A Starters Guide on Compression Moulding And Autoclave

This edition of Knowledge On-The-Go Special Supplement features two key machinery used in the rubber industry viz. Autoclave and Compression Moulding.

This edition of Knowledge On-The-Go Special Supplement features two key machinery used in the rubber industry viz. Autoclave and Compression Moulding.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

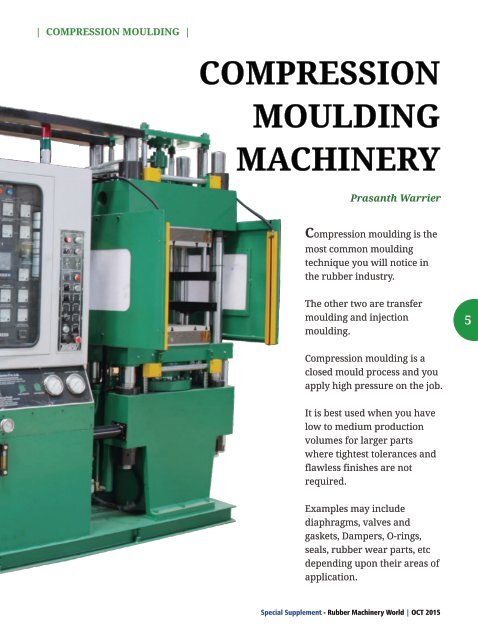

| COMPRESSION MOULDING |<br />

COMPRESSION<br />

MOULDING<br />

MACHINERY<br />

Prasanth Warrier<br />

Compressi<strong>on</strong> moulding is the<br />

most comm<strong>on</strong> moulding<br />

technique you will notice in<br />

the rubber industry.<br />

The other two are transfer<br />

moulding and injecti<strong>on</strong><br />

moulding.<br />

5<br />

Compressi<strong>on</strong> moulding is a<br />

closed mould process and you<br />

apply high pressure <strong>on</strong> the job.<br />

It is best used when you have<br />

low to medium producti<strong>on</strong><br />

volumes for larger parts<br />

where tightest tolerances and<br />

flawless finishes are not<br />

required.<br />

Examples may include<br />

diaphragms, valves and<br />

gaskets, Dampers, O-rings,<br />

seals, rubber wear parts, etc<br />

depending up<strong>on</strong> their areas of<br />

applicati<strong>on</strong>.<br />

Special Supplement - Rubber Machinery World | OCT 2015