KRAL Inside engl.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INSIDE<br />

No. 1 October 2000<br />

With <strong>KRAL</strong> as a partner for unique solutions<br />

Years<br />

<strong>KRAL</strong> anniversary<br />

History and review<br />

Fit for the future<br />

Successful<br />

partnerships<br />

Product innovations<br />

Anniversary raffle<br />

Your ticket to the<br />

Ski World Cup in St. Anton

ANNIVERSARY<br />

50 years of <strong>KRAL</strong> – a wonderful<br />

reason to review the past<br />

as well as a brief look at the future<br />

It has been a long and very intensive journey from the operation<br />

of the first <strong>KRAL</strong> domestic water pump to the state of our high-tech<br />

company with the development and production of screw pumps<br />

and flowmeters.<br />

<strong>KRAL</strong> Volumeters were a useful<br />

addition and increased our market<br />

value worldwide.<br />

Our customers were and are far<br />

more than mere “buyers” of our<br />

products.<br />

Engineer Fritz Huber and his<br />

management team took over<br />

the management of the business<br />

in 1997. Erich and son,<br />

Graduate Engineer Otmar<br />

Kräutler, have been on the board<br />

since that time and created the<br />

best conditions for optimum<br />

management of the future.<br />

From the start we have been<br />

nurturing a culture whereby the<br />

daily work is accomplished<br />

together. This even includes the<br />

families of our staff. This can<br />

only be produced but not<br />

bought. This is the result of<br />

experiencing a company culture<br />

from which the customer will<br />

benefit in the end.<br />

The points are set for the<br />

“<strong>KRAL</strong> train“ regarding the future:<br />

Performance and<br />

commitmend<br />

This positive development has<br />

demanded intense commitment<br />

Oskar Kräutler, Founder of the Company<br />

from our employees and the<br />

company management.<br />

When the founder of our company,<br />

Mr. Oskar Kräutler, started<br />

as a one-man operation with the<br />

production of domestic water-<br />

Erich Kräutler and Fritz Huber<br />

works in 1950, the demand of a<br />

conventional market had to be<br />

accommodated. Consequently,<br />

mainly water pumps and customized<br />

designs have been built.<br />

With the takeover of the<br />

“pumps“ company by his son<br />

Erich Kräutler in 1968, the still<br />

new “screw pumps“ area was<br />

pushed forward as the core<br />

business. Main emphasis was<br />

placed on the oil-firing market<br />

with at that stage already very<br />

difficult media.<br />

We developed a wide range of<br />

products to accommodate the<br />

customer's requirements. The<br />

excellent reputation of our <strong>KRAL</strong><br />

fuel oil pumps became the basis<br />

for the development of pumps<br />

for hydraulic and lubrication<br />

applications.<br />

Otmar Kräutler<br />

If a review of the things that<br />

contributed mainly to the success<br />

is made in the year of the company's<br />

anniversary, the fact that the<br />

“<strong>KRAL</strong> train“ does always run on<br />

two tracks must be mentioned<br />

as one important contribution:<br />

1. To recognize the customer's<br />

requirements and to take the<br />

necessary measures to comply<br />

with them quickly.<br />

2. Establishing and maintaining<br />

good relations with all the<br />

people directly involved with our<br />

products.<br />

Currently Graduate Engineer<br />

Otmar Kräutler works as an advisor.<br />

His comprehensive training<br />

at the Technical University Graz,<br />

his manifold work experience in<br />

other companies and the established<br />

<strong>KRAL</strong> philosophy creates<br />

trust in continuity.<br />

Our main aim is not profit<br />

maximization or market domination<br />

at all costs, but trustful, successful<br />

and permanent co-operation<br />

with our customers and<br />

employees.<br />

Erich Kräutler<br />

2

RETROSPECTIVE<br />

The History<br />

1950<br />

It is impressive to follow all that<br />

has happened in 50 years.<br />

Here the stages of our success<br />

1965<br />

The first years<br />

1950 At the time of the company's foundation, the<br />

product range includes domestic water pumps,<br />

electric motors, industrial water pumps and<br />

gear pumps.<br />

1955 Glandless and quiet running circulation pumps<br />

are developed and produced.<br />

1976<br />

1958 The first screw pumps with two spindles are<br />

built to accommodate the heating technology's<br />

requirements.<br />

1965 The screw pump range is extended, triple screw<br />

pumps are developed and produced in series.<br />

Now screw pumps are produced exclusively.<br />

1976 The plant II on Bildgasse is built.<br />

1977 The production moves into the new building.<br />

1977<br />

1978 The first programmable Heid NC lathe with<br />

quintuple turret and control tape as data medium<br />

is put in operation.<br />

1979 In the office area, flexible working hours<br />

are introduced.<br />

Many new products<br />

1980 The first electronic data processing system<br />

is introduced.<br />

1978<br />

1982 The insert and universal pump series C is<br />

designed. The maximum capacity is designed<br />

for 1750 l/min at 2900 rpm.<br />

1982<br />

3

RETROSPECTIVE<br />

1984<br />

1984 The screw volumeter OM is developed for measuring<br />

the rate of flow. Maximum accuracy ( ±0.1 %)<br />

over a wide measuring range (1:100) characterize<br />

this instrument aside from its sturdiness.<br />

1985 A special twin screw pump, ZC, for special<br />

applications is included in the program. Its capacity<br />

is 400 l/min.<br />

1988<br />

Successful years<br />

1986 A new extended electronic data processing<br />

system is introduced (AUPRO).<br />

1988 Based on shipbuilding requirements, the K pump<br />

series with a maximum capacity of 1300 l/min<br />

at 1450 rpm is developed.<br />

1989 Introduction of CAD for the design.<br />

1990 We celebrate the company's 40th anniversary.<br />

1990<br />

We continue to grow<br />

1992 Extension of plant II. The offices move into the<br />

new company building in June 1992.<br />

1995 Introduction of the quality assurance system<br />

ISO 9001.<br />

1997 Erich Kräutler hands over the company<br />

management to Fritz Huber.<br />

1992<br />

1999 Introduction of flexible working hours for<br />

production and assembly.<br />

2000 This year we celebrate the company's<br />

50th anniversary.<br />

1997<br />

1999<br />

4

OUTLOOK<br />

Fit for the Future<br />

Finding unique solutions with <strong>KRAL</strong> as a partner<br />

Complete customer focus is our<br />

highest goal. We use our competence<br />

for our customers' market<br />

advantage. We developed<br />

our competence in delivering<br />

and measuring of fluids over the<br />

last 50 years and continuously set<br />

measures for further development<br />

