Perfection down to the finest detail: a feel-good bathroom.

Perfection down to the finest detail: a feel-good bathroom.

Perfection down to the finest detail: a feel-good bathroom.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Division Heating Technology<br />

and Sanitary Equipment<br />

Division Kitchens and Refrigeration<br />

Division Steel Technology<br />

Division Windows and Doors<br />

Logistics<br />

AFG Arbonia-Forster-Holding AG<br />

Romanshornerstrasse 4<br />

P.O. Box 134<br />

CH-9320 Arbon<br />

Phone +41 71 447 41 41<br />

Fax +41 71 447 45 88<br />

afgworld@afg.ch<br />

www.afg.ch<br />

H e a t i n g Te c h n o l o g y<br />

H e a t i n g Te c h n o l o g y a n d<br />

S a n i t a r y E q u i p m e n t<br />

H e a t i n g Te c h n o l o g y<br />

H e a t i n g Te c h n o l o g y<br />

K i t c h e n s<br />

a n d R e f r i g e r a t i o n<br />

K i t c h e n s<br />

S t e e l T e c h n o l o g y<br />

W i n d o w s a n d D o o r s<br />

L o g i s t i c s<br />

L o g i s t i c s<br />

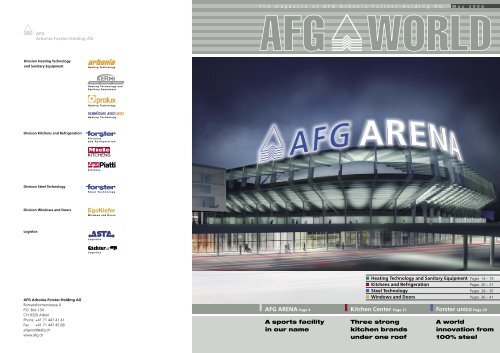

T h e m a g a z i n e o f A F G A r b o n i a - F o r s t e r - H o l d i n g A G M a y 2 0 0 6<br />

AFG ARENA Page 4<br />

A sports facility<br />

in our name<br />

■ Heating Technology and Sanitary Equipment Pages 14 – 19<br />

■ Kitchens and Refrigeration Pages 20 – 27<br />

■ Steel Technology Pages 28 – 35<br />

■ Windows and Doors Pages 36 – 41<br />

Kitchen Center Page 21<br />

Three strong<br />

kitchen brands<br />

under one roof<br />

Forster unico Page 29<br />

A world<br />

innovation from<br />

100% steel

Contents<br />

■ In a nutshell<br />

News ................................................................................ 2<br />

■ Focus<br />

Welcome <strong>to</strong> <strong>the</strong> AFG ARENA ............................................. 4<br />

■ AFG Arbonia-Forster-Holding AG<br />

Construction of <strong>the</strong> new Corporate Center ....................... 10<br />

A new dimension for AFG ................................................. 11<br />

19th General Meeting: rockets ignited! ............................. 12<br />

■ Heating Technology and Sanitary Equipment<br />

Outstanding design expertise ............................................ 15<br />

Selective presence at <strong>the</strong> pulse of <strong>the</strong> markets ................... 16<br />

Kermi: number 1 by far ..................................................... 18<br />

New Marketing Manager, Switzerland for Arbonia and Prolux 19<br />

■ Kitchens and Refrigeration<br />

Three strong kitchen brands under one roof ...................... 21<br />

Forster and Piatti launch <strong>the</strong>ir KITCHEN&YOU courses ....... 22<br />

Awarded presence ............................................................ 24<br />

Book tip: exquisite kitchens ............................................... 24<br />

The Capovino built-in wine cooler ....................................... 25<br />

Miele Kitchens: putting variety on <strong>the</strong> agenda ................... 26<br />

■ Steel Technology<br />

Forster unico – a world innovation .................................... 29<br />

The final cut ...................................................................... 30<br />

New brochure for precision steel tubes .............................. 30<br />

Safety exhibition «Fiera Sicurezza», Milan ......................... 31<br />

Forster <strong>the</strong>rmfix light: <strong>the</strong> new freedom in facade construction 31<br />

The Hallenstadion Zurich in a new light ............................. 32<br />

By hook or by crook: precision steel tubes ......................... 32<br />

Forster fuego light: 90 minutes fire resistance .................... 33<br />

Extending <strong>the</strong> value creation chain .................................... 34<br />

Pure appeal ....................................................................... 35<br />

New: U-Value Calcula<strong>to</strong>r ................................................... 35<br />

■ Windows and Doors<br />

EgoKiefer launches a new world of windows: XL ® ............. 37<br />

EgoKiefer’s new regional headquarters in Wallisellen ......... 38<br />

Monument protection <strong>to</strong> order ......................................... 38<br />

EgoKiefer goes big in St.Gallen ......................................... 39<br />

Minergie ® as a label of quality ........................................... 40<br />

Extension for <strong>the</strong> production facility at Altstätten East ....... 41<br />

Impressum<br />

AFG WORLD, <strong>the</strong> magazine of AFG Arbonia-Forster-<br />

Holding AG, appears three times a year in four<br />

languages in Switzerland, Germany and <strong>the</strong> Czech<br />

Republic, as well as in o<strong>the</strong>r countries around <strong>the</strong> world.<br />

Circulation 17,000 Ex.<br />

Edi<strong>to</strong>rial<br />

AFG Arbonia-Forster-Holding AG<br />

Redaktion AFG WORLD<br />

P.O. Box 134<br />

CH-9320 Arbon<br />

Phone +41 71 447 41 41<br />

Fax +41 71 447 45 88<br />

afgworld@afg.ch<br />

Production<br />

Concept/Layout/Text edi<strong>to</strong>rial:<br />

Erat, Thoma & Herzog Werbeagentur AG BSW,<br />

CH-9401 Rorschach<br />

Printers: Druckerei Flawil AG, 9230 Flawil<br />

Title picture: Visualisation architron<br />

A new image for AFG<br />

Dear Ladies, Gentlemen,<br />

Dear employees<br />

For many years now, AFG Arbonia-Forster-Holding AG (AFG)<br />

has been publishing an employee magazine called VIVA.<br />

This has been an information channel through which it has<br />

advised its personnel of <strong>the</strong> company’s news and latest events.<br />

Since I joined in September 2003, some things at AFG have<br />

changed. Not only have sales almost doubled <strong>to</strong> well exceed<br />

CHF 1 billion, <strong>the</strong> acquisition of several prominent companies<br />

have made us bigger, stronger and more international. Many<br />

of our cus<strong>to</strong>mers know us simply from <strong>the</strong>ir own sec<strong>to</strong>r.<br />

We have developed from <strong>the</strong> so-called «mixed product shop»<br />

<strong>to</strong> become a worldwide manufacturer of construction<br />

equipment. The fact that as a leading manufacturer of<br />

construction equipment, we also make and sell many<br />

o<strong>the</strong>r products is overlooked far more frequently than one<br />

would think.<br />

From now on, we want <strong>to</strong> reach not only our personnel, but<br />

open up <strong>the</strong> boundaries and reach our wordwide cus<strong>to</strong>mers<br />

<strong>to</strong>o. The world has become our market – <strong>the</strong> AFG WORLD.<br />

Today, AFG is engaged in some 80 countries and in 50 of<br />

those, has its own organisations or works in partnership with<br />

o<strong>the</strong>rs. Now its time for you <strong>to</strong> know how AFG has<br />

developed. Above all, we want <strong>to</strong> show you our broad<br />

product range and keep you updated with new innovations<br />

as <strong>the</strong>y happen. Innovations, you see, are of paramount<br />

importance <strong>to</strong> us.<br />

And <strong>to</strong> make sure all our AFG WORLD readers don’t get<br />

bored with <strong>detail</strong>s relating <strong>to</strong> each company division, we<br />

publish a series of magazines called AFG INSIDE, as a<br />

supplement for each of our companies. AFG INSIDE will<br />

publish information that is of interest <strong>to</strong> only a limited reader<br />

group and relates <strong>to</strong> individual AFG companies.<br />

We have not only given our new cus<strong>to</strong>mer and employee<br />

magazine a new name, it will also appear in a new guise. We<br />

are changing nei<strong>the</strong>r our company strategy nor our company<br />

philosophy: what we want for our cus<strong>to</strong>mers is <strong>to</strong> make <strong>to</strong>p<br />

quality products on time and at attractive prices. This way<br />

we will demonstrate our marketability, enhance cus<strong>to</strong>mer<br />

proximity and improve our partners’ competitive edge.<br />

This includes – in line with our concept – a timely and<br />

modern market presence. Marketing, advertising and PR<br />

are constant companions of a company’s routine activities –<br />

<strong>the</strong> same goes for AFG. The front page of our fresh new<br />

employee and cus<strong>to</strong>mer magazine, AFG WORLD, shows<br />

<strong>the</strong> AFG ARENA, which will be complete and ready for use<br />

on <strong>the</strong> outskirts of St.Gallen by mid-2008.<br />

P re l u d e<br />

Besides increasing its innovative strength, AFG has also<br />

accelerated its marketing endeavours in recent years.<br />

Authorising use of <strong>the</strong> name AFG ARENA is an investment –<br />

certainly not an expenditure – in our proprietary brands<br />

of AFG, Kermi, Arbonia, Prolux, Schmidlin ASCO Swiss,<br />

Forster Kitchens and Forster Refrigeration, Miele Kitchens<br />

(labeled «Miele Die Küche» in German-speaking countries),<br />

Piatti Kitchens, Forster Profile Systems and Forster Precision<br />

Steel Tubes, EgoKiefer Windows and Doors, as well as in<br />

our two logistics companies Asta and Gächter.<br />

We want <strong>to</strong> advertise our proprietary brand AFG, <strong>the</strong> brands<br />

of our subsidiaries and <strong>the</strong>ir quality products. Sports and AFG<br />

