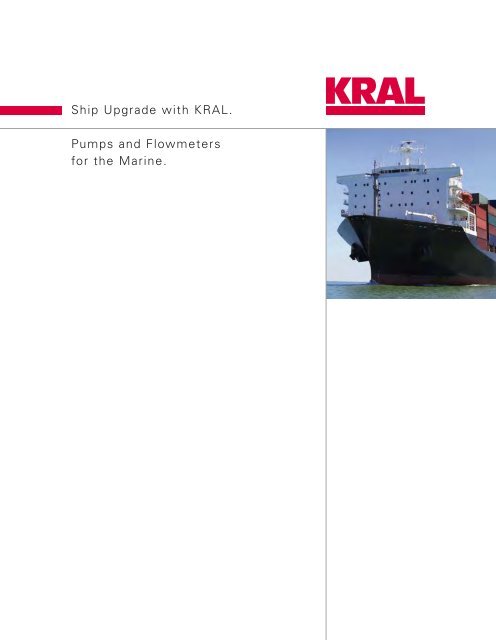

Ship Upgrade with KRAL. Pumps and Flowmeters for the Marine.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Ship</strong> <strong>Upgrade</strong> <strong>with</strong> <strong>KRAL</strong>.<br />

<strong>Pumps</strong> <strong>and</strong> <strong>Flowmeters</strong><br />

<strong>for</strong> <strong>the</strong> <strong>Marine</strong>.

On l<strong>and</strong>.<br />

All measurement results of <strong>the</strong> <strong>KRAL</strong> fuel consumption measurement can be transferred to <strong>the</strong><br />

shipping company via an Internet connection. With <strong>KRAL</strong>, <strong>the</strong> fleet manager has comprehensive<br />

in<strong>for</strong>mation about <strong>the</strong> operating costs <strong>for</strong> fuel. The report time can be defined as desired.<br />

Port.<br />

The port authority evaluates a clean engine room as an important indicator of <strong>the</strong> operational safety<br />

of <strong>the</strong> vessel. Hermetically sealed <strong>KRAL</strong> pumps <strong>with</strong> magnetic coupling contribute significantly to<br />

cleanliness <strong>and</strong> <strong>the</strong>re<strong>for</strong>e to safety on board.<br />

Coast.<br />

In some coastal areas, seagoing vessels must switch over to low-sulfur fuel.<br />

<strong>KRAL</strong> pumps are designed <strong>for</strong> <strong>the</strong> reliable pumping of low-sulfur, low-viscosity fuels.<br />

Open sea.<br />

Fuel is becoming increasingly expensive. The <strong>KRAL</strong> fuel consumption measurement system<br />

measures <strong>the</strong> actual <strong>and</strong> <strong>the</strong> specific fuel consumption. <strong>KRAL</strong> pumps are proven heavy fuel oil<br />

pumps. Constant innovation keeps <strong>the</strong>m state-of-<strong>the</strong>-art.<br />

The components of <strong>the</strong> magnetic coupling are our own development <strong>and</strong> design. That‘s one reason<br />

why <strong>KRAL</strong> is known <strong>for</strong> <strong>the</strong> highest quality. The <strong>KRAL</strong> cylinder lubricating oil measurement indicates<br />

excessive lubrication <strong>with</strong> high precision. That saves expensive lubricating oil <strong>and</strong> protects <strong>the</strong><br />

cylinders against increased wear. Particularly <strong>for</strong> extended voyages on <strong>the</strong> high seas, <strong>KRAL</strong> products<br />

offer enormous savings potential.<br />

Everything OK at sea.<br />

Work at sea presents very special challenges. Seagoing vessels often have to rely on <strong>the</strong>mselves<br />

<strong>for</strong> weeks at a time. In such cases, it must be possible to rely on every component from <strong>the</strong> smallest<br />

nut to <strong>the</strong> largest ship‘s propeller.<br />

With its pumps <strong>and</strong> measuring devices oriented to <strong>the</strong> special needs of ship‘s engines, <strong>KRAL</strong> is a<br />

reliable partner <strong>for</strong> marine. From research to finished product, we clearly focus on quality, efficiency<br />

<strong>and</strong> protection of people, machines <strong>and</strong> <strong>the</strong> environment. So that everything is OK at sea, <strong>and</strong> stays<br />

that way.<br />

In this brochure you will find comprehensive in<strong>for</strong>mation on <strong>the</strong> following subjects:<br />

<strong>Pumps</strong> <strong>and</strong> pumpstations <strong>for</strong> low-sulfur fuels.<br />

Hermetically sealed pumps <strong>with</strong> magnetic coupling.<br />

Fuel consumption measurement.<br />

Cylinder lubricating oil measurement.<br />

2

You will find <strong>the</strong>se Innovative Solutions in this Brochure<br />

Pump stations <strong>for</strong><br />

low-sulfur fuels.<br />

Page 6<br />

Individual pumps <strong>for</strong><br />

low-sulfur fuels.<br />

Page 6<br />

Hermetically sealed<br />

pumps <strong>with</strong> magnetic<br />

coupling <strong>for</strong> distillates<br />

<strong>and</strong> heavy fuel oil.<br />

Page 14<br />

3

Fuel consumption<br />

measurement.<br />

Now <strong>with</strong> GPS data.<br />

Cylinder lubricating oil<br />

measurement. Can help<br />

saving a lot of money.<br />

Page 22<br />

Page 28<br />

4

Customized Solutions<br />

<strong>and</strong> Lots of Great Offers.<br />

The requirements <strong>for</strong> shipping<br />

companies are constantly increasing.<br />

Tight deadlines, dem<strong>and</strong>ing<br />

safety <strong>and</strong> environmental regulations<br />

<strong>and</strong> close calculations are<br />

part of everyday life on <strong>the</strong> high<br />

seas.<br />

We concentrate on customers<br />

that are under pressure. Our<br />

goal is to ease <strong>the</strong> tension <strong>with</strong><br />

our solutions. They can <strong>the</strong>n<br />

concentrate on <strong>the</strong>ir core business,<br />

<strong>the</strong> economically attractive<br />

operation of <strong>the</strong>ir vessels.<br />

<strong>KRAL</strong> is a family-owned company<br />

<strong>with</strong> decades of maritime<br />

experience. Close contact <strong>with</strong><br />

leading shippers has made<br />

it possible <strong>for</strong> us to develop<br />

unique, customized solutions.<br />

An example is provided by <strong>the</strong><br />

pump-stations <strong>for</strong> low-sulfur<br />

diesel fuels.<br />

Our current developments already<br />

satisfy guidelines that will<br />

first take effect in a few years.<br />

We repeatedly optimize entire<br />

series, because refinery processes<br />

or legal provisions change.<br />

Especially successful solutions<br />

often come from customerspecific<br />

developments. Our customers<br />

appreciate our technical<br />

competence <strong>and</strong> <strong>the</strong> cooperative<br />

partnership. The great confidence<br />

in our loyalty allows <strong>the</strong>m<br />

to describe problems entirely<br />

openly, <strong>and</strong> we develop solutions<br />

<strong>for</strong> <strong>the</strong>m.<br />

Christoph Tschegg<br />

CEO<br />

Our Offers<br />

<strong>for</strong> you.<br />

<strong>KRAL</strong> offers a variety of services<br />

<strong>and</strong> in<strong>for</strong>mation <strong>for</strong> shipping<br />

companies.<br />

We present specific offers in this<br />

brochure. The symbol<br />

10<br />

in <strong>the</strong><br />

text draws attention to a special<br />

offer. The number provided in <strong>the</strong><br />

symbol is <strong>the</strong> page on which <strong>the</strong><br />

offer is described.<br />

You receive a checkbook of offers<br />

<strong>with</strong> <strong>the</strong> brochure. Send in <strong>the</strong><br />

checks you want to “cash” or give<br />

<strong>the</strong>m to your <strong>KRAL</strong> consultant. If<br />

you haven‘t received <strong>the</strong> checkbook,<br />

please request it from <strong>KRAL</strong>.<br />

5

2020<br />

January 2020:<br />

A fur<strong>the</strong>r reduction of <strong>the</strong> maximum sulfur<br />

content in heavy fuel oil to 0.5 % is planned.<br />

2015<br />

January 2015:<br />

The sulfur content in ECAs is to be reduced from<br />

<strong>the</strong> current 1.0 % to 0.1 %.<br />

2012<br />

January 2012:<br />

MARPOL Annex VI will reduce <strong>the</strong> sulfur content of heavy fuel oil worldwide<br />

from <strong>the</strong> current 4.5 % to 3.5 %.<br />

August 2012:<br />

The sulfur content in North American ECAs may not exceed 1.0 %.<br />

Today<br />

Only vessels using fuels <strong>with</strong> a maximum sulfur content of 0.1% may now be operated in EU ports.<br />

On <strong>the</strong> coast of Cali<strong>for</strong>nia, vessels <strong>with</strong>in <strong>the</strong> 24 NM zone may only operate <strong>with</strong> fuels that do not<br />

exceed a maximum sulfur content of 1.5 %.<br />

ECAs in <strong>the</strong> Mediterranean, on <strong>the</strong> coast of <strong>the</strong> USA <strong>and</strong> Canada are planned.