of this competence. This<br />

requires fitness in all areas to<br />

maintain our development at a<br />

high standard:<br />

Quality is the top maxim. Our<br />

quality assurance system according<br />

to ISO 9001, certified by<br />

DNV, is our fitness program for<br />

the processes in our company.<br />

Continuous development towards<br />

process-oriented quality<br />

management is in progress and<br />

will link us even closer to our<br />

customers' requirements in the<br />

future.<br />

The most important factor for a<br />

dynamic development is motivated<br />

employees who build competence<br />

by accumulating knowledge<br />

in a purposeful manner. A<br />

training schedule for each<br />

employee is put into practice<br />

through company seminars held<br />

in co-operation with institutions<br />

such as the University of St.<br />

Gallen, University of Erlangen,<br />

Austrian Controller Institute,<br />

Institute for Business Development<br />

and other competent organizations.<br />

Further measures<br />

include individual seminars and<br />

monthly information evenings. A<br />

comprehensive company library<br />

provides topical, relevant, specialized<br />

literature and videos for<br />

individual training. A company<br />

sports group offers opportunities<br />

for physical fitness. The extensive<br />

information available helps<br />

to motivate the employees.<br />

Team spirit, creativity and initiative<br />

are a plus for our customers.<br />

Strategic alliances<br />

To increase the development of<br />

our innovation spiral, the development<br />

efforts have been<br />

strengthened in both our product<br />

groups. The contact with<br />

<strong>KRAL</strong> plant<br />

5

OUTLOOK<br />

<strong>KRAL</strong> sales partners worldwide<br />

our customers has since intensified.<br />

These measures help us to<br />

get to know our customers'<br />

requirements even better and to<br />

create solutions of high benefit.<br />

Being fit for solving application<br />

problems is therefore not just a<br />

slogan but the basis of our<br />

strategy.<br />

The company entered into strategic<br />

alliances with companies<br />

such as J.H. Bornemann in<br />

Obernkirchen for an integrated<br />

approach. For many customers<br />

co-operation like this has become<br />

a reliable approach<br />

towards complete pump packages<br />

as system solutions.<br />

Worldwide representation and<br />

customer service are major concerns<br />

for us. The target of<br />

“being close to the customer“ is<br />

almost fulfilled with 35 sales<br />

partners worldwide. More sales<br />

and service partners will become<br />

active soon in strategically<br />

important markets.<br />

Communication and information<br />

availability have increased continuously.<br />

We at <strong>KRAL</strong> mainly<br />

communicate using email. To<br />

increase the exchange of information,<br />

the <strong>KRAL</strong> homepage<br />

(www.kral.at) was established<br />

recently as a means of providing<br />

current, interactive information.<br />

Our target is to utilize the<br />

options of this instrument for<br />

our customers' and sales partners'<br />

full advantage.<br />

Further aspects of the fitness<br />

for the future are our immense<br />

investments in production<br />

machinery. In the last few years,<br />

state-of-the-art production<br />

machines have been commissioned<br />

to ensure the highest<br />

product quality.<br />

The management can approach<br />

the future in a fit and confident<br />

manner first and foremost due<br />

to the fact that the company<br />

owners, the Kräutler family,<br />

have considered customer satisfaction<br />

and employee satisfaction<br />

as a top priority since the<br />

company's foundation. Issues<br />

such as profit maximization are<br />

put on the back burner compared<br />

with these objectives.<br />

Satisfied customers come first,<br />

which are naturally followed by<br />

satisfactory business results.<br />

Profit optimization programs<br />

direct attention to subjects such<br />

as “mergers and acquisition”<br />

instead of analysis and compli-<br />

Management meeting at <strong>KRAL</strong><br />

ance with customer requests.<br />

This long-term orientation guarantees<br />

that you as our customer<br />

will continuously receive high<br />

performance and optimum service<br />

well into the future.<br />

Fritz Huber<br />

Managing Director<br />

6

PARTNERS<br />

Bornemann<br />

Chance for the Future – The Niche Specialist<br />

screw pumps with the traditional<br />

fields of application:<br />

loading pumps for products<br />

carriers and special tankers<br />

transfer pumps for tank<br />

farms,<br />

process pumps for the petrochemistry.<br />

This co-operation, which is strengthened<br />

by a close personal contact<br />

between the company management,<br />

includes common agencies,<br />

package offers, co-ordination of<br />

the quality assurance system as<br />

well as the product range and<br />

specialization of the production.<br />

Obernkirchen 2000<br />

From Pump Manufacturer<br />

to System Supplier<br />

Merger mania is also going<br />

around in the pump business.<br />

More and more companies merge<br />

due to the necessity to be represented<br />

in the worldwide market.<br />

Like <strong>KRAL</strong>, the north German<br />

pump manufacturer BORNEMANN<br />

considers this as a chance to<br />

provide a better solution : by cooperating<br />

and clearly focusing on<br />

one niche of the market - specializing<br />

in a limited product area and<br />

consequently performing as a<br />

qualified partner for customers in<br />

order to solve their problems.<br />

Both family businesses, <strong>KRAL</strong><br />

and Bornemann, have been cooperating<br />

for more than ten years<br />

following this maxim. Alongside<br />

the triple screw pump specialist<br />

<strong>KRAL</strong>, BORNEMANN has its<br />

place on the market as the world's<br />

leading manufacturer of twin<br />

The exceptional growth of both<br />

companies confirms of this policy.<br />

Michael Bornemann-Galensa<br />

Managing Director<br />

External twin screw pump<br />

Multiphase pump systems for the oil production (PETROZUATA, Venezuela)<br />

7

PARTNERS<br />

PG Marine Group<br />

with <strong>KRAL</strong> in the Global environment of Shipbuilding<br />

and Marine Operations<br />

With the Marine group PG is currently establishing a global network for servicing<br />

the ship construction and marine industries. Especially at this development stage, it<br />

is extremely important to have information on the current position of this branch of<br />

industry, which is based on reliable analyses and facts.<br />

By Roy Norum (45), President c.e.o. of the PG Marine Group, Norway<br />

(ex. Managing Director of COLFAX Pump Group – Division Marine International)<br />