ARENA are key <strong>to</strong> our marketing initiatives in Switzerland and<br />

sit high on <strong>the</strong> agenda. However, we don’t want <strong>to</strong> focus<br />

solely on <strong>the</strong>se measures, but ra<strong>the</strong>r couple a wide-ranging<br />

advertising package with both national and international<br />

impact. Over time, of course, we shall expect this <strong>to</strong> have a<br />

positive impact on our image and <strong>the</strong> sale of AFG products.<br />

We regard AFG WORLD as ano<strong>the</strong>r marketing <strong>to</strong>ol. We want<br />

<strong>the</strong> information we give you on our products and innovations<br />

<strong>to</strong> be more direct, more comprehensive and more current.<br />

We shall also keep you up-<strong>to</strong>-date on AFG’s lesser known<br />

divisions. Our employees, cus<strong>to</strong>mers and suppliers, as well as<br />

selected circles and <strong>the</strong> public make up our most important<br />

target group. Find inspiration in AFG WORLD. We would be<br />

grateful <strong>to</strong> receive any ideas and suggestions you may have<br />

about this publication. On that note, I remain<br />

Yours sincerely<br />

Dr. Edgar Oehler<br />

Chairman of <strong>the</strong> Board of Direc<strong>to</strong>rs and CEO

news<br />

2 I n a n u t s h e l l<br />

100% steel<br />

Forster unico is a completely new profile system with fittings<br />

and accessories for doors, windows and exterior glazing.<br />

The profiles designed as a single-chamber system are heat-<br />

insulated and effortlessly match <strong>the</strong> insulation values<br />

achieved by conventional systems. The basic profile consists<br />

of 100% recyclable steel and contains no plastic insula<strong>to</strong>rs.<br />

This makes Forster unico extremely environmentally-friendly.<br />

This innovation, featuring a unique latticework finish, is<br />

lightweight and simplifies handling in <strong>the</strong> workshop and<br />

during installation. Forster unico <strong>the</strong>refore meets <strong>the</strong> most<br />

stringent technical and physical requirements – and looks<br />

fantastic <strong>to</strong>o. «<br />

Showing its colours<br />

Kermi is presenting a new radia<strong>to</strong>r colour concept<br />

based on current trends in <strong>the</strong> world of living rooms<br />

and <strong>bathroom</strong>s. Edition Soft comprises seven carefully<br />

selected pastel shades – <strong>the</strong>ir soft effect being enhanced by <strong>the</strong><br />

quality matt finish. Edition Nature is inspired by <strong>the</strong> freshness<br />

and expressiveness of water, plants and s<strong>to</strong>ne. The warm<strong>to</strong>ned,<br />

powerful colours in Edition Ethno grasp <strong>the</strong> colours<br />

of exotic cultures, harmonising closely with natural materials.<br />

As an alternative, Edition Metallic reflects on <strong>the</strong> ra<strong>the</strong>r<br />

technical colour world of <strong>the</strong> 1950’s and shows this retro-trend<br />

in four brilliant metallic <strong>to</strong>nes. These four Editions are<br />

available for practically every radia<strong>to</strong>r in <strong>the</strong> Creative radia<strong>to</strong>r<br />

and Kermi Decor ranges, as well as for most flat radia<strong>to</strong>rs,<br />

convec<strong>to</strong>rs and heated walls. «<br />

Multimedia in <strong>the</strong> kitchen<br />

Lovers of sophisticated technology will go for <strong>the</strong> innovative<br />

multimedia kitchen. Internet, TV and radio can be controlled<br />

straight from <strong>the</strong> kitchen. This innovative solution will be<br />

available from Forster and Piatti from <strong>the</strong> middle of <strong>the</strong> year. «<br />

Special offer on air-conditioned cabinet<br />

LongFresh fruit and vegetables: CHF 1860.– instead of CHF 2860.–<br />

Vegetables, fruit and salad are sensitive, natural products. LongFresh provides <strong>the</strong><br />

ideal s<strong>to</strong>rage conditions and keeps <strong>good</strong>s fresh up <strong>to</strong> three <strong>to</strong> five times longer<br />

than a conventional refrigera<strong>to</strong>r.<br />

LongFresh wine cabinet: CHF 1990.– instead of CHF 3490.–<br />

Forster’s LongFresh will create <strong>the</strong> ideal conditions for your bottles of Grand Cru:<br />

■ Constant temperature<br />

■ Optimised humidity<br />

■ Natural air exchange, like in a conventional old cellar<br />

Please call <strong>the</strong> AFG Kitchen Service on +41 71 447 46 46 if you have<br />

any questions or would like <strong>to</strong> place an order.<br />

Arbonia Protect<br />

For <strong>the</strong> first time, Arbonia is offering specifically for sensitive<br />

hygiene applications, a durable anti-microbial radia<strong>to</strong>r coating that<br />

significantly reduces <strong>the</strong> risk of contamination. The function of this<br />

surface coating unique <strong>to</strong> this area is based on silver’s germ-inhibiting<br />

and deadening effect that has been well-established for centuries.<br />

The metal is mixed with <strong>the</strong> coating in <strong>the</strong> form of an additive and offers<br />

scientifically proven, reliable long-term protection against microorganisms<br />

settling and spreading on <strong>the</strong> radia<strong>to</strong>r’s surface. Contact for<br />

people and pets alike, however, is completely harmless. «<br />

Record<br />

noise insulation<br />

Based on EgoKiefer’s MPR2 plastic window, EgoKiefer has<br />

developed a countersash window with unparalleled peak<br />

values when it comes <strong>to</strong> noise insulation: with a proven<br />

labora<strong>to</strong>ry value of 56 decibels, <strong>the</strong> pro<strong>to</strong>type has delivered<br />

a result that is 20 decibels higher than <strong>the</strong> R’ W values of<br />

conventional windows. This latest development fur<strong>the</strong>r<br />

evidences EgoKiefer’s expertise in noise insulation. «

© Visualisierung architron<br />

4 F o c u s<br />

Welcome<br />

<strong>to</strong> <strong>the</strong> AFG ARENA<br />

AFG Arbonia-Forster-Holding AG (AFG) is lending its name <strong>to</strong> St.Gallen’s<br />

new football stadium. From now on, <strong>the</strong> stadium will be called AFG ARENA.<br />

Authorising <strong>the</strong> use of its name is a key component of AFG’s long-term<br />

marketing activities. The decision <strong>to</strong> play godfa<strong>the</strong>r makes AFG a pioneer,<br />

since this is <strong>the</strong> first time that <strong>the</strong> right <strong>to</strong> use a name has been authorised<br />

on a scale of such magnitude and importance.<br />

AFG has decided <strong>to</strong> acquire exclusive and comprehensive<br />

marketing rights with regard <strong>to</strong> <strong>the</strong> name and logo of <strong>the</strong><br />

new stadium in St.Gallen, proclaiming for <strong>the</strong> first time AFG’s<br />

strong presence in <strong>the</strong> worlds of both sport and culture. The<br />

naming rights for <strong>the</strong> AFG ARENA will guarantee AFG even<br />

greater media impact. It is however also a declaration of<br />

allegiance <strong>to</strong> eastern Switzerland as an economic workplace<br />

and location, <strong>the</strong> future significance of which cannot be<br />

overstated. «This is a major step forward as we consistently<br />

continue <strong>to</strong> build up <strong>the</strong> AFG brand, <strong>to</strong> spread its fame – as<br />

well as that of its subsidiary companies – far and wide, <strong>to</strong><br />

increase its value and <strong>to</strong> emphasise above all our close ties<br />

with <strong>the</strong> entire region of eastern Switzerland», said Dr. Edgar<br />

Oehler, Chairman and CEO at AFG. In addition, <strong>the</strong> naming<br />

rights take in<strong>to</strong> account <strong>the</strong> long-term concept of sponsorship,<br />

enabling <strong>the</strong> company <strong>to</strong> develop its competitive edge<br />

optimally over a long period and over a broad field. «AFG’s<br />

timing in taking this step is ideal, for with <strong>the</strong> construction of<br />

<strong>the</strong> stadium, <strong>the</strong> new name AFG ARENA will impact all our<br />

target groups.»<br />

Official opening in summer 2008<br />

Since November 2005, excavation activities at<br />

<strong>the</strong> AFG ARENA site have been at full speed<br />

ahead; by July of this year, some 500,000 cubic<br />

meters of earth will have been removed. At <strong>the</strong><br />

same time, <strong>the</strong> foundation channels are also<br />

being sealed. Wherever this work is complete,<br />

<strong>the</strong> concrete is poured in and <strong>the</strong> first walls<br />

emerge. A host of canalisation and installation<br />

activities are also underway.<br />

Since spring last year, extensive construction<br />

work has been in progress on <strong>the</strong> St.Gallen-<br />

Winkeln mo<strong>to</strong>rway junction and <strong>the</strong> extension<br />

of <strong>the</strong> A1. The AFG ARENA is <strong>to</strong> have its own<br />

approach and exit roads and is <strong>the</strong> lynchpin of<br />

a far-reaching traffic concept.<br />

Football will kick-off in <strong>the</strong> AFG ARENA by as<br />

early as summer 2008. Ikea wants <strong>to</strong> open<br />

its doors in Oc<strong>to</strong>ber 2007, Jelmoli AG and its<br />

tenants will follow suit in March 2008.

