MANMagazine Truck 02/2016 United Kingdom

What truck highlights can customers expect in the 2017 model year? How is the new Euro 6 engine generation being developed? And what role does the topic of digitalisation play in the commercial vehicles sector? This edition of MANmagazine is all about the innovative product and service portfolio presented by MAN at the IAA Commercial Vehicles trade show 2016. In our subject special we’ll be looking at the new models, such as the MAN TGE, and shedding some light on future trends such as platooning.

What truck highlights can customers expect in the 2017 model year? How is the new Euro 6 engine generation being developed? And what role does the topic of digitalisation play in the commercial vehicles sector? This edition of MANmagazine is all about the innovative product and service portfolio presented by MAN at the IAA Commercial Vehicles trade show 2016. In our subject special we’ll be looking at the new models, such as the MAN TGE, and shedding some light on future trends such as platooning.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>02</strong>/<strong>2016</strong><br />

Great Britain<br />

A true MAN among transporters<br />

The new<br />

MAN TGE

<strong>02</strong>/<strong>2016</strong><br />

04<br />

08<br />

06<br />

STORY SPECIAL: IAA <strong>2016</strong><br />

MAN presented an innovative product and<br />

services portfolio at the IAA Commercial Vehicles<br />

<strong>2016</strong> trade show – including the new MAN TGE.<br />

CONTENT<br />

04 On the roads of the Arctic Zone<br />

Interview with the Norwegian truck<br />

driver May-Wenche Figenschau<br />

06 Globetrotters<br />

For adventurers: MAN action mobile<br />

08 MAN at the IAA <strong>2016</strong><br />

All truck highlights at a glance<br />

14 The new MAN TGE<br />

World premiere in Hanover<br />

16 Purely powerful!<br />

The new generation of Euro 6 engines<br />

19 Novel concepts for networking<br />

the transport world<br />

MAN advances the digitalisation process<br />

22 Revolution in the slipstream<br />

Platooning: a solution for the future<br />

26 On location<br />

News from the British MAN market<br />

34 In the land of ice and fire<br />

Underway on Iceland’s glaciers<br />

Great Britain<br />

Performance up. Consumption down.<br />

The new MAN TGX. MAN kann.<br />

We present you with our best tool against cost pressure on the road: the new MAN TGX. With drive tuned ideally for<br />

efficiency and performance, you can gain even more from every single drop of fuel: more distance, more torque and<br />

power, more reserves. Because we have invested no end of expertise in it and incorporated a whole range of<br />

improvements such as MAN EfficientCruise ® and MAN EfficientRoll, LED daytime driving lights, light and rain sensors<br />

and also a new infotainment system. Find out more about the best MAN TGX of all time at www.truck.man<br />

MAN kann.<br />

© Richard Kienberger, thehaeusgens.com, Michel Devries/MAN, Max Kratzer<br />

MASTHEAD<br />

MANmagazine is published twice a year in 16 languages. PUBLISHER MAN <strong>Truck</strong> & Bus, Stefan Klatt (V.i.S.d.P.), Dachauer Straße 667, 80995 Munich, Germany EDITOR IN CHIEF & PROJECT MANAGER Joachim Kelz,<br />

Tel.: +49. 89. 1580-1175, magazin@man.eu, www.man.eu EDITORIAL GREAT BRITAIN Verity Cullum, Judith Sanders PUBLISHER C3 Creative Code and Content GmbH, Heiligegeistkirchplatz 1, 10178 Berlin, Germany<br />

www.c3.co HEAD OF CONTENT UNIT Klaus-Peter Hilger EDITORS & AUTHORS Yasmine Sailer (resp.), Kirti Letsch; freelance authors: Beata Cece, Richard Kienberger, Marcus Schick INTERNATIONAL EDITORS<br />

Patricia Preston (resp., freelance editor), Caroline Evans, Asa C. Tomash PROJECT MANAGEMENT Sara Austen-Schrick GRAPHICS Igor Clukas, Andrea Hüls, Micheline Pollach, Marika Simon, Irina Pascenko (freelancer)<br />

PHOTO EDITORS Elke Maria Latinovic, Samantha Taruvinga COVER Michel Devries/MAN PRODUCTION C3 Creative Code and Content GmbH PRINTING Gotteswinter und Aumaier GmbH, Joseph-Dollinger-Bogen 22,<br />

80807 Munich, Germany REPRODUCTION permitted with reference. Any changes must be coordinated with the editors. ADVERTISING SERVICE Zeitzeichen Vertriebs GmbH, Radka Neumann, Tel.: +49. 8323. 9984630,<br />

radkaneumann@zeitzeichen.de COPYRIGHT ©<strong>2016</strong> MAN and C3 Creative Code and Content GmbH<br />

