Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

sanded and polished <strong>the</strong>m to gleam<strong>in</strong>g perfection. Similarly, for <strong>the</strong> second and<br />

third place trophies, I cut our logo <strong>in</strong>to <strong>the</strong> tops of smaller, two-eared and<br />

earless sp<strong>in</strong>ners donated by Franz Bachmann and Bill Weeks.<br />

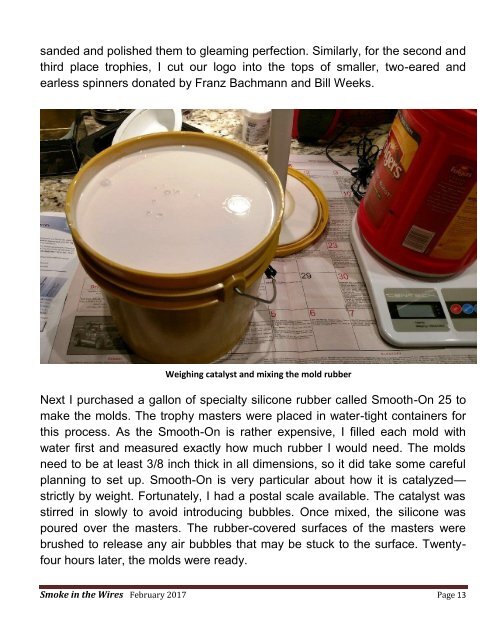

Weigh<strong>in</strong>g catalyst and mix<strong>in</strong>g <strong>the</strong> mold rubber<br />

Next I purchased a gallon of specialty silicone rubber called Smooth-On 25 to<br />

make <strong>the</strong> molds. The trophy masters were placed <strong>in</strong> water-tight conta<strong>in</strong>ers for<br />

this process. As <strong>the</strong> Smooth-On is ra<strong>the</strong>r expensive, I filled each mold with<br />

water first and measured exactly how much rubber I would need. The molds<br />

need to be at least 3/8 <strong>in</strong>ch thick <strong>in</strong> all dimensions, so it did take some careful<br />

plann<strong>in</strong>g to set up. Smooth-On is very particular about how it is catalyzed—<br />

strictly by weight. Fortunately, I had a postal scale available. The catalyst was<br />

stirred <strong>in</strong> slowly to avoid <strong>in</strong>troduc<strong>in</strong>g bubbles. Once mixed, <strong>the</strong> silicone was<br />

poured over <strong>the</strong> masters. The rubber-covered surfaces of <strong>the</strong> masters were<br />

brushed to release any air bubbles that may be stuck to <strong>the</strong> surface. Twentyfour<br />

hours later, <strong>the</strong> molds were ready.<br />

<strong>Smoke</strong> <strong>in</strong> <strong>the</strong> <strong>Wires</strong> <strong>February</strong> <strong>2017</strong> Page 13