Pictures: Nicolas Senn<br />

F o c u s<br />

30th December 2005<br />

12th January 2006<br />

1st February 2006<br />

7th March 2006<br />

14th March 2006<br />

Construction work on east Switzerland’s largest sports facility,<br />

<strong>the</strong> AFG ARENA, began at <strong>the</strong> end of 2005. Drive on <strong>the</strong> A1<br />

past <strong>the</strong> St.Gallen-Winkeln exit and you’ll be sure <strong>to</strong> see <strong>the</strong><br />

huge building site flanked by two striking 20 meter high<br />

AFG ARENA <strong>to</strong>wers, bearing all AFG brands and logos. The<br />

stadium will be officially opened in summer 2008. By <strong>the</strong>n,<br />

public awareness of <strong>the</strong> AFG ARENA’s name will have<br />

gradually established itself, as <strong>the</strong> brand grows <strong>to</strong> become a<br />

household name. «The sooner <strong>the</strong> name is published and <strong>the</strong><br />

sooner <strong>the</strong> AFG brand is integrated in<strong>to</strong> <strong>the</strong> name, <strong>the</strong> more<br />

consistently <strong>the</strong> name of <strong>the</strong> new stadium name can be<br />

communicated and firmly anchored in <strong>the</strong> consciousness of<br />

<strong>the</strong> people», declared Dr. Edgar Oehler, referring <strong>to</strong> <strong>the</strong><br />

company’s collaboration from <strong>the</strong> earliest stages with <strong>the</strong><br />

operating company, Betriebs AG AFG ARENA.<br />

The best of all solutions<br />

The agreement covers <strong>the</strong> construction phase up <strong>to</strong> 2008<br />

and <strong>the</strong>n <strong>the</strong> first ten football seasons until mid-2008, with an<br />

option of prolonging <strong>the</strong> agreement fur<strong>the</strong>r. Dieter Froehlich,<br />

Chairman of <strong>the</strong> Board of Direc<strong>to</strong>rs at FC St.Gallen and Vice<br />

President of Betriebs AG AFG ARENA stresses <strong>the</strong> importance<br />

«The AFG ARENA is an important<br />

step in emphasising our allegiance<br />

<strong>to</strong> <strong>the</strong> region.»<br />

of <strong>the</strong> partnership with AFG. This is why <strong>the</strong> new home<br />

ground for St.Gallen’s football club will logically bear <strong>the</strong><br />

name AFG ARENA.<br />

A common denomina<strong>to</strong>r<br />

AFG, one of Europe’s leading manufacturer’s of construction<br />

equipment, brings <strong>to</strong>ge<strong>the</strong>r a number of major product<br />

brands such as Arbonia, Schmidlin ASCO Swiss and Prolux<br />

(Heating Technology), Kermi (Heating Technology and Sanitary<br />

Equipment), Forster (Precision Steel Tubes and Profile Systems),<br />

Forster (Kitchens and Refrigeration), Miele Kitchens, Piatti<br />

(Kitchens), EgoKiefer (Windows and Doors), Asta and Gächter<br />

(Transport and Logistics). The design of <strong>the</strong> sponsoring<br />

package has taken AFG’s multi-brand strategy in<strong>to</strong> account.<br />

© Visualisierung architron<br />

The structure in figures<br />

Building dimensions<br />

50,000 m 2 site<br />

915,000 m 3 construction volume<br />

500,000 m 3 excavation<br />

162,000 m 2 timbering<br />

83,000 m 3 concrete<br />

11,000 t steel<br />

Construction costs<br />

approx. CHF 300 m<br />

Capacity<br />

Maximum 14 ,000 sitting and 7,000 standing places<br />

for Super League matches:<br />

3,263 places in Sec<strong>to</strong>r A (main stand, north)<br />

4,334 places in Sec<strong>to</strong>r B (east stand)<br />

6,119 places in Sec<strong>to</strong>r C (south stand)<br />

4,334 places in Sec<strong>to</strong>r D (west stand)<br />

Maximum 18 ,050 sitting places for international matches<br />

Leisure and shopping<br />

20,500 m 2 shopping centre, Carrefour being <strong>the</strong> main<br />

tenant (Jelmoli as inves<strong>to</strong>r)<br />

13,500 m 2 IKEA furnishing house<br />

2,000 m 2 restaurants<br />

4,900 m 2 leisure centre<br />

200 m 2 offices/administration<br />

Parking area<br />

Maximum 1,100 cus<strong>to</strong>mer parking spaces in <strong>the</strong><br />

underground car park plus 200 additional adjoining ones<br />

for Saturdays<br />

150 separate spaces for two-wheel vehicles<br />

Over 3 ,000 additional parking spaces (mainly for<br />

use at football events) in St.Gallen’s Winkeln and Gossau<br />

industrial area<br />

7

F o c u s<br />

1st April 2006<br />

1st May 2006<br />

© Visualisierung architron<br />

In addition <strong>to</strong> <strong>the</strong> actual naming right of <strong>the</strong> stadium, <strong>the</strong> essential package<br />

also includes <strong>the</strong> signage inside <strong>the</strong> stadium, <strong>the</strong> names of <strong>the</strong> stands, e.g.<br />

«Piatti Stand» or «EgoKiefer Stand» – as well as VIP and stands for all <strong>the</strong> home<br />

games played by FC St.Gallen. A show kitchen in <strong>the</strong> VIP area and <strong>the</strong><br />

comprehensive banner coverage in <strong>the</strong> AFG ARENA also provide an excellent<br />

communication platform for <strong>the</strong> various product brands belonging <strong>to</strong> <strong>the</strong><br />

AFG concern. Right from its inception, <strong>the</strong> naming of <strong>the</strong> AFG ARENA was<br />

planned as an integrated communication campaign. By combining branding,<br />

sponsoring and communication initiatives, <strong>the</strong> aim is <strong>to</strong> link AFG permanently and<br />

within a short time with <strong>the</strong> popular sport of football and <strong>to</strong> target a high level<br />

of acceptance and impact for <strong>the</strong> AFG ARENA.<br />

Pushing <strong>the</strong> umbrella brand name of AFG in<strong>to</strong> <strong>the</strong> spotlight<br />

The naming right initiative also kicks-off an extensive marketing program for <strong>the</strong><br />

umbrella brand of AFG, as well as <strong>the</strong> brands of its subsidiaries, and is a key <strong>the</strong>me<br />

throughout <strong>the</strong> Group’s long-term marketing activities. «<br />

«An extremely committed partner»<br />

Bill B. Mistura<br />

CEO of Betriebs AG AFG ARENA<br />

What does <strong>the</strong> partnership with<br />

AFG Arbonia-Forster-Holding AG mean <strong>to</strong> you?<br />

Bill B. Mistura: I am highly satisfied with <strong>the</strong> partnership and<br />

proud <strong>to</strong> have found a strong, reliable and extremely<br />

committed partner in AFG. I am delighted that this partner<br />

is one of east Switzerland’s strongest companies that enjoys<br />

a worldwide reputation.<br />

How important is it <strong>to</strong> this partnership that AFG is an<br />

east Swiss company?<br />

Bill B. Mistura: It’s always a question of region and common<br />

identity. Now, with AFG we will demonstrate what we<br />

understand by this. The AFG ARENA is an unmistakable<br />

symbol of confidence and belief in east Switzerland.<br />

AFG has committed <strong>to</strong> FC St.Gallen as a Platinum Member<br />

Sponsor and is <strong>the</strong> club’s major shareholder.<br />

Bill B. Mistura: Put like this, <strong>the</strong> AFG ARENA is <strong>the</strong> logical<br />

consequence <strong>to</strong> an outstanding partnership that is set <strong>to</strong> last.<br />

Naming right partnerships are a matter of course in<br />

o<strong>the</strong>r countries. How relevant is that?<br />

Bill B. Mistura: As <strong>the</strong> stadium’s opera<strong>to</strong>r, we have <strong>to</strong> work<br />

out where <strong>the</strong> funds will come from <strong>to</strong> sustain costefficiency.<br />

