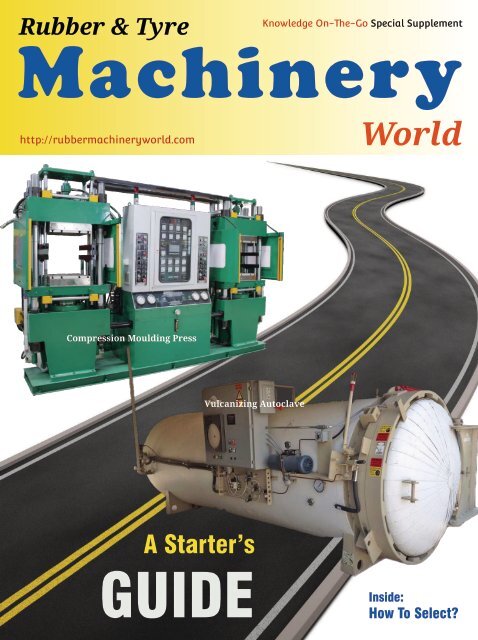

A Starters Guide on Compression Moulding And Autoclave

This edition of Knowledge On-The-Go Special Supplement features two key machinery used in the rubber industry viz. Autoclave and Compression Moulding.

This edition of Knowledge On-The-Go Special Supplement features two key machinery used in the rubber industry viz. Autoclave and Compression Moulding.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Rubber & Tyre<br />

Knowledge On-The-Go Special Supplement<br />

Machinery<br />

http://rubbermachineryworld.com<br />

World<br />

Compressi<strong>on</strong> <strong>Moulding</strong> Press<br />

Vulcanizing <strong>Autoclave</strong><br />

A Starter’s<br />

GUIDE<br />

Inside:<br />

How To Select?

| Editor’s Note |<br />

A Starter’s <str<strong>on</strong>g>Guide</str<strong>on</strong>g><br />

This editi<strong>on</strong> features two key machinery used in the<br />

rubber industry viz. <strong>Autoclave</strong> and Compressi<strong>on</strong><br />

<strong>Moulding</strong>.<br />

<strong>Autoclave</strong> is a vulcanizing equipment, and the other<br />

is the equipment used in your most comm<strong>on</strong> rubber<br />

moulding technique - compressi<strong>on</strong> moulding. These<br />

c<strong>on</strong>tents first appeared <strong>on</strong> our portal and witnessed<br />

high traffic.<br />

This high interest level, prompted us to publish the<br />

details in this Knowledge On-The-Go Special<br />

Supplement.<br />

Our previous issue <strong>on</strong> Mixing Mills was well-received.<br />

Thanks again to each of you - esteemed readers and<br />

supportive advertisers.<br />

While, the last editi<strong>on</strong> was tracking the advancements<br />

of a very popular rubber machinery, this editi<strong>on</strong> is<br />

aimed at fulfilling the curiosity of the new generati<strong>on</strong><br />

of business leaders - who are either taking over from<br />

their parents or those young entrepreneurs setting up<br />

their own venture.<br />

Hence, the theme - ‘A Starter’s <str<strong>on</strong>g>Guide</str<strong>on</strong>g>’.<br />

<strong>Autoclave</strong> is a<br />

vulcanizing<br />

equipment, and the<br />

other is used in your<br />

comm<strong>on</strong> rubber<br />

moulding technique<br />

viz. compressi<strong>on</strong><br />

moulding.<br />

3<br />

I hope you find this special supplement different and<br />

informative.<br />

As always, I welcome your feedback <strong>on</strong><br />

rubbermachineryworld@gmail.com.<br />

rubbermachineri<br />

rubbermachineryworld<br />

+Rubbermachineryworld1<br />

BestRegards<br />

Prasanth Warrier<br />

grp/home?gid=8252803<br />

rubbermachineri<br />

Special Supplement - Rubber Machinery World | OCT 2015

| COMPRESSION MOULDING |<br />

4<br />

Image: Bharaj Machineries Make Automatic Compressi<strong>on</strong> <strong>Moulding</strong> Press<br />

