understand its operations<br />

deeper, the 'mysteriousness' <strong>of</strong> this rubber<br />

machinery disappears faster.<br />

RMW<br />

RUBBER&TYREMACHINERYWORLD<br />

INFORMATIONONEQUIPMENT,TECHNOLOGY,INNOVATION&SUPPLIERS<br />

<br />

........... And More<br />

NEW INFORMATION<br />

DIFFERENTLY<br />

Every Month With<br />

<strong>Rubber</strong> & Tyre Know A<br />

Machinery<br />

World<br />

LEADER<br />

<strong>Rubber</strong> & Tyre<br />

In 10 Questions<br />

rubbermachineryworld.com / tyremachineryworld.com<br />

<strong>Rubber</strong> & Tyre Machinery Technology World | & JUL Innovation 2016<br />

Know Your<br />

Supplier<br />

<strong>Rubber</strong> & Tyre Equipment - Accessories<br />

Special Edition<br />

<strong>Rubber</strong> & Tyre<br />

Machinery<br />

World

WhatIsYourStoryToday?<br />

Every Machinery Has....<br />

Every Technology Has...<br />

And As Equipment Supplier,<br />

YOU Denitely Have...<br />

A Story<br />

Let Equipment Buyers Know You, Your Products & Your Technology Better.<br />

ReachMachineryBuyersFastIn3Steps<br />

1.DISPLAYYourProductsRegularlytoBuyers.<br />

2.COMMUNICATEYourCompetenciesDifferently.<br />

3.ATTRACTMoreBuyerstoYourBrandInformatively.<br />

ADVERTISE On<br />

RUBBER <strong>Rubber</strong><br />

Machinery<br />

World<br />

M<br />

http://rubbermachineryworld.com<br />

M<br />

TYRE Tyre<br />

Machinery<br />

World<br />

M<br />

M<br />

http://tyremachineryworld.com<br />

And SELL MORE<br />

Because we publish digitally on our portal and promote globally,<br />

Buyers get all information <strong>of</strong> Your Products & Solution anytime<br />

and anywhere - on any device (Phone, Tab or Computer).<br />

For more details and your customized advertising, please visit<br />

http://rubbermachineryworld.com<br />

Or email us at engage@rubbermachineryworld.com<br />

InfoPortal|DigitalMagazines|SocialMarketing<br />

Equipment Marketing Redefined<br />

<strong>Rubber</strong> & Tyre Know A<br />

Machinery<br />

World<br />

<strong>Rubber</strong> & Tyre<br />

LEADER<br />

In 10 Questions<br />

Know Your<br />

Supplier<br />

rubbermachineryworld.com / tyremachineryworld.com<br />

<strong>Rubber</strong> & Tyre Equipment - Accessories<br />

Technology & Innovation<br />

Special Edition<br />

<strong>Rubber</strong> & Tyre<br />

Machinery<br />

World<br />

Information On Equipment, Technology, Innovation & Suppliers

KELACHANDRA MACHINES<br />

(MFRS. OF RUBBER INDUSTRIAL MACHINERY)<br />

Chingavanam - 686 531, Kottayam, Kerala. India.<br />

Phone Off: +91- 481-2430325. Fax: +91- 481-2430596<br />

e-mail: km1912@gmail.com

| INSIGHT |<br />

This section is bought to you in association with our brand display partners<br />