Assigning <strong>the</strong> right <strong>to</strong> use a name is an interesting<br />

way of consistently generating funds over a relatively long<br />

period. In Germany, for example, <strong>the</strong>y have known this for<br />

some time.<br />

Switzerland is perhaps not at quite <strong>the</strong> same stage.<br />

The AFG ARENA is <strong>the</strong> first football stadium in <strong>the</strong><br />

country <strong>to</strong> bear <strong>the</strong> name of a company.<br />

Bill B. Mistura: Yes, we’re playing <strong>the</strong> role of pioneer here.<br />

And we’re proud of it <strong>to</strong>o. «<br />

9

10 AFG Arbonia-Forster-Holding AG<br />

A lot of freedom for new ideas: model of <strong>the</strong> new administration building, scheduled <strong>to</strong> open at <strong>the</strong> end of 2007<br />

Construction of <strong>the</strong> new Corporate<br />

Center: <strong>the</strong> first cut of <strong>the</strong> spade in<br />

August 2006<br />

AFG’s rapid growth has updated <strong>the</strong> long-existing plans <strong>to</strong> merge management and administrative<br />

functions in<strong>to</strong> one new, central Corporate Center. Construction of <strong>the</strong> AFG’s new Headquarters<br />

behind <strong>the</strong> Forster Kitchen Center in Arbon (Can<strong>to</strong>n Thurgau) will commence in August this year.<br />

The Corporate Center will be ready for occupation in November/December 2007.<br />

In recent months, AFG has acquired some 13 hectares of land<br />

in Arbon’s agricultural zone, a portion of which will be used<br />

for <strong>the</strong> land exchange. Around eight hectares have since been<br />

converted in<strong>to</strong> an industrial area.<br />

The promising pace at which <strong>the</strong> project is progressing is<br />

also <strong>down</strong> <strong>to</strong> <strong>the</strong> collaboration between <strong>the</strong> <strong>to</strong>wn of Arbon<br />

and <strong>the</strong> Thurgau government, which enabled <strong>the</strong> swift and<br />

non-bureaucratic land exchange and <strong>the</strong> change of use <strong>to</strong><br />

industrial land.<br />

AFG will <strong>the</strong>refore have sufficient industrial land in <strong>the</strong> future <strong>to</strong><br />

be able <strong>to</strong> position all properties at <strong>the</strong> lake in <strong>the</strong> new industrial<br />

Timeless elegance: <strong>the</strong> entrance area with its modern architecture is also an inspiration<br />

area. The new Corporate Center, which will have striking,<br />

large glass facades, is due for completion and occupation<br />

<strong>to</strong>wards <strong>the</strong> end of 2007. AFG, having developed over<br />

<strong>the</strong> last two years in<strong>to</strong> a billion Swiss Franc company, will<br />

<strong>the</strong>n have a functional, extremely appealing administration<br />

building with a modern infrastructure that is fitting for its<br />

size and prominence. The construction of this new Corporate<br />

Center is also a sign of AFG’s clear commitment <strong>to</strong> <strong>the</strong> Arbon<br />

location and <strong>to</strong> <strong>the</strong> important region of Oberthurgau, despite<br />

its endeavours <strong>to</strong> become more international. «<br />

A new dimension for AFG – heating,<br />

ventilation and air-conditioning<br />

The ability <strong>to</strong> develop innovative products is a key fac<strong>to</strong>r <strong>to</strong> AFG’s success. The recent acquisition<br />

of Schmidlin ASCO Swiss AG of Zwingen (Can<strong>to</strong>n Baselland), is ano<strong>the</strong>r logical step for AFG <strong>to</strong>wards<br />

a full range of heating, ventilation and air-conditioning technology.<br />

The integration of Schmidlin ASCO Swiss AG in<strong>to</strong> <strong>the</strong><br />

Heating Technology and Sanitary Equipment division is<br />

creating synergies for AFG with regard <strong>to</strong> developing new<br />

market segments as well as achieving a higher market<br />

penetration for <strong>the</strong> established product ranges via <strong>the</strong><br />

distribution channels both at home and abroad.<br />

The product portfolio focuses on manufacturing underfloor<br />

convec<strong>to</strong>rs, which besides fulfilling <strong>the</strong> conventional<br />

heating function, are also suitable for room cooling, each<br />

model having a specific interface with ventilation systems.<br />

These product features are firstly important for <strong>the</strong><br />

Heating Technology and Sanitary Equipment division’s<br />

strategy. They also satisfy <strong>the</strong> preconditions for <strong>the</strong> company<br />

<strong>to</strong> move in<strong>to</strong> <strong>the</strong> cooling/ventilation sec<strong>to</strong>r of building<br />

technology. Although new <strong>to</strong> AFG, this area will play a key<br />

role in <strong>the</strong> Group’s future strategic alignment. As well as <strong>the</strong><br />

existing, local radiant panel cooling systems, <strong>the</strong> acquisition,<br />

building on <strong>the</strong> expertise in heating technology, is thus<br />

creating far-reaching technical opportunities from local room<br />

ventilation and cooling systems through <strong>to</strong> fully integrated,<br />

apartment ventilation systems. The product range also<br />

includes systems for heating halls and industrial properties.<br />

Time for a new room comfort system<br />

Building on its self-developed and purchased technologies<br />

and <strong>the</strong> expertise it has garnered from its own areas of<br />

heating, refrigeration, ventilation and windows, AFG is<br />

developing a room comfort system that combines <strong>the</strong> core<br />

skills of <strong>the</strong> Heating Technology and Sanitary Equipment<br />

division, Windows and Doors division, as well as <strong>the</strong><br />

Refrigeration business unit. «As <strong>the</strong> climate continues <strong>to</strong><br />

change, <strong>the</strong> demands on working and living areas are getting<br />

higher. The focus is very much on both ecological and health<br />

considerations. The decisive steps have been taken and <strong>the</strong><br />

systems offered on <strong>the</strong> market are being successively extended.<br />

Therein lies <strong>the</strong> goals of AFG’s continued and new<br />

developments» says Dr. Edgar Oehler, Chairman and CEO. «<br />

The requirements placed upon work and living areas are also increasing<br />

from a climatic viewpoint. This situation is creating opportunities in <strong>the</strong><br />

new heating, ventilation and air-conditioning area

AFG Arbonia-Forster-Holding AG<br />

Dr. Edgar Oehler reported a successful business year 2005 at <strong>the</strong> General Meeting held on 21st April 2006<br />

AFG Arbonia-Forster-Holding AG:<br />

rockets ignited!<br />

The 19th Ordinary General Meeting of AFG Arbonia-Forster-Holding AG held on 21st April 2006:<br />

Reviewing a promising business year 2005 and looking forward <strong>to</strong> a successful future.<br />

Dr. Edgar Oehler, Chairman of <strong>the</strong> Board of Direc<strong>to</strong>rs and CEO<br />

welcomed 533 shareholders <strong>to</strong> <strong>the</strong> 19th Ordinary General<br />

Meeting of AFG Arbonia-Forster-Holding AG, held on 21st<br />

April 2006 in <strong>the</strong> packed-out Seeparksaal of Arbon (Can<strong>to</strong>n<br />

Thurgau). He also received over 100 guests from politics,<br />

business and <strong>the</strong> community, including former Swiss Federal<br />

Councillor Dr. Kurt Furgler, State Councillor Dr. Philipp Stähelin,<br />

Government President Dr. Claudius Graf-Schelling, Government<br />

Councillor Dr. Kaspar Schläpfer, Arbon’s new Mayor<br />

Martin Klöti, former State Councillors Dr. h.c. Ernst Rüesch<br />

and Franco Ma<strong>to</strong>ssi, former National State Councillor Ernst<br />

Mühlemann as well as Trudi Züllig-Grauer, widow of <strong>the</strong><br />

company’s founder Jakob Züllig-Grauer, who passed away<br />

in 1999.<br />

The Chairman and CEO first reflected on a <strong>good</strong> business<br />

year 2005 for AFG:<br />

Business Year 2005<br />

During Business Year 2005, AFG Arbonia-Forster-Holding AG<br />

enhanced its market position as an international business<br />

supplier. Net sales rose by 9.5% <strong>to</strong> CHF 1,124 billion.<br />

With <strong>the</strong> exception of <strong>the</strong> heating and plumbing division<br />

suffering under Germany’s weak building and equipment<br />

economy, <strong>the</strong> divisions developed in line with <strong>the</strong> high<br />

expectations. In view of dramatically increased acquisition<br />

costs and <strong>the</strong> fierce competition, income developed<br />

at various rates. The operating profit at EBIT level (profit<br />

before interest and taxes) grew by 7.1% <strong>to</strong> CHF 72.8 million,<br />

this being <strong>down</strong> <strong>to</strong> lower depreciation. The Group’s profit<br />

rose by 4.6% <strong>to</strong> CHF 51.5 million.<br />

13<br />

Perspective<br />

In 2005, AFG managed <strong>to</strong> grow stronger than its competi<strong>to</strong>rs<br />

in its four product divisions of Heating Technology and<br />

Sanitary Equipment, Kitchens and Refrigeration, Steel<br />

Technology, and Windows and Doors, hence gaining market<br />

shares in all areas. Once Dr. Edgar Oehler had acquired <strong>the</strong><br />

majority shareholding of AFG in Oc<strong>to</strong>ber 2003, <strong>the</strong> share<br />

price more than quadrupled.<br />

General Meeting confirms Board of Direc<strong>to</strong>r’s course<br />

The General Meeting unanimously approved all <strong>the</strong> Board<br />

of Direc<strong>to</strong>r’s applications, ruling on a gross dividend payout<br />

of CHF 7.– per owner and CHF 1.40 per nominal share.<br />

Paul Witschi of Rüschlikon (Can<strong>to</strong>n Zurich), was also elected<br />

as a new Board of Direc<strong>to</strong>rs Member. As a former member<br />

of <strong>the</strong> Group’s management, Paul Witschi (63), succeeding<br />

Dr. Ulrich Flückiger after his retirement, has successively<br />

grown <strong>the</strong> global business of <strong>the</strong> Geberit Group.<br />