Requirements & trends<br />

By luck – or rather: by pure business<br />

professionalism - the global<br />

marine environment is a most<br />

clearly defined, and very well<br />

documented field of business,<br />

and reports, analysis, trend research<br />

and financial focus are<br />

easily available to those who seek.<br />

never realized this fact, as their<br />

focus have been more on their<br />

own skills and abilities, than the<br />

facts and demands of the business<br />

environment.<br />

This is the challenge to companies<br />

like <strong>KRAL</strong>, as their high level<br />

of flexibility, wide range of products,<br />

and high base quality enables<br />

them to act – instead of<br />

react – when trends changes the<br />

path to success.<br />

PG Marine Group works closely<br />

with principals such as <strong>KRAL</strong>, to<br />

ensure the integration of information<br />

available from the various<br />

business-chain-elements. This is<br />

why PG focus strongly – and<br />

invests – in participation in all the<br />

various sections of the business.<br />

The mere QDC (quality, delivery,<br />

cost) focus is not enough to<br />

sustain success – the understanding<br />

and ability to adopt to changes<br />

and act for improvements is<br />

more significant to the decisionmakers,<br />

and goes far deeper<br />

than the initial cost-oriented interest<br />

of the buying shipyards.<br />

PG spends resources on making<br />

sure that principals like <strong>KRAL</strong> are<br />

integrated in the OEM (original<br />

equipment manufacturers) chain,<br />

are known in detail by the ship<br />

designers and naval architects,<br />

not least the ship operators and<br />

owners – and cater closely to the<br />

What is not so easily available,<br />

but need significant ”leg-work”<br />

to find, is the underlying trends<br />

and developments which separates<br />

the successful bidders from<br />

the crowd. Such information and<br />

knowledge can only be gained by<br />

close and long-lasting relationships<br />

to the various parts of the<br />

business-chain that forms the<br />

marine community. Many actors<br />

in this fascinating field have<br />

8

PARTNERS<br />

compact, easiest convertible and<br />

lowest cost related to the performance<br />

of the product.<br />

The pump market was dominated<br />

up to the end of the 60’s by<br />

stuffing box sealing systems,<br />

whereas from the 70’s mechanical<br />

seals have taken the market.<br />

Forecasts are that the same will<br />

happen with mag-drives, but the<br />

main obstacle so far has been<br />

the cost-impacts to the initial<br />

buyer – to the detriment of the<br />

ship operators. <strong>KRAL</strong> has significantly<br />

lowered this threshold –<br />

and made these products far<br />

more available.<br />

3) <strong>KRAL</strong> twin-units are another<br />

example of excellent engineering.<br />

Trends at many shipyards -<br />

as well as OEM’s – are clearly to<br />

the advantage of such compact<br />

solutions. Leading Korean<br />

Shipyards e.g. have chosen this<br />

solution to both have more compact<br />

installations, but also save<br />

significantly on installation costs<br />

and utilities.<br />

regional and local service hubs to<br />

keep the expected level of uptime<br />

for the installed equipment.<br />

Similar knowledge at the building<br />

yards is likewise important, but<br />

not enough to secure qualified<br />

positioning, and long term success.<br />

Various trends directly relevant to<br />

the products of <strong>KRAL</strong> in the<br />

recent past, have been picked up<br />

in a most professional way;<br />

1) The market offers lower grades<br />

of fuels – with significant<br />

cost-savings to the operators, but<br />

less fortunate effects for the<br />

lubricity of the pumps.<br />

Application of longer screw-sets,<br />

insert casings with lower friction<br />

and seals adopted to these particulars<br />

secures safe operation of<br />

the heart-components of the<br />

ships’ fuels systems<br />

2) The market asks for hermetically<br />

sealed, leakage-free magnetic<br />

driven pumps. Both in terms<br />

of safety, and in terms of comfort<br />

& service-need, this has emerged<br />

over the last few years as a<br />

desired solution. Traditionally this<br />

has been solved by amending<br />

industrial products – result; overengineered<br />

products which hold<br />

a cost-level far beyond the<br />

request of the market. <strong>KRAL</strong> has<br />

addressed this topic in a purpose-oriented<br />

manner, which lead<br />

to a product that is both the most<br />

<strong>KRAL</strong> participates in the PG<br />

Marine Group as one of the coreprincipals,<br />

where we enable<br />

clients in all parts of the business-chain<br />

to recognize, find and<br />

work with one source for all main<br />

components in our field of business.<br />

This again is a result of<br />

adoption to trends in the market,<br />

as larger packages are more and<br />

more often requested to limit the<br />

number of vendors, reduce logistic<br />

& documentation hassles,<br />

and work on higher procurementvolumes<br />

with each core-supplier.<br />

This global partnership has positioned<br />

both parties in a higher<br />

rank of international players,<br />

enabling us to widen our geographical<br />

orientation significantly.<br />

This not least in terms of aftersales-services.<br />

What makes <strong>KRAL</strong> superior to<br />

other competition for marine operations<br />

