Magmaweld Electrodes

Magmaweld Electrodes

Magmaweld Electrodes

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

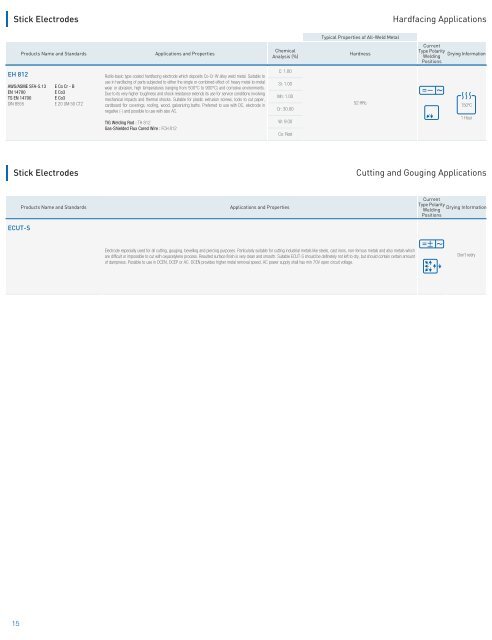

Stick <strong>Electrodes</strong><br />

Hardfacing Applications<br />

Typical Properties of All-Weld Metal<br />

Current<br />

Products Name and Standards Applications and Properties<br />

Chemical<br />

Type Polarity<br />

Hardness<br />

Drying Information<br />

Analysis (%)<br />

Welding<br />

Positions<br />

EH 812<br />

AWS/ASME SFA-5.13<br />

EN 14700<br />

TS EN 14700<br />

DIN 8555<br />

E Co Cr - B<br />

E Co3<br />

E Co3<br />

E 20 UM 50 CTZ<br />

Rutile-basic type coated hardfacing electrode which deposits Co-Cr-W alloy weld metal. Suitable to<br />

use in hardfacing of parts subjected to either the single or combined effect of: heavy metal-to-metal<br />

wear or abrasion, high temperatures (ranging from 500°C to 900°C) and corrosive environments.<br />

Due to its very higher toughness and shock resistance extends its use for service conditions involving<br />

mechanical impacts and thermal shocks. Suitable for plastic extrusion screws, tools to cut paper,<br />

cardboard flor coverings, roofing, wood, galvanizing baths. Preferred to use with DC, electrode in<br />

negative (-) and possible to use with also AC.<br />

TIG Welding Rod : TH 812<br />

Gas-Shielded Flux Cored Wire : FCH 812<br />

C: 1.80<br />

Si: 1.00<br />

Mn: 1.00<br />

Cr: 30.00<br />

W: 9.00<br />

Co: Rest<br />

52 HRc<br />

150ºC<br />

1 Hour<br />

Stick <strong>Electrodes</strong><br />

Cutting and Gouging Applications<br />

Current<br />

Products Name and Standards Applications and Properties<br />

Type Polarity<br />

Drying Information<br />

Welding<br />

Positions<br />

ECUT-S<br />

Electrode especially used for all cutting, gouging, bevelling and piercing purposes. Particularly suitable for cutting industrial metals like steels, cast irons, non-ferrous metals and also metals which<br />

are difficult or impossible to cut with oxyacetylene process. Resulted surface finish is very clean and smooth. Suitable ECUT-S should be definetely not left to dry, but should contain certain amount<br />

of dampness. Possible to use in DCEN, DCEP or AC. DCEN provides higher metal removal speed, AC power supply shall has min 70V open circuit voltage.<br />

Don't redry<br />

15