Logoworld_Web_Pages

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

N. 10<br />

SEP 2016<br />

welcome to our world<br />

DPA BRAZIL<br />

MARCEL DE BARROS<br />

TALKS ABOUT<br />

THE BRAZILIAN MARKET<br />

S a v e t h e d a t e<br />

24NOVEMBER2016<br />

P O L L I N AT I O N DAY | C A S C A I S | P O RT U G A L<br />

MARCEL DE BOTTON<br />

A MAN COMMITTED<br />

TO SUSTAINABILITY<br />

AND TO A BETTER WORLD<br />

YOGGI<br />

MEET THE NEW<br />

YOGGI BOTTLE<br />

THE CARLYLE GROUP<br />

IS PART OF THE FAMILY<br />

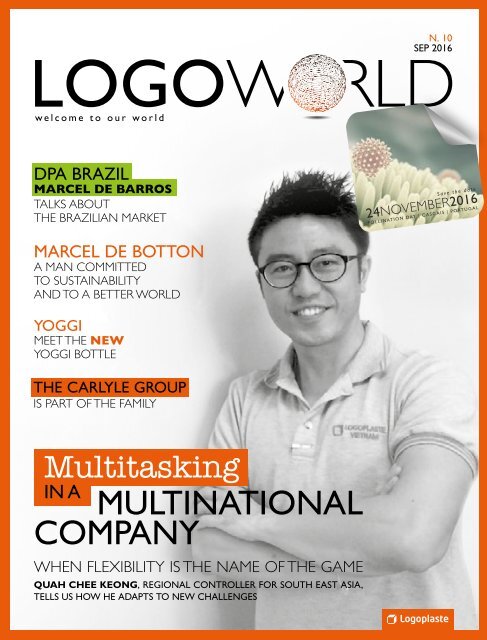

Multitasking<br />

IN A<br />

MULTINATIONAL<br />

COMPANY<br />

WHEN FLEXIBILITY IS THE NAME OF THE GAME<br />

QUAH CHEE KEONG, REGIONAL CONTROLLER FOR SOUTH EAST ASIA,<br />

TELLS US HOW HE ADAPTS TO NEW CHALLENGES

LISA HILLBURN<br />

Corporate HR Director Worldwide

WELCOME TO<br />

LOGOWORLD 2016<br />

My name is Lisa Hillburn and I would like to introduce you<br />

to LOGOWORLD: Logoplaste’s annual magazine – designed<br />

for our external audience of contacts & stakeholders.<br />

LOGOWORLD is the perfect channel to help you understand<br />

what it is like on the inside of a Company<br />

that hardly ever sleeps.<br />

Back in 2008, we launched our first <strong>Logoworld</strong>, the flagship<br />

of our communication channels at the time and after<br />

9 issues, we decided it was due a complete makeover<br />

in terms of look & feel. We wanted something that<br />

graphically portrays who we are, what we do and how we<br />

do it, across the world, so here is our revamped version.<br />

As a multicultural Company, present in 16 countries<br />

and 3 continents, we make it our business to take care<br />

of our teams in all their daily endeavors, to ensure every<br />

day is a good day at Logoplaste.<br />

In this issue we talk to the CEO of DPA in Brazil, we get<br />

to know a little more about our President, Marcel de Botton,<br />

give you an insight into our facts & figures, talk about<br />

our team’s experiences, and give an overview of our Plants.<br />

I would like to take this opportunity to thank our fantastic<br />

editorial team in Corporate HR –Vera Pires, Magda Merali<br />

& Sílvia Alves who make this happen.<br />

We hope you enjoy and your feedback is always welcome!<br />

Lisa Hillburn<br />

Corporate HR Director Worldwide<br />

LOGOWORLD profile<br />

<strong>Logoworld</strong> is an annual magazine.<br />

Published by Logoplaste’s Corporate Human Resources Department<br />

Issue nº 10 / 2016<br />

Design & Layouts Blink Ideas, Portugal<br />

Printing by Formato S.A. Portugal<br />

Copies printed: 500<br />

Cover page<br />

Quah Chee Keong<br />

Regional Controller for Logoplaste South East Asia<br />

© 2016 Logoplaste Consultores Técnicos, S.A. All rights reserved.<br />

Contents may not be reprinted or electronically distributed<br />

without written permission from the publishers.<br />

Contact: communication@logoplaste.com

EDITORIAL<br />

Quah Chee Keong<br />

Regional Controller<br />

South East Asia<br />

Quah Chee Keong<br />

Regional Controller South East Asia<br />

With Logoplaste, in South East Asia, for the last 3 years, Quah Chee<br />

Keong – Regional Controller, is a multitasking person with a diverse<br />

background and an enormous capacity do adapt to new challenges.<br />

We asked Quah to tell us a little about his work.<br />

Come and meet an extremely organized man.<br />

6 75 LOGOWORLD 2016

Multitasking in<br />

a Multinational<br />

Company<br />

When flexibility<br />

is the name of the game<br />

What I do<br />

“As a Regional Controller, I take care of administration,<br />

legal and procedure matters, finance, human resources<br />

and accounting. I also communicate with outsourcers,<br />

consultants, lawyers, auditors, local authorities such<br />

as customs and tax officers. Communication needs to flow<br />

smoothly among all parties, to avoid any misunderstanding.<br />

Furthermore, with close interaction with the local team<br />

at the plants, I actively make sure that they are motivated<br />

and create good energy throughout the team.<br />

Time management is the key to doing it all and doing<br />

it well. Planning, discipline and focus are also very important,<br />

especially when you work on several different tasks<br />

at the same time and you have deadlines to meet.<br />

Another trick I use to organize my schedule is to plan my<br />

trips one or two months in advance, so I can prioritize<br />

tasks effectively. Of course, when you travel it means<br />

that sometimes your days are long so that you get<br />

everything done on time.<br />

The Logoplaste way<br />

All this is easier than it sounds. Logoplaste gives me full<br />

autonomy to make my own decisions. Being responsible<br />

and having responsibility, gives you the advantage of time –<br />

which is precious especially with long time zone differences.<br />

My colleagues<br />

and me<br />

My relationship with my co-workers is very close.<br />

I am a people-oriented manager, open and transparent.<br />

Although when the situation requires result-driven action,<br />

then I actively cooperate and involve the team to deliver<br />

the best and fastest result.<br />

I have always tried to balance between relationship<br />

and result-orientation. The book “The 7 Habits of Highly<br />

Effective People” written by Stephen Convey, has been<br />

guiding me “effectively” on relationship management.<br />

What I most enjoy<br />

The things that I like to do most at Logoplaste, besides<br />

doing my assigned tasks, is meeting new people from various<br />

countries and backgrounds, be it colleagues, suppliers,<br />

consultants, customers. This allows me to know more about<br />

their cultures, their experiences and stories, that most<br />

of the time impress me.<br />

Solid advice<br />

Work hard, learn as much as<br />

you can and do not be calculative<br />

on works assigned by your line<br />

manager or colleagues. Always<br />

stay hungry to learn and do<br />

not stay in your comfort zone.<br />

Challenge yourself constantly<br />

to move to the next level, as the<br />

human will is unlimited.”

INDEX<br />

EDITORIAL<br />

PARTNERS<br />

trust & loyalty<br />

16<br />

DPA<br />

04<br />

MB<br />

20<br />

LUCOZADE RIBENA<br />

SUNTORY SAYS IT ALL<br />

IN ONE SENTENCE<br />

WHO IS THE MAN<br />

BEHIND LOGOPLASTE?<br />

22<br />

LIGHTWEIGHT<br />

CONTAINERS<br />

OPENS US KEG<br />

PRODUCTION LINE<br />

ONE STEP AHEAD<br />

360º solutions<br />

10<br />

26<br />

AWARDS ACROSS<br />

THE GROUP<br />

32<br />

PHBOTTLE<br />

33<br />

NATURE INSPIRED<br />

MANUFACTURING EVENT<br />

34<br />

PREVENT RESIN<br />

PELLET LOSS<br />

36<br />

A BRAND TO MIRROR<br />

PERFORMANCE<br />

8 9 LOGOWORLD 2016

LOGOWORLD<br />

world’s best product<br />

48<br />

THE CARLYLE GROUP<br />

IS PART OF THE FAMILY<br />

50<br />

FOCUS GROUPS IN IBERIA<br />

52<br />

54<br />

CHANGING NAMES<br />

YOGGI<br />

COMPANY<br />

SNAPSHOT<br />

SOCIAL RESPONSIBILITY<br />

100% commitment<br />

56<br />

CORPORATE TELEVISION<br />

WORLDWIDE - LOGOTV<br />

76<br />

40<br />

WHAT DOES IT MEAN<br />

TO BE DIFFERENT,<br />

AS YOU GROW OLDER?<br />

57<br />

CATÓLICA<br />

PLANT DIRECTORY<br />

all around<br />

44<br />

45<br />

CANADA HELPS OUT<br />

LOCAL COMMUNITIES<br />

BY DONATING BOTTLES<br />

WOMEN’S DAY IN BRAZIL<br />

58<br />

ECOVADIS<br />

60 LOGOWORLD<br />

INTERNS<br />

64<br />

65<br />

FRANCE<br />

MEXICO<br />

NETHERLANDS<br />

POLAND<br />

45<br />

THANKSGIVING<br />

FEELS DIFFERENT<br />

66<br />

PORTUGAL<br />

70<br />

SPAIN<br />

71<br />

UKRAINE<br />

UK<br />

72<br />

UK<br />

73<br />

USA<br />

75<br />

VIETNAM

WE HAVE<br />

OPENED<br />

OUR<br />

WORLD

WHO’S THE MAN<br />

BEHIND LOGOPLASTE?<br />

MARCEL DE BOTTON<br />

A man committed to sustainability and to a better world<br />

What is today a multinational operation, started in 1976 as a one-man show. That man, Marcel<br />

de Botton, is today a leader in European Recycling Policies and Logoplaste’s Chairman.<br />

