Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

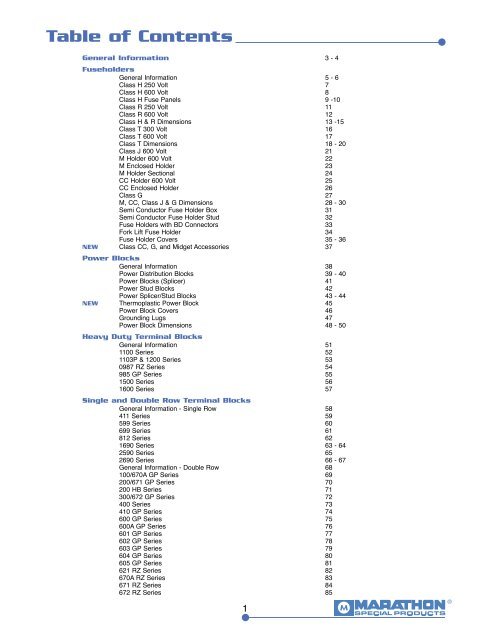

Table of Contents<br />

General Information 3 - 4<br />

Fuseholders<br />

General Information 5 - 6<br />

Class H 250 <strong>Volt</strong> 7<br />

Class H <strong>600</strong> <strong>Volt</strong> 8<br />

Class H Fuse Panels 9 -10<br />

Class R 250 <strong>Volt</strong> 11<br />

Class R <strong>600</strong> <strong>Volt</strong> 12<br />

Class H & R Dimensions 13 -15<br />

Class T 300 <strong>Volt</strong> 16<br />

Class T <strong>600</strong> <strong>Volt</strong> 17<br />

Class T Dimensions 18 - 20<br />

Class J <strong>600</strong> <strong>Volt</strong> 21<br />

M Holder <strong>600</strong> <strong>Volt</strong> 22<br />

M Enclosed Holder 23<br />

M Holder Sectional 24<br />

CC Holder <strong>600</strong> <strong>Volt</strong> 25<br />

CC Enclosed Holder 26<br />

Class G 27<br />

M, CC, Class J & G Dimensions 28 - 30<br />

Semi Conductor Fuse Holder Box 31<br />

Semi Conductor Fuse Holder Stud 32<br />

Fuse Holders with BD Connectors 33<br />

Fork Lift Fuse Holder 34<br />

Fuse Holder Covers 35 - 36<br />

NEW Class CC, G, and Midget Accessories 37<br />

Power Blocks<br />

General Information 38<br />

Power Distribution Blocks 39 - 40<br />

Power Blocks (Splicer) 41<br />

Power Stud Blocks 42<br />

Power Splicer/Stud Blocks 43 - 44<br />

NEW Thermoplastic Power Block 45<br />

Power Block Covers 46<br />

Grounding Lugs 47<br />

Power Block Dimensions 48 - 50<br />

Heavy Duty Terminal Blocks<br />

General Information 51<br />

1100 Series 52<br />

1103P & 1200 Series 53<br />

0987 RZ Series 54<br />

985 GP Series 55<br />

1500 Series 56<br />

1<strong>600</strong> Series<br />

Single and Double Row Terminal Blocks<br />

57<br />

General Information - Single Row 58<br />

411 Series 59<br />

599 Series 60<br />

699 Series 61<br />

812 Series 62<br />

1690 Series 63 - 64<br />

2590 Series 65<br />

2690 Series 66 - 67<br />

General Information - Double Row 68<br />

100/670A GP Series 69<br />

200/671 GP Series 70<br />

200 HB Series 71<br />

300/672 GP Series 72<br />

400 Series 73<br />

410 GP Series 74<br />

<strong>600</strong> GP Series 75<br />

<strong>600</strong>A GP Series 76<br />

601 GP Series 77<br />

602 GP Series 78<br />

603 GP Series 79<br />

604 GP Series 80<br />

605 GP Series 81<br />

621 RZ Series 82<br />

670A RZ Series 83<br />

671 RZ Series 84<br />

672 RZ Series 85<br />

1

Terminal Block Accessories<br />

General Information Kliptite/Quick Connect 86<br />

Single Row Kliptite/Quick Connect 87<br />

Double Row Kliptite/Quick Connect 88<br />

Solder Terminals (ST & 3/4 ST) 89<br />

Solder Terminals (Y, YSY, Z) 90<br />

J, RJ, RJS Jumpers, Wire Clamp, Straddle Plate 91<br />

Fanning Strips 92<br />

Stud & Turret Terminal Blocks 93<br />

Top Mounted Covers 94<br />

Sub Mounted Marking Strips 95<br />

Top Mounted Marking Strips 96<br />

Kulka ¨â Marker and Insulator Strips 97<br />

Kulka ¨â Single Row Marker Strip Dimensions 98<br />

Kulka ¨â Double Row Marker Strip Dimensions 99<br />

Marking Styles 100<br />

Terminal Block Printing 101<br />

Sectional Terminal Blocks<br />

General Information 102<br />

3/8" Sectional Block 103 - 105<br />

1/2" Sectional Block 106 - 107<br />

3/8" DIN Sectional Block 108 - 109<br />

11/16" Sectional Fuse Holder 110<br />

NEW DIN Rail Terminal Blocks<br />

General Information 111<br />

MIK3 112<br />

MIK5 113<br />