Special Supplement - Rubber Machinery World | OCT 2015

| COMPRESSION MOULDING |<br />

COMPRESSION<br />

MOULDING<br />

MACHINERY<br />

Prasanth Warrier<br />

Compressi<strong>on</strong> moulding is the<br />

most comm<strong>on</strong> moulding<br />

technique you will notice in<br />

the rubber industry.<br />

The other two are transfer<br />

moulding and injecti<strong>on</strong><br />

moulding.<br />

5<br />

Compressi<strong>on</strong> moulding is a<br />

closed mould process and you<br />

apply high pressure <strong>on</strong> the job.<br />

It is best used when you have<br />

low to medium producti<strong>on</strong><br />

volumes for larger parts<br />

where tightest tolerances and<br />

flawless finishes are not<br />

required.<br />

Examples may include<br />

diaphragms, valves and<br />

gaskets, Dampers, O-rings,<br />

seals, rubber wear parts, etc<br />

depending up<strong>on</strong> their areas of<br />

applicati<strong>on</strong>.<br />

Special Supplement - Rubber Machinery World | OCT 2015

| COMPRESSION MOULDING |<br />

As shown in the schematic here, in<br />

compressi<strong>on</strong> moulding, you place an<br />

uncured rubber profile in a heated<br />

mould. Then you soften the uncured<br />

rubber by the heat and press them<br />

forcing the rubber compound to fill<br />

the mould cavity. The rubber is thus<br />

made to c<strong>on</strong>form to the shape of the<br />

mould and then you cure it to<br />

produce your finished article.<br />

Schematic From JW Elastomer Engineering <str<strong>on</strong>g>Guide</str<strong>on</strong>g><br />

6<br />

Santec Group Make Compressi<strong>on</strong> <strong>Moulding</strong> Machines inside their Plant<br />

Special Supplement - Rubber Machinery World | OCT 2015

Your World-Wide Partner<br />

For Rubber <strong>And</strong> Tire<br />

Machinery<br />

• PRE-OWNED • NEW • REFURBISHED<br />

Are you seeking affordable and durable machinery?<br />

For tire producti<strong>on</strong>, tire retreading, tire recycling, hoses,<br />

automotive parts, flooring and covering, c<strong>on</strong>veyor belts<br />

manufacturing and other technical rubber goods.<br />

Discuss with us for your requirements of<br />

- Single Machinery - Spares<br />

- Complete Lines - Turnkey Soluti<strong>on</strong>s<br />

You may choose from our varied stock in 17 locati<strong>on</strong>s of<br />

USA, Europe, Middle-East and India that includes Mixers,<br />

Mills, Calenders, Cutters and Splicers, Extruders, Curing<br />

Presses, Tire Building Machines (TBM), Testing and<br />

Finishing Equipment, Injecti<strong>on</strong> Molding Machines as well<br />

as Laboratory equipment.<br />

Through our 8 fully owned subsidiaries in Germany, UK,<br />

USA, Italy, India, China, Spain and Turkey; we provide you<br />

with any type of rubber machinery, tire equipment and<br />

engineering services.<br />

Subscribe to our Newsletters for the latest inventory<br />

catalogue and best equipment deals. For more info, visit<br />

www.pelmar.com<br />

Or email us at silbiger@pelmar.co.il

| COMPRESSION MOULDING |<br />

Compressi<strong>on</strong> <strong>Moulding</strong> Press:<br />

The machinery you will use is<br />

called Compressi<strong>on</strong> <strong>Moulding</strong><br />

Press. These presses are mostly<br />

hydraulically driven, where a<br />

hydraulic pump powers a<br />

hydraulic cylinder (or cylinders)<br />

that drive the ram or slide.<br />

(Cauti<strong>on</strong>: there are pneumatically<br />

powered presses too).<br />

Hence, the terms that apply to a<br />

standard hydraulic press are<br />

relevant here.<br />

Terms & Image Taken from Beckwood Hydraulic Presses and Machinery<br />

8<br />

Hydraulic Press Terms<br />

Stroke: The amount of possible ram travel.<br />

Stroke is the total distance that the ram can<br />

travel, from full extensi<strong>on</strong> to full retracti<strong>on</strong>.<br />