Fur<strong>the</strong>r growth is <strong>down</strong> <strong>to</strong> intensive<br />

internationalisation efforts<br />

Speaking about <strong>the</strong> demands this current year, Dr. Edgar<br />

Oehler emphasised that <strong>the</strong> stronger international alignment<br />

of <strong>the</strong> business has a crucial strategic importance for AFG.<br />

From <strong>the</strong> platform of its two home markets, Switzerland and<br />

Germany, where AFG is firmly established with its brands<br />

and generate 80% of its sales, <strong>the</strong> Group is set <strong>to</strong> take its<br />

activities international. The objective is <strong>to</strong> develop <strong>the</strong><br />

immense market potential in o<strong>the</strong>r significant and growing<br />

markets, including <strong>the</strong> new EU member states, Russia, <strong>the</strong><br />

Middle and Far East, in North and South America, Oceania,<br />

as well as North and South Africa. The first ground-breaking<br />

steps were taken by establishing bases in Shanghai, Beijing,<br />

Dubai and o<strong>the</strong>r locations, as well as gaining access <strong>to</strong> <strong>the</strong><br />

Miele Kitchens distribution network.<br />

Outlook 2006<br />

Dr. Oehler appeared satisfied with business development in<br />

<strong>the</strong> first quarter of 2006. Net sales are more than 10% up on<br />

<strong>the</strong> same period in <strong>the</strong> prior year – despite inclement wea<strong>the</strong>r<br />

conditions impacting <strong>the</strong> business at <strong>the</strong> start of <strong>the</strong> year.<br />

This enabled AFG <strong>to</strong> carry <strong>the</strong> leverage it gained in 2005<br />

through in<strong>to</strong> 2006. As Dr. Oehler explains «AFG ignited <strong>the</strong><br />

rockets in <strong>the</strong> first quarter of 2006.» Development in all four<br />

divisions is promising; <strong>the</strong> increase in sales is having a positive<br />

knock-on effect on income.<br />

«The goal is <strong>to</strong> tap in<strong>to</strong> <strong>the</strong><br />

enormous market<br />

potential in o<strong>the</strong>r key<br />

and growing markets.»<br />

Work hard, play hard<br />

Traditionally, <strong>the</strong> AFG General Meeting also takes in a social<br />

event. Business over and off <strong>to</strong> <strong>the</strong> Frohsinn restaurant in<br />

Arbon, where <strong>the</strong> delegates enjoyed a sumptuous buffet.<br />

Sitting at attractively decorated tables, <strong>the</strong> shareholders <strong>to</strong>ok<br />

<strong>the</strong> opportunity <strong>to</strong> talk among <strong>the</strong>mselves and with business<br />

partners, past and present employees, as well as friends and<br />

acquaintances until late in<strong>to</strong> <strong>the</strong> evening. «

14<br />

Heating Technology<br />

and Sanitary<br />

Equipment<br />

H e a t i n g Te c h n o l o g y a n d<br />

S a n i t a r y E q u i p m e n t<br />

Outstanding design expertise<br />

The Heating Technology and Sanitary Equipment division has brilliant, trendsetting<br />

appeal. Three new models have been recognised with renowned design awards.<br />

Besides <strong>the</strong> high product quality and perfect function,<br />

outstanding design is an unmistakable criterion for all three<br />

division brands. In <strong>the</strong> truest sense of <strong>the</strong> word. Three new<br />

products have been recognised with renowned design prizes:<br />

«iF product design award 2006»<br />

for BAGNOTHERM MOVE<br />

After having demonstrated its special position by achieving<br />

<strong>the</strong> «red dot design award 2005», BANGNOTHERM MOVE<br />

has received ano<strong>the</strong>r design accolade. With a <strong>the</strong>rmal design<br />

that moves. The prestigious panel also paid tribute <strong>to</strong> <strong>the</strong><br />

design harmony and exciting asymmetry combined with<br />

extreme functionality. And <strong>the</strong>re’s no wonder – hand <strong>to</strong>wels<br />

can be conveniently hung from <strong>the</strong> side and <strong>the</strong> design spans<br />

unmistakable, consistent linearity through <strong>to</strong> special, almost<br />

invisibly concealed fastening technology.<br />

Kermi walk-in glass units win accolade<br />

Representative studies clearly prove that <strong>the</strong> <strong>bathroom</strong> is<br />

moving up <strong>the</strong> living world’s agenda. The need for peace<br />

and quiet and <strong>to</strong> get away from it all means <strong>bathroom</strong>s are<br />

growing in size, as is <strong>the</strong> desire <strong>to</strong> cultivate in <strong>the</strong>m an<br />

individual, very personal lifestyle. That’s why Kermi walk-in<br />

glass units are <strong>the</strong> in thing. These wishes can now come true<br />

with redefined shower areas: generously proportioned glass<br />

«<strong>Perfection</strong> <strong>down</strong><br />

<strong>to</strong> <strong>the</strong> <strong>finest</strong> <strong>detail</strong>:<br />

a <strong>feel</strong>-<strong>good</strong><br />

<strong>bathroom</strong>.»<br />

panels carried by stable supports. Precise dimensions and <strong>the</strong><br />

combination of ceiling and wall supports enable integration<br />

in<strong>to</strong> any room layout. The ambitious design claim coupled<br />

with optimised workmanship and carefully selected materials<br />

also won over an international panel. The judges paid <strong>the</strong><br />

highest possible tribute <strong>to</strong> <strong>the</strong> Kermi walk-in glass units with<br />

<strong>the</strong> «red dot design award 2006».<br />

Renowned design award for Credo-Half<br />

The new Credo-Half <strong>bathroom</strong> radia<strong>to</strong>r once again demonstrates<br />

that uncompromising styling does not necessarily<br />

mean compromising on comfort or function. With its striking<br />

asymmetry and exciting contrast between two-dimensional<br />

trim design and filigree criss-cross pipes, it fits seamlessly in<strong>to</strong><br />

<strong>the</strong> clear linearity of modern <strong>bathroom</strong> ambience, with no<br />

compromise on comfort. Hand <strong>to</strong>wels, for example, can<br />

conveniently be draped from <strong>the</strong> side. And nothing disturbs<br />

<strong>the</strong> puristic linearity. The headers, <strong>the</strong> very easy assembly<br />

fastening system and all <strong>the</strong> connections are concealed behind<br />

a screen. Top quality and outstanding heat output make <strong>the</strong><br />

Credo-Half a winning <strong>the</strong>rmal solution for <strong>the</strong> sophisticated,<br />

trendy <strong>bathroom</strong>. The panel of judges thought so <strong>to</strong>o,<br />

recognising it with <strong>the</strong> «iF product design award 2006». «

H e a t i n g Te c h n o l o g y a n d<br />

S a n i t a r y E q u i p m e n t 17<br />

Pure <strong>bathroom</strong> culture: <strong>the</strong> new Credo line by Kermi<br />

Selective presence<br />

at <strong>the</strong> pulse of <strong>the</strong> markets<br />

The continuous presence at <strong>the</strong> most prominent tradeshows both at home and<br />

abroad gives us an important platform for addressing <strong>the</strong> market and demonstrating<br />

our efficiency and innovative strength.<br />

Our most ambitious claims include proximity <strong>to</strong> our cus<strong>to</strong>mers<br />

and hence also a continuous dialogue with our distribution<br />

and specialist partners. A pivotal <strong>to</strong>ol here is <strong>the</strong> continuous<br />

presence at all important tradeshows at regional, national and<br />

international level as an ideal podium for graphic demonstration,<br />

<strong>detail</strong>ed information and intense communication<br />

with our partners.<br />

Kermi Heating Technology and Sanitary Equipment<br />

as a symbol of design and innovation<br />

Whilst <strong>the</strong> international presence at tradeshows in Moscow,<br />

Milan, Paris, Utrecht and Birmingham concentrated on <strong>the</strong><br />

ranges with a relevance for <strong>the</strong> individual countries,<br />

attendance at <strong>the</strong> important regional exhibitions in Hamburg,<br />