MIK10 114<br />

MIK16 115<br />

MIK25 116<br />

DIN Rail Disconnect - MIKTS4 117<br />

Fuse Terminal Block - MIKSI5 118<br />

Ground Terminal Blocks<br />

MIKE4 119<br />

MIKE10 119<br />

MIKE16 119<br />

DIN Rail Adapter 120<br />

Military and Navy Class Terminal Blocks<br />

General Information - Military Class 121<br />

37TB B Series 122<br />

37TB F & 38TB F Series 123<br />

39TB F & 40 TB F Series 124<br />

41TB F & 42TB F Series 125<br />

LD, LS Options 126<br />

General Information - Navy Class 127<br />

3TB, 4TB, 5TB, 6TB Series 128<br />

7TB, 8TB, 9TB, 10TB, 11TB Series 129<br />

15TB, 16TB, 17TB, 25TB, 26TB Series 130<br />

NEW Studded Power Feed Thru Terminal Blocks<br />

General Information - ST722 Family/Cover 131<br />

ST722B25 Series (back mount) 132<br />

ST722S25 Series (slide-in mount) 133<br />

ST722E25 Series (end mount) 134<br />

NEW Single Stud Connection Block - ST710 135<br />

Index 136 - 137<br />

Terms and Conditions 138 - 139<br />

Warnings and Cautions 140<br />

2<br />

Table of Contents

General Information<br />

Marathon Special Products, a REGAL-BELOIT Company, has served the electrical/electronic component industry for over 70<br />

years. Our facility in Bowling Green, Ohio contains all manufacturing and warehousing operations including an extensive electrical<br />

test lab.<br />

We offer a broad range of fuse holders and terminal blocks, including Kulka ¨ terminal blocks. In addition, we have the<br />

expertise to design and manufacture non-standard products for specific customer applications.<br />

On February 1, 1994 Marathon Special Products was registered to ISO 9002 quality standards.<br />

Marathon Special Products also offers a line of DIN sectional terminal blocks.<br />

Agency Approvals:<br />

The majority of products manufactured by Marathon Special Products are Underwriters Laboratories and Canadian Standards<br />

Association approved.<br />

The approval status of products can be found throughout the catalog. Below are the different approval forms and brief<br />

descriptions.<br />

UL Listed by Underwriters Laboratories, products are quality for use in equipment without end use agency<br />

approval when applied within products rated performance.<br />

UR Recognized by Underwriters Laboratories suitable for use only in end use equipment where<br />

Underwriters Laboratories determine acceptability of the combination.<br />

CSA Certified by Canadian Standards Association, suitable for use in other equipment where Canadian<br />

Standards Association determines the suitability of the combination.<br />

Compliance with European Union Low <strong>Volt</strong>age Directive.<br />

Tightening Torque:<br />

Recommended tightening torque is listed for all products, either on the carton label or the product label. All torque<br />

recommendations are based on UL 486. In some cases, because of various connector designs, our recommended torque is<br />

different from the torque tables shown in UL 486. However, these products passed the heating cycling and static heating tests<br />

as specified in UL 486.<br />

Wire Ampacity:<br />

The ampacity of a wire is its current carrying capacity with reference to the cross sectional area of the conductor(s), the<br />

temperature rating of the insulation and ambient temperature.<br />

Marathon specified wire ranges are based on UL approved tests using 75¡ C wire. Wires with temperature ratings other than<br />