Shut Height: The distance between the bed<br />

bolster and the ram bolster when the ram is<br />

fully extended. This is also comm<strong>on</strong>ly<br />

known as the Closed Height. As standard,<br />

this dimensi<strong>on</strong> is usually within “0.25” due<br />

to assembly processes.<br />

Daylight: The distance between the bed<br />

bolster and the ram bolster when the ram is<br />

fully retracted. This is also comm<strong>on</strong>ly<br />

known as the Open Height.<br />

The plate is usually bolted to the bed and<br />

rams substructures.<br />

Bed Height: Bed Height is the distance from<br />

the bottom of the hydraulic press structure<br />

to the working height or top of the bed bolster.<br />

Remote Power Skid: Some press applicati<strong>on</strong>s<br />

may require that the hydraulics be located<br />

remotely from the press itself. Others may<br />

preclude the power system from being able<br />

to be installed at the top around the crown<br />

structure of the press. In these cases, the<br />

power system and even the c<strong>on</strong>trols may be<br />

designed into a separate unit capable of being<br />

placed adjacent to the press or away from the<br />

press.<br />

Bolster: The removable plate that serves as<br />

the working surface for the bed and ram.<br />

Heated Platens: These are plates that have<br />

heating capabilities.<br />

Special Supplement - Rubber Machinery World | OCT 2015

| COMPRESSION MOULDING |<br />

Hydraulic presses are<br />

preferred by your peers in the<br />

industry because they give<br />

Performance, Reliability, and<br />

Versatility. This means you can<br />

get full pressing force (or<br />

t<strong>on</strong>nage) anywhere in the<br />

range of stroke using hydraulic<br />

press unlike a mechanical<br />

press.<br />

10<br />

By varying the ram speed and<br />

other operating parameters,<br />

you can optimize cycle time for<br />

each of your job. Further, you<br />

could customize your bed size;<br />

say lower t<strong>on</strong>nage <strong>on</strong> a larger<br />

work area or higher t<strong>on</strong>nage<br />

<strong>on</strong> a smaller area of work.<br />

You will see that compressi<strong>on</strong><br />

moulding presses offered by<br />

most reputed manufacturers<br />

are vertical and the moulds<br />

can be heated using electric<br />

rods, steam, oil, water or other<br />

medium.<br />

Depending <strong>on</strong> requirement,<br />

your moulds may be fixed to<br />

both the platens; or part fixed<br />

to a platen, or totally free to be<br />

drawn out. When you have<br />

free loose moulds, your<br />

operators need to load and<br />

unload them <strong>on</strong> a press table<br />

manually. You call it charging<br />

(loading) and stripping<br />

(unloading) by hand.<br />

Bharaj Machineries Make Automatic Vacuum Type<br />

Compressi<strong>on</strong> <strong>Moulding</strong> Press<br />

Image: A 60" Mixing Mill With Advanced Features,<br />

On the other hand, the press. When the lower platen<br />

C<strong>on</strong>trols, and Automati<strong>on</strong> from Bharaj Machineries.<br />

presence of ejector pins is raised or lowered in the<br />

or strippers <strong>on</strong> fixed vertical plane, you call it<br />

mould presses will speed upstroking; while in downstroking,<br />

the upper platen is<br />

up your operati<strong>on</strong>.<br />

the driven plate (moving up<br />

One of the platens is and down).<br />

fixed in your<br />

compressi<strong>on</strong> moulding<br />

Hydraulic presses are preferred by your<br />

peers in the industry because they give<br />

Performance, Reliability, and Versatility.<br />

Special Supplement - Rubber Machinery World | OCT 2015

| COMPRESSION MOULDING |<br />

How will you decide (select)?<br />

Apart from safety and ease of<br />

operati<strong>on</strong>s, your final choice<br />

of a compressi<strong>on</strong> moulding<br />

press depends <strong>on</strong> these six<br />

important c<strong>on</strong>siderati<strong>on</strong>s:<br />

12<br />

1. Calculati<strong>on</strong> of the proper<br />

amount of rubber for your<br />

product.<br />

2. Calculating the minimum<br />

amount of energy required<br />

to heat your rubber.<br />

3. Calculating the minimum<br />

time required to heat your<br />

rubber.<br />

4. Identifying the appropriate<br />

heating technique.<br />

5. Predicting the required<br />

force, to ensure that stroke<br />

attains the proper shape for<br />

your rubber.<br />

6. Designing the mould for<br />

rapid cooling after the<br />

rubber has been compressed<br />

into the mould.<br />

A Rec<strong>on</strong>diti<strong>on</strong>ed Press<br />

By Pelmar Engineering<br />

Santec Group Make Compressi<strong>on</strong> <strong>Moulding</strong> Press<br />