can be covered by few<br />

statements – this time from one<br />

that has faced <strong>KRAL</strong> as core competition<br />

formerly seeking counterarguments<br />

against these facts;<br />

9

PARTNERS<br />

C) High Performance / Cost –<br />

factors due to a.m. facts<br />

D) A most complete – and growing<br />

– range of highest quality<br />

products<br />

E) 50 years of history in building<br />

such equipment, with a vast<br />

base of experiences from<br />

various industries & applications<br />

that surpass most competition<br />

<strong>KRAL</strong> Double stations<br />

A) Flexibility, and will to lead<br />

trend-variations at an early stage<br />

of the process<br />

B) Purpose-designed products –<br />

not adopted industrial units –<br />

which address the specific<br />

application<br />

Marine Group and <strong>KRAL</strong> will continue<br />

their growth in all global<br />

markets, relating strongly to facts<br />

mentioned above, and ability &<br />

will to adopt to changes in the<br />

business environment of marine<br />

& offshore industry<br />

Roy Norum<br />

Matter-Hydraulik congratulates<br />

The 50-year <strong>KRAL</strong> anniversary is<br />

reason for me to put down a<br />

few lines on special successes<br />

and experiences, etc.<br />

Well, the first thing I can think of<br />

is the very pleasant and friendly<br />

co-operation with the <strong>KRAL</strong><br />

staff. It has (almost) always<br />

been fun working together with<br />

you and I hope that we can<br />

maintain this status also over<br />

the next 20 years.<br />

We, from the Matter company,<br />

have been working together<br />

with Kräutler for 20 years, and,<br />

according to Erich Kräutler and<br />

Fritz Huber, <strong>KRAL</strong> is also mostly<br />

satisfied with us, apart from the<br />

short delivery dates the Swiss<br />

set for their neighbors…<br />

As junior head of Matter I have<br />

known <strong>KRAL</strong> for some time. I can<br />

still remember very well the old<br />

company premises where everything<br />

was still a little bit “smaller”.<br />

And then the construction of the<br />

new plant took place, and one<br />

has to congratulate <strong>KRAL</strong> on<br />

that. Perhaps the building will<br />

soon be too small again if we (all<br />

together) were to meet Fritz’s<br />

turnover expectations.<br />

With regard to the <strong>KRAL</strong> motto<br />

“fit, not fat”, the following story<br />

comes to mind:<br />

The erection of an exhibition<br />

stand was planned in Zurich<br />

(hydraulics exhibition). On the<br />

last day of installation (Monday),<br />

I received a call from the exhibition<br />

management around 9 ‘o<br />

clock asking if we had forgotten<br />

the exhibition! At 11 am we arrived<br />

at the exhibition. We then<br />

got stuck in with Gregor Toncev.<br />

At 5 pm everything was finished!<br />

Top performance I would say: 6<br />

hours for an exhibition stand.<br />

Special successes of note are<br />

customers such as Sulzer, ABB,<br />

Bobst, etc.<br />

However there are also special<br />

types of orders:<br />

Our simplex filling system with<br />

an OMK 20 still operates perfectly<br />

after 8 years. It is not possible<br />

to do it simpler. And the<br />

accuracy of the containers to be<br />

filled (5 liters + 10 liters) is accurate<br />

to the gram!<br />

We would very cordially like to<br />

congratulate on the “round”<br />

birthday and wish all the best<br />

and much success for the future.<br />

Christoph Matter and the Matter<br />

hydraulics team!<br />

Switzerland representation<br />

10

PARTNERS<br />

SAACKE firing systems<br />

Environmentally aware thermal technology<br />

SAACKE solves “burning“ issues worldwide –<br />

using <strong>KRAL</strong> pumps.<br />

SAACKE burners have been<br />

used on ships of all flags for<br />

more than half a century.<br />

SAACKE has designed a burner<br />

generation that can reliably do its<br />

duty even under most difficult<br />

conditions, stormy weather and<br />

high seas. Engineers and technicians,<br />

who practically moved<br />

their activities away from the<br />

ship to land, introduced SAACKE<br />

burners, examples of quality and<br />

reliability, to additional fields of<br />

application, which were new to<br />

SAACKE at that time.<br />

Today our systems are at home<br />

in all areas of industry, of commerce<br />

and shipping where energy<br />

is required on a large scale<br />

for production processes, for<br />

building district heating systems<br />

or for power generation in<br />

power stations. SAACKE firing<br />

systems are an excellent solution<br />

in the area of residual energy<br />

utilization, for instance of turbine<br />

exhaust gases, in the reheating<br />

of flue gases in power<br />

stations for the reduction of NOx<br />

pollution as well as the thermal<br />

re-combustion, for instance of<br />

waste air emission and in<br />

systems for thermal recycling of<br />

residue. The requirements on<br />

the combustion technology for<br />

industrial heat generation keep<br />

growing while economic and<br />

especially ecological requirements<br />

dominate the development<br />

concepts for future industrial<br />

burner systems.<br />

In order to solve these “burning”<br />

issues in energy and environmental<br />

technology, SAACKE<br />

maintains companies and service<br />

offices throughout the world.<br />

More than 1200 SAACKE<br />

employees are engaged worldwide<br />