“ Nothing, not anything, can be<br />

done without enormous persistence,<br />

without effort, without team work,<br />

without listening to those who work<br />

with us. Encouraging and motivating<br />

your team is much more than<br />

rewarding, it is fundamental for<br />

the success of all.”<br />

Marcel de Botton<br />

Minho University, 2011<br />

Marcel de Botton has always led a double life, dedicated to both the production of rigid plastic<br />

packaging and recycling.<br />

12 13 11 LOGOWORLD 2016

MB

WHO’S THE MAN<br />

BEHIND LOGOPLASTE?<br />

1989<br />

In 1989 Marcel becomes President<br />

of “GIR“ Grupo Intersectorial<br />

da Reciclagem, (Portuguese Intersectorial<br />

Recycling Group).<br />

1990<br />

In 1990 Logplaste’s President assumes<br />

role of Chairman of “APIP” - Associação<br />

Portuguesa da Indústria de Plásticos<br />

(Portuguese Plastic Industry Association),<br />

representing 298 companies and<br />

employing 13,000 people.<br />

1994<br />

Four years later he is Advisory Board<br />

Member of ‘CNE - Centro Nacional<br />

de Embalagem’ (Portuguese National<br />

Package Center).<br />

1995<br />

In 1995, Marcel de Botton is Founder and<br />

Honorary Chairman of EUPC - European<br />

Plastics Converters, representing 23,000<br />

European companies, employing over<br />

1.000.000 people, converting over 24<br />

million tons of polymers per year.<br />

14 15 LOGOWORLD 2016

1999 - 2002<br />

Founder of “Sociedade Ponto Verde”<br />

in Portugal is his next project. Between<br />

1999 and 2002 Marcel is a Board<br />

Member of Plastval - Valorização<br />

de Resíduos Plásticos, S.A. One year<br />

later, Marcel de Botton is Founder<br />

and Vice President of the Board of PIEP<br />

– Innovation in Polymers Engineering<br />

Nucleolus, at Minho University.<br />

2012<br />

2012 is marked by the Foundation<br />

of PETCORE EUROPE, which represents<br />

all members of the PET supply chain.<br />

PETCORE EUROPE is a European<br />

association representing the PET value<br />

chain, including PET manufacturers<br />

(CPME), PET converters (EuPC, Forum<br />

Pet Europe, EuPET), and PET recycling<br />

entities (EuPR). PET is the most collected<br />

and recycled plastic material in Europe.<br />

HONOURS<br />

Distinguished by the President<br />

of the Portuguese Republic with:<br />

/ Insignia of the “Ordem do Mérito<br />

Industrial” on February 28th of 1994<br />

/ Insignia of the “Ordem do Infante<br />

D. Henrique” in January 9th of 2006<br />

Distinguished by the Universidade<br />

do Minho with the ’Doutor Honoris<br />

Causa’ degree in Science and Engineering<br />

of Polymers and Composites.<br />

A life time dedicated to a better world. Those who<br />

have had the opportunity to work with him, say<br />

that Marcel de Botton faces life with a positive<br />

attitude, a tight grip and realist management, never<br />

spending more than is made. His personality has<br />

been forged by life’s trials and by an innate survival<br />

instinct. Never looking back and always hopeful<br />

in the future. Placing his faith in his team has always<br />

paid off and today the results are visible.<br />

2014<br />

Two years later, Marcel de Botton<br />

is Honorary President of INTERFILEIRAS<br />

– Portuguese National Association in the<br />

Recovery, Management and Valorization<br />

of Packaging Waste.<br />

2015<br />

One year later, in 2015, he is Founder<br />

of WFO – WASTE FREE OCEANS<br />

PORTUGAL Association, with the<br />

purpose to solve national issues related<br />

to waste in oceans and other water<br />

courses.

