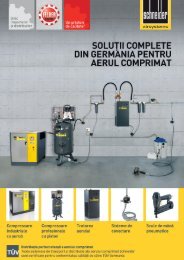

Catalog Schneider Airsystems 2017

Descoperiti gama completa solutii pentru aerul comprimat. Compresoare profesionale mobile cu piston | Compresoare profesionale stationare cu piston | Compresoare industriale cu surub | Solutii pentru tratarea aerului comprimat | Sisteme de conectare pentru aerul comprimat | Scule de mana pneumatice

Descoperiti gama completa solutii pentru aerul comprimat. Compresoare profesionale mobile cu piston | Compresoare profesionale stationare cu piston | Compresoare industriale cu surub | Solutii pentru tratarea aerului comprimat | Sisteme de conectare pentru aerul comprimat | Scule de mana pneumatice

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Which is the right compressor for the job?<br />

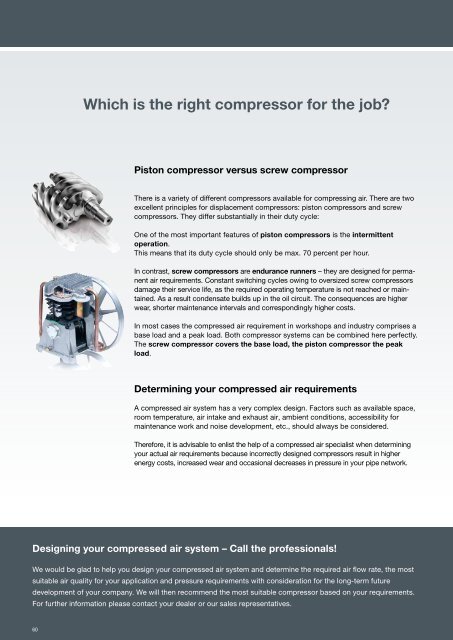

Piston compressor versus screw compressor<br />

There is a variety of different compressors available for compressing air. There are two<br />

excellent principles for displacement compressors: piston compressors and screw<br />

compressors. They differ substantially in their duty cycle:<br />

One of the most important features of piston compressors is the intermittent<br />

operation.<br />

This means that its duty cycle should only be max. 70 percent per hour.<br />

In contrast, screw compressors are endurance runners – they are designed for permanent<br />

air requirements. Constant switching cycles owing to oversized screw compressors<br />

damage their service life, as the required operating temperature is not reached or maintained.<br />

As a result condensate builds up in the oil circuit. The consequences are higher<br />

wear, shorter maintenance intervals and correspondingly higher costs.<br />

In most cases the compressed air requirement in workshops and industry comprises a<br />

base load and a peak load. Both compressor systems can be combined here perfectly.<br />

The screw compressor covers the base load, the piston compressor the peak<br />

load.<br />

Determining your compressed air requirements<br />

A compressed air system has a very complex design. Factors such as available space,<br />

room temperature, air intake and exhaust air, ambient conditions, accessibility for<br />

maintenance work and noise development, etc., should always be considered.<br />

Therefore, it is advisable to enlist the help of a compressed air specialist when determining<br />

your actual air requirements because incorrectly designed compressors result in higher<br />

energy costs, increased wear and occasional decreases in pressure in your pipe network.<br />

Designing your compressed air system – Call the professionals!<br />

We would be glad to help you design your compressed air system and determine the required air flow rate, the most<br />

suitable air quality for your application and pressure requirements with consideration for the long-term future<br />

development of your company. We will then recommend the most suitable compressor based on your requirements.<br />

For further information please contact your dealer or our sales representatives.<br />

60