Your final choice of a compressi<strong>on</strong><br />

moulding press depends <strong>on</strong> these six<br />

important c<strong>on</strong>siderati<strong>on</strong>s.<br />

You try to optimize the Time,<br />

Temperature and Pressure<br />

– the three critical<br />

parameters for your<br />

moulding process.<br />

Manufacturers compete to<br />

offer your robust hydraulic<br />

presses with superior drives<br />

and c<strong>on</strong>trols, advanced levels<br />

of hydraulics and<br />

instrumentati<strong>on</strong> features.<br />

Special Supplement - Rubber Machinery World | OCT 2015

World<br />

World<br />

| COMPRESSION MOULDING |<br />

Advantages and Disadvantages<br />

of Compressi<strong>on</strong> <strong>Moulding</strong><br />

Process<br />

The advantages of compressi<strong>on</strong><br />

rubber moulding are lower cost<br />

of your moulds, the large sizes of<br />

mouldings possible, and the<br />

relatively quick changeover<br />

between different moulds<br />

helping you expedite shorter<br />

producti<strong>on</strong> runs.<br />

Additi<strong>on</strong>ally, there are no tooling<br />

features like gates, spruces or<br />

runners that could increase the<br />

time for your mould to enter the<br />

cavity or potentially affect the<br />

aesthetics of your product.<br />

The main disadvantage is your<br />

output when loaded and<br />

unloaded manually. This<br />

increases your cost <strong>on</strong> skilled<br />

labour.<br />

There is product wastage too<br />

as compressi<strong>on</strong> moulding is<br />

not precise like injecti<strong>on</strong><br />

rubber moulding. Since<br />

Presses Inside A Plant of Elastomer Engineering Ltd UK<br />

thermal c<strong>on</strong>ductivity of<br />

rubber is poor and you<br />

often place your profile<br />

into the cavity ‘cold’,<br />

your cure times are<br />

l<strong>on</strong>ger.<br />

Additi<strong>on</strong>al difficulties<br />

you face will be from<br />

positi<strong>on</strong>ing the blank<br />

properly in the cavity<br />

and the difficulty to<br />

c<strong>on</strong>trol the ‘flash’<br />

that results from the<br />

additi<strong>on</strong>al material<br />

placed in the cavity.<br />

Unsuitable for complex<br />

moulding, compared to a<br />

transfer moulding or<br />

injecti<strong>on</strong> moulding, your<br />

product c<strong>on</strong>taminati<strong>on</strong> is also<br />

higher in compressi<strong>on</strong><br />

moulding.<br />

Summarizing, compressi<strong>on</strong><br />

moulding is the most<br />

comm<strong>on</strong> moulding technique<br />

that you will find in rubber<br />

industry and the comm<strong>on</strong><br />

machinery for this process is<br />

the a hydraulic compressi<strong>on</strong><br />

moulding press.<br />

RMW<br />

13<br />

Technology & Innovati<strong>on</strong> Rubber Machinery World<br />

Product Z<strong>on</strong>e Rubber Machinery World<br />

Know Your Supplier Rubber Machinery World<br />

RUBBER Rubber<br />

Machinery<br />

M<br />

M<br />

Technology<br />

&<br />

Innovati<strong>on</strong><br />

ProductZ<strong>on</strong>e M<br />

RUBBER Rubber<br />

Machinery<br />

Rubber Machinery<br />

& Accessories<br />

Know Your Supplier<br />

Pracsol Chemicals & Machinery<br />

‘Practical Soluti<strong>on</strong>s’ <strong>on</strong> Equipment<br />

Simplified<br />

In C<strong>on</strong>versati<strong>on</strong> With<br />

Harish Nene, Chief Executive Ofcer<br />

RUBBER Rubber<br />

Machinery<br />

World<br />

M<br />

M<br />

M<br />

Special<br />

Editi<strong>on</strong><br />

REACH 3X...DIFFERENTLY<br />

Only <strong>on</strong> http://rubbermachineryworld.com<br />

Thru Buyer-Oriented Editi<strong>on</strong>s To Market Your Equipment Soluti<strong>on</strong>s Differently.<br />