01<br />

PARTNERS<br />

TRUST & LOYALTY

PARTNERS<br />

DPA<br />

Marcel de Barros, CEO of Dairy Partners Americas,<br />

talks about the Brazilian market<br />

Marcel de Barros<br />

Dairy Partners Americas CEO<br />

Fabio Salik, Logoplaste’s Managing Director in Brazil, asked Marcel<br />

de Barros, DPA’s CEO, to give a quick view on the chilled dairy/<br />

yogurt market, on the challenges Brazil’s industry is up against<br />

and on how DPA looks into the future.<br />

18 19 LOGOWORLD 2016

01<br />

LOGOWORLD<br />

SOCIAL RESPONSABILITY<br />

ONE STEP AHEAD<br />

PARTNERS<br />

Can you tell us a little about DPA in Brazil?<br />

DPA Brazil is a joint venture between Fonterra and Nestlé<br />

that began operations in Latin America in 2003. In 2014,<br />

there was a reorganization, with Fonterra taking a 51%<br />

stake and Nestlé 49%. DPA operates in the chilled dairy<br />

market in Brazil.<br />

How does DPA see the yogurt market in<br />

Brazil? How does it compare to the European<br />

and North American markets?<br />

North America and Europe have mature markets in<br />

terms of consumption per capita, mainly growing through<br />

innovation. On the other hand, the Brazilian market has<br />

growth potential in both directions: consumption per<br />

capita and by innovation.<br />

What are the main challenges<br />

when operating in Brazil?<br />

To operate in Brazil, a company needs to be ready<br />

to face important challenges, such as dealing with a deficient<br />

and expensive logistic infrastructure, under qualified work<br />

force, exchange rate vulnerability, etc. Apart from these,<br />

the recent political and economic instability is disturbing<br />

the business environment. However, Brazil is a market with<br />

tremendous growth opportunities and DPA is betting on it.<br />

How can Logoplaste help<br />

with some of these challenges?<br />

DPA Brazil is entering a strong expansion phase that should<br />

accelerate in the next few years. We seek partners and<br />

suppliers that can follow our growth, contributing with<br />

innovative products and solutions, having an excellent level<br />

of service at competitive prices; and always maintaining<br />

the expected quality levels.<br />

What does DPA seek in its suppliers?<br />

What are the main attributes?<br />

To become a DPA supplier in Brazil, a company must<br />

go through an appraisal process called “Vendor Approval”.<br />

In this process, it evaluates the quality, the financial<br />

performance of the supplier, as well as its compliance<br />

with local legislation, including labor & environment<br />

laws. Only after the supplier has passed all stages, it is fit<br />

to do business with DPA.<br />

In addition, to stay competitive in such a dynamic<br />

market as the yogurt one, DPA expects its suppliers<br />

to be world class, constantly bringing innovation into<br />

their production processes and products, and to be aware<br />

of consumer trends such as environmental sustainability.<br />

Suppliers also need to permanently search for cost<br />

reductions and higher quality.<br />

PLANT DIRECTORY

The relationship with Logoplaste Brazil<br />

began in 1997 and has been solid until today.<br />

What makes a relationship last so long?<br />

An open and honest dialog between both companies<br />

is the keystone to the relationship between DPA Brazil<br />

and Logoplaste. It promotes the fulfillment of both parties’<br />

expectations.<br />

The market is still concentrated on liquid yogurts<br />

and basic pulps. After the launch of the Greek segment,<br />

(that DPA Brazil inaugurated in 2012 with NESTLÉ GREGO),<br />

the market is becoming more dynamic through innovation<br />

and new launches. Brazilian consumers were waiting<br />

for better quality yogurts with superior flavor and<br />

consistency.<br />

Long lasting partnerships are based on the alignment<br />

of business strategies, on sharing the same values and<br />

on conducting business the same way.<br />

In the next 3 years, we expect to see consumers migrating<br />

to higher added-value products, such as self-indulging<br />

and healthier yogurts (lactose free, gluten free, etc).<br />

Our expectation is to continue this partnership<br />

with Logoplaste on the long run, as long as the above<br />

premises hold true.<br />

Does DPA have other in-house operations?<br />

What are the advantages of having<br />

a “through the wall” setup as Araras?<br />

No, DPA does not have other in-house operations.<br />

This category is extremely dynamic and requires great speed<br />

from all elements of the supply chain. An in-house operation<br />

allows for this dynamism and eliminates transaction costs.<br />

How does DPA see the future of yogurts?<br />

What are market perspectives? And product<br />

tendencies?<br />

As Brazilians are eating more at home, we will also keep<br />

focus on the chilled dessert segment, which is still small<br />

in the country. The launch of CHANDELLE CHANTILLY<br />

is bringing new consumers to the segment, satisfying<br />

the demand for a ready to eat dessert that is not only<br />

convenient but also delicious!<br />

Considering the economic situation, and the growth<br />

of channels such as Cash & Carry, we expect to see<br />

demand evolving to larger formats and multipacks, followed<br />

by promotions catching consumers’ attention and offering<br />

better deals and “Value for Money”.<br />

The chilled dairy market in Brazil still has many growth<br />

opportunities. Although the category has a high penetration<br />

rate, the per-capita consumption is low (less than<br />

7 kilos per person/per year), well below the average<br />

of neighboring countries.<br />

Consumption occurs throughout the day, especially between<br />

meals. It is seen as a healthy and tasty snack, leaving room<br />

to promote more frequency in the consumption routine.<br />

20 21 LOGOWORLD 2016

01<br />

PLANT DIREcTORy<br />

LOGOWORLD<br />

SOcIAL RESPONSABILITy<br />

ONE STEP AHEAD<br />

PARTNERS

PARTNERS<br />

Lucozade Ribena Suntory<br />

says it all in one sentence<br />

Inspiration can come from long-term business relationships<br />

When Satvinder Dhillon, Head of Packaging Development at Lucozade Ribena Suntory, asked<br />

her team to come up with a sentence to describe their relationship with Logoplaste’s Group,<br />

the result was unexpected.<br />

“ While you may not have a great marriage without<br />

a partnership. We have proven that you can certainly<br />

have a great partnership without a marriage! ”<br />

This is how one member of the LRS Packaging Team described the past 3 years working with<br />

Chris Clarke, UK R&D Manager Logoplaste Innovation Lab and his team.<br />

On March 9th 2016, both companies got together in Coleford for a Technical Meeting.<br />

Logoplaste presented the results of the 6-month study which has used different oxygen scavenger materials.<br />

A cross learning and information share to support future decision-making on packaging development.<br />

22 23 LOGOWORLD 2016

01<br />

PLANT DIRECTORY<br />

LOGOWORLD<br />

SOCIAL RESPONSABILITY<br />

ONE STEP AHEAD<br />

PARTNERS<br />

Logoplaste Innovation Lab<br />

Susana Garcia | Raw Material Consultant<br />

Luis Barros | Laboratory Technician<br />

Joana Silva | INOV Contacto Trainee<br />

Chris Clarke | UK R&D Manager<br />

Lucozade Ribena Suntory<br />

Yann Maurice | Packaging Director,<br />

SBFE and Centre of Excellence<br />

Leonie Watson | SBFE, Stability Group Manager<br />

Paul Jones | Analytical Scientist<br />

Louise Durham | Analytical Scientist<br />

Bridgitte Davies | Micro Biologist<br />

Alison Nyman | Packaging development /<br />

Baseball Project Manager

PARTNERS<br />

Lightweight Containers<br />

opens US keg<br />

production line<br />

24 25 LOGOWORLD 2016

01<br />

PARTNERS<br />

L<br />

ightweight Containers BV is the<br />

company behind the KeyKeg and<br />

UniKeg brands. These unique lightweight kegs combine<br />

groundbreaking R&D and advanced production methods<br />

with a clear understanding of what the customers need.<br />

The result is two complete families of one-way kegs<br />

that stand out in the market due to their innovation, quality,<br />

convenience, safety and sustainability.<br />

In May, Lightweight Containers issued a press release<br />

explaining the start-up:<br />

“Lightweight Containers has started up a new production line<br />

to make KeyKeg Slimlines and UniKegs. The new line<br />

is in Joliet, Illinois (US). The fully automated computer and<br />

robot-driven line can produce the entire Slimline and UniKeg<br />

series depending on demand. Logoplaste supports and oversees<br />

the line’s daily production.<br />

With the new line, Lightweight Containers is preparing<br />

for the rapid growth it anticipates in the United States. Anita<br />

Veenendaal, CCO of Lightweight Containers, says, “In the last<br />

six years, our worldwide sales have grown by more than 40%<br />

a year. A production line in the US will en-able us to respond<br />

to the growing demand more quickly and flexibly. We also know<br />

that there’s broad support from the American society for setting<br />

up a factory there, since we’re contributing to the US economy.”<br />

Concentration on R&D, sales, and marketing<br />

The new plant was designed in close collaboration<br />

with the manufacturing specialist Logoplaste. Logoplaste<br />

takes care of organizing the line’s daily production.<br />

Jan Veenendaal CEO of Light-weight Containers has this<br />

to say about this partnership: “Working with Logoplaste<br />

is enabling us to grow faster in the US, as well as to concentrate<br />

more on R&D, sales, and marketing. Logoplaste is a highly professional<br />

production partner who completely shares our views<br />

on quality and continuity. The new production line is a logical<br />

consequence of our strategy of producing as closely as possible<br />

to our customers.”<br />

The same language<br />

David Batey, Regional Commercial Director for Logoplaste<br />

NCEE: “Logoplaste and Lightweight Containers are both<br />

ambitious, successful family firms and we speak the same<br />

language. Besides that Lightweight Containers knows the ins<br />

and outs of both the production line and the manufacturing<br />

process through and through. Because of this we were able to<br />

round off the preparations quickly, professionally and successfully.<br />

The start of the fully automated production line went well<br />

and we’re now producing at full capacity.”<br />

Lightweight Containers is well known for the one-way 20-<br />

and 30-liter KeyKeg. The family-owned company, market<br />

leader in high-quality one-way kegs, develops, produces, and<br />

sells the KeyKeg and guarantees the continuity and quality<br />

of the KeyKeg concept.<br />

This revolutionary and successful one-way keg develops<br />

and leads the market for one-way kegs and is available<br />

in 10, 20- and 30-liter versions. Breweries, wineries and<br />

other beverage companies prefer and use KeyKegs all over<br />

the world, as they are especially suited for carbonated<br />

and still beverages.<br />

KeyKegs are currently sold to clients in more than<br />

52 countries. KeyKegs are produced in Germany,<br />

the Netherlands and the US. Further expansion of<br />

production plants is planned.<br />

Logoplaste Joliet is excited with this challenge and happy<br />

to be a part of the production of this innovative,<br />

sustainable concept.<br />

PLANT DIRECTORY LOGOWORLD SOCIAL RESPONSABILITY ONE STEP AHEAD<br />

“Logoplaste is a highly professional<br />

production partner who completely<br />

shares our views on quality<br />

and continuity.”