Essen and Nuremberg clearly symbolised design and innovation,<br />

function and solution orientation.<br />

Kermi Therm X2: setting new benchmarks in <strong>the</strong> flat radia<strong>to</strong>r sec<strong>to</strong>r<br />

Innovation<br />

On <strong>the</strong> heating technology side is <strong>the</strong> new award-winning<br />

Credo Linie and Therm X2 as a genuine innovation in <strong>the</strong> flat<br />

radia<strong>to</strong>r sec<strong>to</strong>r and <strong>the</strong> new radia<strong>to</strong>r coating and colour<br />

concept, which carefully considers both <strong>the</strong> growing need for<br />

hygiene as well as <strong>the</strong> desire for individual surfaces. Not<br />

forgetting <strong>the</strong> fur<strong>the</strong>r completion of <strong>the</strong> xnet surface<br />

tempering system and <strong>the</strong> unique Kermi renovation range.<br />

The new Credo product group, accompanied by <strong>the</strong> equally<br />

highly-prized shower cabin highlights Toca, Toca XP and <strong>the</strong><br />

new walk-in glass units, was ano<strong>the</strong>r attention-grabbing<br />

design <strong>the</strong>me in <strong>the</strong> plumbing sec<strong>to</strong>r. «Standard not special<br />

production», promised <strong>the</strong> new, movable side wall variants in<br />

<strong>the</strong> Ibiza 2000 range – a real problem solver in particular<br />

<strong>bathroom</strong> situations. And Kermi demonstrates a knack for<br />

meeting market requirements with its «The Right Centre»<br />

special service package.<br />

Everything <strong>the</strong> market wants: Ibiza 2000 – <strong>the</strong> full range<br />

Arbonia – with unmistakable design<br />

and special solution expertise<br />

Arbonia’s tradeshow presence was set apart by its presentation<br />

of <strong>the</strong> new BAGNOTHERM range, which is now even<br />

more charismatic and appealing thanks <strong>to</strong> <strong>the</strong> addition of<br />

BAGNOTHERM MOVE. Ano<strong>the</strong>r focal point is Arbonia’s<br />

unparalleled expertise when it comes <strong>to</strong> bespoke solutions,<br />

demonstrating once again its flexibility and ability <strong>to</strong> adapt<br />

<strong>to</strong> practically any planning situation and any cus<strong>to</strong>mer<br />

requirement – whe<strong>the</strong>r angled, bent, as a radia<strong>to</strong>r bank<br />

or bannister. «<br />

Arbonia impressively demonstrates its skill in creating bespoke solutions<br />

Unique design with multiple variations:<br />

<strong>the</strong> new Arbonia BAGNOTHERM line

18<br />

Kermi: number 1 by far<br />

The bi-annual survey conducted by «markt intern» nominated Kermi<br />

<strong>the</strong> Number 1 Supplier for 2005 in <strong>the</strong> shower cubicle sec<strong>to</strong>r.<br />

20,000 tradesman were surveyed, putting Kermi ahead of<br />

<strong>the</strong> rest. This clearly demonstrates that Kermi’s products and<br />

services are correctly positioned and recognised accordingly.<br />

And by <strong>the</strong> very target group that in <strong>the</strong> first instance<br />

has <strong>to</strong> compete under intense pressure everyday. On closer<br />

consideration, it also becomes clear that <strong>the</strong> key Kermi<br />

philosophies such as unrestricted quality, market-oriented<br />

range policy, innovative technology and broad sales support<br />

is both seen and experienced. No reason <strong>to</strong> sit on our laurels,<br />

but ra<strong>the</strong>r an incentive <strong>to</strong> fur<strong>the</strong>r increase our strengths,<br />

especially where <strong>the</strong> Kermi brand did not achieve a <strong>to</strong>p place.<br />

With an incentives package that moves us even closer <strong>to</strong><br />

our goal. «<br />

10 years of market presence in Russia<br />

Even more pioneering spirit was required when Kermi<br />

geared its first offensive <strong>to</strong>wards Russia in 1996.<br />

Today, Russia is still considered an important market<br />

in Kermi’s internationalisation concept.<br />

It all began 10 years ago with <strong>the</strong> right vision and a lot of<br />

intuition. High-level activities in <strong>the</strong> building sec<strong>to</strong>r in Russia<br />

promised for <strong>the</strong> future a significant, growing market<br />

potential. From initial talks emerged interesting relationships.<br />

In collaboration with base dealers, <strong>the</strong> initial focus was<br />

on <strong>the</strong> Heating Technology sec<strong>to</strong>r and <strong>the</strong> metropolises of<br />

Moscow and St.Petersburg.O<strong>the</strong>r regions were <strong>the</strong>n covered<br />

and Kermi is now one of Russia’s most important suppliers,<br />

especially in <strong>the</strong> flat radia<strong>to</strong>r sec<strong>to</strong>r. Creative radia<strong>to</strong>rs,<br />

xnet panel heaters and high-quality shower cubicles for<br />

luxury dwellings are also distributed in collaboration with<br />

H e a t i n g Te c h n o l o g y a n d<br />

S a n i t a r y E q u i p m e n t<br />

New Marketing Manager,<br />

Switzerland for Arbonia and Prolux<br />

Arbonia AG and Heizkörper Prolux AG appointed a new Marketing<br />

Manager for Switzerland on 1st April 2006.<br />

Rolf Schaufelberger<br />

Marketing Manager, Switzerland<br />

Arbonia and Prolux<br />

Mr Rolf Schaufelberger is a skilled and experienced<br />

professional for this demanding role. A graduate Sales<br />

Manager, his former activities in <strong>the</strong> heating technology<br />

sec<strong>to</strong>r as well as in combustibles, fuels and lubricants<br />

has provided him with <strong>the</strong> expertise required <strong>to</strong> significantly<br />

enhance <strong>the</strong> fur<strong>the</strong>r success of Arbonia and Prolux brands<br />

in Switzerland.<br />

The graphic shows <strong>the</strong> new organisation of <strong>the</strong> market<br />

region, including contact partners and contact data. «<br />

12 partners. Kermi’s mobile exhibition gives it a presence at<br />

numerous tradeshows and ideal home exhibitions. And<br />

this year’s «Aqua<strong>the</strong>rm» show in Moscow, one of <strong>the</strong> most<br />

significant in <strong>the</strong> region, was <strong>the</strong> ideal occasion for<br />

celebrating <strong>the</strong> company’s ten-year anniversary with some<br />

key cus<strong>to</strong>mers. «<br />

Organisation and contacts, Switzerland<br />

within <strong>the</strong> heating and plumbing sec<strong>to</strong>r<br />

Arbonia AG<br />

Vaios Doukas<br />

Marketing Manager,<br />

Switzerland<br />

Rolf Schaufelberger<br />

Phone +41 71 447 47 12<br />

doukas.vaios@arbonia.ch<br />

Phone +41 71 447 47 31<br />

schaufelberger.rolf@arbonia.ch<br />

Heizkörper Prolux AG<br />

Alois Schöpfer<br />

Phone +41 71 447 47 30<br />

schoepfer.alois@prolux-ag.ch<br />

At <strong>the</strong> anniversary celebrations, Mr Lebedinski,<br />

Dr. Schönborn and Mr Habermann (left <strong>to</strong> right)<br />

expressed <strong>the</strong>ir thanks for <strong>the</strong> positive working relationship

20 Kitchens and Refrigeration<br />

Kitchens<br />

and Refrigeration<br />

Three strong kitchen brands<br />

under one roof<br />

Now open, <strong>the</strong> first joint Kitchen Center: Forster Kitchens, Miele Kitchens and Piatti Kitchens,<br />

three of Switzerland’s leading kitchen suppliers can now be found under one roof – in <strong>the</strong> new<br />

AFG Kitchen Center Graubünden in Chur.<br />

Since September 2005, Miele Kitchens has been part of AFG<br />

Arbonia-Forster-Holding AG. Dr. Edgar Oehler predicted a<br />

hugely successful future for <strong>the</strong> three kitchen suppliers as<br />

soon as <strong>the</strong> acquisition was finalised. In Chur, his vision is<br />

now becoming reality. Forster Steel kitchens, Miele Kitchens<br />

and Piatti Wooden kitchens have <strong>the</strong>ir ranges on over 500 m 2<br />

of show room under just one roof.<br />

For Dr. Oehler, <strong>the</strong> AFG Kitchen Center in Chur is also a<br />

commitment <strong>to</strong> south-east Switzerland. «The region has<br />

demonstrated a penchant for ground-breaking architecture<br />

with a number of buildings. This in turn is making kitchen<br />

requirements more discerning.» He now wants <strong>the</strong> three<br />

kitchen suppliers <strong>to</strong> meet this demand.<br />

Three brands under one roof<br />

Forster offers steel kitchens in Swiss quality. With <strong>the</strong>ir clear<br />

lines and vibrance, <strong>the</strong>y fit seamlessly in<strong>to</strong> any modern,<br />

classic living area. Steel makes <strong>the</strong> kitchens <strong>to</strong>ugh, easy <strong>to</strong><br />

