INK COOLING SYSTEM **** - Duo-Technik GmbH

INK COOLING SYSTEM **** - Duo-Technik GmbH

INK COOLING SYSTEM **** - Duo-Technik GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>INK</strong> <strong>COOLING</strong> <strong>SYSTEM</strong> <strong>****</strong><br />

Information under<br />

www.duo-technik.de<br />

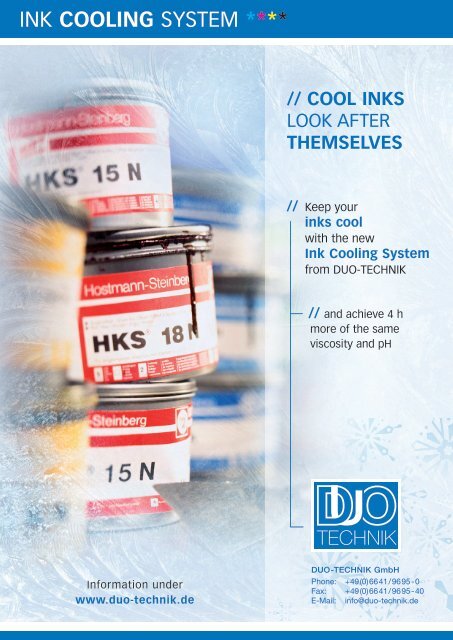

// COOL <strong>INK</strong>S<br />

LOOK AFTER<br />

THEMSELVES<br />

// Keep your<br />

inks cool<br />

with the new<br />

Ink Cooling System<br />

from DUO-TECHNIK<br />

// and achieve 4 h<br />

more of the same<br />

viscosity and pH<br />

DUO-TECHNIK <strong>GmbH</strong><br />

Phone: +49(0)6641/9695-0<br />

Fax: +49(0)6641/9695-40<br />

E-Mail: info@duo-technik.de

COLOR MANAGEMENT<br />

// Which factors need to<br />

be monitored?<br />

// Viscosity<br />

// PH<br />

// Temperature<br />

With the right viscosity the converting of the inks are improved.<br />

We suggest: for inks: 22-23 sec. Ford cup 4;<br />

for water based varnishes: 20-21 sec. Ford cup 4.<br />

The adhesion of the ink onto the sheet will be improved with the correct<br />

pH-value. In addition the drying results will be improved, too. Basically, the<br />

pH-value should decline from printing unit 1 to the last printing unit. The<br />

pH-value of the first printing unit should be 9-9,5 and should be dropped by<br />

0,2 per each further printing unit. However, it should never be lower than 8.<br />

The ink temperature is influenced by the ambient temperature and the<br />

friction of the inks in the ink circulation of the printing machine. With a fix<br />

temperature the change of viscosity and pH can be controlled and kept on<br />

a stable value. The temperature should be set between 20 and 22 °C (see<br />

chart 1).

<strong>INK</strong> <strong>COOLING</strong> <strong>SYSTEM</strong> <strong>****</strong><br />

The systems temperature control, viscosity control and pH control are modular<br />

concepts. This means that you can decide which system is the right one<br />

for your needs. The following examples make clear when and which combination<br />

is reasonable for you.<br />

Initial position 1: For each job change a new ink with adapted viscosity and<br />

pH is brought to the printing machine. Here, a ink cooling system is sufficient<br />

to hold the viscosity and the pH steady until the end of the printing job.<br />

Initial position 2: You produce mainly with the base colours without changing<br />

these at a new job. Here, we recommend installing all systems.<br />

With consideration of the results of the test series for ink cooling it has to<br />

be the goal to reach the aim temperature as fast as possible and keeps then<br />

the temperature stable for the rest of the time. With the <strong>Duo</strong>-<strong>Technik</strong> ink<br />

cooling it is possible to bridge a temperature gap of 10 °C in only 3 minutes.<br />

Furthermore as a result of our own ink circulation we are reducing the micro<br />

foam building. The following technical facts are characterizing the system:<br />

• The ink cooling is working with a central cold water unit (3-5 °C)<br />

• The electrical connection is only 1,5 KW for each printing unit<br />

• The cold water is pumped through a double-walled heat exchanger<br />

until the goal temperature is reached<br />

• With a separate ink circulation continuously ink is brought through<br />

the heat exchanger<br />

• The total system is connected with the cleaning system of the printing<br />

machine that no further actions for cleaning has to be taken place<br />

// Which system is the right<br />

one for me?<br />

// THE DUO-TECHNIK<br />

<strong>INK</strong> <strong>COOLING</strong>

VISCOSITY CONTROLS<br />

IS THE 2ND STEP? Viscosity is a proportion to measure the capability of the flow of a fluid. The<br />

higher the viscosity is the less the capability of the flow is. There is no defined<br />

dimension unit for the viscosity. Several dimensions are common: Centi Poise<br />

-> 50 [mPa*s]; Poise -> 0,5 [P]; DIN-Cup 4 -> 16 [s]; Pascalsecond -> 0,05<br />

[Pa*s]; Engler -> 6,62; Ford-Cup 4 -> 22 [s]. Means first of all the right system<br />

needs to be defined for each customer.<br />

DUO-TECHNIK <strong>GmbH</strong><br />

Phone: +49(0)6641/9695-0<br />

Fax: +49(0)6641/9695-40<br />

E-Mail: info@duo-technik.de<br />

Furthermore the viscosity depends on the temperature of the fluid (see chart<br />

2), means the viscosity is automatically decreasing with a higher temperature<br />

without any changes of the ink. In consequence of this we suggest to start<br />

with the temperature to have a base for the viscosity comparison.<br />

100<br />

ŋ/mPa s<br />

10<br />

1<br />

water<br />

ethanol<br />

mercury<br />

olive oil<br />

acetone<br />

-100 -50 0 50 100 150<br />

T/°C