<strong>KRAL</strong> pumps are already today working problem-free <strong>with</strong><br />

ULSD (ultra-low-sulfur diesel).<br />

We would be pleased to show you <strong>the</strong> results of our successful<br />

long-term tests. 11<br />

Carefree Into <strong>the</strong><br />

ECA Future!<br />

A number of new guidelines <strong>and</strong> regulations having to do <strong>with</strong> sulfur emissions<br />

on <strong>the</strong> high seas <strong>and</strong> in coastal regions (ECA – Emission Control Area) will be<br />

coming into effect in coming years. Will it still be possible to use existing fuel<br />

pumps or is an upgrade necessary? What happens when <strong>the</strong> rules become<br />

even stricter? Are pumps sold today also suitable <strong>for</strong> <strong>the</strong> low-sulfur fuels of <strong>the</strong><br />

future?<br />

Many questions. <strong>KRAL</strong> has <strong>the</strong> answers. We already have pumps that can<br />

operate <strong>with</strong> <strong>the</strong> sulfur limits of <strong>the</strong> future.

<strong>Pumps</strong> <strong>and</strong> Stations <strong>for</strong> Low-Sulfur Fuels<br />

Everybody‘s talking<br />

about ”low-sulfur“.<br />

Pump housing damaged due to<br />

inadequate lubrication.<br />

Low-sulfur fuels can damage pumps.<br />

Regulations <strong>and</strong> st<strong>and</strong>ards<br />

such as MARPOL Annex<br />

VI or EC Directive 2005/33/<br />

EC are in <strong>for</strong>ce. These rules<br />

limit <strong>the</strong> sulfur emissions<br />

in Emission Control Areas<br />

(ECA). That protects our<br />

environment.<br />

In comparison to heavy<br />

fuel oil, <strong>the</strong> marine fuels<br />

DMA, DMB <strong>and</strong> DMZ have<br />

a lower viscosity. We would<br />

be happy to personally<br />

show you what was of<br />

importance <strong>for</strong> <strong>the</strong> intensive<br />

development of <strong>the</strong> pumps<br />

<strong>and</strong> pump-stations. 11<br />

The screws of three screw<br />

pumps require lubrication.<br />

This lubrication becomes<br />

less effective <strong>with</strong> increasing<br />

pressure <strong>and</strong> sinking<br />

viscosity. That can result<br />

in rapid wear of <strong>the</strong> pump<br />

housing.<br />

*ECA = Emission Control Area.<br />

In order to assure our customers<br />

<strong>the</strong> highest degree<br />

of operational security <strong>and</strong><br />

a technological leadership,<br />

research <strong>and</strong> development<br />

play a very important role<br />

at <strong>KRAL</strong>. Reliable pumping<br />

of low-viscosity, low-sulfur<br />

fuels is ensured by specially<br />

developed processes <strong>for</strong><br />

<strong>the</strong> surface treatment of<br />

<strong>the</strong> screws <strong>and</strong> <strong>the</strong> screw<br />

housing.<br />

Can existing pumps still be used?<br />

The drastic changes to regulations<br />

will require considerable<br />

investment from shipowners.<br />

<strong>KRAL</strong> helps you reach a decision<br />

as to whe<strong>the</strong>r existing<br />

pumps can still be<br />

used. The table helps <strong>with</strong><br />

an initial estimation.<br />

With <strong>the</strong> friendly assistance of<br />

<strong>the</strong> SS Hohentwiel.<br />

Make use of our offer to<br />

evaluate existing equipment<br />

<strong>for</strong> suitability <strong>for</strong> low-sulfur<br />

fuels. 11<br />

Evaluate suitability of your pumps.<br />

Criterion<br />

Alphanumerical serial number,<br />

delivered prior to February 1, 2002.<br />

Numerical serial number up to 134999,<br />

delivered as of February 2, 2002 until<br />

September 2004.<br />

Series K <strong>and</strong> M <strong>with</strong> mechanical seal<br />

or magnetic coupling <strong>and</strong> pump stations<br />

DS, DKC, DMC <strong>with</strong> numerical serial<br />

numbers from <strong>and</strong> including 135000,<br />

delivered after September 2004.<br />

Minimum viscosity<br />

6 cSt<br />

4 cSt<br />

1.4 cSt<br />

8

PACIFIC OCEAN<br />

24 NM ECA<br />

Cali<strong>for</strong>nia<br />

<strong>KRAL</strong> pump <strong>for</strong> low-sulfur<br />

fuels.<br />

ECAs of <strong>the</strong> Cali<strong>for</strong>nian Coast.<br />

Safety on board.<br />

Will converting to new <strong>KRAL</strong> technology ready<br />

you <strong>for</strong> <strong>the</strong> future?<br />

Low-sulfur fuels have a<br />

flash point of 140 °F. The<br />

risk of an engine room fire<br />

due to a fuel leak <strong>the</strong>re<strong>for</strong>e<br />

increases considerably.<br />

This dangerous situation<br />

can be avoided <strong>with</strong> a<br />

hermetically sealed <strong>KRAL</strong><br />

pump <strong>with</strong> magnetic coupling.<br />

Many things are changing<br />

due to <strong>the</strong> change of solutions <strong>for</strong> low-sulfur<br />

In <strong>the</strong> course of developing<br />

regulations. There may be fuels, we carried out longterm<br />

tests <strong>with</strong> ULSD<br />

open questions. Are <strong>the</strong><br />

new <strong>KRAL</strong> pumps <strong>for</strong> lowsulfur<br />

fuels also suitable <strong>for</strong> tests were very successful.<br />

(ultra-low-sulfur diesel). The<br />

future, stricter regulatory <strong>KRAL</strong> pumps are already<br />

limitations? How do <strong>the</strong> suitable <strong>for</strong> <strong>the</strong> fuels of <strong>the</strong><br />

sulfur limit values develop? future. You will have peace<br />

What does <strong>the</strong> new ISO of mind <strong>for</strong> many years <strong>with</strong><br />

8217 fuel st<strong>and</strong>ard mean <strong>for</strong> an upgrade to new <strong>KRAL</strong><br />

fuel pumps?<br />

technology.<br />

If you are interested, we<br />

would be pleased to show We would be happy to tell<br />

you <strong>the</strong> changes to <strong>the</strong> ISO you <strong>the</strong> exciting story of<br />

8217 <strong>and</strong> <strong>the</strong>ir significance how we arrived at carrying<br />

<strong>for</strong> fuel pumps.<br />

out tests <strong>with</strong> ULSD.<br />

11 11<br />

9

<strong>Pumps</strong> <strong>and</strong> Stations <strong>for</strong> Low-Sulfur Fuels<br />

<strong>KRAL</strong> double station series<br />

DMC.<br />

HFO <strong>and</strong> low-sulfur fuels<br />

are very different. The<br />

following applies <strong>for</strong> HFO:<br />

<strong>the</strong> operating temperature<br />

can reach 300 °F, abrasive<br />

contents can endanger <strong>the</strong><br />

seal, <strong>and</strong> <strong>the</strong> viscosity is<br />

sufficiently high. The following<br />

applies <strong>for</strong> distillates:<br />

<strong>the</strong> operating temperature<br />

can reach 140 °F, distillates<br />

are clean, viscosity can be<br />

very low, <strong>and</strong> <strong>the</strong> flash point<br />

is 140 °F.<br />

Hermetically sealed pump <strong>with</strong><br />

magnetic coupling.<br />

Should <strong>the</strong> same pump be used <strong>for</strong> HFO <strong>and</strong> low-sulfur fuels?<br />