clean and hygienic. Miele Kitchens are known for <strong>the</strong>ir<br />

international, leading design. Their elegant radiance comes<br />

from timeless styling and a mix of quality materials. At <strong>the</strong><br />

same time, Miele Kitchens always go for trendsetting<br />

technology. Piatti is Switzerland’s market leader. The woodbased<br />

kitchens consistently set new standards with <strong>the</strong>ir<br />

innovations, which include trend colours, high-gloss designs<br />

or new multimedia kitchens. All three brands have one<br />

common thread: <strong>the</strong> plethora of colours, materials and layout<br />

variants can create any bespoke dream kitchen. «<br />

AFG Kitchen Center Graubünden<br />

AFG Küchenzentrum Graubünden<br />

Kornquader<br />

Kasernenstrasse 97<br />

CH-7000 Chur<br />

Phone +41 81 255 72 72<br />

www.afg.ch<br />

Opening Hours<br />

Monday <strong>to</strong> Friday: 08.30 – 12.00 / 13.30 – 17.30 hrs<br />

Saturday: 09.00 – 16.00 hrs

22 Kitchens and Refrigeration<br />

Forster and Piatti launch<br />

<strong>the</strong>ir KITCHEN&YOU courses<br />

Find out your needs and benefit from <strong>the</strong> experience<br />

of real kitchen professionals: KITCHEN&YOU provides<br />

knowledge and ideas.<br />

The planning and building of a bespoke kitchen is a<br />

demanding task. Many building owners are increasing<br />

overwhelmed with an abundance of enquiries, a<br />

consequence of new concepts, materials and equipment.<br />

The two leading kitchen manufacturers, Forster and Piatti<br />

have identified this problem. They are launching a special<br />

series of courses – KITCHEN&YOU. Accompanied by<br />

experienced kitchen professionals, one can learn what <strong>the</strong>ir<br />

requirements are and obtain ideas on various solutions.<br />

There are three course modules available, each focussing<br />

on different <strong>the</strong>mes. All courses are offered throughout<br />

Switzerland in both German and French.<br />

The series started in April 2006 and will continue <strong>to</strong> be<br />

offered for <strong>the</strong> entire year. Detailed information can<br />

be found under www.kuechenprofis.ch. Registration<br />

ei<strong>the</strong>r by phone on +41 44 835 54 66 or e-mail <strong>to</strong>:<br />

kuechenprofis@piatti.ch. «<br />

STEAMER&YOU<br />

Everything you need <strong>to</strong> know about <strong>the</strong> latest generation<br />

of steamers<br />

Programme<br />

■ Find out what you need from a steamer<br />

■ Basic facts about steamers<br />

■ Differences between <strong>the</strong> brands<br />

■ Performance and price<br />

■ Cooking with <strong>the</strong> new steamers<br />

■ Evening meal and information exchange<br />

References<br />

Unbiased professional chefs with sound<br />

steamer knowledge<br />

Course dates<br />

30 events – see www.kuechenprofis.ch<br />

Venues<br />

Arbon, Basel, Berne, Bussigny, Carouge, Chur, Dietlikon,<br />

Ebikon, St.Gallen, Thun, Winterthur, Zurich<br />

Course fee<br />

CHF 50.–, including evening meal<br />

PLAN&YOU<br />

Everything you need <strong>to</strong> know about planning your<br />

dream kitchen<br />

Programme<br />

■ Find out what you need from a kitchen<br />

■ The only restrictive fac<strong>to</strong>r is space<br />

■ Comfort – Functionality – Ergonomics<br />

■ Cooker or equipment island?<br />

■ Colour, style, material and design trends<br />

■ Interior kitchen values<br />

References<br />

Proven, experienced kitchen professionals<br />

Course dates<br />

22 events – see www.kuechenprofis.ch<br />

Venues<br />

Arbon, Basel, Berne, Bussigny, Carouge, Chur, Dietlikon,<br />

Ebikon, St.Gallen, Winterthur, Zurich<br />

Course fee<br />

None<br />

FUTURE LIVING&YOU<br />

Everything you need <strong>to</strong> know about future technology<br />

in <strong>the</strong> kitchen<br />

Programme<br />

■ Future technologies for laymen<br />

■ Find out what your needs and interests are<br />

■ Your kitchen as <strong>the</strong> crosspoint of technology<br />

■ Telecommunication and entertainment electronics<br />

in <strong>the</strong> kitchen<br />

■ Which trends are emerging?<br />

■ When is <strong>the</strong> best time <strong>to</strong> invest?<br />

References<br />

Proven, experienced kitchen professionals<br />

Course dates<br />

14 events – see www.kuechenprofis.ch<br />

Venues<br />

Arbon, Basel, Berne, Bussigny, Carouge, Chur, Dietlikon,<br />

Ebikon, St.Gallen, Winterthur, Zurich<br />

Course fee<br />

None

Kitchens and Refrigeration 25<br />

Awarded presence<br />

At <strong>the</strong> «Habitat et Jardin» exhibition in Lausanne (Can<strong>to</strong>n Vaud),<br />

Bruno Piatti AG appearing with Forster Küchen- & Kühltechnik AG<br />

(Kitchens and Refrigeration), won <strong>the</strong> coveted award for <strong>the</strong> most<br />

appealing exhibition stand. Piatti and Forster are setting technical innovation<br />

benchmarks in Switzerland. The two firms lived up <strong>to</strong> <strong>the</strong>ir reputation at <strong>the</strong><br />

«Habitat et Jardin» exhibition in Lausanne.<br />

A panel of judges appraised <strong>the</strong> appearance of 560 exhibi<strong>to</strong>rs and were most<br />

inspired by Piatti and Forster’s closed stand concept. They rewarded <strong>the</strong> creativity,<br />

<strong>the</strong> kitchen concepts being demonstrated and <strong>the</strong> special atmosphere with <strong>the</strong><br />

«Prix du meilleur stand» award. «<br />

Tradeshow<br />

Book tip:<br />

exquisite<br />

kitchens<br />

For <strong>the</strong> reader, <strong>the</strong> book develops<br />

<strong>the</strong> kitchen as a central area of<br />

domestic living. The authors looked<br />

at <strong>the</strong> kitchen with regard <strong>to</strong> its<br />

architectural, cultural, social and<br />

economic significance. Important<br />

development trends and pioneering<br />

recipes from over <strong>the</strong> centuries<br />

(Frankfurt cuisine, standard kitchens,<br />

eat-in kitchens), basic design principles,<br />

<strong>the</strong> hottest trends, <strong>the</strong> changing needs<br />

of <strong>to</strong>day’s kitchen area users<br />

(patchwork families, single households),<br />

as well as culinary aspects are all<br />

presented. In short: a book that every<br />

21st Century kitchen should have! The new series entitled «Edition Wohnen»<br />

presents in a succinct, clear way selected <strong>the</strong>mes from <strong>the</strong> wide subject of living.<br />

It is aimed at both those readers with a general interest in culture, as well as<br />

experts in <strong>the</strong> field. The series is published by ETH Wohnforum, Zurich.<br />

AFG Arbonia-Forster-Holding AG has supported <strong>the</strong> project both financially as well<br />

as with graphical material and is pleased with <strong>the</strong> success of <strong>the</strong> activity. «<br />

ISBN 3-7643-7280-X<br />

Published by Klaus Spechtenhauser<br />

In paperback<br />

Language: German<br />

Price: CHF 44.–<br />

116 b/w and 59 colour pho<strong>to</strong>s,<br />

48 b/w drawings<br />

160 pages, weight: 630 g<br />

The Capovino<br />

built-in wine<br />

cooler<br />

For <strong>the</strong> «savoir-vivre» of wine connoisseurs: Wine<br />

lovers have a reputation for taking life ra<strong>the</strong>r easy.<br />

«Savoir-vivre» <strong>the</strong>y say with pleasure as <strong>the</strong>y savour<br />

<strong>the</strong> precious drops. The Capovino from Forster,<br />

<strong>the</strong> world’s first built-in wine cooler for both red and<br />

white wine now promises you pure enjoyment.<br />

As wine experts know: a wine will only develop its full<br />

potential when it’s at <strong>the</strong> right temperature. None<strong>the</strong>less,<br />

even restaurants often serve wine that is ei<strong>the</strong>r <strong>to</strong>o warm or<br />

<strong>to</strong>o cold. A fauxpas that never needs <strong>to</strong> happen at home<br />

again. Forster, you see, is presenting a world innovation:<br />

Capovino, <strong>the</strong> first built-in wine cooler with adjustable<br />

temperature zones. This cabinet is able <strong>to</strong> cool both white<br />

wine and red wine <strong>to</strong> <strong>the</strong> correct temperature. To <strong>the</strong> delight<br />

of all hosts and wine lovers, this means wine at <strong>the</strong> right<br />

temperature is always <strong>to</strong> hand.<br />

www.forster-kuechen.ch<br />

Phone +41 71 447 41 41<br />

Fax +41 71 447 46 50<br />

Perfect s<strong>to</strong>rage conditions for red and white wine<br />

The secret of <strong>the</strong> Capovino lies in its separate cooling zones,<br />

which can be regulated individually <strong>to</strong> between 5° C and 18° C<br />

and offer perfect s<strong>to</strong>rage conditions for 36 <strong>to</strong> 56 bottles of<br />

red and white wine on six shelves. It’s up <strong>to</strong> <strong>the</strong> individual <strong>to</strong><br />

decide how many bottles should be cooled <strong>to</strong> which<br />

temperature – this is done by an intermediate shelf that can<br />

be moved any number of times. It also has an attractive<br />

design – simple and timeless, <strong>the</strong> Capovino certainly catches<br />

<strong>the</strong> intrigued eye. The specialities it s<strong>to</strong>res can be appraised<br />

through UV-absorbant glass doors. The quality, harmonious<br />

LED lighting protects <strong>the</strong> wine from undesirable warming.<br />

The Capovino reveals <strong>the</strong> true experts and highlights <strong>the</strong><br />

«savoir-vivre» in which all wine lovers bask. «<br />

«The love of wine is more<br />

than pure enjoyment.<br />

It’s a way of life.»

