A Starters Guide on Compression Moulding And Autoclave

This edition of Knowledge On-The-Go Special Supplement features two key machinery used in the rubber industry viz. Autoclave and Compression Moulding.

This edition of Knowledge On-The-Go Special Supplement features two key machinery used in the rubber industry viz. Autoclave and Compression Moulding.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

| AUTOCLAVE |<br />

Of all safety-related c<strong>on</strong>cerns, the most<br />

critical are those which relate to the door’s<br />

operati<strong>on</strong>. The manufacturer of your<br />

autoclave should ensure that the door seals<br />

tightly against rated pressure at the highest<br />

shell temperature; operate readily and<br />

quickly and meets all safety guidelines of a<br />

pressure vessel.<br />

Regular testing is a must al<strong>on</strong>g with fool<br />

proof interlock mechanisms to prevent<br />

door opening under pressure.<br />

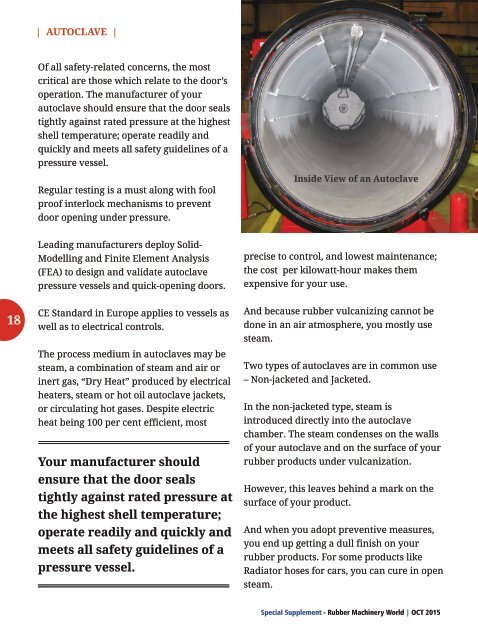

Inside View of an <strong>Autoclave</strong><br />

Leading manufacturers deploy Solid-<br />

Modelling and Finite Element Analysis<br />

(FEA) to design and validate autoclave<br />

pressure vessels and quick-opening doors.<br />

precise to c<strong>on</strong>trol, and lowest maintenance;<br />

the cost per kilowatt-hour makes them<br />

expensive for your use.<br />

18<br />

CE Standard in Europe applies to vessels as<br />

well as to electrical c<strong>on</strong>trols.<br />

The process medium in autoclaves may be<br />

steam, a combinati<strong>on</strong> of steam and air or<br />

inert gas, “Dry Heat” produced by electrical<br />

heaters, steam or hot oil autoclave jackets,<br />

or circulating hot gases. Despite electric<br />

heat being 100 per cent efficient, most<br />

Your manufacturer should<br />

ensure that the door seals<br />

tightly against rated pressure at<br />

the highest shell temperature;<br />

operate readily and quickly and<br />

meets all safety guidelines of a<br />

pressure vessel.<br />

<strong>And</strong> because rubber vulcanizing cannot be<br />

d<strong>on</strong>e in an air atmosphere, you mostly use<br />

steam.<br />

Two types of autoclaves are in comm<strong>on</strong> use<br />

– N<strong>on</strong>-jacketed and Jacketed.<br />

In the n<strong>on</strong>-jacketed type, steam is<br />

introduced directly into the autoclave<br />

chamber. The steam c<strong>on</strong>denses <strong>on</strong> the walls<br />

of your autoclave and <strong>on</strong> the surface of your<br />

rubber products under vulcanizati<strong>on</strong>.<br />

However, this leaves behind a mark <strong>on</strong> the<br />

surface of your product.<br />

<strong>And</strong> when you adopt preventive measures,<br />

you end up getting a dull finish <strong>on</strong> your<br />

rubber products. For some products like<br />

Radiator hoses for cars, you can cure in open<br />

steam.<br />

Special Supplement - Rubber Machinery World | OCT 2015