Third, on entering <strong>the</strong> ECA<br />

<strong>the</strong> specified emission<br />

values have to be reached<br />

<strong>and</strong> <strong>the</strong> switch over process<br />

must be finished at this<br />

time.<br />

In order to avoid <strong>the</strong> switch<br />

over procedure, <strong>KRAL</strong> recommends<br />

pump stations<br />

of <strong>the</strong> DKC/DMC series in a<br />

separate line <strong>for</strong> low-sulfur<br />

fuels.<br />

Discuss your ideas about<br />

dual-fuel operation <strong>with</strong><br />

<strong>KRAL</strong>.<br />

11<br />

<strong>KRAL</strong> pumps are designed<br />

<strong>for</strong> <strong>the</strong>se operating conditions.<br />

Three things are<br />

of particular importance<br />

when switching from HFO<br />

to distillates. First, due to<br />

<strong>the</strong> different operating temperature,<br />

engine manufacturers<br />

limit <strong>the</strong> temperature<br />

gradients to a max. of 36 °F<br />

per minute. Switching can<br />

<strong>the</strong>re<strong>for</strong>e involve a great<br />

deal of time. Second, during<br />

this time expensive distillate<br />

is wasted <strong>for</strong> mixing.<br />

<strong>KRAL</strong> recommends a separate line <strong>for</strong> low-sulfur fuels.<br />

10

Our Offers<br />

The development of<br />

pumps <strong>for</strong> low-sulfur<br />

fuels.<br />

Suitability of existing<br />

equipment.<br />

The new ISO 8217.<br />

Ultra-low-sulfur diesel<br />

(ULSD).<br />

<strong>KRAL</strong> trusts in quality<br />

through technical competence,<br />

because we want to<br />

offer our customers peace<br />

of mind. We have carried<br />

out intensive research <strong>and</strong><br />

development <strong>and</strong> offer you<br />

reliable solutions. We are<br />

pleased to show you <strong>the</strong><br />

exciting development of<br />

pumps <strong>and</strong> pump stations<br />

because we are sure that<br />

this will streng<strong>the</strong>n your<br />

confidence in <strong>KRAL</strong>.<br />

The question of whe<strong>the</strong>r<br />

you can continue to use<br />

your existing equipment <strong>for</strong><br />

low-sulfur fuels is important<br />

because this involves<br />

cost. Making technically<br />

sound <strong>and</strong> future-oriented<br />

decisions is a difficult task<br />

due to <strong>the</strong> complexity of<br />

<strong>the</strong> topic. We would be<br />

happy to help you answer<br />

this question.<br />

The fuel st<strong>and</strong>ard ISO<br />

8217 has been significantly<br />

amended. A new type of<br />

fuel has been included, <strong>the</strong><br />

specifications of known<br />

types have been partially<br />

changed <strong>and</strong> new specifications<br />

have been added.<br />

We would be happy to<br />

personally show you what<br />

has changed <strong>and</strong> what<br />

influence <strong>the</strong> changes have<br />

on <strong>the</strong> selection of pumps.<br />

It wasn‘t that easy to find<br />

low-sulfur fuels <strong>for</strong> our<br />

research <strong>and</strong> development.<br />

The creativity of our<br />

engineers was challenged.<br />

An interesting story, which<br />

raises confidence in <strong>the</strong><br />

suitability <strong>for</strong> <strong>the</strong> future of<br />

<strong>KRAL</strong> pumps <strong>and</strong> stations.<br />

Let us know if you are<br />

interested in our tests <strong>with</strong><br />

ULSD.<br />

Blending or dual-fuel<br />

operation?<br />

How will you fulfill <strong>the</strong><br />

rules in <strong>the</strong> ECAs? Should<br />

you switch over a longer<br />

period from HFO to lowsulfur<br />

fuels (blending)?<br />

Or do you decide in favor<br />

of separate fuel systems<br />

<strong>for</strong> both fuel types (dual<br />

fuel)? <strong>KRAL</strong> is happy to<br />

offer technical assistance<br />

<strong>and</strong> expertise as well as<br />

specific solutions. We<br />

invite you to discuss your<br />

plans <strong>with</strong> <strong>KRAL</strong> at an early<br />

stage. We promise you a<br />

know-how benefit.<br />

11

<strong>Pumps</strong> <strong>and</strong> Stations <strong>for</strong> Low-Sulfur Fuels<br />

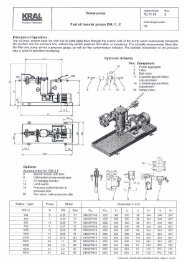

Heating system.<br />

An electrical or fluid<br />

heating system to pre-heat<br />

highly viscous liquids.<br />

Reversing valve.<br />

For switching to <strong>the</strong> st<strong>and</strong>by<br />

pump or filter cleaning.<br />

Expansion valves.<br />

In order to prevent excessive<br />

internal pressure in<br />

<strong>the</strong> switched off part of<br />

<strong>the</strong> block due to <strong>the</strong>rmal<br />

expansion, <strong>the</strong>re are two<br />

small expansion valves<br />

installed in <strong>the</strong> cylinder of<br />

<strong>the</strong> switch over valve.<br />

Constant feed<br />

pressure.<br />

The pressure maintaining<br />

valve ensures a constant<br />

feed pressure, even <strong>with</strong><br />

fluctuating fuel flow.<br />

Various liquids.<br />

The manually, electrically<br />

or pneumatically activated<br />

two-way valve serves <strong>the</strong><br />

purpose of switching between<br />

two alternative fuels.<br />

Simple connections.<br />

Suction- <strong>and</strong> feed piping<br />

can be simply connected<br />

to <strong>the</strong> easily accessible<br />

front side of <strong>the</strong> station.<br />

Temperature<br />

measurement.<br />

Two <strong>the</strong>rmometers are<br />

optionally available to<br />

monitor <strong>the</strong> liquid temperature.<br />

Pressure switch.<br />

A pressure switch serves<br />

<strong>the</strong> purpose of additional<br />

pressure monitoring.<br />

12

Permanent pressure<br />

monitoring.<br />

A pressure gauge installed<br />

in <strong>the</strong> middle of <strong>the</strong> station<br />

allows <strong>for</strong> easy monitoring<br />

of <strong>the</strong> feed pressure.<br />

Various sealing.<br />

Several shaft seal options<br />

are available. The hermetically<br />

sealed magnetic<br />

coupling provides reliable<br />

<strong>and</strong> safe operation.<br />

Suction strainer<br />

monitoring.<br />

The suction gauges can<br />

be used to monitor <strong>the</strong><br />

degree of soiling of <strong>the</strong><br />

strainer.<br />

Pump variations.<br />

The double station can be<br />

equipped <strong>with</strong> <strong>KRAL</strong> three<br />

screw pumps of <strong>the</strong> KFT<br />

series up to 232 psi or <strong>the</strong><br />

MF series up to 580 psi.<br />

Non return valves.<br />

Prevent back flow of liquid<br />

into <strong>the</strong> pump.<br />

Screws.<br />

The surfaces of <strong>the</strong><br />

screws <strong>and</strong> <strong>the</strong> housing<br />

are coated <strong>and</strong> hardened<br />

to h<strong>and</strong>le low sulfur-fuels.<br />

<strong>KRAL</strong> pumps have already<br />

passed long-term tests <strong>with</strong><br />

ULSD (ultra-low-sulfur diesel).<br />

Differential pressure<br />

monitoring.<br />

A different pressure indication<br />

<strong>with</strong> optional display<br />

or electrical output signal<br />

can be installed to monitor<br />

<strong>the</strong> differential pressure at<br />

<strong>the</strong> strainers.<br />

Cooling fins.<br />

To cool <strong>the</strong> fuel that is<br />

internally bypassed.<br />

Leak oil detection.<br />

The oil pan can be equipped<br />

<strong>with</strong> leak detection.<br />

13

Not Every Fire is<br />

this Romantic.<br />

For example, fire on board. A fire in <strong>the</strong> engine room not only makes it impossible<br />

to maneuver <strong>the</strong> vessel, it also means an enormous risk <strong>for</strong> <strong>the</strong> crew <strong>and</strong><br />

<strong>the</strong> cargo.