26<br />

03

<strong>02</strong>/<strong>2016</strong><br />

MY MAN<br />

On the roads of the<br />

Passionate driver:<br />

May-Wenche Figenschau<br />

received her truck driver’s<br />

licence three years ago.<br />

Arctic Zone<br />

May-Wenche Figenschau is working as a<br />

truck driver in the Tromsø region of northern<br />

Norway. After many years as a taxi operator,<br />

she got her truck driver’s licence in 2013 and<br />

today is one of two female truck drivers<br />

working for the transport company Pedersen &<br />

Sonn AG, which owns a fleet of 62 commercial<br />

vehicles.<br />

Ms Figenschau, which truck do you<br />

drive? Mine is an MAN TGS with a D26<br />

engine. The 8 x 4 dump truck with automatic<br />

transmission was delivered just last year,<br />

meets the Euro 6 standard and features an<br />

automatic transmission.<br />

You work north of the Arctic Circle and<br />

therefore often drive on snow and ice.<br />

What makes this a different experience?<br />

The most important factor is to remain calm<br />

and not to become frenzied, for it actually<br />

happens time and again that especially the<br />

tyres on the front axles won’t obtain enough<br />

grip and will start to slide.<br />

What are the special challenges for your<br />

truck? In my vehicle, I transport slag from a<br />

tunnel construction site. As the time frame is<br />

rather tight, we load as much as is technically<br />

feasible – with the total weight then exceeding<br />

50 tonnes. That’s permitted because we don’t<br />

use public roads and might merely cross a<br />

few. Considering the overall load, the many<br />

potholes on the off-road paths are fairly<br />

daunting, but the MAN suspension absorbs<br />

the impact really well.<br />

En route at the polar circle: The MAN<br />

TGS also handles snow and ice<br />

conditions in a reliable fashion.<br />

© Richard Kienberger<br />

What must a truck driver in northern<br />

Norway be mindful of? The critical factors<br />

are the weather and the road conditions, and<br />

we also must look out for the many elk and<br />

reindeer when on the road. Yet we’re used to<br />

that up here in the north.<br />

What do you particularly appreciate<br />

about your MAN vehicle? I’m very happy<br />

with my truck. Ergonomics are great, the<br />

driver’s seat and steering wheel can be<br />

adjusted perfectly. I’m not especially tall,<br />

which poses a problem in many other trucks.<br />

In addition, the MAN has an awesome sound<br />

system. That’s a good thing in this line of<br />

work, for you normally sit alone in your cab.<br />

When you look back, what would have<br />

been the most remarkable experience<br />

you’ve had as a truck driver so far? I<br />

remember it like it was yesterday. We were<br />

working on the Sørkjos Tunnel. The temperature<br />

dropped to 0° Celsius that day, so the<br />

ground was very slippery. Just before reaching<br />

the hill summit where we were supposed to<br />

dump our load, there was no moving forward<br />

any more. I therefore had to manoeuvre that<br />

heavy truck backwards down a steep, icy<br />

slope, with my heart racing as I did, of course.<br />

In that situation, I was very grateful for my<br />

MAN, because it can handle even such intimidating<br />

conditions.<br />

04<br />

05

<strong>02</strong>/<strong>2016</strong><br />

GLOBE-<br />

TROTT ERS<br />

THE FREE AND INDEPENDENT exploration of<br />

the world’s most remote corners is a lifelong<br />

vision harboured by many. Daniela and Stephan<br />

Wirths in Saalfelden, Austria, offer the solutions<br />

to make this dream come true. Together with 13<br />

employees, the two owners of the company<br />

Action Mobil build exclusive all-wheel motor<br />

homes on MAN chassis – the perfect vehicle for<br />

adventurers and world travellers.<br />

Each and every truck is manufactured<br />

strictly to order, ranging from a modest<br />

two-axle vehicle with a basic configuration,<br />

up to a 12-metre-long luxury wheeler with<br />

540 hp, floor heating and even an integrated<br />

garage for a compact car. “The quality and reliability<br />

of the undercarriage plays an<br />

important and, literally, carrying role,” says<br />

Stephan Wirths. “In terms of a body built by<br />

Action Mobil, the chassis must be a perfect<br />

match, meeting very high standards. Neither<br />

the mechanics nor the electronics of vehicles<br />

on an MAN basis have ever disappointed us.”<br />

The Wirths team is especially proud that<br />

their conversions have passed the stringent<br />

testing processes of MAN’s production team<br />

and are therefore MAN-certified. This distinction<br />

is also appreciated by customers such as<br />

Tina and Jakob Haeusgen, who are currently<br />

touring Australia on board their expedition<br />

vehicle, “Aloisius”: “This is already our second<br />

MAN and we have always been very happy with<br />

the durability of the frames, the design and the<br />

driving comfort. The international dealership<br />

and service network was also a decisive factor<br />

– for safety comes first,” recounts Jakob<br />

Haeusgen. The Action Mobil with an MAN TGM<br />

18.340 4x4 BB chassis was “always our biggest<br />

dream, for it’s tantamount to high-quality<br />

workmanship, innovation and many decades<br />

of experience,” raves Haeusgen.<br />

Strong companion: The MAN TGM named<br />

“Aloisius” is currently touring Australia<br />

with its owners, Tina and Jakob Haeusgen.<br />

© thehaeusgens.com<br />

45 000<br />

kilometres<br />

was the distance covered by Tina<br />

and Jakob Haeusgen while trucking<br />

through Australia with their MAN.<br />

06<br />

07

IAA STORY SPECIAL<br />

<strong>02</strong>/<strong>2016</strong><br />

640 hp. The 640-hp performance class with<br />

the new MAN D38 engine had previously been<br />

reserved for the heavy-duty transport version<br />

and is available for almost all variants of the<br />

MAN TGX D38 with the new generation of<br />

engines. With the new D38, MAN offers additional<br />

performance categories of 540 hp and<br />

580 hp – and thereby adds 20 hp to both<br />

versions. Furthermore, the D38 engine already<br />

achieves its maximum of 3,000 Newton<br />

metres of torque even at low engine speeds.<br />

Optimised for fleet operations, the new D26<br />

offers a performance range from 420 hp to<br />

500 hp together with low dead weight and<br />

reduced fuel consumption. In all new D38, D26<br />

and D20 engines, MAN applies a novel and<br />

more reactive catalyser material for the SCR<br />

system. Thus, combustion and the after-treatment<br />

of exhaust gases are optimised, resulting<br />

in further lowered consumption levels.<br />

In combination with the new versions of<br />

MAN’s TipMatic gears, which come with individually<br />

adjusted driving programmes for all<br />

MAN at the IAA:<br />

Top performance with three world premieres<br />

MAN presented a stateof-the-art<br />

truck range at the<br />

IAA Commercial Vehicles<br />

<strong>2016</strong> trade fair. Next to<br />

digital products and<br />

services, the focus was<br />

on engine innovations,<br />

transmission functionality<br />

and design.<br />

W<br />

ith more than 200 000<br />

visitors the MAN booth at<br />

the IAA trade fair (held<br />

from September 21-29 in<br />

Hanover, Germany) was<br />

one of the most visited<br />

ones of the show. This was no surprise, as it was<br />

the first IAA where MAN presented itself as a<br />

strong part of the VW <strong>Truck</strong> & Bus GmbH. On<br />

an area of 10 000 sqm MAN featured three<br />

world premieres – the TGX 18.640 PerformanceLine<br />

Edition, MAN TGE and the new<br />

NEOPLAN Tourliner – and presented for the<br />

first time the new brand RIO, a digital cloud<br />

based platform, which wants to revolutionize<br />

the future of freight transport.<br />

One of the absolute highlights in the truck<br />

sector was the world premiere of the new<br />

MAN TGE product series. With a maximum<br />

admissible total weight of 5.5 tonnes, this light<br />

commercial vehicle completes MAN’s comprehensive<br />

product portfolio. The TGE is principally<br />

designed for light distribution operations<br />

and crafts and trade businesses (more<br />

about the TGE on pages 14-15).<br />

ANOTHER HIGHLIGHT AT IAA <strong>2016</strong> certainly<br />

was the engine programme, which has been<br />

optimised in a number of ways. The new<br />

engines already meet the Euro 6c exhaust<br />

standard, resulting in significantly improved<br />

fuel consumption along with enhanced performance<br />

and vehicle dynamics, coupled with<br />

customarily high reliability. Customers can<br />

now choose from an engine portfolio with<br />

14 performance levels, ranging from 150 hp to<br />

© MAN<br />

World premiere: The new MAN TGE<br />

draws lots of visitors to the exhibition<br />

stand. The light transporter rounds out<br />

MAN's product portfolio.<br />

In the spotlight: The MAN MAN<br />

TGX PerformanceLine with 640<br />

hp was the star of the show.<br />

purposes, the MAN series feature highly<br />

efficient, economical and environmentally<br />

friendly drive trains. The new gear functions<br />

are consistent in functionality, available for all<br />

12-gear systems of the new TG generation and<br />

are organised in five different gear switching<br />

programmes. The FLEET programme has been<br />

optimised for fleet vehicles in the longdistance<br />

transport sector. As it permits solely<br />

automatic gear changes during normal<br />

driving operations, FLEET is deliberately<br />

designed for fuel-efficient driving. In contrast,<br />

the PROFI gear shifting configuration allows<br />

for manual gear changes at any time, with the<br />

kickdown function for accelerated shifting<br />

down also generally active. PROFI allows experienced<br />

drivers who have undergone MAN<br />

ProfiDrive training to harness the efficiency<br />

potential of their vehicles even more effectively.<br />