26 27 LOGOWORLD 2016

02<br />

ONE STEP AHEAD<br />

360º solutions

ONE STEP AHEAD<br />

AWARDS ACROSS THE GROUP<br />

July 2016<br />

LOGOPLASTE<br />

received the<br />

SUSTAINABILITY<br />

EXCELLENCE AWARD<br />

SC Johnson was pleased to announce that Logoplaste was<br />

the recipient of its 2016 Sustainability Excellence Award.<br />

Logoplaste received the Sustainability Excellence Award<br />

for helping SC Johnson pioneer the first 100 percent postconsumer<br />

recycled Windex® bottle, providing a win for the<br />

company, a win for consumers and a win for the environment.<br />

Winners were announced at the 2nd Annual Top Supplier<br />

Award ceremony on June 30th, 2016, during an SC Johnson<br />

supplier recognition event in Chicago. The event celebrated<br />

critical suppliers that contributed to the company’s growth<br />

and underscored the company’s commitment to quality<br />

and innovation. “We are thrilled to celebrate these world-class<br />

suppliers who contribute so much to SC Johnson’s success,” said<br />

Kelly M. Semrau, Senior Vice President - Global Corporate Affairs,<br />

Communication and Sustainability. “Congratulations to all the<br />

award winners not only for operational excellence and the many<br />

product innovations they’ve supported, but on delivering beyond<br />

expectations.”<br />

Logoplaste’s Team and Filipe de Botton were honored<br />

to receive the award. “It is an honor to, once again (and<br />

on a row!), be part of the awards ceremony as a winning<br />

supplier. Logoplaste strives to meet Partner expectations,<br />

especially when it comes to protecting the environment.<br />

We are all very happy to be a part of this 100% postconsumer<br />

recycled project and will keep on delivering on a<br />

daily basis our engagement with SC Johnson.”<br />

28 29 LOGOWORLD 2016

PARTNERS<br />

02<br />

ONE STEP AHEAD<br />

MAY 2016<br />

Ecover<br />

Ocean Bottle<br />

wins Green Good<br />

Design Award 2016<br />

Logoplaste Innovation Lab with the Ecover Ocean bottle<br />

project just won the Green Good Design Award 2016<br />

in the packaging category.<br />

Architecture, landscape architecture, urban planning<br />

projects, product, packaging, and graphic designs from over<br />

20 nations were awarded with Green GOOD DESIGN 2016,<br />

representing the world’s most important manufacturers<br />

and design firms. This also includes the leading FORTUNE<br />

500 corporations that are forwarding a new emphasis on a<br />

more sustainable design and environment worldwide.<br />

The original GOOD DESIGN founded in Chicago in 1950<br />

remains the oldest and most important Awards Program<br />

worldwide.<br />

For 2016 Green GOOD DESIGN, the Chicago Athenaeum<br />

received hundreds of submissions from around the world.<br />

Members of The European Center’s International Advisory<br />

Committee - worldwide leaders in the design industry - served<br />

as the jury and selected over 100 products, programs, people,<br />

environmental planning, and architecture as outstanding<br />

examples of Green Design from 22 nations.<br />

SOCIAL RESPONSABILITY<br />

LOGOWORLD<br />

PLANT DIRECTORY<br />

This is the 8th year The Chicago Athenaeum institution<br />

has developed this very specialized edition of the original<br />

GOOD DESIGN program.<br />

Green GOOD DESIGN identifies and emphasizes the<br />

world’s most important examples of sustainable design<br />

and to develop a public awareness program to the general<br />

public about which global companies are doing the best job<br />

ecological and sustainable design for our world environments.

March 2016<br />

Logoplaste<br />

São Cristóvão<br />

wins an Ipiranga<br />

Award<br />

Logoplaste São Cristóvão, Brazil, wins Best Service<br />

Level award at an Ipiranga’s event.<br />

The award was included in the MAIS Ipiranga<br />

Supplier Program, where vendors are rated<br />

in the following categories: Technical Quality,<br />

Commercial Relationship and Service Level.<br />

Logoplaste São Cristóvão reached an impressive<br />

mark of 100% OTIF (on time in full deliveries) during<br />

the whole year of 2015.<br />

February 2016<br />

Logoplaste<br />

Innovation<br />

Lab wins Gold<br />

at the German<br />

Design Awards<br />

The iconic bottle ECOVER wins the prestigious Gold<br />

award at the German Design Awards 2016.<br />

Present to receive the trophy were Logoplaste<br />

Innovation Lab members: Helder Almeida, Head<br />

of Project, and Carlos Rego, Designer Coordinator.<br />

The Jury’s statement on the project summarizes<br />

the basic ideas that were taken into consideration<br />

when creating ECOVER:<br />

“Ecover Ocean bottle is the first bottle manufactured out<br />

of recycled plastic to include 10 % ocean plastic waste.<br />

The form of the bottle is the result of rigorously applying<br />

the skeleton design principles of microorganisms in nature.<br />

With the help of bionics, this design was able to reduce<br />

the material usage by 20 % in comparison to conventional<br />

plastic bottles – with the same level of stability<br />

and functionality. The Ecover Ocean bottle is an excellent,<br />

sustainable product that deals with the problem of plastic<br />

waste in the ocean and brings the topics of recycling<br />

and sustainability to a higher level. An exemplary solution.”<br />

30 31 LOGOWORLD 2016

PARTNERS<br />

02<br />

ONE STEP AHEAD<br />

November 2015<br />

Logoplaste<br />

wins 2 nd place at<br />

the SAP Quality<br />

Awards<br />

Logoplaste’s SAP Project “Treasury Management System<br />

including Bank Communication Management” won Silver<br />

in the category of “Fast Delivery” projects.<br />

Representing Logoplaste was Rui Marques (SAP<br />

Project Manager) and Isabel Machado (Corporate Cash<br />

Manager). The project had the participation of Stratesys,<br />

partner specialized in SAP.<br />

The new solution optimizes the management of<br />

Corporate Treasury in 18 countries. Key projects aspects<br />

are: immediate access to balance in each bank account,<br />

faster access to real time and quality information,<br />

improvement in standardization across the department,<br />

85% increase in processes automation, and increased<br />

control and saving in bank commissions.<br />

October 2015<br />

Ribena 1,5 Lt<br />

bottle wins<br />

the Horners<br />

Bottlemakers<br />

Award 2015<br />

The ceremony took place at the Worshipful Horners<br />

Annual Banquet and there to receive the prize was Chris<br />

Clarke, Logoplaste Innovation Lab, and Head of Lucozade<br />

Ribena Suntory Packaging Development, Satvinder Dhillon.<br />

This award recognizes innovation in the field of plastic<br />

bottles, and is organized in association with the British<br />

Plastic Federation.<br />

SOCIAL RESPONSABILITY<br />

LOGOWORLD<br />

PLANT DIRECTORY

32 33 LOGOWORLD 2016

PARTNERS<br />

02<br />

LOGOWORLD<br />

SOCIAL RESPONSABILITY<br />

ONE STEP AHEAD<br />

October 2015<br />

UK Plastic Industry Awards 2015<br />

Logoplaste UK, was the winner of the Best Environmental or Energy Efficiency Program of the Year.<br />

The event took place at the London Hilton on Park Lane with more the 500 people present.<br />

PLANT DIRECTORY

ONE STEP AHEAD<br />

PHBOTTLE<br />

PHBottle Project keeps rolling<br />

pedro lopes<br />

Project Manager<br />

Logoplaste Innovation Lab is part of a Consortium brought together to develop<br />

a bottle, where the raw material is entirely made from fruit wastewater.<br />

On April 18th in Brussels, Maria Eugenia Zacarias and Pedro Lopes participated<br />

in a workshop, where Pedro presented “PHB: Opportunities for Rigid Packaging.”<br />

PHBottle, funded by the European Commission, aims to develop a biodegradable<br />

material (PHB, polyhydroxybutyrate) by fermentation of food industry byproducts<br />

(juice processing wastewater). This is where the raw material<br />

will come from.Logoplaste Innovation Lab will design the bottle and study<br />

the PHB conditions for both injection stretch blow moulding and extrusion<br />

blow moulding. The team will also be responsible of the industrial validation.<br />

A daring innovative concept and a challenge for all involved.<br />

34 35 LOGOWORLD 2016

PARTNERS<br />

Nature inspired<br />

manufacturing event<br />

02<br />

ONE STEP AHEAD<br />

PLANT DIRECTORY<br />

LOGOWORLD<br />

SOCIAL RESPONSABILITY<br />

On December 2015, Carlos Rego, Designer Coordinator at Logoplaste Innovation<br />

Lab, was invited to as speaker and to participate in a discussion panel at the Nature<br />

Inspired Manufacturing Workshop organized by the University of Cambridge<br />

and Heriot Watt University. This event consisted of ten lectures from diverse fields<br />

of Biomimetics, from plants biomechanics applied to the build of cars frameworks<br />

and aeronautics, natural vision systems applied to the design of a new generation<br />

of groundbreaking microprocessors, natural perception and learning principles<br />

applied to robotics and AI, natural surgery processes… and many other amazing<br />

subjects. Carlos Rego talked about the integration of Biomimicry Methodology<br />

in a business innovation process to gain a competitive edge. Logoplaste Innovation<br />

Lab was the only company present related with packaging development.