Hermetically Sealed <strong>KRAL</strong> <strong>Pumps</strong> <strong>with</strong> Magnetic Coupling<br />

No more problems <strong>with</strong><br />

mechanical shaft seal.<br />

Maintenance-free magnetic<br />

couplings reduce <strong>the</strong> life cycle<br />

cost.<br />

Reduce life cycle costs.<br />

Costs <strong>for</strong> replacement parts<br />

<strong>and</strong> maintenance of mechanical<br />

shaft seals increase<br />

<strong>the</strong> lifecycle costs.<br />

Mechanical shaft seals in<br />

<strong>KRAL</strong> three screw pumps<br />

are state-of-<strong>the</strong>-art technology.<br />

However, even when<br />

used correctly, <strong>the</strong>y are<br />

still wear parts. This means<br />

costs <strong>for</strong> replacement parts<br />

<strong>and</strong> maintenance.<br />

<strong>KRAL</strong> magnetic couplings<br />

are maintenance-free. The<br />

magnetically coupled pump<br />

already pays <strong>for</strong> itself after<br />

3 years. We would be happy<br />

to calculate <strong>the</strong> pay-off period<br />

toge<strong>the</strong>r <strong>with</strong> you. 19<br />

Test out a pump at no charge<br />

to convince yourself.<br />

19<br />

Heavy fuel oil residue in a<br />

pump.<br />

Prevent pump failure.<br />

Heavy fuel oil residue can<br />

result in pump failure.<br />

In order to reduce friction,<br />

<strong>the</strong> sliding surfaces of<br />

mechanical shaft seals<br />

require lubrication by <strong>the</strong><br />

pumped medium. The liquid<br />

comes into contact <strong>with</strong> air<br />

at <strong>the</strong> seal surfaces. Heavy<br />

oil reacts <strong>with</strong> atmospheric<br />

oxygen <strong>and</strong> <strong>for</strong>ms coking<br />

that damages <strong>the</strong> sliding<br />

surfaces.<br />

<strong>KRAL</strong> magnetic couplings<br />

are hermetically sealed.<br />

The fuel does not have any<br />

contact <strong>with</strong> air <strong>and</strong> does<br />

not <strong>for</strong>m residue.<br />

We have such confidence<br />

in our solution that we are<br />

prepared to offer a lifetime<br />

guarantee <strong>for</strong> <strong>the</strong> seal. 19<br />

A properly sealed pump keeps<br />

<strong>the</strong> engine room clean.<br />

Keep your engine room<br />

clean.<br />

Vessels can be permanently<br />

denied access to ports if<br />

<strong>the</strong>y present a pollution<br />

risk.<br />

In some ports <strong>the</strong> Port<br />

Authority inspects <strong>the</strong><br />

condition of incoming vessels.<br />

A clean engine room<br />

is an important evaluation<br />

criterion <strong>and</strong> serves as an<br />

indicator of <strong>the</strong> good condition<br />

of <strong>the</strong> vessel. Dirty<br />

<strong>and</strong> oily pumps make a bad<br />

impression.<br />

Pump leaks are made impossible<br />

<strong>with</strong> hermetically<br />

sealed magnetic couplings.<br />

The engine room stays<br />

clean <strong>and</strong> safe.<br />

Magnetic couplings are<br />

designed <strong>for</strong> an operating<br />

temperature up to 482 °F.<br />

Enable high pre-heating<br />

temperatures.<br />

Mechanical shaft seals<br />

reach <strong>the</strong>ir limitations at<br />

pre-heating temperatures of<br />

HFO 500 <strong>and</strong> 700.<br />

Refineries produce increasing<br />

amounts of lighter<br />

distillates out of a barrel<br />

of crude oil. This results in<br />

decreasing quality of <strong>the</strong><br />

remaining residual oil. That<br />

is also <strong>the</strong> reason why HFO<br />

500 <strong>and</strong> 700 came onto <strong>the</strong><br />

market. These fuels must<br />

be pre-heated to<br />

356 °F instead of to 300 °F,<br />

as is <strong>the</strong> case <strong>for</strong> HFO 380,<br />

in order to reach <strong>the</strong> low<br />

injection viscosity. Mechanical<br />

face seals can be used<br />

up to 356 °F, meaning <strong>the</strong>y<br />

are at <strong>the</strong>ir limits.<br />

Magnetically coupled <strong>KRAL</strong><br />

pumps can be operated<br />

at up to 482 °F. We would<br />

be happy to explain how<br />

<strong>the</strong> change in HFO quality<br />

led to <strong>the</strong> development of<br />

<strong>the</strong> pump <strong>with</strong> magnetic<br />

coupling. 19<br />

16

Advantage:<br />

The containment of <strong>the</strong> magnetic coupling completely encloses<br />

<strong>the</strong> liquid between <strong>the</strong> pipe connections.<br />

Disadvantage:<br />

Interruption of <strong>the</strong> sealing contour by <strong>the</strong> necessary leakage of<br />

<strong>the</strong> mechanical shaft seal.<br />

Greatly reduce risk of fire.<br />

Pump damage due to<br />

incorrect commissioning.<br />

Avoid blockage due to<br />

solid materials.<br />

Fire on board is one of <strong>the</strong><br />

biggest risks <strong>for</strong> crew <strong>and</strong><br />

cargo.<br />

Fuel leaks <strong>and</strong> spray present<br />

an ignition source, which<br />

can quickly spread into a<br />

fire throughout <strong>the</strong> entire<br />

engine room. According<br />

to SOLAS, high pressure<br />

fuel lines must be double<br />

walled. This does not apply<br />

to booster module pumps,<br />

although mechanical face<br />

seals present a risk of considerable<br />

leakage.<br />

In order to close this safety<br />

gap, <strong>KRAL</strong> has been highly<br />

recommending pumps<br />

<strong>with</strong> magnetic coupling <strong>for</strong><br />

years. The containment can<br />

of <strong>the</strong> magnetic coupling is<br />

an absolutely secure barrier.<br />

The risk of fire is greatly<br />

reduced.<br />

Ano<strong>the</strong>r fire risk originates<br />

in <strong>the</strong> regulation of lowsulfur<br />

fuels. Operating in<br />

ECAs practically requires<br />

<strong>the</strong> use of distillates fuels.<br />

However, MDO has a flashpoint<br />

of 140 °F.<br />

A MDO leak at a mechanical<br />

shaft seal is extremely<br />

dangerous given <strong>the</strong> hot<br />

surfaces in <strong>the</strong> engine<br />

room.<br />

The completely sealed magnetic<br />

coupling also avoids<br />

this fire risk.<br />

Running <strong>the</strong> pump dry can<br />

damage <strong>the</strong> mechanical<br />

shaft seal.<br />

Mechanical shaft seals<br />

require <strong>for</strong>ced lubrication.<br />

Purging <strong>and</strong> filling is required<br />

prior to <strong>the</strong> startup of<br />

a pump. If this work is not<br />

carried out, <strong>the</strong> mechanical<br />

face seal will run dry <strong>and</strong><br />

can be destroyed.<br />

<strong>KRAL</strong> magnetic couplings<br />

provide additional protection<br />

in <strong>the</strong> event of incorrect<br />

commissioning.<br />

Magnetic coupling vs.<br />

mechanical shaft seal.<br />

Magnetic coupling<br />

Maintenance<br />

interval: 40,000 h 10,000 h<br />

Temperature: 482 °F 300 °F<br />

Easy retrofit: Details on page 18.<br />

Solid materials in <strong>the</strong> fuel<br />

can lead to blocking <strong>and</strong><br />

damaging <strong>the</strong> pump.<br />

In many cases it is not<br />

worth to repair <strong>the</strong> pump,<br />

<strong>and</strong> it must be replaced.<br />

The magnetic coupling can<br />

prevent damage to <strong>the</strong><br />

pump if screws block. The<br />

motor uncouples from <strong>the</strong><br />

pump. The cause can be<br />

corrected <strong>and</strong> <strong>the</strong> pump<br />

restarted.<br />

Mechanical shaft seal<br />

Cost:<br />

The magnetic coupling pays <strong>for</strong> itself after<br />

maximum 3 years of operation.<br />

17

Easy retrofit to magnetically<br />

coupled pumps.<br />

In order to keep <strong>the</strong> retrofit<br />

from previous <strong>KRAL</strong> pumps<br />

<strong>with</strong> mechanical shaft seal<br />

to <strong>KRAL</strong> pumps <strong>with</strong> magnetic<br />

coupling simple, <strong>KRAL</strong><br />

offers conversion kits that<br />

keep <strong>the</strong> foot <strong>and</strong> pipe<br />

connection dimensions unchanged.<br />

Two reasons cause<br />

some dimensions of <strong>the</strong><br />

magentically coupled pump<br />

to change:<br />

New <strong>KRAL</strong> flange <strong>for</strong> <strong>the</strong><br />

accommodation of an<br />

Association of German<br />

Machine <strong>and</strong> Plant<br />

Builders (VDMA) pump<br />

mounting bracket.<br />

Possibly necessary,<br />

larger electrical motor<br />

to compensate <strong>for</strong> <strong>the</strong><br />

losses of <strong>the</strong> magnetic<br />

coupling.<br />

Initial situation: Previous <strong>KRAL</strong> pump <strong>with</strong> mechanical face seal.<br />