The OFFROAD programme is designed<br />

for driving on unpaved roads. The gears shift<br />

quicker and at higher engine speeds, with<br />

manual gear changes optional at any time.<br />

With delayed switching, OFFROAD allows for<br />

maximum performance on ascents, while<br />

effectively utilising engine brake power on<br />

descents. With the COLLECT programme,<br />

MAN offers a gear software system that has<br />

08<br />

09

IAA STORY SPECIAL<br />

<strong>02</strong>/<strong>2016</strong><br />

New brand icon: From now on, all<br />

TG production series vehicles<br />

will feature the chrome bar with the<br />

MAN lion highlighted in black.<br />

been specially optimised for waste collection<br />

vehicles. Oriented towards the deployment<br />

conditions of vehicles with tail or side loader<br />

structures, the gear shift strategy is tailored to<br />

extended stopping intervals with activation<br />

of the auxiliary drives and frequent starts.<br />

The EMERGENCY programme is specially<br />

designed for emergency vehicles. Gears<br />

change quicker and at higher engine speeds,<br />

offering rescue staff maximum acceleration<br />

potential of the vehicle when on an emergency<br />

mission. Whereas FLEET and PROFI are<br />

standard gear programmes for normal driving<br />

operations, OFFROAD, EMERGENCY and<br />

COLLECT are auxiliary programmes that are<br />

available alongside normal driving mode and<br />

can be selected by the driver to meet specific<br />

deployment conditions.<br />

THE NEW EDITION of the EfficientLine<br />

concept was another highlight exhibited at<br />

the IAA. The TGX EfficientLine 3 combines all<br />

technical and aerodynamic fuel saving<br />

measures in a single truck, featuring yet<br />

again improved fuel efficiency when<br />

compared to its predecessor. To back up this<br />

claim with facts and figures, an MAN TGX<br />

18.500 4x2 BLS EfficientLine 3 tractor trailer<br />

and a TGX 18.480 4x2 BLS EfficientLine 2 went<br />

on a test run throughout Europe. The tour<br />

comprised six stages over a distance of nearly<br />

4,000 kilometres covering six countries. On<br />

the topographically demanding sections of<br />

the route, the new anticipatory Efficient-<br />

Cruise Tempomat was able to demonstrate its<br />

entire efficiency. In the new generation, it<br />

comes combined with the EfficientRoll freewheeling<br />

function. This takes effect on fairly<br />

gentle inclines or slightly hilly route sections,<br />

when the gears switch into neutral to completely<br />

utilise vehicle momentum without<br />

any drag losses. The German technical inspection<br />

authority TÜV Süd accompanied the<br />

trip, and certified that in comparison to its<br />

predecessor model, the new TGX EfficientLine<br />

3 accomplished a consumption savings rate of<br />

6.35% due to its more efficient drive train.<br />

In terms of design, MAN was showcasing<br />

the TG series starting with 7.5 tonnes at the<br />

IAA <strong>2016</strong>. As a trade mark, the lion logo hereby<br />

comes to the fore. Placed on the chrome bar<br />

above the radiator, the MAN lion now stands<br />

out more sharply against the new high-lustre<br />

black background. The logo also makes a<br />

Savings package: The TGX EfficientLine 3<br />

combines all technical and aerodynamic fuel<br />

saving features in a single truck.<br />

© MAN<br />

4 000<br />

kilometres<br />

is the distance travelled across Europe<br />

by an MAN TGX EfficientLine 3 and a<br />

MAN TGX EfficientLine 2. This trial run<br />

proved the once again enhanced<br />

efficiency of the new model as compared<br />

to its predecessor.<br />

New steering wheels: Recessed<br />

grips and the MAN lion on the<br />

impact absorber enhance the<br />

value of the steering wheel.<br />

Classy interior: The limited special<br />

edition of the MAN PerformanceLine features<br />

a rather outstanding design inside.<br />

10<br />

11

IAA STORY SPECIAL<br />

Powerful and economical: The new 15.2-litre MAN D38<br />

six-cylinder in-line engine already achieves a torque of<br />

between 2,700 and 3,000 Nm at speeds of merely 900 rpm.<br />

stronger appearance in the cab and now<br />

adorns the impact absorber of the steering<br />

wheel. In addition, the TGX and TGS have<br />

received newly patterned cooling air inlets.<br />

Aerodynamically optimised radiator fins now<br />

give the front a compact and contained appearance.<br />

As of the IAA <strong>2016</strong> date, the new<br />

exterior design will be standard in all new<br />

TGX and TGS lines that meet Euro 6 exhaust<br />

standards. All TG models now present a bright<br />

and sophisticated appearance, brought about<br />

by warmer colours with new materials and<br />

seat covers, stylishly complemented by the<br />

succinct design of the steering wheel. The<br />

recessed grips of the new standard steering<br />

wheels offer outstanding handling ergonomics<br />

during driving. The driver’s workplace in<br />

all models is also upgraded by a new infotainment<br />

system, automated headlight control<br />

and wiper sensors.<br />

Another notable highlight of the IAA –<br />

and not just in design terms – was an<br />

exclusive special edition of the new TGX D38<br />

with 640 hp, which is limited to 100 vehicles.<br />

This PerformanceLine Edition features exceptional<br />

design extras both inside and out, with<br />

its top-end engine capacity showcasing<br />

maximum performance on the road.<br />

AN IMPORTANT ISSUE regarding After Sales<br />

was addressed at the IAA <strong>2016</strong> with the presentation<br />

of the MAN Original Oil. These<br />

engine, axle and gear oils have been especially<br />

customised for MAN vehicles and offer<br />

supreme quality with regard to efficiency,<br />

performance, protection against wear and<br />

tear and prolonged service life of the truck. At<br />

the same time, the usage of MAN’s Original<br />

Oil reduces overall operating costs, as it<br />

permits a service interval of up to 140,000 kilometres<br />

and a distance of up to 850,000 kilometres<br />

for diesel particulate filters. MAN<br />

Original Oil will be obtainable in many<br />

European countries as of early 2017.<br />

Also premiering at the IAA <strong>2016</strong> was the<br />

new portfolio of MAN TopUsed purchase warranties<br />

offered for both the drive train and<br />

the entire vehicle. The new portfolio offers<br />

suitable products for MAN TopUsed trucks,<br />

including vehicles with a D38 engine, as well<br />

as for MAN and NEOPLAN tour coaches. Three<br />

different terms are available, extending over<br />

either six months, one year or two years. The<br />

novelty aspect in these purchase warranties<br />

is the elimination of any deductible for the<br />

drive train throughout the total time period,<br />

while the deductible for the entire vehicle is<br />

reduced to 20% throughout the whole term.<br />

The age of the vehicle is no longer a criteria for<br />

closing a warranty agreement, but rather<br />

complemented by a suitable warranty<br />

extension offered on the basis of the vehicle’s<br />

mileage. The new TopUsed purchase warranties<br />

can also be combined with an individual<br />

service agreement and are available since<br />

1 October <strong>2016</strong>.<br />

LAST BUT NOT LEAST, MAN turned the<br />

spotlight on new approaches to networking<br />

the transport world during the trade fair. A<br />

dedicated area focusing on innovation and<br />

digitalisation topics illustrated prospects for<br />

future digital services and offerings that<br />

customers can use to optimise their logistics<br />

processes and monitor commodity flows<br />

more efficiently on the basis of intelligent<br />

networking. More information on the subject<br />

of digitalisation is on pages 19-21. In Hanover,<br />

MAN also presented new solutions for<br />

eMobility.<br />

640<br />

horsepower<br />

are available for almost all MAN TGX<br />

D38 variants coming from the new<br />

engine generation – and not just in<br />

heavy-duty transport models.<br />

© MAN<br />

12

IAA STORY SPECIAL<br />

<strong>02</strong>/<strong>2016</strong><br />

Much stowage space: In its<br />

largest version, the box-type<br />

van offers a load volume of<br />

18.4 cubic metres.<br />

The new<br />

MAN TGE<br />

The vehicle class previously starting at<br />

7.5 tonnes will now begin at 3.0 tonnes<br />

of admissable total weight: With its new<br />

TGE, MAN is putting a light commercial<br />

vehicle on wheels that will set forth to<br />

find users primarily in distribution<br />

traffic and construction businesses.<br />

Ergonomic design:<br />

The instrument panel is distinctly<br />

structured. Robust fabric in high-end<br />

MAN quality ensures durability.<br />

From 3.0 to 44 tonnes: With a<br />

weight span of 41 tonnes, MAN<br />

advances towards becoming a<br />

full-range provider while finding<br />

the right answer for every<br />

transport need. Conceived as a<br />

flexible tool for professionals, the new<br />

MAN will primarily cover the smaller jobs in<br />

logistics and construction businesses.<br />

Yet other sector-specific demands made by<br />

trade or passenger transport will also<br />

become new fields of application for the<br />

small motor truck made by MAN, when<br />

dealing with transport loads up to 5.5 tonnes<br />

of admissable total weight.<br />

MAN clearly applies its leading role and<br />

experience in the building trade and<br />

transport construction to the MAN TGE as<br />

well, while offering to customers not only its<br />

established competence in the light commercial<br />

vehicle segment, but also by lending<br />

support in finding specific solutions for their<br />

line of business. It is also certain that the professional<br />

support expertise anchored in truck<br />

know-how, as well as a wide range of other<br />

services, will set standards in the TGE<br />

segment and will enthuse its audience in the<br />