37<br />

7 PROVEN STRATEGIES<br />

TO METHODICALLY GROW<br />

YOUR BUSINESS<br />

<strong>Rubber</strong> & Tyre Machinery World | JUL 2016

38

Source: Web<br />

39

Attention: Equipment Buyers & Users<br />

<strong>Rubber</strong> And Tyre Machinery<br />

Now Has An Online Address<br />

RUBBER <strong>Rubber</strong><br />

Machinery<br />

World<br />

M<br />

http://rubbermachineryworld.com<br />

M<br />

TYRE Tyre<br />

Machinery<br />

World<br />

M<br />

M<br />

http://tyremachineryworld.com<br />

- Power Your Business Forward With Authentic Information<br />

On<br />

- Equipment & Allied Machinery<br />

- Technology<br />

- Equipment Suppliers<br />

- Read, Absorb & Implement Ideas From<br />

- Insightful Interviews Of Leaders<br />

- Informative <strong>Art</strong>icles<br />

- Special e-Editions & e-Books<br />

- Short Updates Curated from the World Of Machinery Every<br />

Thursday In Your Inbox<br />

- Resourceful Downloads For Day-to-Day Use<br />

- Plan For Your Conferences & Expo from event dates<br />

- Book Store with Best <strong>Rubber</strong> Books For Your Quick Buy<br />

- Key Documents/Directories to take Powerful Business<br />

Decisions Available For Purchase.<br />

- Left-Oriented Clean Layout for your easy reading.<br />

- Follow Us on Twitter, Google+, LinkedIn & Pinterest.<br />

http://rubbermachineryworld.com<br />

http://tyremachineryworld.com<br />

FREE Access On All Your Devices<br />

JOIN OUR READERS FROM 130+COUNTRIES<br />

SUBSCRIBE TODAY FOR FREE & BENEFIT

GET CUSTOM MACHINED<br />

ROLLERS, SCREWS, FIXTURES & MOULDS<br />

FOR ALL YOUR RUBBER AND<br />

PROCESSING MACHINERY.<br />

AT OUR STATE-OF-THE-ART CNC MACHINING<br />

CENTERS, WE GUARANTEE YOU<br />

■ IN-HOUSE CAD CAM STUDIO<br />

■ 3 AND 4 AXIS MACHINING CAPABILITIES<br />

■ ACCURATE AND RELIABLE INSPECTION<br />

REPORTS THROUGH IN-HOUSE CNC CMM<br />

■ SKILLED AND TRAINED MANPOWER<br />

■ TIMELY DELIVERY<br />

■ 24x7 POWER BACK-UP<br />

UNFAILING PARTNER AND DEPENDABLE SUPPORT<br />

FOR YOUR DESIGN TO MANUFACTURING NEEDS<br />

AUTUS CONSULTING @2016<br />

Excellent 4th Axes Precision CNC Machining Capability for Customized Heavy Rollers. Please contact<br />

SubAero Precision Machining<br />

(An ISO 9001:2008 Certified Company)<br />

HURCO DCX 32 Vertical Machining Centre<br />

Corp Office: 8/Trivedi Niwas, New Nagardas Road,<br />

Andheri (East), Mumbai - 400 069, India.<br />

Ph: +91-22-28256599, +91-22-28378478 (Fax)<br />

www.subaero.com | Email: info@subaero.com

Stay Updated On <strong>Rubber</strong> & Tyre<br />

Machinery And <strong>The</strong>ir Suppliers.<br />

INFORMATION PORTAL | E-MAGAZINES | INTERVIEWS | KNOWLEDGE PARTNERS | DOWNLOADS<br />

........... And More<br />

<strong>Rubber</strong> And Tyre Machinery<br />

Now Has An Online Address<br />

RUBBER <strong>Rubber</strong><br />

Machinery<br />

World<br />

M<br />

http://rubbermachineryworld.com<br />

M<br />

TYRE Tyre<br />

Machinery<br />

World<br />

M<br />

M<br />

http://tyremachineryworld.com<br />

INFORMATION ON EQUIPMENT,<br />

TECHNOLOGY, INNOVATION &<br />

SUPPLIERS<br />

........... And More<br />

Know More On EQUIPMENT SUPPLIERS And <strong>The</strong>ir SOLUTIONS For YOU<br />

KELACHANDRA<br />

MACHINES<br />

racsol.com<br />

Practical Solution<br />

www.<br />

........... And More<br />

Email: rubbermachineryworld@gmail.com<br />

©2016 – ePublished by <strong>Rubber</strong> Machinery World in JULY 2016<br />

Content For Free eDistribution & Download