All conversion kits are delivered<br />

by <strong>KRAL</strong> pre-mounted.<br />

The illustrations to <strong>the</strong><br />

right show <strong>the</strong> different<br />

installation scenarios.<br />

We can help you <strong>with</strong> <strong>the</strong><br />

retrofit upon request.<br />

19<br />

Conversion situation 1: The electric motor remains unchanged: identical power <strong>and</strong><br />

size. The unit has grown somewhat longer due to <strong>the</strong> <strong>KRAL</strong> flange <strong>for</strong> <strong>the</strong> accommodation<br />

of <strong>the</strong> Association of German Machine <strong>and</strong> Plant Builders (VDMA) pump mounting<br />

bracket. The pump foot is <strong>the</strong> same as that <strong>for</strong> <strong>the</strong> pump <strong>with</strong> mechanical face seal.<br />

The pipe connection dimensions are retained. The length change is compensated <strong>for</strong><br />

<strong>with</strong> adapter sleeves in order to maintain <strong>the</strong> foot installation dimensions.<br />

Everything included.<br />

Floor anchoring.<br />

The appropriate foot is<br />

mounted to <strong>the</strong> pump.<br />

Dimensional drawings.<br />

Are included in <strong>the</strong> conversion<br />

package.<br />

2D <strong>and</strong> 3D CAD data.<br />

Integrate <strong>the</strong> new pump<br />

unit into your system<br />

drawing.<br />

Upon request you can<br />

receive <strong>the</strong>se on CD ROM.<br />

Conversion situation 2: The next larger electric motor must be used. <strong>KRAL</strong> manufactures<br />

<strong>and</strong> mounts a special foot <strong>with</strong> which <strong>the</strong> foot installation dimensions <strong>and</strong><br />

<strong>the</strong> pipe connection dimensions are retained. Adapter sleeves are not necessary.<br />

18

Our Offers<br />

Test a pump <strong>for</strong> free.<br />

Lifetime guarantee.<br />

Help <strong>with</strong> start-up.<br />

Background knowledge.<br />

We st<strong>and</strong> behind our products.<br />

That‘s why we feel<br />

confident about making<br />

this offer. Replace your<br />

pumps <strong>with</strong> mechanical<br />

face seal, regardless of <strong>the</strong><br />

manufacturer, <strong>with</strong> <strong>KRAL</strong><br />

pumps <strong>with</strong> magnetic<br />

coupling. You receive a<br />

<strong>KRAL</strong> pump <strong>with</strong> magnetic<br />

coupling <strong>for</strong> your booster<br />

module <strong>for</strong> a test period<br />

of up to one year at no<br />

charge. We will take <strong>the</strong><br />

pump back if it doesn‘t<br />

meet your expectations.<br />

Magnetic couplings are<br />

hermetically sealed over<br />

<strong>the</strong>ir entire service life.<br />

We guarantee this <strong>for</strong> <strong>the</strong><br />

lifetime <strong>for</strong> <strong>the</strong> seal.<br />

Ask <strong>for</strong> <strong>the</strong> guarantee<br />

conditions from <strong>KRAL</strong>.<br />

Pay-off period<br />

calculation.<br />

A new pump brings many<br />

advantages, but also often<br />

raises questions among<br />

<strong>the</strong> crew <strong>and</strong> technicians.<br />

At your request we support<br />

you in <strong>the</strong> installation<br />

<strong>and</strong> commissioning of<br />

your new <strong>KRAL</strong> pump. We<br />

will be pleased to quote<br />

commissioning <strong>and</strong> startup<br />

services.<br />

Interested? Get in touch<br />

<strong>with</strong> <strong>KRAL</strong>.<br />

Refinery processes, heavy<br />

fuel oils, research <strong>and</strong><br />

development. One change<br />

follows ano<strong>the</strong>r. In an<br />

exciting presentation we<br />

show you <strong>the</strong> technological<br />

development behind <strong>the</strong><br />

magnetic couplings <strong>for</strong><br />

<strong>KRAL</strong> three screw pumps.<br />

Simply ask your <strong>KRAL</strong><br />

consultant.<br />

Just ask about our pump<br />

upgrade project.<br />

We have created a life<br />

cycle cost program <strong>for</strong><br />

<strong>KRAL</strong> pumps <strong>with</strong> magnetic<br />

coupling. We assist you<br />

in <strong>the</strong> calculation of <strong>the</strong><br />

individual pay-off period of<br />

your upgrade project.<br />

19

Innovative Solutions <strong>for</strong> Increased Safety<br />

Optimal safety <strong>and</strong> significantly<br />

reduced operating costs.<br />

High outputs.<br />

<strong>KRAL</strong> pumps <strong>with</strong><br />

magnetic coupling are<br />

available <strong>for</strong> heavy fuel<br />

oils applications up to<br />

766 gpm.<br />

No fuel residue.<br />

Due to <strong>the</strong> sealed magnetic<br />

coupling, <strong>the</strong> fuel does<br />

not get in contact <strong>with</strong> air.<br />

There<strong>for</strong>e heavy fuel oil<br />

cannot react <strong>with</strong> oxygen,<br />

<strong>for</strong>m coking <strong>and</strong> cause<br />

damage. This eliminates a<br />

significant source of pump<br />

failure.<br />

Temperature-resistant up<br />

to 482 °F.<br />

Protection against<br />

overload.<br />

In contrast to mechanical<br />

face seals, <strong>the</strong> materials of<br />

<strong>the</strong> magnetic coupling are<br />

significantly more temperature-resistant.<br />

Highly viscous<br />

heavy fuel oils, which<br />

need to be pre-heated to approx.<br />

356 °F can be pumped<br />

<strong>with</strong>out a problem.<br />

In <strong>the</strong> event of an overload,<br />

<strong>the</strong> motor uncouples from<br />

<strong>the</strong> pump. The magnetic<br />

field is resynchronized as<br />

soon as <strong>the</strong> motor has<br />

come to a st<strong>and</strong>still. The<br />

pump can be restarted.<br />

20

The function.<br />

The torque of <strong>the</strong> electric<br />

motor is transferred <strong>with</strong>out<br />

contact through <strong>the</strong><br />

magnetic coupling to<br />

<strong>the</strong> pump screws. This<br />

is achieved via several<br />

magnets located on two<br />

rotors – one connected to<br />

<strong>the</strong> motor <strong>and</strong> one to <strong>the</strong><br />

pump shaft. Both rotors<br />

rotate in sync when in<br />

operation.<br />

Hermetically sealed.<br />

The containment can is <strong>the</strong><br />

seal element of <strong>the</strong> <strong>KRAL</strong><br />

pump. It completely encloses<br />

<strong>the</strong> pump shaft <strong>with</strong><br />

<strong>the</strong> inner rotor. The pump<br />

is totally encapsulated <strong>and</strong><br />

hermetically sealed.<br />

Optimized construction.<br />

<strong>KRAL</strong> has already been<br />

building magnetically coupled<br />

pumps <strong>for</strong> more than<br />

a decade. We have refined<br />

<strong>and</strong> optimized <strong>the</strong> magnetic<br />

coupling <strong>for</strong> three screw<br />

pumps to make it suitable<br />

<strong>for</strong> industrial applications<br />

while making it economically<br />

attractive. We design<br />

all components ourselves.<br />

Pump <strong>and</strong> magnetic<br />

coupling are <strong>the</strong>re<strong>for</strong>e<br />

perfectly matched.<br />

The magnetic coupling<br />

is wear-free.<br />

The magnetic coupling is a<br />

non contact coupling. The<br />

pump screws are driven<br />

contact free through <strong>the</strong><br />

magnets on <strong>the</strong> outer <strong>and</strong><br />

inner rotor.<br />

Where nothing grinds,<br />

nothing can wear.<br />

Safety margin <strong>for</strong><br />

start-up.<br />

The magnetic coupling<br />

completely replaces <strong>the</strong><br />

mechanical face seal.<br />

That reduces <strong>the</strong> risk of<br />

start-up damage due to<br />

running dry.<br />

21

There are more<br />

Effective Ways<br />

to Save Money.<br />

Fuel consumption accounts <strong>for</strong> a considerable portion of vessel operating<br />

costs. A great deal of experience <strong>and</strong> exceptional measuring technology<br />

are necessary to acquire reliable measured values <strong>for</strong> fuel consumption.<br />

<strong>KRAL</strong> offers both. With our help you can save where it makes sense.