ONE STEP AHEAD<br />

Prevent Resin Pellet Loss<br />

It’s all about cleaning the seas<br />

ZERO %<br />

LOSS<br />

IMAGEM OCEANO<br />

36 37 35 LOGOWORLD 2016

PARTNERS<br />

02<br />

ONE STEP AHEAD<br />

B<br />

ack in 2009, Operation Clean Sweep<br />

was set up to tackle unintentional spills<br />

from the plastics industry which is one of the sources<br />

of plastic pellets in the oceans.<br />

“We have all experienced<br />

the potential for a small quantity<br />

of plastic pellets that can end up<br />

on the floor at any point during<br />

the plastic manufacturing process;<br />

pellets can fall to the floor from<br />

process, during cleaning<br />

of equipment or, in most cases<br />

at the time of delivery either from<br />

bags into bins or from the tanker<br />

delivery into our silos. These pellets<br />

then can find their way into drains<br />

and they make their way into<br />

the waste water systems, the risk<br />

of getting into the ocean increases<br />

and subsequently into the food chain.”<br />

This year, a study to Quantity Pellet Emissions in the UK has<br />

been produced by Eunomia on behalf of the environmental<br />

charity Fidra. The report estimates plastic pellet loss<br />

at 0.001% to 0.01% of pellets handled by the processor.<br />

This estimate is based on reviewing existing studies<br />

on pellet loss.<br />

To tackle this important issue, British Plastics Federation<br />

challenged its associates by inviting plastic industry<br />

companies to reduce the loss of pellets to the environment.<br />

Although procedures were already in place to avoid spills<br />

and pellet loss in Logoplaste’s plants, Stephen Mancey*<br />

embraced the challenge and committed to ZERO% loss not<br />

only for the United Kingdom, but for all the NCEE Region.<br />

The main objective of plastic industries is to protect<br />

the environment by having zero pellets entering the water<br />

systems and eventually the sea.<br />

*Logoplaste’s Managing Director for NCEE – North, Central and Eastern Europe<br />

SOCIAL RESPONSABILITY<br />

LOGOWORLD<br />

PLANT DIRECTORY

ONE STEP AHEAD<br />

A BRAND TO MIRROR<br />

PERFORMANCE<br />

Logoplaste Innovation Lab has a new image<br />

We go behind the scenes to find out how Logoplaste’s<br />

Innovation Lab new rebrand came to be. Design & Biomimicry<br />

Manager, Carlos Rego, tells us how this change came about.<br />

38 39 LOGOWORLD 2016

PARTNERS<br />

02<br />

ONE STEP AHEAD<br />

L<br />

ogoplaste Innovation Lab, part of the<br />

Logoplaste Group, felt that their current<br />

logo was not portraying what the company is today.<br />

It has matured with time, and gained more experience<br />

in the development of innovative packaging solutions that<br />

answer to Partners’ most challenging and complex requests.<br />

The company’s success is based on their 360 degree view<br />

of the package development process. All the variables<br />

of the innovation process are answered, human and<br />

technical factors are taken into consideration, as well<br />

as economic, environmental and social.<br />

The symbol, as whole, represents the 4 axis of the<br />

innovation process, always present in the development<br />

of any packaging, making the product relevant, feasible,<br />

viable and sustainable.<br />

Each curve is a variable: Human, Technical, Economic and<br />

Sustainability. The waves portray Logoplaste’s Innovation<br />

Lab flexibility and adaptation to new challenges and<br />

contexts.<br />

“Life” has a triple meaning:<br />

• Our solutions improve the quality of life of those who<br />

use them<br />

• Our solutions are more reliable<br />

• Our solutions are more sustainable<br />

The new brand was developed by the Design team over<br />

the past year and half, a well thought out process, matured<br />

overtime.<br />

On Logoplaste Innovation Lab<br />

An independent division of<br />

Logoplaste Group exclusively<br />

dedicated to the research<br />

and development of the most<br />

Desirable, Feasible, Viable and<br />

Sustainable Packaging solutions.<br />

SOCIAL RESPONSABILITY<br />

LOGOWORLD<br />

PLANT DIRECTORY<br />

The outer circle shows the company’s globality, supported<br />

by the European and United States hubs.<br />

3 colours are used. Carlos Rego tells us what they represent<br />

and also explains the new slogan, “Packaging Solutions<br />

for Life”:<br />

• Orange – vibrant, creativity, ability to overcome our own<br />

limits<br />

• Dark grey – elegance, maturity, responsibility and discipline<br />

• Light brown – friendship, honesty, sincerity and authenticity

40 41 LOGOWORLD 2016

03<br />

SOCIAL RESPONSIBILITY<br />

100% commitment

SOCIAL RESPONSIBILITY<br />

What does it mean<br />

to be ,<br />

as you grow older?<br />

Making a difference…<br />

…can go a long way into the future.<br />

The transition from adolescence into adulthood<br />

faces young people with new situations and<br />

difficult choices. Young people with special<br />

needs have the same aspirations to being an<br />

“adult” as anyone else, yet their options are<br />

often limited, and they need more support to<br />

reach their goals.<br />

For most young adults with special needs,<br />

graduating from high school brings them into a<br />

“no man’s land” of care provision, as specialized<br />

support is no longer provided, making most<br />

of the vocational training and employment<br />

opportunities unreachable.<br />

Although there are no official statistics, within<br />

the population served by CADIn many young<br />

adults are in this situation. They lead extremely<br />

secluded lives without a meaningful life-project<br />

and few prospects for the future. Moreover, the<br />

overwhelming majority of these young adults go<br />

on living with their parents, with very restricted<br />

social networks and little contact with their<br />

age-peers.<br />

At CADIn we have been creating and<br />

implementing projects for these youngsters<br />

since 2005.<br />

42 43 LOGOWORLD 2016

ONE STEP AHEAD<br />

PARTNERS<br />

03<br />

PLANT DIRECTORY<br />

LOGOWORLD<br />

SOCIAL RESPONSABILITY

SOCIAL RESPONSIBILITY<br />

WORK EMPOWERMENT<br />

One of the first special projects created by CADIn is aimed at<br />

promoting socio-professional integration amongst youngsters<br />

with high-functioning Autism Spectrum Disorders (ASD) or<br />

Asperger’s Syndrome. Many people with Autism or Asperger’s<br />

Syndrome achieve academic success, but struggle to find and<br />

maintain work, because of their deficit in communication and<br />

social skills. CADIn’s team works in two fronts to promote<br />

sustainable employment for them:<br />

Helping young adults meet the needs of the labor market,<br />

through training in soft skills, job hunting and strategies for<br />

success in the workplace<br />

Helping employers, as well as co-workers, embrace<br />

neurodiversity, through training focused on the characteristics<br />

of workers with ASD and workplace management<br />

SUCCESS CASE<br />

Nuno is one of CADIn’s long time clients,<br />

and a success story. Nuno had a previous<br />

job experience at a service station<br />

and finally found professional satisfaction,<br />

and integration, as an Administrative<br />

Assistant in the Department of Human<br />

Resources of Sport Lisboa e Benfica.<br />

Nuno and his workplace tutoR<br />

44 45 LOGOWORLD 2016

ONE STEP AHEAD<br />

PARTNERS<br />

STEP BY STEP, HAND IN HAND<br />

“A Par e Passo” is an idiomatic expression that conveys of the many people whose lives CADIn, its corporate<br />

the idea of walking “in pairs” and “step by step”. partners and volunteers, are helping to improve.<br />

This was the name chosen for yet another project, CADIn’s<br />

befriending & mentoring program for young adults living The fact is everyone is unique, so let us embrace people’s<br />

with neurodevelopmental disorders and other mental differences and give them a chance to live a meaningful<br />

health problems.<br />

and fulfilling life.<br />

This project aims to fight isolation and to promote inclusion<br />

For more information on CADIn please visit www.cadin.net.<br />

of young adults with special needs through the support<br />

Logoplaste’s Social Responsibility Program is fully devoted<br />

of volunteer befrienders & mentors.<br />

to CADIn.<br />

In Pairs - each volunteer will work directly with<br />

a beneficiary, offering support and guidance<br />

03<br />

PLANT DIRECTORY LOGOWORLD SOCIAL RESPONSABILITY<br />

Step by step - supported by this relationship,<br />

beneficiaries take small steps to get out of their isolation,<br />

become more active, socialize, pick up old<br />

hobbies and discover new ones, as well as look<br />

for training and employment opportunities<br />

Mónica, one of the volunteers has been a befriender<br />

to M. for 6 months. In their meetings they have gone<br />

out for walks, visits to museums and challenged their fears<br />

at a treetop adventure park. These are but two examples<br />

Can you make<br />

a difference<br />

in someone’s life?<br />

M. & Mónica (volunteer)

SOCIAL RESPONSIBILITY<br />

CANADA HELPS OUT<br />

LOCAL COMMUNITIES<br />

BY DONATING<br />

milk<br />

Always alert to what they can do for their community, Logoplaste Edmonton and Logoplaste Burnaby,<br />

both contributed with bottles to help children build igloos.<br />

Logoplaste Edmonton donated the milk jugs to a Boys and Girls Club in WETASKIWIN ALBERTA.<br />

The Club runs a day care center that looks after local children. They also work very closely with social<br />

services providing care for disadvantaged children and children who have been taken into care.<br />