75¡ C are approved while observing NEC Article 310 wire tables for allowable ampacities of insulated conductors. Marathon<br />

voltage and amperage ratings remain constant and are independent of the temperature rating of the wire using in application.<br />

Wire gauges and type must remain within the Marathon specified ranges to be UL approved. However, UL approval for higher<br />

currents may be obtained in some end-use applications.<br />

3

Wire Chart:<br />

Stranded wire sizes and ampacity for 75¡ C copper wire.<br />

Tolerances for Catalog Dimensions:<br />

General Information<br />

Length Dimensions Tolerance All Other Dimensions Tolerance<br />

1.0Ó-5.0Ó .030 X.XÓ .050<br />

5.1Ó-10.0Ó .050 X.XXÓ .030<br />

10.1Ó-15.0Ó .060 X.XXXÓ .010<br />

Note: Catalog Dimensions are for Guidance only and are not to be construed as inspection standards.<br />

This catalog is intended to present product data that will help the end user with design application. Since changes to products<br />

occur, it is recommended that the end user request samples for evaluation. Marathon Special Products reserves the right to<br />

change or update without notice.<br />

4

5-37.Fuseholders 11/20/03 11:21 AM Page 5<br />

Fuse Holders<br />

General Information:<br />

Marathon has been manufacturing quality fuse holders for over 30 years. The key word is quality. It is<br />

incorporated into every Marathon fuse holder, right along with design.<br />

The product line includes a broad range of holders to accommodate the following fuses: Class H, K, R, T,<br />

J, CC, G, CD and M (miscellaneous).<br />

The majority of these fuse holders are available in 250 and <strong>600</strong> volts at current ratings from 30 through <strong>600</strong><br />

amperes.<br />

The Class R, T, J, CD and CC fuse holders have passed 200,000 ampere high current interrupt testing in<br />

accordance with UL standard UL 512 for fuse holders.<br />

Class R and CC fuse holders have a rejection feature which prevents the insertion of a fuse with lower<br />

interrupting rating. The size of Class T and J fuse holders prevent the insertion of a fuse with lower<br />

interrupting rating.<br />

Fuse Clips:<br />

Marathon fuse holders are equipped with the patented ÒCool Clip¨Ó. This fuse clip is standard on all 30<br />

through 200 amp fuse holders. The heat generated in a fuse clip can actually reduce the life of the fuse, the<br />

clip and the conductor, as well as the protection power of the fusing device. No longer is it necessary for heat<br />

build up to rob equipment of protection and extended life.<br />

MarathonÕs revolutionary ÒCool Clip ¨ Ó is the result of an extensive analytical optimization process. Heat is<br />

dissipated so well through the ÒCool Clip ¨ Ó the conductor acts as a heat sink and at the same time eliminates<br />

broken or sprung fuse clips.<br />

Reinforcing members are available for most Marathon fuse holders, for use where an extra tight connection<br />

is required. These are recommended for electric heat or where high ambients are present.<br />

To comply with Automotive Industry Standard ET-2 use the following options:<br />

¥ Class H Holder with Reinforcing Member<br />

¥ 30 Amp use SP Connector or Copper Box Connector<br />

¥ 60 Amp use Copper Box Connector<br />

5<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:21 AM Page 6<br />

Fuseholders<br />

Wire Connectors:<br />

Marathon fuse holders are available with three types of wire connectors.<br />

6<br />

Fuse Holders<br />

S — Screw Connector<br />

An economical connector for use with a wire, or either a ring or spade type terminal. Screw is #10-32 steel.<br />

SQ – Screw Connector w/Quick Connects<br />

Same as screw connector with additional quick connect options.<br />

SP — Sems Pressure Connector<br />

A positive pressure connector eliminating the need for a wire terminal. Ideal for use where there is a vibration problem. Sems<br />

pressure screw is #10-32 steel.<br />

SPQ – Sems Pressure Connector w/Quick Connects<br />

Same as Sems connector with additional quick connect options.<br />

B — Box Connector<br />

Suitable for use with stranded or solid wire. Connector is aluminum tin plated.<br />