1. TECHNOLOGY & INNOVATION Editi<strong>on</strong><br />

Communicating One Technology At A Time...Differently<br />

2. PRODUCT ZONE Editi<strong>on</strong><br />

Promoting One Product At A Time...Differently.<br />

Knowledge On-The-Go Special Supplement<br />

Rubber & Tyre<br />

Machinery<br />

http://rubbermachineryworld.com<br />

World<br />

Updated Criteri<strong>on</strong> Checklist To Select Your Two-Roll Mill<br />

PLUS<br />

BUYERs SPECIAL<br />

On One Key Topic<br />

At A Time<br />

...............Differently<br />

3. KNOW YOUR SUPPLIER Editi<strong>on</strong><br />

PromoteYourBrandOn<br />

Special Supplement - Rubber Machinery World | OCT 2015<br />

Advertising One Supplier At A Time...Differently<br />

RUBBER Rubber<br />

Machinery<br />

World<br />

Knowledge On-The-Go Special Supplement<br />

File Picture From Wiki<br />

MIXING MILL<br />

Inside<br />

Rubber Machinery World<br />

RUBBER Rubber<br />

Machinery<br />

M<br />

A New Generati<strong>on</strong> Mi l<br />

A Story Of<br />

Woes To Wows!!<br />

HOW TO SELECT YOUR<br />

RUBBER & TYRE MACHINERY?<br />

Inside<br />

M<br />

World<br />

Jacob Peled<br />

Pelmar Engineering<br />

Rakesh Sharma<br />

AMCL Machinery<br />

Insightful Advices From 6 CEOs<br />

<strong>And</strong>reas Limper<br />

HF Mixing Group<br />

Arul Shanmugavelu<br />

L&T - Kobelco Machinery<br />

Peter Haan<br />

Siemens AG<br />

Harish Nene<br />

Pracsol<br />

Top 25 Things You Should Know to Discuss with Mixer Rebuilder<br />

Special Supplement<br />

M<br />

M

| AUTOCLAVE |<br />

VULCANIZING AUTOCLAVE<br />

Prasanth Warrier<br />

14<br />

Image: B<strong>on</strong>dtech <strong>Autoclave</strong><br />

You use an <strong>Autoclave</strong> or Vulcanizer<br />

(Vulcanizing autoclave) to c<strong>on</strong>vert natural<br />

rubber into a cured and chemically<br />

Vulcan, the process was named<br />

cross-linked rubber product. A vulcanized vulcanizati<strong>on</strong> (or vulcanisati<strong>on</strong>).<br />

rubber is less sticky and gives you<br />

superior mechanical properties.<br />

Your friends in rubber industry use<br />

autoclaves to cure tires, hoses, and many<br />

Rubber Vulcanizati<strong>on</strong> (a term coined by other products but not limited to<br />

Thomas Hancock) “process” was<br />

vulcanizati<strong>on</strong> and forming of extrudates<br />

discovered accidentally by Charles<br />

(like car radiator hoses), rubber mats,<br />

Goodyear in 1839.<br />

sleeves, joints, gaskets and boots. Typically<br />

these are products that you cannot achieve<br />

If you are curious about history, this is <strong>on</strong> a standard press-based compressi<strong>on</strong><br />

how it goes – Charles Goodyear left a piece moulding process.<br />

of natural rubber mixed with sulphur <strong>on</strong> a<br />

hotplate <strong>on</strong>e evening. Overnight, it turned Depending <strong>on</strong> the type of your rubber, the<br />

into elastic rubber and that caught his vulcanizing process can occur from room<br />

attenti<strong>on</strong>! Since sulphur and heat were temperature (as in Silic<strong>on</strong>e) up to 350°F<br />

associated with the ancient Roman god (170°C) or more like in case of Tire.<br />

