Magmaweld Electrodes

Magmaweld Electrodes

Magmaweld Electrodes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

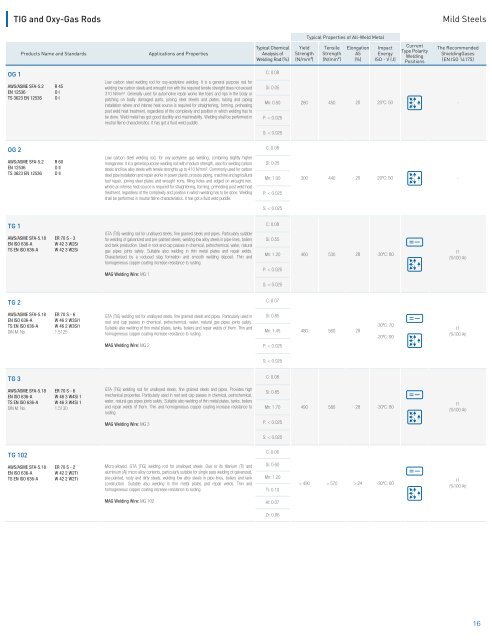

TIG and Oxy-Gas Rods<br />

Mild Steels<br />

Typical Properties of All-Weld Metal<br />

Products Name and Standards<br />

Applications and Properties<br />

Typical Chemical<br />

Analysis of<br />

Welding Rod (%)<br />

Yield<br />

Strength<br />

(N/mm²)<br />

Tensile<br />

Strength<br />

(N/mm²)<br />

Elongation<br />

A5<br />

(%)<br />

Impact<br />

Energy<br />

ISO - V (J)<br />

Current<br />

Type Polarity<br />

Welding<br />

Positions<br />

The Recommended<br />

ShieldingGases<br />

(EN ISO 14175)<br />

OG 1<br />

AWS/ASME SFA-5.2<br />

EN 12536<br />

TS 3623 EN 12536<br />

R 45<br />

O I<br />

O I<br />

Low carbon steel welding rod for oxy-acetylene welding. It is a general purpose rod for<br />

welding low carbon steels and wrought iron with the required tensile strenght does not exceed<br />

310 N/mm². Generally used for automotive repair works like tears and rips in the body or<br />

patching on badly damaged parts, joining steel sheets and plates, tubing and piping<br />

installation where and intense heat source is required for straightening, forming, preheating<br />

post weld heat treatment, regardless of the complexity and position in which welding has to<br />

be done. Weld metal has got good ductility and machinability. Welding shall be performed in<br />

neutral flame characteristics. It has got a fluid weld puddle.<br />

C: 0.08<br />

Si: 0.05<br />

Mn: 0.50<br />

P: < 0.025<br />

280 450 20 20ºC: 50 -<br />

S: < 0.025<br />

OG 2<br />

AWS/ASME SFA-5.2<br />

EN 12536<br />

TS 3623 EN 12536<br />

R 60<br />

O II<br />

O II<br />

Low carbon steel welding rod, for oxy-acetylene gas welding, containing slightly higher<br />

manganese. It is a general purpose welding rod with medium strength, used for welding carbon<br />

steels and low alloy steels with tensile strenghts up to 410 N/mm². Commonly used for carbon<br />

steel pipe installation and repair works in power plants, process piping, machine and agricultural<br />

tool repair, joining steel plates and wrought irons, filling holes and edged on wrought iron,<br />

where an intense heat source is required for straightening, forming, preheating post weld heat<br />

treatment, regardless of the complexity and position in which welding has to be done. Welding<br />

shall be performed in neutral flame characteristics. It has got a fluid weld puddle.<br />