Copper Box Connectors are available on 30 and 60 amp fuse holders. Add CU after the catalog number.<br />

Wire Ranges:<br />

All wire ranges shown in the fuse holder section are the ranges of the wire connector that is used as a component of the<br />

fuse holder assembly.<br />

Ordering Code:<br />

Reinforcing Amp Connector<br />

Member Rating Style<br />

Applications:<br />

R F 30A 3 B CU<br />

Designates Class H # of Poles Copper Box<br />

Fuse Holder Connector<br />

F = 250 <strong>Volt</strong> Rating (Optional)<br />

6F = <strong>600</strong> <strong>Volt</strong> Rating<br />

Marathon fuse holders can be used in various applications, including control panels, lighting and heating circuits, motor circuits,<br />

circuit breaker protection, switchgear equipment, appliances, electric heat, air conditioning and refrigeration equipment,<br />

elevator systems and transformer protection.

5-37.Fuseholders 11/20/03 11:21 AM Page 7<br />

Class H & K Fuse Holder - 250 <strong>Volt</strong><br />

Specifications:<br />

¥ Have Been Tested & Approved for<br />

10,000 Amp Interrupting Capacity<br />

¥ Patented Cool Clip¨ Design<br />

¥ UL Listed File No. E35113<br />

¥ CSA Cert. File No. LR21455<br />

¥<br />

30 & 60 Amp:<br />

¥ Clip, Copper Alloy, Tin Plated<br />

100 Amp:<br />

200 Amp:<br />

400 & <strong>600</strong> Amp:<br />

Catalog#:<br />

¥ Clip, Copper Alloy, Tin Plated<br />

¥ Clip, One Piece Aluminum, Tin Plated<br />

¥ Clip, Copper Alloy, Tin Plated<br />

Base Wire Fuse<br />

Std. Reinforced Poles Amp Materials Range Size Fuses<br />

F30A1S RF30A1S 1<br />

F30A2S RF30A2S 2 #10-#22 AWG CU<br />

F30A3S RF30A3S 3<br />

F30A1SP RF30A1SP 1<br />

F30A2SP RF30A2SP 2 30 #10-#14 AWG CU 9/16Ó DIA BY 2Ó<br />

F30A3SP RF30A3SP 3<br />

F30A1B RF30A1B 1<br />

F30A2B RF30A2B 2 Thermoplastic #6-#14 AWG CU A2Y<br />

F30A3B RF30A3B 3 CRN<br />

F60A1SQ* RF60A1SQ* 1 NLN<br />

F60A2SQ* RF60A2SQ* 2 #10-#22 AWG CU NON<br />

F60A3SQ*<br />

F60A1B<br />

F60A2B<br />

F60A3B<br />

RF60A3SQ*<br />

RF60A1B<br />

RF60A2B<br />

RF60A3B<br />

3<br />

1<br />

2<br />

3<br />

60<br />

#2-#14 AWG CU<br />

#2-#12 AWG AL<br />

13/16Ó DIA BY 3Ó<br />

NRN<br />

OT<br />

OTN<br />

RLN<br />

RF100A1B<br />

RF100A2B<br />

RF100A3B<br />

1<br />

2<br />

3<br />

100 Phenolic<br />

#2/0-#14 AWG CU<br />

#2/0-#12 AWG AL<br />

1Ó DIA BY 5 7/8Ó<br />

RF<br />

F200A1BE<br />

F200A3BE<br />

SAME 1<br />

3<br />

200 Polyester<br />

250 MCM-<br />

#6 AWG CU AL<br />

1 1/2Ó DIA BY<br />

7 1/8Ó<br />

RF400A1B<br />

RF400A3B<br />

F<strong>600</strong>A1B<br />

F<strong>600</strong>A3B<br />

N/A<br />

1<br />

3<br />

1<br />

3<br />

400<br />

<strong>600</strong><br />

Phenolic<br />

(2) 350 MCM-<br />

#6 AWG CU AL<br />

(2) 500 MCM-<br />

#4 AWG CU AL<br />

2 13/32Ó DIA BY<br />

8 5/8Ó<br />