Fuel Consumption Measurement<br />

This is unique: fuel consumption measurement proven<br />

over 15 years has never experienced so many innovations.<br />

The “Fuel Consumption Bible“<br />

explains technical details.<br />

Experience is <strong>the</strong> most<br />

important thing.<br />

Pressure pulsations must be<br />

compensated <strong>for</strong>.<br />

BEM 800 integrates GPS data.<br />

The innovation –<br />

integration of GPS data.<br />

Fuel consumption per<br />

nautical mile.<br />

Those who are unfamiliar<br />

<strong>with</strong> fuel consumption<br />

measurement don‘t st<strong>and</strong><br />

a chance <strong>and</strong> have to learn<br />

<strong>the</strong> hard way.<br />

Starting <strong>with</strong> ma<strong>the</strong>matics<br />

to calculate error propagation<br />

according to Gauß<br />

makes <strong>the</strong> requirement <strong>for</strong><br />

highly precise measurement<br />

devices clear. In most<br />

applications a differential<br />

measurement is required<br />

<strong>with</strong> a flowmeter in each –<br />

<strong>the</strong> supply <strong>and</strong> return line of<br />

<strong>the</strong> engine. The consumption<br />

is calculated from two<br />

individual measurements,<br />

this is where Gauß comes<br />

into play. We would be<br />

happy to explain that to you<br />

personally.<br />

26<br />

Additionally <strong>the</strong> injection<br />

pumps cause powerful pressure<br />

pulsations. The flow<br />

direction reverses briefly<br />

over <strong>and</strong> over, <strong>the</strong> temperatures<br />

in <strong>the</strong> inlet <strong>and</strong> return<br />

flow vary. The success of<br />

<strong>the</strong> measurement also depends<br />

upon <strong>the</strong> installation<br />

location. We would like to<br />

show you what despite <strong>the</strong><br />

rough operating conditions<br />

has to be done to create<br />

compensated <strong>and</strong> corrected<br />

measurement values you<br />

can trust.<br />

26<br />

With 15 years of experience,<br />

we are familiar <strong>with</strong><br />

conditions on board. Our<br />

electronics are perfectly<br />

matched <strong>for</strong> <strong>the</strong> <strong>KRAL</strong> flow<br />

meters. The software contains<br />

our entire measurement<br />

technology knowledge<br />

about <strong>the</strong> fuel system.<br />

The flow reversal <strong>and</strong> <strong>the</strong><br />

temperature differences in<br />

<strong>the</strong> suppy <strong>and</strong> return flow<br />

are taken into account.<br />

Our brochure “Fuel consumption<br />

measurement <strong>for</strong><br />

diesel engines“ is known<br />

as “The Fuel Consumption<br />

Bible“ in <strong>the</strong> industry. There<br />

you can find out more on<br />

this subject.<br />

The <strong>KRAL</strong> fuel consumption<br />

measurement previously did<br />

not include location in<strong>for</strong>mation.<br />

The new BEM 800 FCM<br />

adds on-board geodata to <strong>the</strong><br />

highly precise consumption<br />

measurement values <strong>and</strong><br />

provides in<strong>for</strong>mation about<br />

<strong>the</strong> fuel consumption per<br />

nautical mile.<br />

The basis – <strong>KRAL</strong> Volumeter<br />

<strong>and</strong> BEM 500.<br />

The new BEM 800 FCM<br />

receives <strong>the</strong> exact consumption<br />

values from <strong>the</strong><br />

long proven system of <strong>the</strong><br />

<strong>KRAL</strong> Volumeter as flowmeter<br />

devices <strong>and</strong> BEM 500 as<br />

evaluation electronics.<br />

The success of <strong>the</strong> measurement<br />

begins <strong>with</strong> <strong>the</strong> quality<br />

of <strong>the</strong> flowmeter devices<br />

used. Volumeters are <strong>the</strong><br />

most exact displacement<br />

meters in <strong>the</strong> world <strong>and</strong> are<br />

<strong>the</strong>re<strong>for</strong>e <strong>the</strong> prerequisite <strong>for</strong><br />

adequately precise measuring<br />

values of <strong>the</strong> complete<br />

system.<br />

<strong>KRAL</strong> Volumeter, due to<br />

<strong>the</strong>ir functionality, measure<br />

bidirectional. This is why it<br />

is easy to take fuel backflow<br />

into account <strong>with</strong> <strong>the</strong> <strong>KRAL</strong><br />