Logoplaste Burnaby got 437 bottles together so that COMOX VALLEY CHAMBE OF COMMERCE<br />

could build an igloo for the children.<br />

The igloo was built to be part of one of the children’s activities during the Winterjam festival<br />

that is held every January in the Comox valley. This festival is a 31-day multi-venue music, entertainment,<br />

food and winter sports spectacular.<br />

Igloo construction took 12 hours and provided tons of fun for the kids.<br />

milk<br />

437<br />

12 1<br />

igloo<br />

of fun<br />

Both results were amazing:<br />

perfect constructions for happy children!<br />

46 47 LOGOWORLD 2016

ONE STEP AHEAD<br />

PARTNERS<br />

03<br />

On March 8th Logoplaste Brazil paid tribute<br />

to all female employees, by celebrating INTER-<br />

NATIONAL WOMEN’S DAY in a special way.<br />

In all plants across the country, for every shift, women were presented<br />

with chocolates, making it an unforgettable day for all, as they were not<br />

expecting it. THE HR TEAM WAS VERY HAPPY WITH THE RESULT.<br />

SOCIAL RESPONSABILITY<br />

LOGOWORLD<br />

THANKSGIVING feels DIFFERENT<br />

Doing good for others, in an efficient way…<br />

NOVEMBER 2015<br />

PLANT DIRECTORY<br />

/<br />

Each year, in November, just before the THANKSGIVING<br />

HOLIDAY, Logoplaste Plainfield, Chicago, Racine, Logoplaste<br />

Innovation Lab and Logoplaste Headquarters collect food<br />

for a local Food Pantry.<br />

This year, a team of 13, put together 69 boxes in 35 minutes!<br />

Since it was so efficient, the next hour was spent sorting<br />

donated food.<br />

The project involves not only the donation, but also working<br />

for a couple of hours putting together the holiday gift boxes<br />

for families in need.<br />

It is a great challenge for the team to map out the most<br />

efficient process flow to building the gift boxes with the goal<br />

of beating the time record from the prior year.<br />

/<br />

13<br />

69 35

48 49 LOGOWORLD 2016

04<br />

LOGOWORLD<br />

world’s best product

LOGOWORLD<br />

THE CARLYLE GROUP<br />

IS PART OF THE FAMILY<br />

Logoplaste and The Carlyle Group addressing the HQ team<br />

The Carlyle Group agrees to partner with current shareholders<br />

of Logoplaste. The investment will foster further growth and fuel<br />

international expansion in US and Europe.<br />

50 51 LOGOWORLD 2016

ONE STEP AHEAD<br />

PARTNERS<br />

O<br />

n June 27th 2016 The Carlyle Group<br />

issued the following press release, creating<br />

a milestone in Logoplaste’s<br />

history:<br />

The Carlyle Group (Nasdaq: CG) announced that it has<br />

reached a partnership agreement with the family-owned<br />

business Logoplaste Group (Logoplaste) to support the<br />

continued growth of the Company. The agreement will<br />

reinforce the financial strength of Logoplaste and increase<br />

its investment capacity.<br />

Capital for this investment will come from Carlyle Europe<br />

Partners IV (CEP IV), a European upper-mid-market buyout<br />

fund. The transaction is expected to close in the third<br />

quarter of 2016, subject to customary closing requirements<br />

and regulatory approvals.<br />

Logoplaste is a global designer and manufacturer of valueadded<br />

rigid plastic packaging solutions to a wide range<br />

of blue-chip clients, with its origin and roots in Portugal.<br />

Celebrating its 40th anniversary this year, the company<br />

reported sales in 2015 of €468 million and employs 2,000<br />

people in 16 countries across 4 continents.<br />

Filipe de Botton, Co-CEO of Logoplaste said: “We are<br />

delighted to partner with The Carlyle Group to support Logoplaste’s<br />

global growth plans. The combination of Carlyle’s global presence,<br />

experience in our markets and financial strength will help<br />

us to take advantage of the exciting opportunities available to us.<br />

We are proud of our strong reputation and entrepreneurial<br />

culture, of our 2,000 colleagues who have helped to build the<br />

company, and of our commitment to serving our global partners.<br />

We look forward, with the support of our new partner, Carlyle,<br />

to further building on these foundations.”<br />

Alexandre Relvas, Co-CEO of Logoplaste commented:<br />

“Logoplaste’s management<br />

team has been impressed with<br />

Carlyle’s partnership approach.<br />

As the company celebrates its<br />

40th anniversary, Logoplaste looks<br />

forward to a brighter future which<br />

will bring exciting opportunities<br />

to our colleagues and partners. “<br />

Alex Wagenberg, Managing Director, The Carlyle Group said:<br />

“Logoplaste is globally renowned for innovation and customer<br />

service due to the commitment of its global team of talented<br />

managers and employees. The company holds a strong position in<br />

a growing sector, and is also well positioned for future expansion<br />

due to its innovative R&D capabilities, efficient operating model,<br />

and partnership with longstanding blue chip customers. We look<br />

forward to working with Filipe, Alexandre and all the management<br />

team to further develop the company, using the expertise Carlyle<br />

has in helping to grow international businesses, along with our<br />

strong experience in opening new global markets for leading<br />

European-based packaging companies.”<br />

Credit Suisse and PLMJ advised Logoplaste and its<br />

shareholders. Barclays and Linklaters served as advisors to<br />

The Carlyle Group for the transaction.<br />

SOCIAL RESPONSABILITY<br />

04<br />

PLANT DIRECTORY LOGOWORLD

LOGOWORLD<br />

FOCUS GROUPS IN IBERIA<br />

Focus Groups in Iberia: 22 plants spread out in 580.000 km²<br />

52 53 LOGOWORLD 2016

SOCIAL RESPONSABILITY<br />

ONE STEP AHEAD<br />

PARTNERS<br />

04<br />

LOGOWORLD<br />

F<br />

ocus Group meetings are an important part<br />

of Logoplaste’s DNA, for it is where teams<br />

have a chance to express their ideas and concerns.<br />

Each meeting, anywhere around the world, has employees as<br />

well as HR representatives. Meetings are informal, but every<br />

word counts.<br />

Iberia shares the same HR Team, 5 dedicated professionals<br />

that have the largest plant concentration in the world to take<br />

care of.<br />

When it comes to planning their route, Iberian HR divides into<br />

groups and starts assigning plants.<br />

/<br />

/<br />

/<br />

/<br />

Iberia HR TEAM<br />

In meetings, the teams<br />

show similar characteristics<br />

Since the majority either belong<br />

to Logoplaste’s origin or to the first<br />

internationalization phase, they can analyze<br />

the before and after along the company’s<br />

timeline<br />

Project the future, what are the next steps<br />

yet stay focused on the here and now<br />

Have tremendous work experience they<br />

are eager to share with others<br />

Get involved in all aspects of the meeting<br />

PLANT DIRECTORY<br />

As time goes by, HR has found that the two countries are not<br />

so different as one would initially think.<br />

/<br />

Speak out from the heart<br />

Keeping the region happy, focused and productive.<br />

That is the Iberian’s HR objective.

LOGOWORLD<br />

CHANGING NAMES<br />

Same team, same commitment to excellence,<br />

just a different name<br />

This year two Corporate Departments, seeded at Headquarters in Cascais, underwent a name<br />