long run. This would especially include customer-friendly<br />

support around the clock.<br />

OVERALL, THE MAN TGE offers two wheelbases,<br />

three roof heights and likewise three<br />

vehicle length choices. Other than the closed<br />

box-type van and glazed hatchback, additional<br />

chassis with single or double cabins that<br />

come as a standard order with platform body<br />

also enhance the bodywork range. There is<br />

much variety in offered drive trains as well.<br />

5.5<br />

tonnes<br />

of admissable total weight is the punch<br />

packed by the new MAN TGE. In the MAN<br />

vehicle lineup, it covers the transport<br />

class of 3.0 to 5.5 tonnes.<br />

© Michel Devries/MAN<br />

Depending on the admissable total weight<br />

between 3.0, and 5.5 tonnes, a choice of front<br />

drives, all-wheel drives and rear drives is part<br />

of the configuration range. The maximum<br />

stowage volume of the closed box-type van<br />

amounts to roughly 18 cubic metres, while the<br />

performance of installed TDI engines cover a<br />

tight arc from 75 kW/1<strong>02</strong> hp up to 130 kW/177<br />

hp. Always included is the Emergency Braking<br />

Assistant (EBA), which will monitor traffic<br />

participants ahead and actively supports the<br />

driver in case of any sudden pattern changes.<br />

In addition, a telematics system provides information<br />

on logistics and services via<br />

numerous parameters.<br />

Generally speaking, the new MAN TGE<br />

wows with best TCO values. An optimised<br />

cost-benefit ratio and low depreciation trends<br />

also reflect outstanding efficiency and value.<br />

Xxxx This is a blind caption Xxxx<br />

please Best handling: text. But not The more balanced as 4<br />

chassis lines. Xxxxx offers Xxxxx maximum Xxxxx comfort Xxxxx<br />

with high load xxxx reserves. Xxxxx<br />

14<br />

15

IAA STORY SPECIAL<br />

<strong>02</strong>/<strong>2016</strong><br />

Next generation: The MAN plant in<br />

Nuremberg produces the new<br />

Euro 6 engines for trucks (right) as<br />

well as for buses (left).<br />

diagnosis, or OBD), which indirectly entails<br />

further emissions reduction. “This was, and<br />

still remains, a challenging project, requiring<br />

teams from engine and transmission development,<br />

from construction, from vehicle integration,<br />

and from process and project management<br />

to work hand-in-hand since the second<br />

half of 2014. Nearly 100 MAN employees from<br />

a broad range of disciplines participated in this<br />

endeavour,” reports Weiskirch.<br />

AMONG THE MANY MAN SPECIALISTS was<br />

Thorsten Oberpenning, Project Manager D2x<br />

Engine at MAN. The mechanical and automotive<br />

engineer was significantly involved in<br />

PURELY<br />

POWERFUL!<br />

The new Euro 6c emissions standard for commercial vehicles<br />

takes effect in 2017. Developers at the MAN engine plant in<br />

Nuremberg have raised the performance and efficiency of the<br />

next engine generation to a new level.<br />

© Florian Generotzky<br />

Important station on the<br />

assembly line: The<br />

pre-assembled cylinder head<br />

is set into the crankcase.<br />

“Our target:<br />

reduce emissions<br />

and enhance<br />

performance.”<br />

Thorsten Oberpenning, Project Manager<br />

D2x Engine at MAN<br />

B<br />

arely emitting a sound, the<br />

engine leaves the final stage on<br />

the D2x assembly line at 12:58 in<br />

the afternoon. A plexiglass door swings shut.<br />

Transported by lift and a conveyor belt, the<br />

aggregate is on its way to the testing area,<br />

where all engine functionalities must prove<br />

their worthiness on the bench. Around 250<br />

engines roll off the line every day at MAN’s<br />

plant in Nuremberg, with 70% built as<br />

compliant with Euro 6 regulations. Today is a<br />

little different, however. Fitted into the daily<br />

production schedule, the first Euro 6 engine<br />

from the next generation has just marked its<br />

premiere: an assembly process under routine<br />

line conditions. This rather significant occasion<br />

is duly applauded by Dr Christian Weiskirch,<br />

Head of the Engine Performance and Emissions<br />

D2x department, and his team. “This is the<br />

result of two and a half years of extremely<br />

intensive development,” explains the engineer<br />

Weiskirch. The goal: refining Euro 6 technology<br />

to comply with the next step, the Euro 6c<br />

standard, which will become mandatory in<br />

Europe as of January 2017.<br />

One of the key points contained in the regulation<br />

is that new measurement procedures<br />

will analyse the low emission values in real<br />

driving conditions and not just on the test<br />

bench. The “6c” step once more lowers the<br />

threshold for self-monitoring (onboard<br />

and responsible for the innovation process<br />

throughout the entire project phase. “Euro 6c<br />

is yet another major technological challenge,”<br />

elaborates Oberpenning. “The idea is to even<br />

further reduce CO2 emissions of already very<br />

sophisticated engines. At the same time, it<br />

was important to us to keep increasing efficiency<br />

and thereby guarantee stable emission<br />

values for up to 700,000 kilometres of road<br />

performance.” Using the new portable<br />

emissions measuring system (PEMS) allows<br />

for monitoring CO2 emissions during<br />

operation. “We managed to improve the performance<br />

of the D26 engine by 20 hp, and its<br />

torque by 200 newton metres, while demonstrably<br />

maintaining stable, low emissions,”<br />

says a satisfied Oberpenning. Due to this<br />

optimised torque, the engine now requires<br />

markedly fewer interposition changes to<br />

either reach or maintain full torque performance.<br />

“This increases the driving comfort<br />

considerably,” explains the project manager.<br />

And last but not least, the “500” goes back on<br />

the door of the D26. The hp figure has<br />

remained an important factor for truck and<br />

bus operators. Achieving the project goal to<br />

lower fuel consumption by about 2.5% is no<br />

less significant. “Cost and performance-conscious<br />

shipping companies and fleet<br />

operators simply love to hear that,” knows<br />

Thorsten Oberpenning.<br />

What can now be exactly expressed in<br />

precise figures and performance values<br />

actually emerged from a distinctly challenging<br />

innovation process for the developers. “The<br />

complexity of the tasks increased significantly<br />

16<br />

17

IAA STORY SPECIAL<br />

<strong>02</strong>/<strong>2016</strong><br />

“All specialist<br />

departments<br />

worked in tandem<br />

for Euro 6c.”<br />

Dr Christian Weiskirch, Head of Engine Performance<br />

and Emissions D2x at MAN<br />

Detailed work: An MAN employee<br />

applies assembly fittings to a<br />

connector in the pre-assembled<br />

cylinder head.<br />

as we moved closer to the Euro 6c level. To<br />

achieve our ambitious targets, everyone<br />

involved had to think outside the box from the<br />

onset and further intensify communications<br />

within the team. Whether production, procurement<br />

or controlling: Everyone actively<br />

contributed ideas and plans to enable the<br />

necessary parallelisation of these processes,”<br />

reports Weiskirch. The REACH regulation<br />

decreed by legislators, for example, mandates<br />

that main and big-end bearings must be<br />

composed of lead-free materials in future. The<br />

engine interior now reacts much more sensitively<br />

to the tiniest impurities and original dirt<br />

from the manufacturing process. The result is<br />

an entirely new assembly procedure. “We now<br />

build the engine interior under clean-room<br />

conditions and deliver it as a completely preassembled<br />

and closed system, cleanly packed<br />

in foil, directly to the assembly line,” explains<br />

Oberpenning.<br />

CONSIDERING THE MANY DETAILS and sophisticated<br />

performance traits of the new<br />

engine generation, it is almost a pity that the<br />

new Euro 6 unit looks practically identical to<br />

its predecessors at first. One noticeable<br />

feature is the circular ribbed housing in the<br />

engine front, which conceals the speed-controlled<br />

coolant pump. “It enables a demandactuated<br />

pumping of coolant. This innovation<br />

substantially contributes to engine efficiency<br />

and thus fuel savings,” states Oberpenning.<br />

When less coolant is needed, such as in longdistance<br />

travel mode for example, the<br />

required mechanical output of the water<br />

pump can be reduced by 80%. This is a benefit<br />

for both truck and bus transmissions. “We<br />

emphasise the commonalities of truck and<br />

bus engines. An extensive parity range of<br />

data and components allows us merge the developments<br />

in the bus and truck segments in<br />

an optimised fashion,” states Thorsten<br />

Oberpenning. Both engines were displayed at<br />

the MAN exhibit area at the <strong>2016</strong> IAA Commercial<br />

Vehicles Fair in Hanover. Visually, the<br />

bus engine merely differs by a flatter oil pan,<br />

several applied alternators and generators, as<br />

well as a projecting air-conditioning compressor.<br />

Obviously, bus interiors require a much<br />

higher climate-control effort than those of<br />

trucks. According to Oberpenning, the development<br />

results are “innovative standards of<br />

the highest level”. And the entire team is<br />

already certain: “This new generation of<br />

engines is a milestone on the way to a great<br />

future, for both MAN and its customers.”<br />

Unit check after endurance run: The<br />

newly developed engine generation is<br />

tested here – and approved of.<br />

The MAN development team (left to right): Thomas Binzer (Head of Engine Construction for the D20/26<br />

Series), Dr Christian Weiskirch (Head of Engine Performance and Emissions D2x), Thorsten Oberpenning<br />

(Project Manager D2x Engine), Stefan Scholz (Head of Engine Preseries Centre)<br />