Special Supplement - Rubber Machinery World | OCT 2015

Attenti<strong>on</strong>: Equipment Buyers & Users<br />

Rubber <strong>And</strong> Tyre Machinery<br />

Now Has An Online Address<br />

- Power Your Business Forward With Authentic Informati<strong>on</strong><br />

On<br />

- Equipment & Allied Machinery<br />

- Technology<br />

- Equipment Suppliers<br />

- Read, Absorb & Implement Ideas From<br />

- Insightful Interviews Of Leaders<br />

- Informative Articles<br />

- Special e-Editi<strong>on</strong>s & e-Books<br />

- Short Updates Curated from the World Of Machinery Every<br />

Thursday In Your Inbox<br />

- Resourceful Downloads For Day-to-Day Use<br />

- Plan For Your C<strong>on</strong>ferences & Expo from event dates<br />

- Book Store with Best Rubber Books For Your Quick Buy<br />

- Key Documents/Directories to take Powerful Business<br />

Decisi<strong>on</strong>s Available For Purchase.<br />

- Left-Oriented Clean Layout for your easy reading.<br />

- Follow Us <strong>on</strong> Twitter, Google+, LinkedIn & Pinterest.<br />

http://rubbermachineryworld.com<br />

FREE Access On All Your Devices<br />

http://rubbermachineryworld.com<br />

AUTHENTIC INFORMATION TO SOURCE MACHINERY WISELY<br />

JOIN OUR READERS FROM 68+ COUNTRIES<br />

SUBSCRIBE TODAY FOR FREE & BENEFIT

| AUTOCLAVE |<br />

The Machinery<br />

<strong>Autoclave</strong>s are predominantly cylindrical<br />

pressure vessels with lids or doors to<br />

process your rubber parts that require<br />

exposure to elevated pressure and<br />

temperature. They are available in a wide<br />

range of sizes and design pressures in<br />

horiz<strong>on</strong>tal (or sometimes vertical)<br />

c<strong>on</strong>figurati<strong>on</strong>.<br />

16<br />

The key comp<strong>on</strong>ent of your autoclave is<br />

the door. For a manufacturer, this is also<br />

the critical comp<strong>on</strong>ent in cost of autoclave<br />

c<strong>on</strong>structi<strong>on</strong>. On <strong>on</strong>e hand, your operator<br />