26 Kitchens and Refrigeration<br />

Miele Kitchens:<br />

putting variety on <strong>the</strong> agenda<br />

Part of <strong>the</strong> international furniture exhibition, Europe’s most important kitchen<br />

furniture exhibition, «Eurocucina» was held from 5th <strong>to</strong> 10th May 2006 in <strong>the</strong> new exhibition<br />

halls in Milan, with Miele’s kitchen innovations making a huge debut.<br />

After <strong>the</strong> exhibition, Managing Direc<strong>to</strong>rs of Warendorfer<br />

Küchen GmbH – Dr. Edgar Oehler, Kerstin Loeser and Dr. Uwe<br />

Steinmeyer had a permanent presence – were highly satisfied<br />

with how <strong>the</strong> exhibition had gone: a host of experts visiting<br />

<strong>the</strong> convincing exhibition stand, high-quality, professional<br />

dialogue and inspired cus<strong>to</strong>mer reactions <strong>to</strong> <strong>the</strong> innovations<br />

on show.<br />

Luminous surfaces and lines<br />

On a stand shared with Miele built-in appliances, Miele<br />

Kitchens presented in five fascinating new kitchens two<br />

innovative, leading <strong>the</strong>mes: light and work<strong>to</strong>ps. The moodlight<br />

concept is unique, illuminating surfaces and lines – pure<br />

emotion. Warendorfer Küchen GmbH reveals how coloured<br />

moodlight, based on <strong>the</strong> latest LED technology, makes <strong>the</strong><br />

Miele kitchen perceptibly emotional. And it would not be <strong>the</strong><br />

Miele Kitchens brand if this technology were unable <strong>to</strong> show<br />

<strong>the</strong> worklight in a new guise: <strong>the</strong> worklight and <strong>the</strong> cabinet’s<br />

new interior lighting with <strong>the</strong> new orientation light in both<br />

cabinets and drawers offer functionality and new cus<strong>to</strong>mer<br />

benefits.<br />

Even more design freedom<br />

The new work<strong>to</strong>p concept systematically incorporates <strong>the</strong><br />

work<strong>to</strong>p in<strong>to</strong> <strong>the</strong> overall design of Miele kitchens: <strong>the</strong><br />

material and colour of <strong>the</strong> work<strong>to</strong>p edging can be designed<br />

<strong>to</strong> match <strong>the</strong> kitchen front. Five different work<strong>to</strong>p thicknesses,<br />

252 material/colour variants for <strong>the</strong> edging and<br />

192 material/colour combinations for <strong>the</strong> work surfaces<br />

<strong>to</strong> choose from! Inspiring, new design freedom for <strong>the</strong><br />

work<strong>to</strong>ps – matched <strong>to</strong> Miele kitchens.<br />

The handleless Miele kitchen: <strong>the</strong> L14 range<br />

with <strong>the</strong> new micro-structure finish in black and<br />

beige featuring <strong>the</strong> new moodlight concept<br />

Also making <strong>the</strong>ir debut are two completely new kitchen<br />

ranges: <strong>the</strong> handleless Miele kitchen, which has been<br />

available since early April (12 ranges are on offer) and <strong>the</strong><br />

line with <strong>the</strong> novel, three-section front, which shows its true<br />

beauty in wood with <strong>the</strong> combination of horizontal and<br />

vertical graining (7 ranges).<br />

More variety in syn<strong>the</strong>tics<br />

The new F16 range rounds out <strong>the</strong> extensive offering with a<br />

syn<strong>the</strong>tic variant. Whilst Miele kitchen designers have long<br />

been able <strong>to</strong> plan <strong>to</strong> any colour requirement when it comes <strong>to</strong><br />

finish, until now <strong>the</strong>y have been confined <strong>to</strong> 18 syn<strong>the</strong>tic decor<br />

types. That’s now about <strong>to</strong> change: high-quality HPL fronts<br />

in 160 colours offer a bold, robust alternative <strong>to</strong> <strong>the</strong> new<br />

micro-structure finish fronts.<br />

This innovative advancement is rounded-out by five new,<br />

self-arranged brand-typical handles – unmistakable unique<br />

selling points. Warendorfer gives its brand kitchen what is<br />

needs most: recognition and fascination, innovation and<br />

emotion.<br />

All expert visi<strong>to</strong>rs were able <strong>to</strong> take away with <strong>the</strong>m<br />

information on <strong>the</strong> entire innovation package on a CD-ROM<br />

New: <strong>the</strong> LED lighting in <strong>the</strong> draws and front<br />

shelves<br />

Design<br />

New: <strong>the</strong> cabinet’s interior lighting with backlit<br />

glass shelves<br />

created jointly with Miele – an explanation of all innovative<br />

features – as well as a film on a new DVD. Information that<br />

<strong>the</strong>y could enjoy again at home as a «cinema experience». «<br />

The new three-section front with <strong>the</strong> new lobe handle and moodlight<br />

concept (light line below <strong>the</strong> work<strong>to</strong>p). N70 range, light oak and L73<br />

mirror finish, NCS special colour, aubergine<br />

New: <strong>the</strong> LED-lit glass rear panels make <strong>the</strong><br />

alcove system in<strong>to</strong> a showroom

28 S t e e l Te c h n o l o g y<br />

Steel Technology<br />

Forster unico – a world innovation<br />

A world innovation was debuted at <strong>the</strong> very first attendance at <strong>the</strong> «fensterbau/frontale»<br />

exhibition from 22nd <strong>to</strong> 25th March 2006 in Nuremberg: Forster unico, <strong>the</strong> profile system from<br />

100% steel for heat-insulated doors and windows.<br />

Perfect timing for showing <strong>the</strong> youngest member in <strong>the</strong><br />

Forster system family <strong>to</strong> a large audience in <strong>the</strong> Germanspeaking<br />

area. Our largest export market, Germany was <strong>the</strong><br />

obvious choice. The positive feedback from <strong>the</strong> expert visi<strong>to</strong>r<br />

as well as from our representatives demonstrates that this<br />

system has a positive future ahead.<br />

New products, new contacts<br />

The Forster <strong>the</strong>rmfix light system was presented as ano<strong>the</strong>r<br />

innovation. This system allows a facade glass panel <strong>to</strong> be<br />

simply mounted <strong>to</strong> steel, aluminium or wooden substructures.<br />

Forster <strong>the</strong>rmfix light has been successfully tested on <strong>the</strong><br />

criteria required <strong>to</strong> use <strong>the</strong> CE mark. Also presented were<br />

several innovations and product upgrades for fire-proofing<br />

and safety.<br />

The highlight: Forster unico – a world innovation<br />

The exhibition set a new record with specialist visi<strong>to</strong>rs<br />

numbering over 100,000. The exhibition now also has a<br />

much more international orientation. We welcomed<br />

visi<strong>to</strong>rs from 23 countries <strong>to</strong> our stand.<br />

Winners of innovation award<br />

During <strong>the</strong> exhibition, <strong>the</strong> innovation award «Architektur-<br />

Fenster-Fassade» was awarded for <strong>the</strong> first time by<br />

NürnbergMesse GmbH and <strong>the</strong> specialist magazine<br />

«xia Intelligente Architektur». We entered <strong>the</strong> competition<br />

with <strong>the</strong> Forster unico system and were awarded <strong>the</strong> first<br />

prize in category 2 – products of high architectural quality:<br />

testimony <strong>to</strong> <strong>the</strong> fact that <strong>the</strong> system is highly revered in<br />

<strong>the</strong> world of architecture.<br />

Attendance at <strong>the</strong> exhibition can <strong>the</strong>refore be considered<br />

a huge success for Forster Profile Systems. «<br />

The Forster Profile Systems stand is ready for <strong>the</strong> stampede of visi<strong>to</strong>rs<br />

World innovation

S t e e l Te c h n o l o g y 31<br />

Brilliant surfaces in consistently high quality<br />

The final cut<br />

Facades, windows and doors from high-grade stainless steel are architectural<br />

trend products. A demanding material, one which does not forgive mistakes<br />

in planning or workmanship. Forster Profile Systems offers new high-grade steel<br />