Volumeter.<br />

The <strong>KRAL</strong> BEM 500<br />

electronics unit is specially<br />

designed <strong>for</strong> <strong>KRAL</strong> flowmeter<br />

devices. Two Volumeters<br />

can be connected to <strong>the</strong><br />

BEM 500. With its optional<br />

sensors, <strong>the</strong> BEM 500<br />

registers fuel backflows <strong>and</strong><br />

temperature differences in<br />

<strong>the</strong> supply <strong>and</strong> return flow.<br />

BEM 800 uses <strong>the</strong><br />

measurement results of<br />

<strong>the</strong> BEM 500.<br />

The highly precise consumption<br />

values from <strong>the</strong> BEM<br />

500 are transferred to <strong>the</strong><br />

new BEM 800 <strong>and</strong> toge<strong>the</strong>r<br />

<strong>with</strong> <strong>the</strong> on-board GPS data<br />

can now be displayed as fuel<br />

consumption per nautical<br />

mile on a clearly structured<br />

display.<br />

24

Torque <strong>and</strong> shaft rotational<br />

speed.<br />

Specific fuel consumption<br />

per engine.<br />

Data acquisition <strong>and</strong> transfer.<br />

Remote display.<br />

SFOC measurement<br />

per engine.<br />

Power measurement.<br />

Data acquisition, transfer<br />

<strong>and</strong> statistics.<br />

Consumption measurement<br />

display on <strong>the</strong> bridge.<br />

Fuel consumption is influenced<br />

by factors such as<br />

swell <strong>and</strong> current. The precise<br />

<strong>KRAL</strong> fuel consumption<br />

measurement indicates<br />

that. The consumption value<br />

changes immediately.<br />

In order to reliably save<br />

fuel over a long voyage,<br />

<strong>the</strong> engines must operate<br />

at <strong>the</strong>ir optimal operating<br />

points. The specific fuel<br />

oil consumption (SFOC)<br />

in g/kWh is a value that is<br />

lowest <strong>for</strong> a defined load<br />

range specified by <strong>the</strong><br />

engine manufacturer.<br />

The new <strong>KRAL</strong> BEM 820<br />

ADV can process measuring<br />

values <strong>for</strong> torque <strong>and</strong> shaft<br />

rotational speed <strong>and</strong> calculate<br />

<strong>and</strong> display <strong>the</strong> SFOC<br />

<strong>with</strong> <strong>the</strong> fuel consumption<br />

in mass units. In this way<br />

<strong>the</strong> operator can move towards<br />

<strong>the</strong> optimal operating<br />

point <strong>for</strong> saving fuel.<br />

Engines on board are often<br />

already equipped <strong>with</strong> a<br />

power meter. With <strong>the</strong> BEM<br />

840 EKW, <strong>KRAL</strong> offers <strong>the</strong><br />

possibility of processing<br />

<strong>the</strong> measured power <strong>and</strong><br />

calculating <strong>the</strong> specific fuel<br />

consumption in g/kWh <strong>with</strong><br />

<strong>the</strong> fuel consumption. Fuel<br />

consumption, output generated<br />

<strong>and</strong> SFOC are clearly<br />

shown on only one screen.<br />

The fleet manager wishes<br />

to evaluate <strong>and</strong> document<br />

<strong>the</strong> operating costs of his<br />

fleet in order to derive costreduction<br />

measures <strong>for</strong> <strong>the</strong><br />

future from this.<br />

BEM 800 has a storage<br />

capacity of one year. The<br />

innovation has templates<br />

<strong>for</strong> saving <strong>and</strong> displaying<br />

saved measuring values<br />

such as fuel consumption,<br />

SFOC <strong>and</strong> data concerning<br />

<strong>the</strong> day‘s voyage <strong>and</strong> total<br />

voyage. The recorded data<br />

can be transferred via an<br />

USB interface or by e-mail.<br />

Some vessels have no fuel<br />

consumption display on <strong>the</strong><br />

bridge.<br />

The <strong>KRAL</strong> BEM 810 RD is a<br />

remote display <strong>and</strong> control<br />

unit that takes measuring<br />

values <strong>for</strong> fuel consumption<br />

from <strong>the</strong> BEM 500 <strong>and</strong><br />

presents <strong>the</strong>m on a dimmable<br />

display. As an option,<br />

<strong>the</strong> BEM 810 RD can read in<br />

GPS data in order to display<br />

<strong>the</strong> fuel consumption per<br />

nautical mile <strong>and</strong> speed.<br />

Operation is quite simple.<br />

The display is dimmed <strong>with</strong><br />

a button. Data can be selected<br />

from <strong>the</strong> BEM 500 <strong>and</strong><br />

displayed <strong>with</strong> <strong>the</strong> second<br />

button. Data of <strong>the</strong> BEM 800<br />

family can be repeated.<br />

We can show you <strong>the</strong> many<br />

possibilities <strong>with</strong> models<br />

<strong>and</strong> software that simulate<br />

operation.<br />

26<br />

25

Our Offers<br />

Printout of a bunker receipt.<br />

Bunker monitoring <strong>for</strong><br />

LFO <strong>and</strong> MDO.<br />

The necessity of highly<br />

precise flowmeters.<br />

Simulation of a BEM 800.<br />

Help <strong>with</strong> installation<br />

<strong>and</strong> start-up.<br />

Vessel operators don‘t<br />

want to rely only on <strong>the</strong><br />

bunker receipt, <strong>the</strong>y want<br />

to confirm <strong>the</strong> bunkered<br />

quantity <strong>the</strong>mselves.<br />

<strong>KRAL</strong> BEM 830 BKR<br />

acquires measuring values<br />

from <strong>the</strong> BEM 500 to<br />

double check <strong>the</strong> refueling<br />

process. The to be bunkered<br />

quantity can be set as<br />

target value. The <strong>KRAL</strong> system<br />

shows <strong>the</strong> remaining<br />

time <strong>and</strong> <strong>the</strong> transferred<br />

amount. BEM 830 BKR<br />

can print out a tank receipt<br />

<strong>with</strong> <strong>the</strong> bunker data.<br />

Each <strong>KRAL</strong> Volumeter is<br />

delivered <strong>with</strong> its own<br />

calibration certificate.<br />

The measuring values of<br />

<strong>the</strong> <strong>KRAL</strong> Volumeter can<br />

be traced back to national<br />

st<strong>and</strong>ards. With our<br />

system you have good<br />

arguments <strong>for</strong> discussing<br />

inconsistencies.<br />

We help you calculate<br />

<strong>the</strong> measurement errors<br />

according to Gauß <strong>for</strong><br />

<strong>KRAL</strong> Volumeter <strong>and</strong> <strong>for</strong><br />

o<strong>the</strong>r, less precise flowmeter<br />

devices <strong>with</strong> <strong>the</strong> help of<br />

a program. Toge<strong>the</strong>r <strong>with</strong><br />

you, we discuss <strong>the</strong> importance<br />

of highly precise<br />

individual measurement<br />

devices <strong>for</strong> <strong>the</strong> precision of<br />

<strong>the</strong> overall system. We discuss<br />

<strong>the</strong> system precision<br />

you need.<br />

We demonstrate <strong>the</strong><br />

various possibilities of<br />

BEM 800 devices <strong>with</strong> a<br />

simulation software even<br />

prior to <strong>the</strong> installation. In<br />

this way you can convince<br />

yourself of <strong>the</strong> simple operation<br />

<strong>and</strong> <strong>the</strong> in<strong>for</strong>mation<br />

content of <strong>the</strong> system.<br />

Training.<br />

We offer training seminars<br />

on installation, operation<br />

<strong>and</strong> usage of <strong>the</strong> measuring<br />

value analyses.<br />

With this knowledge you<br />

become experts in <strong>the</strong><br />

measurement <strong>and</strong> saving<br />

of fuel.<br />

Basically you can install<br />

<strong>and</strong> start up <strong>the</strong> <strong>KRAL</strong> fuel<br />

consumption measurement<br />

yourself. If you want<br />

to be entirely sure, make<br />

use of our many years of<br />

experience <strong>and</strong> let us help<br />

you.<br />

The operating conditions<br />

in <strong>the</strong> low-pressure fuel<br />

system.<br />

With an interesting Power-<br />

Point presentation we<br />

show you <strong>the</strong> cause <strong>for</strong><br />

pressure pulsations in <strong>the</strong><br />

low-pressure fuel system<br />

<strong>and</strong> <strong>the</strong> possibility of short<br />

reverse flow events. The<br />

influences on <strong>the</strong> flowmeter<br />

<strong>and</strong> <strong>the</strong> compensation<br />

<strong>for</strong> possible measurement<br />

errors are illustrated.<br />

26

Fuel Consumption Measurement<br />

If you need:<br />

High Precision Single Line<br />

Fuel Consumption Measurement.<br />

If you need:<br />

High Precision Differential Fuel<br />

Consumption Measurement.<br />

If you need:<br />

Remote Display.<br />

Optional: Geodata<br />

(Fuel Consumption per NM).<br />

If you need:<br />

BEM 300.<br />

BEM 500.<br />

GPS<br />

<strong>KRAL</strong> Volumeter ® .<br />

<strong>KRAL</strong> Volumeter ® . <strong>KRAL</strong> Volumeter ® .<br />

GPS<br />

BEM 810 RD.<br />

Geodata (Fuel Consumption<br />

per NM).<br />

Data Storage.<br />

Data Transfer.<br />

Multi-Engine System up to<br />

5 Engines.<br />

BEM 800 processor.<br />

BEM 800 15" display.<br />

If you need:<br />

Specific Fuel Consumption<br />

Measurement incl. Torque <strong>and</strong><br />

Rotation Speed Processing.<br />

Multi-Engine System up to<br />

5 Engines.<br />

BEM 820 ADV.<br />

If you need:<br />

Measurement <strong>and</strong> Monitoring<br />

of <strong>the</strong> Engine Per<strong>for</strong>mance.<br />

Multi-Engine System up to<br />

5 Engines.<br />

BEM 840 EKW.<br />

If you need:<br />

Bunkering Monitoring System.<br />

BEM 830 BKR.<br />

If you need:<br />

Multi-Engine System up to<br />

16 Engines.<br />

Data Storage.<br />

Data Transfer.<br />

Report Print.<br />

Project Specific Solutions.<br />

BEM 900.<br />

<strong>KRAL</strong> Volumeter ® .<br />

Up to 32 <strong>KRAL</strong> Volumeter ®<br />

possible.<br />

27

Faith, Hope<br />

<strong>and</strong> Believe?<br />

Or certainty instead?<br />

Manufacturers of 2-stroke crosshead engines specify <strong>the</strong> cylinder lubricating oil<br />

quantity. You can only hope that <strong>the</strong> specifications are observed.<br />

Excessive lubrication costs a lot of money. With <strong>the</strong> <strong>KRAL</strong> cylinder lubricating<br />

oil measurement you replace hope <strong>with</strong> precise measuring values.