to achieve that objective.<br />

SAACKE develops, plans and<br />

manufacturers customized combustion<br />

systems for all areas of<br />

industry, commerce and shipping.<br />

From the arctic to the tropics,<br />

SAACKE engineering is a<br />

household word in the world of<br />

heat generation and constitutes<br />

the current state of the art.<br />

Because SAACKE products are<br />

distributed worldwide, they<br />

obviously have to meet highest<br />

quality requirements and applicable<br />

regional standards.<br />

In order to ensure highest quality<br />

for our customers, we are<br />

dependent on reliable but also<br />

innovative suppliers who take<br />

up the challenge of constantly<br />

changing markets. Our business<br />

relationship with <strong>KRAL</strong> started<br />

more than 25 years ago with the<br />

introduction of pumps in the proven<br />

compact design. Since that<br />

time, continuously sound advice<br />

and support with problem solutions,<br />

the consideration of a<br />

wide range of individual needs<br />

with the resulting success for<br />

us, has made <strong>KRAL</strong> an indispensable<br />

partner to us.<br />

SAACKE uses <strong>KRAL</strong> pumps for<br />

the supply of oil burners with<br />

light and heavy oil in marine and<br />

land-based systems for energy<br />

generation, waste incineration<br />

and for many other applications.<br />

In <strong>KRAL</strong> we have found a flexible<br />

partner for screw pumps and<br />

underscored this partnership<br />

with an agreement, which bundles<br />

our pump requirements and<br />

ensures that all SAACKE companies<br />

worldwide purchase <strong>KRAL</strong><br />

products at the same conditions<br />

and are able to make use of the<br />

proven <strong>KRAL</strong> service.<br />

We wish <strong>KRAL</strong> all the best on<br />

their 50-year anniversary and<br />

look forward to continued fruitful<br />

co-operation.<br />

SAACKE – the symbol of reliability.<br />

Stefan Cordes<br />

Purchase Manager<br />

11

TECH NEWS<br />

<strong>KRAL</strong> Screw Pump<br />

with Magnetic Coupling<br />

The economy of firing systems and drive units is further improved<br />

by the use of <strong>KRAL</strong> screw pumps with magnetic couplings.<br />

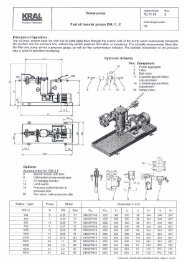

Cross section view of a block aggregate with magnetic coupling<br />

<strong>KRAL</strong> screw pumps serve<br />

all rotary positive displacement<br />

cally sealed stainless steel can<br />

mainly for the pumping of oils<br />

pumps. Most shaft seals such<br />

seals the pump from the<br />

for firing systems in power sta-<br />

as lip seals, mechanical seals and<br />

atmosphere. High-performance<br />

tions for electrical generation<br />

packings create friction in the<br />

permanent magnets transfer<br />

and on ships for propulsion.<br />

highly sensitive sealing clearan-<br />

motor torque to the pump shaft.<br />

Because of the economic rele-<br />

ce. They require fluid for dischar-<br />

The magnetic coupling operates<br />

vance, operators place high<br />

ging the frictional heat. The gas<br />

without friction. The most deci-<br />

demands on the operational<br />

evolution or even evaporation of<br />

sive point is that the magnetic<br />

safety and reliability of such<br />

systems. Unintenionally long<br />

this fluid leads to dangerous dry<br />

run, which may cause the failure<br />

coupling is as reliable and durable<br />

as the pump itself. And the<br />

Booster-module with<br />

<strong>KRAL</strong> screw pumps<br />

delays in docks or purchase<br />

of the seal. These seals show a<br />

magnetic coupling operates<br />

of electricity due to failure of<br />

certain leakage.<br />

without leakage, so that the<br />

the power station are very<br />

Instead of the seal, a hermeti-<br />

environment remains clean.<br />

The selection of magnetic coup-<br />

expensive. Leaking seals require<br />

lings requires some expert<br />

expensive cleaning not to<br />

knowledge and <strong>KRAL</strong> has there-<br />

mention the hazard for man and<br />

fore developed a special soft-<br />

equipment.<br />

ware program for magnetic couplings.<br />

<strong>KRAL</strong> offers standard<br />

In order to seal the pump part<br />

screw pumps as a block unit<br />

from the atmosphere, screw<br />

with magnetic coupling and<br />

pump require shaft sealing like<br />

electric motor for capacities up<br />

to 550 l/min and maximum pressure<br />

of 16 bar.<br />

Georg Napp-Zinn<br />

Magnetic coupling as sealing element,<br />

inner and outer rotor for the transmission<br />

of the torque from the motorto<br />

the pump shaft<br />

Product Manager Screw Pumps<br />

12

TECH NEWS<br />

<strong>KRAL</strong> Volumeter ®<br />

Precision flowmeters for rough operating conditions<br />

With the <strong>KRAL</strong> Volumeter ® , <strong>KRAL</strong> concentrates on flowmeters that operate according to the<br />

“classic” operating principle of positive-displacement meters. In today’s rather “trendy”<br />

environment of electronic measuring instruments, <strong>KRAL</strong> consistently innovates the Volumeter<br />

and offers the market measuring instruments with laboratory measuring precision. Due to the<br />

sturdy design, they also provide reliable measuring results in rough industrial environments.<br />

This report describes the unique technical measuring advantages of the Volumeter. In the<br />

following issues of <strong>Inside</strong> an application report and an overview of other flow measuring<br />