2.5%<br />

fuel savings<br />

is the lowered consumption rate of the<br />

new engine generation – with enhanced<br />

performance and increased torque.<br />

© Florian Generotzky<br />

© MAN<br />

Novel concepts<br />

for networking the transport world<br />

In order to advance the intelligent management of<br />

logistics processes, MAN has developed a new digitalisation<br />

strategy that includes transport chain parties as<br />

well as data providers and users. Their interexchange<br />

creates a networked eco-system, which greatly<br />

enhances efficiency within the transport industry.<br />

Today, a multi-faceted range of<br />

information gathered on truck<br />

deployment can already be<br />

mirrored digitally. Not only are<br />

driving times and resting periods<br />

of drivers registered, for example,<br />

but the vehicle’s technical operational data is<br />

also stored. Transport companies can<br />

continuously monitor their load conditions,<br />

including the state of refrigerated goods. Fleet<br />

management systems and GPS applications<br />

18<br />

19

IAA STORY SPECIAL<br />

<strong>02</strong>/<strong>2016</strong><br />

offer the option of tracking route data and<br />

distance profiles, all the way up to individual<br />

loading and unloading stops during a tour.<br />

This creates a multitude of advantageous<br />

applications and services. Workshops can<br />

predict and plan ahead for the maintenance<br />

requirements of a vehicle and its components.<br />

Transport companies can use stored working<br />

hours of drivers to better manage personnel<br />

disposition. Precisely recorded fuel consumption<br />

per distance data greatly facilitates a<br />

much more exact calculation of the cost<br />

factor diesel than ever before. Recorded<br />

distance data also provides the basis for the<br />

professional training of drivers to effectively<br />

harness the whole efficiency potential of the<br />

overall truck system. With its Connected<br />

CoDriver programme, MAN even offers the<br />

option of training drivers directly on the job,<br />

as a trainer provides virtual attendance and<br />

driving advice based on real-time data.<br />

WHILE THE COST EFFICIENCY of single<br />

vehicles and vehicle fleets has remained at<br />

the centre of current telematics applications<br />

until now, the full potential offered by digitalising<br />

the transport industry has not yet been<br />

fully utilised so far. In cargo transport, 35% of<br />

loading capacities are still not allocated in an<br />

optimised fashion. Beyond individual<br />

transport companies, all industry players lack<br />

real-time information regarding available<br />

transport capacities and correlating exact localisation<br />

and deployability. Hauliers, dispatchers<br />

and truck drivers often possess inadequate<br />

information about logistics processes<br />

and employ a multitude of different IT<br />

systems, even though intelligent management<br />

of logistical workflows increasingly<br />

demands a comprehensive and integrated<br />

approach. This context signifies that the individual<br />

participants in the transport chain, as<br />

well as their infrastructure, ought to be more<br />

strongly interconnected and data be made interchangeable.<br />

In the light of these developments, MAN<br />

established a dedicated business area to<br />

advance digitalisation within the transport<br />

industry with new solutions and services. It is<br />

hereby essential to think more strongly along<br />

the lines of logistics processes, rather than in<br />

the established structures of a brand manufacturer,<br />

states Markus Lipinsky, Head of Telematics<br />

and Digital Solutions at MAN: “As our<br />

customers operate vehicle fleets comprising<br />

several brands, we must respond to this<br />

customer need and not just look through<br />

MAN-tinted glasses.”<br />

THINKING OUTSIDE THE BOX will also<br />

become a guideline when it comes to the integration<br />

of new partnering and business<br />

models. In May <strong>2016</strong>, MAN <strong>Truck</strong> & Bus<br />

announced its investment in the US company<br />

FR8 Revolution. Based in California’s Silicon<br />

Valley, the start-up has developed a comprehensive<br />

“operating system” for an interconnected<br />

transport industry, which provides<br />

“We interconnect all partners in the<br />

transport chain by exchanging data.”<br />

Frank Tinschert, Vice President Telematics and Digital Solutions at MAN<br />

forwarders, transport companies and drivers<br />

with an integrated and transparent platform<br />

for load planning on the basis of real-time<br />

data. The open and cross-brand platform<br />

offers the choice of making apps available to<br />

all participating target audiences. With its<br />

stake in FR8, MAN will proactively help shape<br />

the digital transformation of the industry,<br />

gather experience and apply the know-how to<br />

business models in Europe. The specific<br />

technical basis and interfaces will also be<br />

defined by MAN Telematics and Digital<br />

Solutions. As of 2017, the requisite interfaces<br />

will become available for every MAN truck to<br />

enable the data exchange needed for<br />

optimised networking.<br />

MAN’s goal is to substantially advance the<br />

digitalisation process in the commercial<br />

vehicle and transport industry – and also, as<br />

the initiator of a brand-new product category,<br />

to occupy a leading market position. To this<br />

end, a completely new brand marked its world<br />

premiere at the IAA Commercial Vehicles <strong>2016</strong><br />

trade fair in Hanover, Germany: RIO. The RIO<br />

brand stands for a digital cloud-based<br />

platform that will shape the future of the<br />

entire industry.<br />

35%<br />

of loading<br />

capacities<br />

are not fully exhausted today. MAN<br />

intends to change that through the<br />

utilisation and networking of data.<br />

© Andreas Pohlmann<br />

Believes in big data: At MAN, Frank<br />

Tinschert is responsible for the<br />

development of a comprehensive<br />

digital information platform.<br />

“The goal of our<br />

platform is real<br />

added value for<br />

customers.”<br />

Frank Tinschert<br />

“Digital Solutions” for a partnering future<br />

With “Digital Solutions,” MAN offers a based on capacities, not necessarily on brand.<br />

platform that pools not only its own services, The brand itself will become a crucial factor,<br />

but also those rendered by partners. Frank for example, when it comes to fuel consumption.<br />

Tinschert, Vice President Telematics and Digital<br />

Solutions at MAN, explains why the integration What are the advantages for partners in<br />

of partners involved in the logistics process are this cooperation? In the world of transport<br />

part of the core concept of new digital business and logistics, networking and collaboration<br />

models.<br />

play a defining role. When analysing global<br />

supply chains today, there are many participants<br />

and the exchange of information in this<br />

Mr Tinschert, what are the goals of the<br />

“Digital Solutions” platform? We intend to increasingly accelerating world of logistics<br />

create a shared platform for the participation processes and delivery deadlines is crucial.<br />

of different partners involved in transport Further processing this information to create<br />

and logistics processes. As all aspects relevant value-added services represents a substantial<br />

to business activities are taken into account, advantage for our partners. It enables them to<br />

reach customers that would have been more<br />

difficult to canvass otherwise. Thus, the cooperation<br />

also offers sales-related benefits to the<br />

partnering parties.<br />

To what extent has the partner network<br />

already been developed? We are at the very<br />

beginning of expansion and therefore remain<br />

consciously open. Every customer should use<br />

the applications contained within the platform<br />

that are suitable for business and the intended<br />

purpose. We strive to find as many partners<br />

from different business areas as possible who<br />

have understood that an island approach is no<br />

longer a good solution. Only then will we<br />

create added value for both the customers and<br />

our own marketing processes. When looking<br />

further ahead, added economic value is also<br />

this creates added value for customers. This created by better utilisation of infrastructure<br />

open standard is unique in the commercial and by seriously addressing topics such as<br />

vehicle industry.<br />

urban access via electric mobility.<br />

Which factors drove the decision to Which kind of potential can you predict<br />

open the platform for partners and their for the future? Such a platform provides the<br />

solutions? The decisive point is that fleet opportunity to not just project added value<br />

solutions can be only viewed comprehensively<br />

from a fleet perspective. Depending on the business models. One example would be the<br />

services, but to also develop entirely new<br />

fleet's focal point, there is a diverse range of so-called platooning approach, where several<br />

demands that far exceed the commercial trucks follow each other closely, thereby<br />

vehicle unit per se. When it comes to taking advantage of the slipstream. The<br />

transport services, it is not relevant which vehicle up front will have the highest fuel<br />

tractor unit is doing the job, but rather which consumption of course, so it is worth considering<br />

how these benefits might be shared,<br />

transport capacities with correlating parameters,<br />

remaining driving times and drivers especially when platooning takes place across<br />

are available. Based on that, the operator will fleets. These are the topics that we will tackle<br />