2 29/32Ó DIA BY<br />

10 3/8Ó<br />

*UL Recognized File No. E35113<br />

Contact Factory for Stud Options<br />

7<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:21 AM Page 8<br />

Fuseholders<br />

Class H & K Fuse Holders - <strong>600</strong> <strong>Volt</strong><br />

Specifications:<br />

¥ Have Been Tested & Approved for<br />

10,000 Amp Interrupting Capacity<br />

¥ Patented Cool Clip¨ Design<br />

¥ UL Listed File No. E35113<br />

¥ CSA Cert. File No. LR21455<br />

¥<br />

30 & 60 Amp:<br />

¥ Clip, Copper Alloy, Tin Plated<br />

100 Amp:<br />

200 Amp:<br />

400 & <strong>600</strong> Amp:<br />

Catalog#:<br />

¥ Clip, Copper Alloy, Tin Plated<br />

¥ Clip, One Piece Aluminum, Tin Plated<br />

¥ Clip, Copper Alloy, Tin Plated<br />

Base Wire Fuse<br />

Std. Reinforced Poles Amp Materials Range Size Fuses<br />

6F30A1S R6F30A1S 1<br />

6F30A2S R6F30A2S 2 #10-#22 AWG CU<br />

6F30A3S R6F30A3S 3<br />

6F30A1SP R6F30A1SP 1<br />

6F30A2SP R6F30A2SP 2 30 #10-#14 AWG CU 13/16Ó DIA BY 5Ó<br />

6F30A3SP R6F30A3SP 3<br />

6F30A1B<br />

6F30A2B<br />

R6F30A1B<br />

R6F30A2B<br />

1<br />

2<br />

Phenolic<br />

#6-#14 AWG CU<br />

A6Y<br />

CRS<br />

6F30A3B R6F30A3B 3 NLS<br />

6F60A1B<br />

6F60A2B<br />

6F60A3B<br />

R6F60A1B<br />

R6F60A2B<br />

R6F60A3B<br />

1<br />

2<br />

3<br />

60<br />

#2-#14 AWG CU<br />

#2-#12 AWG AL<br />

1 1/16Ó DIA BY<br />

5 1/2Ó<br />

NOS<br />

NRS<br />

OTS<br />

R6F100A1B<br />

R6F100A2B<br />

R6F100A3B<br />

1<br />

2<br />

3<br />

100<br />

#2/0-#14 AWG CU<br />

#2/0-#12 AWG AL<br />

1 11/32Ó DIA BY<br />

7 7/8Ó<br />

RES<br />

RFS<br />

RLS<br />

6F200A1BE<br />

6F200A3BE<br />

SAME 1<br />

3<br />

200 Polyester<br />

250 MCM-<br />

#6 AWG CU AL<br />

1 3/4Ó DIA BY<br />

9 5/8Ó<br />

R6F400A1B<br />

R6F400A3B<br />

6F<strong>600</strong>A1B<br />

6F<strong>600</strong>A3B<br />

N/A<br />

1<br />

3<br />

1<br />

3<br />

400<br />

<strong>600</strong><br />

Phenolic<br />

(2) 350 MCM-<br />

#6 AWG CU AL<br />

(2) 500 MCM-<br />

#4 AWG CU AL<br />

2 29/32Ó DIA BY<br />

11 5/8Ó<br />

3 7/16Ó DIA BY<br />

13 3/8Ó<br />

Contact Factory for Stud Options<br />

8

5-37.Fuseholders 11/20/03 11:21 AM Page 9<br />

Class H & K Fuse Panels<br />

30 and 60 Amp 250 <strong>Volt</strong><br />

Specifications:<br />

¥ Base, General Purpose Phenolic, 150¡ C<br />

¥ Patented Cool Clip¨ Design<br />

¥ Clip, Copper Alloy, Tin Plated<br />

¥ Reinforcing Member Available<br />

¥ Bus Bars are Available with #2/0 - #14 Awg or 250 MCM - #6 Wire Ranges<br />

¥ Consult Factory for Special Requirements<br />

¥ UL Recognized File No. E35113<br />

¥ CSA Certified File No. LR21455<br />

¥<br />

Reinforcing Member<br />

Class H Fuse Distribution Panels<br />

Number of Poles 2, 3, 4 or 6<br />

R H 4 0 B 2 L<br />

Amp Rating of Poles<br />