must be able to open and close the door<br />

quickly and easily; <strong>on</strong> the other, the door<br />

must satisfy stringent safety requirements<br />

of manufacturing and usage.<br />

Tyre Vulcanizing in <strong>Autoclave</strong>s (Web)<br />

<strong>Autoclave</strong> Image From Web<br />

Rubber vulcanizing is a batch<br />

process. Your autoclave door<br />

must be of full diameter to<br />

allow easy access to the<br />

chamber inside.<br />

Let me explain.<br />

Rubber vulcanizing is a batch process. Your<br />

autoclave door must be of full diameter to<br />

allow easy access to the chamber inside. So<br />

you need a fast-acting door to reduce batch<br />

change time and increase productivity.<br />

Depending <strong>on</strong> the size of your autoclave<br />

and manufacturer’s offered features, there<br />

are several types of fast-opening doors.<br />

An autoclave design is driven by various<br />

safety standards, primary am<strong>on</strong>g them<br />

being the ASME Pressure Vessel Code.<br />

Special Supplement - Rubber Machinery World | OCT 2015

| AUTOCLAVE |<br />

Of all safety-related c<strong>on</strong>cerns, the most<br />

critical are those which relate to the door’s<br />

operati<strong>on</strong>. The manufacturer of your<br />

autoclave should ensure that the door seals<br />

tightly against rated pressure at the highest<br />

shell temperature; operate readily and<br />

quickly and meets all safety guidelines of a<br />

pressure vessel.<br />

Regular testing is a must al<strong>on</strong>g with fool<br />

proof interlock mechanisms to prevent<br />

door opening under pressure.<br />

Inside View of an <strong>Autoclave</strong><br />

Leading manufacturers deploy Solid-<br />

Modelling and Finite Element Analysis<br />

(FEA) to design and validate autoclave<br />

pressure vessels and quick-opening doors.<br />

precise to c<strong>on</strong>trol, and lowest maintenance;<br />

the cost per kilowatt-hour makes them<br />

expensive for your use.<br />

18<br />

CE Standard in Europe applies to vessels as<br />

well as to electrical c<strong>on</strong>trols.<br />

The process medium in autoclaves may be<br />

steam, a combinati<strong>on</strong> of steam and air or<br />

inert gas, “Dry Heat” produced by electrical<br />

heaters, steam or hot oil autoclave jackets,<br />

or circulating hot gases. Despite electric<br />

heat being 100 per cent efficient, most<br />

Your manufacturer should<br />

ensure that the door seals<br />

tightly against rated pressure at<br />

the highest shell temperature;<br />

operate readily and quickly and<br />

meets all safety guidelines of a<br />

pressure vessel.<br />

<strong>And</strong> because rubber vulcanizing cannot be<br />

d<strong>on</strong>e in an air atmosphere, you mostly use<br />

steam.<br />

Two types of autoclaves are in comm<strong>on</strong> use<br />

– N<strong>on</strong>-jacketed and Jacketed.<br />

In the n<strong>on</strong>-jacketed type, steam is<br />

introduced directly into the autoclave<br />

chamber. The steam c<strong>on</strong>denses <strong>on</strong> the walls<br />

of your autoclave and <strong>on</strong> the surface of your<br />

rubber products under vulcanizati<strong>on</strong>.<br />

However, this leaves behind a mark <strong>on</strong> the<br />

surface of your product.<br />

<strong>And</strong> when you adopt preventive measures,<br />

you end up getting a dull finish <strong>on</strong> your<br />

rubber products. For some products like<br />

Radiator hoses for cars, you can cure in open<br />

steam.<br />

Special Supplement - Rubber Machinery World | OCT 2015

KELACHANDRA MACHINES<br />

(MFRS. OF RUBBER INDUSTRIAL MACHINERY)<br />

Chingavanam - 686 531, Kottayam, Kerala. India.<br />

Ph<strong>on</strong>e Off: +91- 481-2430325. Fax: +91- 481-2430596<br />

e-mail: km1912@gmail.com

| AUTOCLAVE |<br />

Additi<strong>on</strong>ally, if you have brightly colored<br />

articles, the jacketed autoclave lends a<br />

good surface finish <strong>on</strong> your rubber product.<br />

The vulcanizing process in an autoclave is<br />

a functi<strong>on</strong> of temperature and time.<br />

20<br />

The jacketed autoclaves has a double wall.<br />

Steam is circulated in the jacket to provide<br />

heating. There is no direct c<strong>on</strong>tact of<br />

steam with your rubber products. An<br />

inert gas (like Nitrogen) is then introduced<br />

in the autoclave to eliminate oxidati<strong>on</strong>.<br />

(Oxidati<strong>on</strong> aids polymer degradati<strong>on</strong> and<br />

hence you need to eliminate them).<br />

Gases are normally poor c<strong>on</strong>ductors of<br />

heat and thus increases the curing time.<br />

You may also come across this process<br />

referred to as “gas curing” by technologists.<br />

Traditi<strong>on</strong>ally, in most applicati<strong>on</strong>s there is<br />

no indicati<strong>on</strong> of when your cure is<br />

complete. For this reas<strong>on</strong>, to ensure that all<br />

comp<strong>on</strong>ents in the autoclave have been<br />

universally cured, your process cycle times<br />

are usually l<strong>on</strong>ger than is necessary.<br />

Modern autoclaves come with PLC<br />

c<strong>on</strong>trolled systems and offer extended<br />

features including variable temperatures,<br />

pressures, cycle times, cycle and system<br />

alarms, multiple cycle recipe storage and<br />

selecti<strong>on</strong>.<br />

Operator C<strong>on</strong>soles with HMI provide an<br />

operator friendly interface with touch<br />

screens, for cycle parameter entry, cycle/<br />

system/alarm status m<strong>on</strong>itoring, operating<br />

and diagnostic messages.<br />

Separate Images of C<strong>on</strong>trols and HMI Screen (Inset) from different sources<br />

<strong>on</strong> web (Only for representati<strong>on</strong> purpose).<br />