methods will follow.<br />

The first Volumeter<br />

What is so special about the<br />

<strong>KRAL</strong> Volumeter ® ?<br />

Product presentations immediately<br />

raise the question among<br />

readers as to the benefit in the<br />

intended application. For a<br />

quick orientation we provide<br />

this advance information:<br />

<strong>KRAL</strong> Volumeters are flowmeters.<br />

They continuously<br />

measure the flow rate of<br />

liquids (0.1 to 7,500 l/min,<br />

optional mass conversion).<br />

<strong>KRAL</strong> Volumeter are part of<br />

the category of positive<br />

displacement meters and<br />

work according to the screw<br />

spindle principle.<br />

A major characteristic is the<br />

high measuring accuracy<br />

(± 0.1 % of the measured<br />

value) over a wide measuring<br />

range (1:100).<br />

Another particular feature is<br />

that the measuring accuracy<br />

typical for laboratories is also<br />

achieved in rough industrial<br />

conditions (for instance with<br />

high system pressures or<br />

pressure vibrations in the fluid<br />

flow), characteristics that<br />

exclude one another in other<br />

flowmeters.<br />

<strong>KRAL</strong> Volumeter ® - the<br />

original has a history<br />

The <strong>KRAL</strong> Volumeter has an<br />

independent production group<br />

of Kräutler GmbH & Co.<br />

Approximately 20 years ago we<br />

developed the Volumeter for an<br />

internal requirement. We needed<br />

an accurate flowmeter for<br />

our pump test stand. We did not<br />

find a suitable instrument on the<br />

market that met our requirements<br />

for measuring accuracy<br />

over a wide measuring range<br />

under the rough operating conditions<br />

of a pump test stand.<br />

Since <strong>KRAL</strong> had more than 30<br />

years of experience in the manufacture<br />

of screw pumps, we had<br />

the idea of reversing the operating<br />

principle of the pumps. On a<br />

pump we determined the flow<br />

that rotated the screws by<br />

means of a pulse generator fitted<br />

to the drive shaft. We consequently<br />

developed the<br />

Volumeter further and were able<br />

to bypass the limitations of<br />

other flow metering systems. In<br />

the meantime we have developed<br />

an instrument program that<br />

has proved itself under many<br />

industrial requirements.<br />

The series clearly show the<br />

customer benefit<br />

<strong>KRAL</strong> Volumeters are classified<br />

in series. The classification<br />

refers to the material of the<br />

flowmeter or its field of application.<br />

This explains the benefit.<br />

All series designations start with<br />

OM standing for oil meter. This<br />

reflects our <strong>KRAL</strong> history. <strong>KRAL</strong><br />

Volumeters of series OMG are<br />

manufactured of grey cast iron.<br />

The universal possibilities are<br />

apparent through the wide flow<br />

range of 0.1 to 7,500 l/min, permissible<br />

system pressure of 250<br />

bar and the temperature range<br />

from –40 to +260 °C.<br />

OME is the economy version.<br />

This series answers the request<br />

for an economical flowmeter.<br />

With a flow range of 0.1 to 150<br />

l/min, a permissible pressure up<br />

to 40 bar and a temperature<br />

range from –20 to +100 °C, we<br />

have concentrated on the most<br />

frequently required operating<br />

parameters and equipped the<br />

instrument only with what is<br />

really needed. OME has an alu-<br />

13

TECH NEWS<br />

<strong>KRAL</strong> Volumeter ® - Flowmeter Overview<br />

Series OMG OMH OMK OMS OME OMX<br />

Classification Universal High pressure Chemically Stainless Economy Custom design<br />

resistant<br />

Flow range<br />

(l/min) 0,1 - 7.500 0,1 - 3.000 0,2 - 150 3,5 - 1.050 0,1 - 150 0,1 - 7.500<br />