changes to better portray what they do and who they do it for.<br />

CPA<br />

=<br />

PCM<br />

Contracts and Project Analysis<br />

Pricing and Contract Management<br />

x<br />

CPA - Contracts and Project Analysis,<br />

has, after careful consideration, decided<br />

to change their name to PCM – Pricing<br />

and Contract Management.<br />

Why this change of name, well-established<br />

within Logoplaste?<br />

The reason is simple. It was noted, over time,<br />

in meetings with Partners that the previous<br />

designation, CPA, did not lead to the immediate<br />

understating of the department’s scope.<br />

And at times, it created a certain confusion.<br />

As a Customer oriented department, PCM<br />

changed their name to avoid uncertainty<br />

and doubt. The team remains the same,<br />

as well as does the commitment level and effort<br />

towards internal and external clients.<br />

Only the name changed.<br />

54 55 LOGOWORLD 2016

PARTNERS<br />

LPM<br />

=<br />

APM<br />

Logoplaste Performance Management<br />

Audits and Performance Management<br />

x<br />

ONE STEP AHEAD<br />

SOCIAL RESPONSABILITY<br />

04<br />

LOGOWORLD<br />

Internal Audits, an important part of daily life<br />

at the plants<br />

The Logoplaste Performance Management (LPM)<br />

was created in 2008 to address issues regarding<br />

industrial performance. At the time the department<br />

comprised essentially of managing the industrial KPI<br />

system and initiated the preferred supplier initiative.<br />

Since the departments inception, the team has<br />

initiated and participated in many group projects while<br />

broadening its responsibilities and today, the team<br />

concentrates its effort on three key focus areas:<br />

Industrial Performance – monitoring the performance<br />

evolution of all plants and provide a platform to<br />

permit effective benchmarking.<br />

Asset Conservation – promoting effective asset<br />

conservation by implementing tools (SAP-PM) and<br />

developing methodologies to permit the good<br />

management of all maintenance and repair activities<br />

at the plants.<br />

Internal Audits – measuring compliance against<br />

corporate processes (logistics), evaluating the<br />

effectiveness of controls and validating the<br />

reliability of the SAP against physical counts<br />

and other documented evidences<br />

The internal audits are taking on an increasingly<br />

import role in the organization because these<br />

interventions not only measure and guarantee<br />

corporate compliance, but also afford the plants<br />

the opportunity to share and learn “best practices”,<br />

ensure that they have a good understanding of group<br />

language (terminologies and concepts) and align<br />

their day-to-day routines, procedures and processes<br />

in their continuous strive to be “best in class”.<br />

This year LPM decided to change its name to APM<br />

(Audits and Performance Management) to better<br />

characterizing the department’s mission/objective.<br />

Same team, same responsibilities, just a different name.<br />

PLANT DIRECTORY

LOGOWORLD<br />

Yoggi<br />

Meet the new Yoggi bottle<br />

The bottle that wants to inspire Portuguese<br />

to see the positive side of life’s little daily problems.<br />

56 57 LOGOWORLD 2016

SOCIAL RESPONSABILITY<br />

ONE STEP AHEAD<br />

PARTNERS<br />

NEW!<br />

#Élíquido!<br />

04<br />

Y<br />

oggi, leading Portuguese brand for liquid<br />

yogurt, just announced its new bottle,<br />

with a strong campaign focused on social media. Aligned<br />

with the brand’s strategy and values, Yoggi handles<br />

the little daily problems with humor, under the new<br />

signature “#Élíquido!”, which means “#It’s liquid!”<br />

The project for the new bottle started in 2014,<br />

at Logoplaste’s Innovation Lab CAD Department,<br />

as a project to optimize weight. At the time Yoggi,<br />

was restructuring its communication strategy. It was a great<br />

opportunity to modernize the package’s Design Language,<br />

making it more distinctive, unique and relevant for both<br />

the brand and its consumers.<br />

Lactalis accepted the challenge and Logoplaste’s Innovation<br />

Lab Design team presented 3 proposals for the redesign.<br />

To give the brand a “fresher” look, nothing better than<br />

the Refresh proposal to be chosen and developed until<br />

the industrial production phase, and of course, presentation<br />

to the market.<br />

The solutions found by Logoplaste Innovation Lab allowed<br />

a weight reduction from 11 to 9 grams in each produced unit.<br />

The reduction in raw material also encompassed<br />

the bottle’s sleeve – the label. Around 70 million bottles<br />

are produced a year, estimating a reduction in raw material<br />

of about 18%, which translated into about 140 tons.<br />

For 30 years in the Portuguese market, “Yoggi continues<br />

to grow and innovate. As market leader in this segment,<br />

it is crucial to accompany the latest trends and be close<br />

to our target audience” refers Nathalie Julia, Lactalis Nestlé,<br />

Group Marketing Manager.<br />

“The new bottle is out<br />

with a modern and appealing<br />

design, keeping Yoggi’s signature<br />

and quality taste. In the back,<br />

we innovated with over 200<br />

positive as well as creative<br />

sentences, that will inspire<br />

and surprise teenagers.”<br />

LOGOWORLD<br />

PLANT DIRECTORY

LOGOWORLD<br />

CORPORATE TELEVISION<br />

WORLDWIDE<br />

Is it worth it?<br />

Last year Logoplaste’s Internal Communications<br />

Department had a big challenge: to launch a corporate<br />

television program for the plants.<br />

Why television? Because is it an appealing way to<br />

transmit information.<br />

Broadcasted news looks good, information is short and<br />

straight to the point, strong images and exciting movies<br />

grab people’s attention. Content can be divided into<br />

programs, making it easy to organize the loop.<br />

The objective was to deliver not only a global<br />

messages worldwide, but also to provide plants with<br />

a new channel for their plant specific information.<br />

As a multinational company, Logoplaste wanted<br />

to create more involvement with all its team, sharing<br />

the same corporate message at the same time.<br />

One year later the results are very good. Employees<br />

enjoy the new channel and are always up to date<br />

on what is going on worldwide.<br />

A universal corporate TV project, with a centralized<br />

back office, is powerful solution making it very easy<br />

to manage and update. Logoplaste has 12 official<br />

languages and broadcasts are localized for each country,<br />

but the message is always the same.<br />

On top of the corporate loop, plants can upload their<br />

specific information which serves a double purpose.<br />

On the one hand, this content is relevant to the<br />

teams at that plant, so it makes the channel even more<br />

useful. On the other hand, people pay more attention<br />

to the global, corporate, information as they know<br />

the broadcast also contains content that is relevant<br />

to their day-to-day work.<br />

58 59 LOGOWORLD 2016

PARTNERS<br />

Católica<br />

Back to School<br />

ONE STEP AHEAD<br />

Following last year’s success, 2015 saw a new session of The Logoplaste International Series at the renowned Católica<br />

University in Lisbon. Tailored courses and hard work for the group, but it paid off and everyone found the contents useful<br />

and the teachers captivating. Another feature of this course is the innate team-building component: “meeting people from<br />

other geographies, whom which we work almost every day”.<br />

SOCIAL RESPONSABILITY<br />

Participants’ thoughts on the course:<br />

/ Facilitators were very good, showing great expertise in their areas<br />

/ Group interactions and practical role play where an important component<br />

/ The training stimulated a simple concept “learn to listen and learn to understand”<br />

04<br />

LOGOWORLD<br />

PLANT DIRECTORY

LOGOWORLD<br />

Ecovadis<br />

Why Ecovadis?<br />

60 61 LOGOWORLD 2016

ONE STEP AHEAD<br />

PARTNERS<br />

E<br />

covadis: what does it do, for who and how:<br />

“EcoVadis’ Corporate Social Responsibility<br />

(CSR) Assessments help companies to monitor<br />

environmental, ethical, and social practices of suppliers<br />

and business partners across 150 purchasing categories,<br />

110 countries and 21 CSR indicators.<br />

Over 130 industry leaders such as Verizon, Merck, Coca<br />

Cola Enterprises, Heineken, Johnson & Johnson, L’Oreal,<br />

Renault-Nissan, ING Bank, and Nokia use EcoVadis<br />

to reduce risk, drive innovation and foster transparency<br />

and trust among over 25,000 trading partners.”<br />

It basically gives a clear picture, for both the supplier<br />

and the buyer, of how the company is doing in terms<br />

of sustainability and corporate social responsibility.<br />

Logoplaste has enrolled with Ecovadis and in the last<br />

2 years improvements have been reported. Ecovadis helps<br />

in measuring what is being done as well as how it is being<br />

done.<br />

Ecovadis also serves as a challenger do to better and more.<br />

To improve the environmental performance In 2015,<br />

Logoplaste launched a worldwide campaign asking<br />

employees to take even more care when using water.<br />

Water saving awareness embraced both the workplace<br />

and home.<br />

SOCIAL RESPONSABILITY<br />

04<br />

PLANT DIRECTORY LOGOWORLD<br />

In today’s competitive market it is essential to know exactly<br />

where you stand and where do you want to go regarding<br />

these two fundamental areas.<br />

/<br />

/<br />

/<br />

/<br />

/<br />

/<br />

/<br />

/<br />

/<br />

ECOVADIS METHODOLOGY COVERS 21 CRITERIA ACROSS THE 4 THEMES:<br />

ENVIRONMENT<br />

Energy consumption<br />

Water<br />

Biodiversity<br />

Local pollution<br />

Materials, chemicals & Waste<br />

Air emissions<br />

Green house gases<br />

Product use / End of life<br />

Costumer health & Safety<br />

/<br />

/<br />

/<br />

/<br />

/<br />

/<br />

/<br />

/<br />

social<br />

Health & Safety<br />

Working conditions<br />

Labor relations<br />

Career management<br />

Child & Forced labor<br />

Freedom of association<br />

Non discrimination<br />

Fundamental human rights<br />

ethics<br />

/ Corruption & Bribery<br />

/ Anti-competitive practices<br />

/ Fair marketing<br />

supply chain<br />

/ Environment<br />

/ Labor practices & Human rights

LOGOWORLD<br />

2016 Summer Internships at<br />

Logoplaste Headquarters<br />

Corporate Finance has 2 interns<br />

62 63 LOGOWORLD 2016

C<br />

orporate Finance Department hosted<br />

2 interns for their Summer<br />

Internships: a 1 st year Business Management<br />

student and a MBA graduate. The experience each<br />

is getting will shape their future career decisions.<br />

Sofia Meneses, Corporate Finance Director, believes<br />

it is not only important, but a responsibility, to help<br />

young adults as they prepare for their professional life.<br />

PARTNERS<br />

ONE STEP AHEAD<br />

Let’s meet the interns...<br />

Country: Portugal, Cascais | Location: Headquarters | Hosting Department: Corporate Finance<br />