arrive at a decision – and first of all one that is in the years to come.<br />

20<br />

21

<strong>02</strong>/<strong>2016</strong><br />

Experience a day with the platooning developers at MAN<br />

on their test trip for yourself by watching the video at<br />

> youtu.be/fHibsfiIrhk<br />

Revolution in the<br />

SLIPSTRE AM Digitalisation<br />

23<br />

is also having a resounding<br />

impact on the field of transport and logistics.<br />

During the “European <strong>Truck</strong> Platooning<br />

Challenge <strong>2016</strong>”, MAN tested highly complex<br />

technologies for networked convoys on the<br />

roads. The demo trip was only the beginning.<br />

© Max Kratzer<br />

22

<strong>02</strong>/<strong>2016</strong><br />

Gathered at the MAN <strong>Truck</strong><br />

Forum in Munich on 4 April,<br />

journalists, employees and<br />

guests stood in anticipation of<br />

the starting signal, which was<br />

delivered by none other than<br />

Alexander Dobrindt. The German Minister<br />

of Transport had travelled to Bavaria for the<br />

best of reasons and announced a “milestone<br />

for digital mobility”, before symbolically<br />

pressing the red start button that would send<br />

two MAN trucks on a trip to Rotterdam to<br />

attend the European <strong>Truck</strong> Platooning<br />

Challenge <strong>2016</strong>.<br />

The call for participation had been made<br />

by the Dutch government, which held the EU<br />

Council Presidency in the first half of <strong>2016</strong>.<br />

<strong>Truck</strong> platoons of various manufacturers<br />

journeyed to Rotterdam in a radial pattern<br />

from Germany, Sweden and Belgium with the<br />

aim of testing platooning technologies as a<br />

solution for the future transport of goods.<br />

Dense traffic is not an obstacle: The<br />

platooning technology also makes<br />

allowances for other road users.<br />

The MAN developers have been working<br />

on autonomous driving technologies for<br />

several years. They believe it conceivable that<br />

truck platoons could be introduced in Europe<br />

by the year 2<strong>02</strong>0. Naturally, the implementation<br />

depends on legal parameters, for the EU<br />

member states as well as partners from<br />

industry and transportation planning must<br />

first harmonise traffic regulations and legislation<br />

and develop a coherent and comprehensive<br />

system for all brands.<br />

The next step in this direction was taken<br />

in Berlin on 13 April <strong>2016</strong>. On that day,<br />

Minister of Transport Alexander Dobrindt set<br />

off another important start signal, namely in<br />

the shape of a legislative draft expanding the<br />

legal framework for self-driving cars. It<br />

proposes that automated driving systems<br />

may assume an ever growing range of driving<br />

responsibilities. “Automated and networked<br />

“This is indeed<br />

a milestone for<br />

digital mobility.”<br />

Alexander Dobrindt, German Federal Minister of<br />

Transport and Digital Infrastructure<br />

Working together: (Left to right)<br />

Joachim Drees, CEO of MAN<br />

<strong>Truck</strong> & Bus, Andreas Renschler,<br />

CEO of Volkswagen <strong>Truck</strong> & Bus,<br />

and German Federal Minister of<br />

Transport Alexander Dobrindt<br />

press the start button for the<br />

European <strong>Truck</strong> Platooning<br />

Challenge.<br />

driving is the greatest revolution in mobility<br />

since the invention of the automobile,” said<br />

Dobrindt. “We want to put this technology on<br />

the roads.” And MAN is ready to supply the<br />

right vehicles for this challenge.<br />

THIS DIGITAL TECHNOLOGY opens up<br />

entirely new possibilities for making the<br />

transport industry more efficient as well as<br />

more sustainable. In so-called platooning, or<br />

networked driving in a convoy formation, the<br />

distance between two or three vehicles is continuously<br />

kept to a minimum with the help of<br />

state-of-the art technology. While synchronised<br />

driving patterns and slipstream<br />

benefits allow for a reduction in both fuel<br />

consumption and emissions of up to 10%, this<br />

strategy also eases the stress of drivers over<br />

long distances.<br />

Yet what about safety? During the test<br />

drive to Rotterdam, for example, cars were repeatedly<br />

squeezing in between the two<br />

trucks. According to Xaver Römersperger,<br />

who occupied the passenger seat in the<br />

leading truck, this is no reason for concern:<br />

“The system is prepared for such situations<br />

and automatically decouples the platoon,”<br />

explains the MAN development engineer. The<br />

articulated trucks initially make room for the<br />

other road user and return to their original<br />

platoon formation as soon as that traffic participant<br />

has left the gap between the two<br />

trucks. In addition, the computer-controlled<br />

vehicle reacts much faster than any person<br />

could. Digital technology could therefore<br />

effectively assist in the prevention of<br />

accidents, for 90% of all traffic crashes are<br />

caused by human error. European countries<br />

alone register more than 30,000 accidents<br />

annually. The modern advanced driver assistance<br />

systems (ADAS) actually make driving<br />

in platoon formation safer for everyone on<br />

the road.<br />

ONCE IN ROTTERDAM, the platoons were<br />

received by Melanie Schultz van Haegen, the<br />

Dutch Minister of Infrastructure and the Environment.<br />

“We are currently showing the<br />

world that we’re ready for truck platooning<br />

reaching beyond borders and for an entirely<br />

new era of mobility,” she said when greeting<br />

the participants. MAN project manager<br />

Daniel Heyes was also very pleased: “Our<br />

technology has proven successful over the<br />

long distance.” The task ahead now, says<br />

Heyes, is to constructively channel the excitement<br />

that the demonstration tour created<br />

among all manufacturers. “This platooning<br />

challenge set an example: We must take the<br />

next steps in automated driving together.”<br />

Successful final rehearsal: Daniel Heyes,<br />

Project Leader Platooning at MAN,<br />

was pleased with the Rotterdam test trip.<br />

10%<br />

fuel savings<br />

is the maximum reduced consumption<br />

level of trucks driving in platoon<br />

formation. This would also reduce CO ²<br />

emissions by the same amount.<br />

© Max Kratzer (1), MAN (2)<br />

The platooning technology<br />

ITS G5 antenna<br />

Camera<br />

Radar<br />

Lidar (laser scanner)<br />

Steering system<br />

Following vehicle<br />

10 m<br />

PLATOONING is a system for coordinating vehicles in road<br />

traffic, whereby two or more trucks follow another closely in a<br />

convoy formation by utilising technical driving assistance and<br />

guidance systems as well as car-to-car communications. The<br />

vehicle clearance amounts to about 10 to 15 metres or a halfsecond<br />

of driving time. All of the trucks incorporated in the<br />

platoon formation – making up the entire articulated truck<br />

convoy – are connected through a so-called electronic drawbar.<br />

The vehicle up front sets the speed and direction during the<br />

distance. The necessary guidance commands are signalled to<br />

the following vehicles via WLAN, which in turn return feedback<br />

to the leading truck.<br />

Leading vehicle<br />

Vehicle communication via WLAN (ITS G5)<br />

Continuous exchange of information such as:<br />

▪▪Status of the platoon<br />

▪▪Speed, acceleration and braking delays<br />

▪▪Approximate GPS position<br />

24<br />

25

<strong>02</strong>/<strong>2016</strong><br />

MAN has<br />

the muscle<br />

for heavy-duty lifting jobs<br />

150<br />

tonnes<br />

is the weight of the trucks that support<br />

crane operations and are always<br />

fully loaded for optimised leverage.<br />

“The new D38 Euro 6 engine with<br />

560 hp was a natural choice, as<br />

the wide range of torque with up<br />

to 2,900 Nm is very impressive.”<br />

John Sutch, Managing Director, John Sutch Cranes<br />

With locations in Liverpool and<br />

Manchester, John Sutch Cranes<br />

provides lifting operations<br />

across a wide industry range.<br />

The mobile crane hire and<br />

machine installation<br />

specialist John Sutch Cranes<br />

operates an MAN fleet to<br />

support the most complex<br />

and challenging national<br />

projects.<br />