Special Supplement - Rubber Machinery World | OCT 2015

| AUTOCLAVE |<br />

When you invite offers to purchase an<br />

autoclave, you should not be surprised if<br />

price variati<strong>on</strong>s c<strong>on</strong>fuses you or you are<br />

unable to comprehend immediately – be<br />

it prices am<strong>on</strong>g manufacturers and<br />

between features.<br />

Price is sensitive to some factor and<br />

insensitive to others.<br />

For eg:, doubling the design pressure<br />

might increase the cost of the autoclave<br />

by over fifty percent. <strong>And</strong> doubling the<br />

diameter might more than double your<br />

purchase price. On the other hand, you<br />

may find that increases in length are<br />

inexpensive (relatively).<br />

So, your purchase price varies as a<br />

functi<strong>on</strong> of what has been designed and<br />

built into your proposed autoclave.<br />

Price is sensitive to some factor<br />

and insensitive to others.<br />

Opti<strong>on</strong>s of features offered by your suppliers<br />

has to be carefully decided so as to optimize<br />

your overall investment.<br />

Operati<strong>on</strong> Cycle<br />

Your typical cycle of autoclave curing has the<br />

following steps.<br />

The autoclave is loaded with your rubber<br />

comp<strong>on</strong>ent, and the c<strong>on</strong>necti<strong>on</strong>s are made<br />

to the autoclave. The door is closed and<br />

locked. Pressure is applied until the required<br />

level is attained. The circulati<strong>on</strong> fan starts.<br />

Heating begins and is maintained at a<br />

specified ramp up rate. Once the required<br />

21<br />

Special Supplement - Rubber Machinery World | OCT 2015

| AUTOCLAVE |<br />

temperature is reached, a timed soak<br />

at that temperature begins and runs for<br />

the necessary durati<strong>on</strong>. At the end of<br />

the soak period, the cooling functi<strong>on</strong><br />

brings the temperature down to a set<br />

value at a specified ramp rate. The<br />

vessel is depressurized and the<br />

circulati<strong>on</strong> stopped.<br />

Steam curing requires a great deal of<br />

manual work from <strong>on</strong>e processing<br />

stage to the other, and this also<br />

c<strong>on</strong>tributes to the high cost of your<br />

autoclave cured products.<br />

Hence, some of your new generati<strong>on</strong><br />

peers advocate the more advanced<br />

microwave process.<br />

Summarizing autoclaves are pressure<br />

vessels for rubber product<br />

vulcanizati<strong>on</strong>, available in a wide<br />

range of sizes. A disc<strong>on</strong>tinuous curing<br />

method, the curing of your rubber<br />

comp<strong>on</strong>ent takes place in a vessel<br />

(autoclave) where pressurized steam<br />

is the medium of heating.<br />

RMW<br />

Send Us Your Blog Suggesti<strong>on</strong> Or Your Article<br />

rubbermachineryworld@gmail.com<br />

22<br />

SELL MORE<br />

WHEN BUYERS VISIT FOR<br />

AUTHENTIC INFO ON MACHINERY<br />

Promote Your Brand On<br />

RUBBER Rubber<br />

Machinery<br />

World<br />

M<br />

M<br />

Special Supplement - Rubber Machinery World | OCT 2015

Every<br />

Every<br />

<strong>And</strong><br />

As A<br />

Machinery<br />

Technology<br />

Has....<br />

Has...<br />

Equipment Supplier, You Denitely Have...<br />

A Story<br />

Which One is Your’s Today?<br />

Promote Your Brand Through Stories <strong>on</strong><br />

Equipment, Technology, Innovati<strong>on</strong> & More<br />

With Buyers From Over 68 Countries Only On<br />

RUBBER Rubber<br />

Machinery<br />

World<br />

M<br />

Equipment Marketing Redefined<br />

C<strong>on</strong>tact: rubbermachineryworld@gmail.com<br />

M

INFORMATION ON EQUIPMENT,<br />

TECHNOLOGY, INNOVATION &<br />

SUPPLIERS<br />

Email: rubbermachineryworld@gmail.com<br />

Website: http://rubbermachineryworld.com<br />

©2015 – ePublished by Rubber Machinery World in Oct 2015<br />

C<strong>on</strong>tent For Free eDistributi<strong>on</strong> & Download