Internship Coach: Sofia Meneses, Director of Corporate Finance<br />

Intern: Manuel Lourenço<br />

Age: 32<br />

Status: taking 1 year of from work at<br />

Montepio Bank (since 2009)<br />

School: The Lisbon MBA International<br />

2016 – MBA Nova+Católica<br />

Course: MBA<br />

Intern: Mariana Sousa<br />

Age: 19<br />

Status: 1st year student<br />

School: Católica Lisbon SBE (CLSBE)<br />

Course: Business Management<br />

SOCIAL RESPONSABILITY<br />

04<br />

LOGOWORLD<br />

One of the MBA requirements is for students to internship.<br />

Manuel Lourenço chose Logoplaste, he applied and was<br />

accepted. With an exclusive background in Banking, this<br />

internship will help Manuel have contact, on the one hand,<br />

with business and industrial side of Logoplaste, and on the<br />

other, with the bank-company dynamics, from a client’s<br />

point of view.<br />

So, we asked Manuel how is the Summer Internship going<br />

on different levels…<br />

• On a work level – “Luck was on my side, as I started my<br />

internship in a time when Logoplaste is about to undergo a<br />

major transformation in its capital structure. Change phases are<br />

always intense processes, great learning opportunities”<br />

• Team integration – “I was well received. The company is<br />

opened minded and informal, but at the same time strict and<br />

professional”<br />

• Personally – “I feel at home at Logoplaste. I have support to<br />

perform my tasks and structure from my superiors”<br />

• Impact on MBA studies – “Until the end of the MBA,<br />

students can choose their courses. This internship will help me<br />

pick in a productive and conscious way”<br />

Manuel believes this internship is essential for his last<br />

semester, helping him decided which elective courses to<br />

choose, where he wants to focus his efforts, and what he<br />

would like to do in the near future.<br />

Mariana is enrolled in the CLSBE Mentoring Program and<br />

her Mentor happens to be Filipe de Botton, Logoplaste’s<br />

Co-CEO, so it was a natural that her Summer Internship<br />

be at Logoplaste.<br />

A Summer Internship is always short, but it gives students<br />

hands-on-the-job experience. Currently Mariana is working<br />

on bank contracts and SAP.<br />

Mariana likes being here: “The work environment is really good<br />

and everyone is kind as well as professional. I like what I am<br />

doing and have learnt a lot, by shadowing and by doing.”<br />

As a 1st Year Management Student, Mariana finds that<br />

practical knowledge is important and well looked upon. She<br />

also likes to see how you apply in real life, what you have<br />

learned in the classroom. This experience will encourage<br />

to study harder, as she has seen it is useful in the near<br />

future.<br />

On a persona level Mariana tell us: “It has been a challenge<br />

to come to work during vacation time, but it is worth it. This<br />

internship is making me grow as a person and as a professional.”<br />

PLANT DIRECTORY

64 65 LOGOWORLD 2016

PLANT DIRECTORY<br />

all around<br />

05

LOGOWORLD<br />

SOCIAL RESPONSABILITY<br />

ONE STEP AHEAD<br />

PARTNERS<br />

05<br />

PLANT DIRECTORY

PLANT DIRECTORY<br />

PORTUGAL<br />

CASCAIS HQ<br />

All 4 YOUth<br />

Helping the next generation by<br />

providing tools to jump start<br />

their career.<br />

Logoplaste is part of the Alliance for Youth, a Nestlé<br />

initiative to help young adults enter the employment<br />

market. The program provides them with tools so they<br />

can prepare a cv and a cover letter, create their profile on<br />

Linked In, look for a job in a pro-active and smart manner,<br />

as well as handle themselves in an interview.<br />

In June, Logoplaste HQ hosted Nestlé, and the other<br />

companies, for a work session in Cascais. Participating<br />

companies included Sonae, Graphicsleader, Vodafone, The<br />

Navigator Company, BPI Bank and BA Vidro.<br />

68 67 LOGOWORLD 2016

ONE STEP AHEAD<br />

PARTNERS<br />

PORTUGAL<br />

CASCAIS HQ<br />

Jacksonville University<br />

visits Headquarters<br />

SOCIAL RESPONSABILITY<br />

LOGOWORLD<br />

05<br />

Jacksonville University’s Executive MBA students, USA,<br />

went on an European field trip. Their agenda included<br />

a visit to Logoplaste and Logoplaste Innovation Lab’s<br />

headquarters in Cascais.<br />

The team was enthusiastic about their guided<br />

tour, especially on the presentations about work<br />

methodology, project and customer management.<br />

When we asked them for a group photo, they were<br />

very well prepared, for they even brought their school<br />

banner.<br />

PLANT DIRECTORY

PLANT DIRECTORY<br />

PORTUGAL<br />

MEALHADA<br />

Who is the best in TotaL<br />

Productive Maintenance?<br />

Logoplaste Mealhada, Portugal, is a plant with Total<br />

Productive Maintenance project running for the past few<br />

years.<br />

Every year the plant pays tribute to an employee<br />

as a way to:<br />

Vitor has been with Logoplaste for 19 years. Through<br />

time he has held different positions. Today he is part<br />

of the Maintenance Team.<br />

/ Recognize extraordinary work a person did throughout<br />

the year, in various areas within the plant<br />

Encourage and distinguish employees efforts during<br />

the year<br />

/ Motivate by interlinking the team with the plants<br />

objectives<br />

In 2015 the Certificate for Excellence, rewarding<br />

pristine performance and full collaboration in TPM,<br />

was given to Vitor Alves.<br />

Jorge Valentim e Vítor Alves<br />

Vitor won because:<br />

/<br />

/<br />

/<br />

/<br />

He actively participated in the improvement of the plant’s overall performance<br />

He always shared his knowledge with everyone who was interested to learn<br />

He shows a committed level on a daily basis, learning, growing and improving<br />

He reinvests what he has learned into the plant so that both, Vitor and Logoplaste, grow side by side<br />

70 69 LOGOWORLD 2016

SOCIAL RESPONSABILITY<br />

ONE STEP AHEAD<br />

PARTNERS<br />

PORTUGAL<br />

Guarda<br />

Logoplaste Guarda, long<br />

lasting tradition<br />

João Adaixo from Logoplaste Guarda has worked<br />

for Logoplaste since January 1st 1977 making him<br />

our longest serving employee.<br />

PORTUGAL<br />

Santa Iria<br />

Directly from<br />

the Partner…<br />

“Logoplaste is quite<br />

reliable and flexible,<br />

embracing in a committed,<br />

speedy and professional way<br />

all innovation and continuous<br />

improvement projects”.<br />

Miguel Mira<br />

Procurement & Planning Director – Portugal<br />

LOGOWORLD<br />

05<br />

PLANT DIRECTORY

PLANT DIRECTORY<br />

SPAIN<br />

Guadalajara<br />

Logoplaste Guadalajara<br />

certified in Energy<br />

Management System –<br />

ISO 50001<br />

Congratulations are in order for Guadalajara as the<br />

plant, integrated as a member of Lactalis Nestlé<br />

team, receives the ISO 500001 certification.<br />

The factory announced at the end of last year<br />

that they would be pursing this certification focused<br />

on efficient use of energy.<br />

SPAIN<br />

Vilches<br />

Unexpected visit<br />

by a motorcycle gang<br />

Logoplaste Vilches, in Spain, had a surprise visit<br />

from Sin Riders – a motor cycle gang, whose motto<br />

is “on the road with alcohol free bear”.<br />

They came to the plant and spent some time learning<br />

all about Stretch Blow Molding production.<br />

Amazement came when they saw how a pre-form<br />

becomes a bottle. A different day for Sin Rides<br />

and for the Vilches team as well.<br />

72 71 LOGOWORLD 2016

SOCIAL RESPONSABILITY<br />

ONE STEP AHEAD<br />

PARTNERS<br />

UKRAINE<br />

Commemorating 7 years<br />

of existence<br />

Logoplaste Ukraine had its 7th year anniversary last<br />

January 13th and decided to celebrate combining<br />

a training and a party.<br />

The 8 hour training was focused on “Effective<br />

teamwork and Corporate values” and afterwards<br />