C: 0.08<br />

Si: 0.05<br />

Mn: 1.00<br />

P: < 0.025<br />

300 440 20 20ºC: 50<br />

-<br />

S: < 0.025<br />

TG 1<br />

AWS/ASME SFA-5.18<br />

EN ISO 636-A<br />

TS EN ISO 636-A<br />

ER 70 S - 3<br />

W 42 3 W2Si<br />

W 42 3 W2Si<br />

GTA (TIG) welding rod for unalloyed steels, fine grained steels and pipes. Particularly suitable<br />

for welding of galvanized and pre-painted steels, welding low alloy steels in pipe-lines, boilers<br />

and tank production. Used in root and cap passes in chemical, petrochemical, water, natural<br />

gas pipes joints safely. Suitable also welding in thin metal plates and repair welds.<br />

Characterized by a reduced slag formation and smooth welding deposit. Thin and<br />

homogeneous copper coating increase resistance to rusting.<br />

MAG Welding Wire: MG 1<br />

C: 0.08<br />

Si: 0.55<br />

Mn: 1.20<br />

P: < 0.025<br />

460 530 28 -30ºC: 80<br />

I1<br />

(%100 Ar)<br />

S: < 0.025<br />

TG 2<br />

C: 0.07<br />

AWS/ASME SFA-5.18<br />

EN ISO 636-A<br />

TS EN ISO 636-A<br />

DIN M. No.<br />

ER 70 S - 6<br />

W 46 2 W3Si1<br />

W 46 2 W3Si1<br />

1.5125<br />

GTA (TIG) welding rod for unalloyed steels, fine grained steels and pipes. Particularly used in<br />

root and cap passes in chemical, petrochemical, water, natural gas pipes joints safely.<br />

Suitable also welding of thin metal plates, tanks, boilers and repair welds of them. Thin and<br />

homogeneous copper coating increase resistance to rusting.<br />

Si: 0.85<br />

Mn: 1.45<br />

480 560 28<br />

-30ºC: 70<br />

-20ºC: 90<br />

I1<br />

(%100 Ar)<br />

MAG Welding Wire: MG 2<br />

P: < 0.025<br />

S: < 0.025<br />

TG 3<br />

C: 0.08<br />

AWS/ASME SFA-5.18<br />

EN ISO 636-A<br />

TS EN ISO 636-A<br />

DIN M. No.<br />

ER 70 S - 6<br />

W 46 3 W4Si 1<br />

W 46 3 W4Si 1<br />

1.5130<br />

GTA (TIG) welding rod for unalloyed steels, fine grained steels and pipes. Provides high<br />

mechanical properties. Particularly used in root and cap passes in chemical, petrochemical,<br />

water, natural gas pipes joints safely. Suitable also welding of thin metal plates, tanks, boilers<br />

and repair welds of them. Thin and homogeneous copper coating increase resistance to<br />

rusting.<br />

Si: 0.85<br />

Mn: 1.70<br />

490 580 28 -30ºC: 80<br />

I1<br />

(%100 Ar)<br />

MAG Welding Wire: MG 3<br />

P: < 0.025<br />

S: < 0.025<br />

TG 102<br />

C: 0.06<br />

AWS/ASME SFA-5.18<br />

EN ISO 636-A<br />

TS EN ISO 636-A<br />

ER 70 S - 2<br />

W 42 2 W2Ti<br />

W 42 2 W2Ti<br />

Micro-alloyed, GTA (TIG) welding rod for unalloyed steels. Due to its titanium (Ti) and<br />

aluminium (Al) micro alloy contents, particularly suitable for single pass welding of galvanized,<br />

pre-painted, rusty and dirty steels, welding low alloy steels in pipe-lines, boilers and tank<br />

construction. Suitable also welding in thin metal plates and repair welds. Thin and<br />

homogeneous copper coating increase resistance to rusting.<br />

Si: 0.60<br />

Mn: 1.20<br />

Ti: 0.10<br />

> 490<br />

> 570 > 24 -30ºC: 60<br />

I1<br />

(%100 Ar)<br />

MAG Welding Wire: MG 102<br />

Al: 0.07<br />

Zr: 0.06<br />

16