<strong>KRAL</strong> Solutions <strong>for</strong> Cylinder Lubricating Oil Measurement<br />

<strong>KRAL</strong> cylinder lubricating oil measurement<br />

<strong>for</strong> 2-stroke crosshead engines.<br />

The <strong>KRAL</strong> cylinder lubricating oil measurement enables <strong>the</strong><br />

measurement of <strong>the</strong> injection quantity <strong>for</strong> <strong>the</strong> first time.<br />

A real money machine!<br />

Excess lubrication can result<br />

in additional operating cost<br />

of up to USD 270,000* per<br />

engine <strong>and</strong> year.<br />

At USD 1,700 per ton,<br />

lubricating oil is significantly<br />

more expensive than fuel.<br />

It not only lubricates <strong>the</strong><br />

cylinders, it also protects<br />

<strong>the</strong>m against corrosion <strong>and</strong><br />

sedimentation <strong>with</strong> <strong>the</strong> help<br />

of additives. The additives<br />

make lubricating oil expensive.<br />

Operating costs rise<br />

when too much lubricating<br />

oil is injected. The spectrum<br />

<strong>for</strong> setting <strong>the</strong> lubricating oil<br />

quantity extends from<br />

mechanically assisted injection<br />

systems to computercontrolled<br />

systems. The<br />

injection quantity throughout<br />

<strong>the</strong> entire load area<br />

often doesn‘t agree <strong>with</strong><br />

<strong>the</strong> injection quantities programmed<br />

in <strong>the</strong> controlled<br />

system. Only measuring<br />

offers in<strong>for</strong>mation that ist<br />

not provided by any control<br />

system.<br />

The <strong>KRAL</strong> cylinder lubricating<br />

oil measurement fills<br />

this gap <strong>and</strong> enables highly<br />

precise measurement.<br />

Deposits between <strong>the</strong> piston<br />

rings.<br />

Avoid engine damage.<br />

Too much lubricating oil<br />

damages pistons <strong>and</strong><br />

cylinders.<br />

Lubricating oil contains<br />

additives <strong>for</strong> protection<br />

against corrosion <strong>and</strong><br />

sedimentation. Too much<br />

lubrication can result in additive<br />

deposits between <strong>the</strong><br />

piston rings. Piston rings<br />

can break. That‘s expensive.<br />

With <strong>the</strong> <strong>KRAL</strong> lubricating<br />

oil measurement, <strong>the</strong><br />

operator receives correct<br />

measuring values. The<br />

injection quantity can be set<br />

exactly <strong>with</strong> this in<strong>for</strong>mation.<br />

That prevents engine<br />

damage.<br />

Take fuel quality into<br />

account.<br />

The quantity of lube oil<br />

depends upon <strong>the</strong> sulfur<br />

content of <strong>the</strong> fuel.<br />

When combusted, sulfur<br />

reacts to become sulfur<br />

dioxide, which, through sulfur<br />

trioxide in combination<br />

<strong>with</strong> water, has a strongly<br />

corrosive effect <strong>and</strong> attacks<br />

<strong>the</strong> cylinder liner. After each<br />

bunkering it must be tested<br />

whe<strong>the</strong>r <strong>the</strong> sulfur content<br />

has changed in comparison<br />

to <strong>the</strong> previously used fuel.<br />

In case that <strong>the</strong> fuel is<br />

different, <strong>the</strong> lubricating oil<br />

quantity must be adjusted.<br />

Engine manufacturers provide<br />

operators <strong>with</strong> aids, <strong>for</strong><br />

example, setting tables.<br />

Savings of up to<br />

USD 270,000* annually.<br />

Let us explain where we<br />

see <strong>the</strong> great potential <strong>for</strong><br />

savings. 32<br />

The <strong>KRAL</strong> lubricating oil<br />

measurement shows<br />

whe<strong>the</strong>r <strong>the</strong> manufacturer<br />

specifications are actually<br />

being achieved.<br />

* Trade&Technical Press,<br />

September 25, 2006<br />

30

Graphic 1: The injectors cause strong pulsations <strong>and</strong> backflows.<br />

Graphic 2: Lubricating oil measurement over <strong>the</strong> course of a day.<br />

The measurement error in comparison to <strong>the</strong> level measurement<br />

converges toward zero.<br />

The best possible measurement precision<br />

is extremely important.<br />

Due to <strong>the</strong> interaction of <strong>the</strong><br />

actions of a number of injectors,<br />

<strong>the</strong> lubricating oil flow<br />

in <strong>the</strong> supply flow is not<br />

constant, but ra<strong>the</strong>r chaotic.<br />

This is a difficult measuring<br />

task that encompasses<br />

strong flow fluctuations <strong>and</strong><br />

periodic backflows.<br />

With some injection systems,<br />

<strong>the</strong> lubricating oil also<br />

serves as servo oil <strong>for</strong> <strong>the</strong><br />

operation of <strong>the</strong> injectors.<br />

The movement of <strong>the</strong><br />

injection pistons cause<br />

pulsations <strong>and</strong> considerable<br />

backflow quantities in <strong>the</strong><br />

oil flow as a consequence<br />

(see graphic 1). In addition,<br />

<strong>the</strong> cylinders of <strong>the</strong> engine<br />

are supplied <strong>with</strong> varying<br />

lubricant quantities at<br />

different times. The oil flow<br />

is anything but constant.<br />

Difficult in terms of measuring<br />

is that <strong>the</strong> lubricating oil<br />

quantity to be measured is<br />

far less than <strong>the</strong> total flow<br />

quantity dominated by <strong>the</strong><br />

servo oil dem<strong>and</strong>. Because<br />

a considerable part of <strong>the</strong><br />

lubricating oil is directed<br />

back from <strong>the</strong> injector to a<br />

reserve tank, <strong>the</strong> consumption<br />

measurement<br />

is only successful as a<br />

differential measurement<br />

of two measuring values in<br />

<strong>the</strong> case of systems <strong>with</strong><br />

a ring line. In addition to<br />

this, backflows must be<br />

recognized <strong>and</strong> subtracted<br />

<strong>for</strong> a current measurement<br />

value.<br />

The temperature in <strong>the</strong> oil<br />

tank can be significantly<br />

less than in <strong>the</strong> injectors<br />

close to <strong>the</strong> hot engine.<br />

This means that density<br />

differences of <strong>the</strong> cylinder<br />

oil at <strong>the</strong> two measuring<br />

points must also be taken<br />

into account.<br />

<strong>KRAL</strong> Volumeter are highly<br />

precise flowmeter devices<br />

(see graphic 2). They<br />

function equally in both<br />

flow directions. They are<br />

equipped <strong>with</strong> a sensor<br />

that recognizes <strong>the</strong> rotation<br />

direction of <strong>the</strong> screws <strong>and</strong><br />

<strong>with</strong> a temperature sensor.<br />

They <strong>the</strong>re<strong>for</strong>e take into<br />

account <strong>the</strong> special properties<br />

of <strong>the</strong> oil flow <strong>and</strong><br />

deliver exact measurement<br />

results.<br />

We would be pleased to<br />

present our measurements<br />

Graphic 3: The actual lubricating<br />

oil consumption is<br />

considerably greater than <strong>the</strong><br />

specification of <strong>the</strong> engine<br />

manufacturer. There is a lot of<br />

potential <strong>for</strong> saving here.<br />

to you. 32<br />

31

Our Offers<br />

Great savings potential.<br />

We see savings potential<br />

of up to USD 270,000 per<br />

engine <strong>and</strong> year. Let <strong>KRAL</strong><br />

show you how we come to<br />

this conclusion.<br />

* Trade&Technical Press,<br />

September 25, 2006<br />

Practical experience.<br />

<strong>KRAL</strong> technicians have<br />

measured <strong>the</strong> lubricating<br />

oil quantities of engines<br />

equipped <strong>with</strong> lubricating<br />

oil systems from Wärtsilä<br />

<strong>and</strong> MAN. Let us demonstrate<br />

this good practical<br />

experience.<br />

Help <strong>with</strong><br />

commissioning.<br />

<strong>KRAL</strong> offers a precision<br />

system <strong>with</strong> <strong>the</strong> cylinder<br />

lubricating oil measurement.<br />

In order to make use<br />

of all advantages, <strong>KRAL</strong><br />

can assist in <strong>the</strong> selection<br />

of <strong>the</strong> installation location<br />

<strong>and</strong> <strong>with</strong> <strong>the</strong> start-up as<br />

required.<br />

32

<strong>KRAL</strong> Solution <strong>for</strong> Optimal Cylinder Lubricating Oil Measurement<br />

BEM 500<br />

Supply flow<br />

Ring line<br />

<strong>with</strong> injectors<br />

Piston of <strong>the</strong><br />

diesel engine<br />

Return flow<br />

Optional<br />

33

<strong>KRAL</strong>-USA, Inc., P.O. Box 2990, Mat<strong>the</strong>ws NC 28106, 901A Mat<strong>the</strong>ws-Mint Hill Road, Mat<strong>the</strong>ws NC 28105, USA<br />

Tel.: (704) 814-6164, Fax: (704) 814-6165, www.kral-usa.com, e-mail: sales@kral-usa.com<br />

Edition Z08/11. All rights reserved. Subject to change.