Max. pressure<br />

(bar) 250 420 40 40 40 630<br />

Temperature range<br />

(°C) -20 - 200 -20 - 200 -20 - 100 -20 - 100 -20 - 100 -40 - 200<br />

14

TECH NEWS<br />

minum casing. The measuring<br />

signal is directly taken from the<br />

screws. The instrument design<br />

is production-optimized. The<br />

high measuring accuracy is retained<br />

despite all the concentration<br />

on the “most popular” operating<br />

parameters.<br />

OMH is the flowmeter for the<br />

high-pressure area. As standard<br />

it is designed for a system pressure<br />

of up to 420 bar. For special<br />

applications on oil platforms<br />

we have already produced<br />

designs up to 1,035 bar. The<br />

special task of a high-precision<br />

flowmeter for high-pressure<br />

applications is that the measuring<br />

chamber must not change<br />

under pressure to the extent<br />

that the measuring accuracy<br />

would drop. The <strong>KRAL</strong><br />

Volumeter is an in-line meter,<br />

the liquid flows through the<br />

instrument without being<br />

deflected. This permits a small<br />

casing shape. Among the highpressure<br />

meters on the market,<br />

the OMH is definitely among the<br />

most compact.<br />

Accuracy [% of rate]<br />

Viscosity [mm 2 /s]<br />

+1,0<br />

+0,3<br />

+0,1<br />

-0,1<br />

-0,3<br />

-1,0<br />

100000<br />

10000<br />

1000<br />

200<br />

100<br />

20<br />

10<br />

5<br />

2<br />

1<br />

Linearity<br />

1 10 50 100 150<br />

Measuring Range<br />

1<br />

± 0,3 %<br />

± 1,0 %<br />

2<br />

continuous operation<br />

accuracy ± 0,1%<br />

Flowrate [% of Q nom ]<br />

short-term operation<br />

± 0,1 %<br />

± 0,3 %<br />

1 10 50 100 150<br />

200 mm 2 /s<br />

20 mm 2 /s<br />

2 mm 2 /s<br />

sure vibrations), which are frequently<br />

not even known, but<br />

result in velocity changes in the<br />

liquid. If the measuring accuracy<br />

drops excessively outside the<br />

specified flow rate, the entire<br />

measuring result is often inexplicably<br />

incorrect. The <strong>KRAL</strong><br />

Volumeter shows the actual<br />

flow rate even under such conditions.<br />

<strong>KRAL</strong> Volumeter ®<br />

Specialty 3 – high measuring<br />

accuracy under rough operating<br />

conditions<br />

<strong>KRAL</strong> Volumeters are extremely<br />

sturdy. They are in-line flowmeters,<br />

which is why there is no<br />

exertion of force through directional<br />

changes of the liquid. In<br />

general, the <strong>KRAL</strong> Volumeter is<br />

insensitive to system vibrations<br />

and pressure pulsations. The following<br />

diagram shows pressure<br />

pulsations of a hydraulic fluid of<br />

±50 bar superimposed on a static<br />

operating pressure of approximately<br />

160 bar.<br />

OMK is equipped with plastic<br />

screws made of PTFE and has a<br />

casing of stainless steel. It is the<br />

Volumeter that is chemically<br />

resistant in a large number of<br />

liquids and is employed especially<br />

in aggressive and non-lubricating<br />

liquids.<br />

OMS (stainless steel) is entirely<br />

made of stainless steel (1.4301<br />

or 1.4401).<br />

For individual customer wishes<br />

we offer special designs and<br />

special materials. These meters<br />

are then designated OMX.<br />

<strong>KRAL</strong> Volumeter ®<br />

Specialty 1 – highly accurate<br />

flow measurement<br />

The market for sensors to register<br />

process parameters is<br />

huge. After temperature and<br />

pressure measurement, the<br />

demand for flow metering sensors<br />

ranks in third position. Flow<br />

sensors range from simple flow<br />

monitors up to high-precision<br />

flowmeters. <strong>KRAL</strong> concentrates<br />

on the highly accurate flow measurement<br />

in industrial applications.<br />

Examples are flow measuring<br />

tasks in development and<br />

production test stands as well<br />

as the consumption measurement<br />

in industrial diesel<br />

engines.<br />

The Linearity diagram above<br />

shows the measuring accuracy<br />

of the <strong>KRAL</strong> Volumeter OMG<br />

series. The linearity curve over a<br />

wide range is situated in the<br />

band around ± 0.1 % of the<br />

measured value (yellow). This is<br />