THE PRODUCT PORTFOLIO of MAN <strong>Truck</strong> &<br />

Bus UK made such a lasting impression on<br />

specialist John Sutch Cranes that founder and<br />

Managing Director John Sutch added a new<br />

MAN TGX 26.560 6x4 D38 to his fleet. The new<br />

truck is plated at 150 tonnes gross train<br />

weight. Sutch explains why MAN remains his<br />

first choice for crane support work: “We have<br />

eight 150-tonne trucks in the fleet and they<br />

are all MANs. Simply because they have never<br />

once let us down. Carrying the ballast needed<br />

for the cranes to operate, the trucks function<br />

as support vehicles to the cranes and travel<br />

throughout the UK fully loaded.”<br />

Supported by a highly trained operative<br />

staff and an in-house team that incorporates<br />

rigging, transport and project management,<br />

the crane fleet is at the centre of the company.<br />

“We have never been disappointed by the<br />

MAN crew or their vehicles. They go in at<br />

night for repair and maintenance and are<br />

ready to go back out the next morning,<br />

without us suffering any downtime,” lauds<br />

Sutch. “MAN <strong>Truck</strong> & Bus Manchester has<br />

provided us with excellent service for the last<br />

20 years, and we are still running vehicles<br />

that are about 10 years old. The operators like<br />

them and they are reliable.” MAN has enjoyed<br />

an excellent reputation in crane ballast and<br />

heavy plant and low-loader operations for a<br />

long time. As John Donnelly, MAN’s heavy<br />

haulage specialist, remarked: “The image that<br />

MAN has perfected makes us the first choice<br />

for entrepreneurs such as John Sutch when<br />

they are looking to expand their fleets.”<br />

26<br />

27

<strong>02</strong>/<strong>2016</strong><br />

Showpiece carrier<br />

for expanding recovery firm<br />

Auto vehicle specialist in Worcestershire adds MAN TGL<br />

to its original fleet to meet growing business demand.<br />

Appreciated for its reliability and<br />

added service value, the new<br />

addition to AVS Recovery’s fleet<br />

also stands out visually.<br />

“This will certainly<br />

be the showpiece<br />

of our fleet.”<br />

Simon Chance, owner of AVS Recovery<br />

CAR RECOVERY SPECIALIST AVS Recovery<br />

sourced its first brand-new truck from MAN<br />

<strong>Truck</strong> & Bus UK recently. Run by Simon<br />

Chance together with his wife, Karen, and<br />

based in Kidderminster, Worcestershire, AVS<br />

Recovery has opted for a 12-tonne MAN TGL<br />

chassis with a slide bed body supplied by<br />

transportation system manufacturer Roger<br />

Dyson of Droitwich.<br />

Chance explains his choice: “I worked for<br />

AVS Recovery for a number of years and was<br />

happy to grab the opportunity and buy the<br />

company eight years ago. It was a huge leap for<br />

my wife and I, but we diligently worked on it<br />

and have succeeded in building it up since<br />

then.” While the MAN TGL is the first<br />

brand-new vehicle of this size for AVS<br />

Recovery, the small company had been well<br />

acquainted with MAN’s product range: “I<br />

know a number of people in the haulage<br />

industry who run them, and they are all<br />

impressed by economy and reliability. Also,<br />

unlike some manufacturers, MAN does not<br />

ask for thousands of pounds worth of warranties<br />

before you even buy a vehicle.”<br />

As emphasised by Chance, this purchase<br />

represents a major investment for his<br />

company. When initially taking over AVS<br />

Recovery, its staff comprised just four and<br />

has since then grown to 12, with 24-hour operations<br />

and contracted to work for a dozen<br />

major insurance companies. “I want the<br />

vehicle to look right and create the right impression<br />

for our business. In addition I have<br />

spent a few thousand on lights and horns,<br />

just because I love my vehicles!” The TGL will<br />

be added to the 11-strong fleet. Simon added:<br />

“While still operating an older fleet, we have<br />

brought the vehicles up to standard, but this<br />

will become the showpiece of the fleet. I<br />

therefore also intend to show it at a number<br />

of events, either by itself or when carrying<br />

other exhibit vehicles.”<br />

ROGER DYSON Sales Manager Tony Rayner<br />

observes that the budding growth of AVS<br />

Recovery is due to a lot of hard work: “They<br />

really deserve to do well, and we were happy<br />

to create this personalised body for him and<br />

look forward to seeing it out on the road,<br />

whether it’s working or at exhibitions.” Tony<br />

Bobs of MAN adds: “Simon has clearly done a<br />

great deal of research before committing to<br />

buying the brand-new recovery vehicle for<br />

his business. MAN is delighted to have met<br />

his requirements and that he is such an enthusiastic<br />

ambassador for our brand.”<br />

Configurations for<br />

every customer<br />

Specialised-vehicle hire firm receives two upgraded and<br />

configured MAN TGS 35.480 8x2 rigids to meet the<br />

precise demands of a high-end customer.<br />

Responding to the specific needs<br />

as outlined by a customer,<br />

specialist vehicle firm LC Vehicle<br />

Hire turned to MAN <strong>Truck</strong> & Bus<br />

UK. It ultimately took delivery of<br />

two hookloader vehicles fitted<br />

with LX hi-roof sleeper cabs and draw bars.<br />

Antony Fensom, fleet engineer with LC Vehicle<br />

Hire, said: “Our customer Celtic Recycling<br />

came to us looking for a hookloader and<br />

trailer with a sleeper cab. We have a few older<br />

MAN vehicles and we knew that the TGS would<br />

meet their requirements for manoeuvrability<br />

as well as offering greater fuel economy.”<br />

ONCE CELTIC RECYCLING saw the offered<br />

specifications and possible options, the<br />

hazardous waste specialist entered into an<br />

agreement for a five-year lease. Mark Smith,<br />

transport manager for Celtic Recycling, adds:<br />

Celtic Recycling specialises in<br />

recovery, management and<br />

recycling of redundant heavy<br />

electrical equipment.<br />

“We have actually operated an MAN since<br />

2013 and have been very happy with it. So we<br />

knew the benefits and advantages of the new<br />

lease model.”<br />

Covering an area from Cornwall to<br />

Cumbria, 95% of the recycling and recovery<br />

company’s operations comprise driving on<br />

motorways. The new vehicles have been<br />

upgraded with increased engine capacity to<br />

accommodate running at 44 tonnes when<br />

pulling a drag, an air deflector kit to alleviate<br />

drag and improve mpg, and a larger fuel tank.<br />

“Everyone so far is delighted with the new<br />

TGS, and we are hoping that, over the long<br />

term, the benefits will also show in the mpg<br />

results. The trucks are additions to our fleet<br />

and have been brought in to meet the<br />

demands of an increased workload.”<br />

Steve Walsh from MAN explains that “the<br />

spec required a multi-axle rigid drawbar with<br />

the comfort, power and fuel efficiency of a<br />

tractor unit. Using an increasingly popular 8x2<br />

rear lift chassis configuration, Celtic Recycling<br />

now runs perfectly matched vehicles with<br />

reduced costs and more efficiency.”<br />

28<br />

29

<strong>02</strong>/<strong>2016</strong><br />

All that is new<br />

with a powerhouse partner<br />

Love at first sight: When<br />

nephew and driver Joshua<br />

Hughes saw the TGX 26.560,<br />

he was smitten.<br />

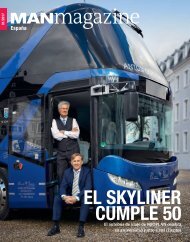

NEOPLAN Select is first<br />

choice for operator<br />

MAN TRUCK & BUS UK once again benefited<br />

from its reputation for quality and service to<br />

secure a contract with Bicester-based Grayline<br />

Coaches. The operator has just taken delivery<br />

of a NEOPLAN Tourliner Select P20 and says<br />

MAN offers “peace of mind due to service and<br />

quality”. Paul Gray, Operations Manager at<br />

Grayline, said he was impressed with the specification<br />

and manufacturing quality offered<br />

by the new Select range: “We have operated<br />

MAN-powered vehicles for many years<br />

because of their reliability, economy and performance.<br />

This new Tourliner fits in with the<br />

rest of our fleet, and our drivers and passengers<br />

are impressed with the overall package.”<br />

“We have operated<br />

MAN-powered<br />

vehicles for many<br />

years because<br />

of their reliability,<br />