considerably below the limits of<br />

± 0.3 % (orange area) applied by<br />

calibration services.<br />

Flowrate [% of Q nom ]<br />

<strong>KRAL</strong> Volumeter ®<br />

Specialty 2 – wide measuring<br />

range<br />

Many flowmeters achieve the<br />

promised measuring accuracy<br />

for a very small viscosity and<br />

flow range. With the <strong>KRAL</strong><br />

Volumeter, the high measuring<br />

accuracy of ± 0.1 % is maintained<br />

over a wide range of viscosity<br />

and flow. This is impressively<br />

demonstrated by the “Measuring<br />

Range” diagram.<br />

This characteristic is important<br />

for many industrial applications.<br />

Although systems are frequently<br />

designed for maximum values<br />

of the operating parameters,<br />

these vary in real operation. The<br />

maximum permissible flow is<br />

not permanent. In addition there<br />

are often liquid pulsations (pres-<br />

p<br />

[bar]<br />

200<br />

100<br />

10 20<br />

Boring<br />

30<br />

Tunnel-boring Hydraulics<br />

Return stroke<br />

t [ms]<br />

Prospects<br />

In the next edition we will describe<br />

applications where <strong>KRAL</strong><br />

Volumeter are employed because<br />

of their special characteristics.<br />

In the issue following that we<br />

will show the <strong>KRAL</strong> Volumeter<br />

in the environment of other flow<br />

measuring methods.<br />

Thomas Flauger<br />

Product Manager Volumeter<br />

15

ANNIVERSARY<br />

<strong>KRAL</strong> Employee<br />

statements<br />

3 x 1 week Ski World Cup<br />

in St. Anton and many other prizes<br />

in the great <strong>KRAL</strong> anniversary raffle<br />

Meeting where the greatest compete.<br />

Participate and you will be part of it with a bit of luck.<br />

Learning where there is work<br />

Daniel Kullich, third year apprentice<br />

mechanic at <strong>KRAL</strong>: “50<br />

years means that the company<br />

is steadfast. I wanted to<br />

learn my trade in a company<br />

where I will also be able to<br />

work later on. As <strong>KRAL</strong> apprentice,<br />

focus is on exact and<br />

independent working. Always<br />

knowing that help is there<br />

when required. The varied<br />

activities, the training program<br />

and the modern infrastructure<br />

form the basis of a<br />

successful apprenticeship.”<br />

It pays to be quick.<br />

The first 50 entries each will<br />

receive a quality pocket knife.<br />

Therefore: Don’t even think.<br />

Reply quickly. And be off with the<br />

winning card to the post office.<br />

Do it today!<br />

Development fascinates<br />

Herbert Hopp, with <strong>KRAL</strong> for<br />

20 years, works in the screw<br />

milling shop. To him quality<br />

and responsibility are the driving<br />

forces in his work: “It is<br />

fascinating what is possible in<br />

terms of development. I have<br />

experienced that one faces<br />

new challenges time and<br />

again to achieve new performance<br />

data. The more difficult<br />

it becomes, the more<br />

involved I am. Up to now we<br />

have actually achieved everything<br />

– this fills me with pride.<br />

This forward thinking also provides<br />

security for the future.”<br />

3 x 1 week to the Ski<br />

World Cup in St. Anton<br />

From the 3rd to the 10th of<br />

February 2001. For 2 people<br />

including room with half board<br />

and two tickets to the World Cup.<br />

3 x glass design by<br />

Reingard Kräutler<br />

Unique designer pieces of highest<br />

elegance. More about this in<br />

the next INSIDE.<br />

44 x filled backpacks.<br />

If you know <strong>KRAL</strong>, there is a<br />

chance of victory.<br />

If you wish to participate, please<br />

answer the questions on the<br />

enclosed winning postcard. If<br />

you have carefully read the<br />

anniversary brochure <strong>KRAL</strong><br />

INSIDE, the answers to our<br />

winning questions will come<br />

very easily to you. We wish you<br />

success and lots of luck!<br />

Publication for business partners and employees of <strong>KRAL</strong>. Editor: Engineer Fritz Huber, Design: Ender Werbung<br />

Kräutler GmbH & Co., Bildgasse 40, A-6893 Lustenau, Austria, Phone: +43 / 55 77/86644-0, Fax: +43 / 55 77 / 8 84 33, E-mail: kral@kral.at<br />

16