economy and<br />

performance.”<br />

Paul Gray, Operations Manager at Grayline<br />

The travel logistics expert is reassured: “As operations<br />

manager, I can sleep easily at night<br />

knowing that the vehicle can go anywhere in<br />

Europe and has full back-up and support.”<br />

Grayline Coaches not only considers the<br />

NEOPLAN a great product in terms of quality,<br />

but also appreciates the formidable priceperformance<br />

ratio. MAN sales executive Jeff<br />

Edwards, who acted as the customer liaison in<br />

the Grayline Coaches purchase, said: “We are<br />

delighted that Grayline recognises the quality<br />

and support services associated with<br />

NEOPLAN coaches.”<br />

The NEOPLAN Tourliner Select offers an<br />

impressive range of specifications, including<br />

53 reclining seats with three-point seat belts, a<br />

centre toilet, air conditioning, DVD player with<br />

additional monitors, refrigerator, drinks<br />

machine and an Eberspächer heater.<br />

From a performance perspective, the Euro<br />

6-compatible vehicle features a 12.4-litre MAN<br />

D26 engine, producing 440 hp, as well as an<br />

AS Tronic 12-speed automated gearbox.<br />

refrigerator, DVD player and three-point seat<br />

belts. The Euro 6 standard performance comes<br />

from a 12.4-litre MAN D26 engine producing<br />

44o hp and an AS Tronic 12-speed automated<br />

gearbox. KB Coaches owner Andy Francis<br />

Longtime MAN customer<br />

chooses an MAN TGX<br />

26.560 XXL Centenary<br />

edition truck as its first<br />

brand-new vehicle.<br />

When independent freight<br />

forwarder and logistics<br />

company Genesis 2014<br />

was looking for its first<br />

brand-new vehicle, MAN<br />

<strong>Truck</strong> & Bus UK was the<br />

supplier of choice. Manager Marcus Hughes,<br />

himself a devotee to the MAN brand, admits<br />

that he also gave in to family pressure when<br />

his nephew spotted his dream truck – the<br />

MAN TGX 26.560 XXL Centenary edition.<br />

Hughes explains: “As a company, we have<br />

always run MAN. As the business has<br />

expanded and grown in recent years, we<br />

found ourselves sourcing older vehicles from<br />

MAN.” Nowadays, Genesis 2014 operates 15<br />

trucks for its freight forwarding and logistics<br />

business and needed to re-evaluate fleet costs.<br />

The company considered running costs and<br />

fuel efficiency, as well as the requirements to<br />

meet Euro 6 standards. “When my nephew<br />

Joshua Hughes, who is also a driver here,<br />

spotted this specific truck, he knew it was<br />

exactly what he wanted, and we entered into a<br />

three-year rental contract,” recalls Hughes. “I<br />

like the MAN brand anyway, and he wanted a<br />

560, so it all worked out very well. There is no<br />

point in operating vehicles that the drivers<br />

don’t like, and all our drivers like MAN trucks.<br />

In fact, I have placed an order for four more<br />

TGX 26.480s.”<br />

Based in Stoke-on-Trent, Genesis 2014 has<br />

contracts with Amazon and Marks & Spencer<br />

and the new truck travels nationwide. MAN<br />

sales executive Paul Hollamby adds: “The firm<br />

has remained loyal to MAN over the years and<br />

it is great that they have remained with us to<br />

invest in their first brand-new truck.”<br />

To greater lengths with<br />

NEOPLAN Tourliner<br />

GLOUCESTERSHIRE-BASED KB COACHES has<br />

taken delivery of a NEOPLAN Select Tourliner<br />

from MAN <strong>Truck</strong> & Bus UK. MAN sales<br />

executive Jeff Edwards said: “The 13.8-metrelong<br />

chassis is the longest we offer and is<br />

certainly the longest in the KB Coaches fleet.”<br />

For safety, the customer opted for reversing<br />

and centre door cameras, while passenger<br />

comfort is enhanced by a fresh- water-flushing<br />

toilet, air conditioning, a drinks machine and<br />

observed: “We are very happy with the performance<br />

of our new Tourliner Select. It is the<br />

largest vehicle in our fleet, and initially we<br />

were a little apprehensive about its length, but<br />

the rear steer allows for great manoeuvrability.<br />

We are also impressed by the fuel economy<br />

of such a large vehicle.”<br />

13.8<br />

metres<br />

is the chassis length, which renders the<br />

NEOPLAN Select Tourliner the longest<br />

vehicle in the fleet of KB Coaches.<br />

30<br />

31

<strong>02</strong>/<strong>2016</strong><br />

<strong>Truck</strong>s To Go for soil<br />

Diabolical looks, great taste:<br />

The newly delivered MAN TGL<br />

is designed to turn heads and<br />

deliver the thirst-quenching goods.<br />

Cheers<br />

to devilish design!<br />

TGL and a 12-tonne MAN TGL, the brewery<br />

team also liked how its local MAN dealership,<br />

Imperial Commercials Peterborough, cares<br />

for both the trucks and customer service. “All<br />

the vehicles promote different ales, but this<br />

new truck promoting our Green Devil beer is<br />

certainly eye-catching,” said Mashford.<br />

Recycling company relies on four new MAN TGS tippers<br />

to handle its landfill restoration business<br />

THE SOUTHAMPTON-BASED company Inert<br />

Recycling received four new TGS 35.400 8x4<br />

tippers from MAN <strong>Truck</strong> & Bus UK through<br />

the <strong>Truck</strong>s To Go scheme. The vehicles were<br />

provided via MAN Rental and are on a full<br />

repair and maintenance contract.<br />

Colin Donnelly, Transport Manager at<br />

Inert, explained that “we currently run a fleet<br />

of 25 tippers. Our Managing Director Keith<br />

Larner thought that the time was right to trial<br />

a new tipper model to compare performance<br />

against our existing fleet of 23 Mercedes<br />

trucks.” As the MANs were available through<br />

Poised for deployment: A total of four<br />

new MAN TGS 35.400 8x4 tippers will<br />

support landfill restoration efforts in the<br />

south of England.<br />

the <strong>Truck</strong>s To Go scheme, the company signed<br />

up for all four and was able to deploy them all<br />

within just two weeks. Inert Recycling also<br />

found itself rather impressed by the services<br />

provided, both by the sales team based in<br />

Southampton and the MAN fitters at Fareham.<br />

“This arrangement has proven to be a<br />

very good deal for us, and though we are still<br />

at an early stage in their promising performance,<br />

we are certainly looking to doing<br />

more business with MAN in the future,” says<br />

Donnelly. The trucks will be servicing Inert<br />

Recycling’s landfill restoration business by<br />

carrying contaminant-free inert soil to<br />

former landfill sites in the south of England.<br />

MAN Sales Executive Aaron Tamplin said:<br />

“The <strong>Truck</strong>s To Go scheme offers customers<br />

the opportunity to acquire ready-built trucks<br />

and bodies without the standard factory build<br />

lead times. Customers such as Inert Recycling,<br />

that were looking for a standard vehicle to<br />

fulfil their tipper needs, are thereby offered a<br />

fast and cost-effective solution.”<br />

“The time was right<br />

to trial a new tipper<br />

model to compare.”<br />

Colin Donnelly, Transport Manager, Inert Recycling<br />

NEIL GALLOWAY, Operations Director at<br />

Independent brewery toasts its new MAN TGL delivery<br />

truck, which is styled to draw attention.<br />

Quirky and innovative, the awardwinning<br />

brewery Oakham Ales<br />

is saluting MAN <strong>Truck</strong> & Bus UK<br />

for its latest flag-bearer. The<br />

company has recently taken<br />

delivery of a 7.5-tonne MAN<br />

TGL 8.180BB at their Peterborough base, and<br />

the truck is certainly making an impact with<br />

a striking design that promotes the popular<br />

and prize-winning Green Devil Indian Pale<br />

Ale. The vehicle is supplied on a five-year<br />

contract hire agreement. MAN sales executive<br />

Terry Mashford said: “For a growing company<br />

such as Oakham Ales, the contract hire option<br />

was the best solution to meet its business<br />

needs.” Already operating a 7.5-tonne MAN<br />

Oakham Ales, observed that “we are not<br />

haulage operators, so the five-year contract<br />

hire means that we benefit the most from our<br />

vehicles in terms of running costs, repair and<br />

maintenance. We are indeed well looked after<br />

by our dealer, and when we needed another<br />

vehicle, returning to MAN seemed an obvious<br />

choice.” Marketing Manager Nigel Wattam<br />