0 = 60 Amps All Poles<br />

1 = 30 Amps All Poles<br />

2 = 30,60 Any Combination<br />

3 = 30, 60, 60 Any Combination<br />

Load Termination<br />

S = Wire Binding Screw<br />

B = Box Connector #2 - 14 CU<br />

#6 - 14 CU<br />

P = SEMS Pressure Screw<br />

Q = .250 Male Quick Connect<br />

C = Combination of the Above<br />

(consult factory)<br />

Ordering Code:<br />

9<br />

Entry of Bus Bar<br />

(Only if Bused)<br />

F-Front L-Lateral<br />

Line Terminations<br />

Code Same As Load Termination.<br />

Omit if line Termination is Same as<br />

Load (S, B, P, Q or C).<br />

OR<br />

Busing Arrangements<br />

1 = Special Busing (consult factory)<br />

2 = Poles Bused by Pairs<br />

3 = Poles Bused by Threes<br />

4 = Bused by Fours<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:21 AM Page 10<br />

Fuseholders<br />

Class H & K Fuse Panels (Cont.)<br />

30 and 60 Amp 250 <strong>Volt</strong><br />

Poles Dimensions (IN) (MM) Poles Dimensions (IN) (MM)<br />

No. L No. L<br />

2 2.50 63.5 4 5.00 127.0<br />

3 3.75 95.25 6 7.50 190.5<br />

Circle/Indicate one item per pole and<br />

number of poles. The items to be indicated<br />

are within the rectangles.<br />

Bussing is only available on line side.<br />

If bussing, indicate lug size 2/0 or 250mcm<br />

(F = Front entry L = Lateral entry)<br />

Consult factory for other modifications.<br />

Fuse Distribution Panel Options<br />

10<br />

Dimensions<br />

(IN)<br />

(MM)

5-37.Fuseholders 11/20/03 11:21 AM Page 11<br />

Class R Fuse Holders - 250 <strong>Volt</strong><br />

Specifications:<br />

¥ Have Been Tested & Approved for 200,000 Amp Interrupting Capacity<br />

¥ Patented Cool Clip¨ Design<br />

¥ UL Listed File No. E35113<br />

¥ CSA Certified File No. LR21455<br />

¥<br />

30 & 60 Amp:<br />

¥ Clip, Copper Alloy, Tin Plated, with Patented Reject Member<br />

100 Amp:<br />

200 Amp:<br />

400 & <strong>600</strong> Amp:<br />

Catalog#:<br />

¥ Clip, Copper Alloy, Tin Plated<br />

¥ Clip, One Piece Aluminum, Tin Plated, with Reject Pin<br />

¥ Clip, Copper Alloy, Tin Plated, with Reject Pin<br />

Base Wire Fuse<br />

Std. Reinforced Poles Amp Materials Range Size Fuses<br />

R30A1S 1<br />

R30A2S 2 #10-#22 AWG CU<br />

R30A3S 3<br />

R30A1SP 1<br />

R30A2SP 2 30 Thermoplastic #10-#14 AWG CU 9/16Ó DIA BY 2Ó<br />

R30A3SP 3<br />

R30A1B 1 A2D-R<br />

R30A2B 2 #6-#14 AWG CU A2K-R<br />

R30A3B 3 DLN-R<br />

R60A1S* 1 FLNR<br />

R60A2S* SAME 2 #10-#22 AWG CU FRN-R<br />

R60A3S*<br />

R60A1B<br />

R60A2B<br />

R60A3B<br />

3<br />

1<br />

2<br />

3<br />

60 Thermoplastic<br />

#2-#14 AWG CU<br />

#2-#12 AWG AL<br />

13/16Ó DIA BY 3Ó<br />

KLNR<br />

KTS-R<br />

LLNRK<br />

LPN-RK<br />

R100A1B<br />

R100A2B<br />

R100A3B<br />

1<br />

2<br />

3<br />

100 Phenolic<br />

#2/0-#14 AWG CU<br />

#2/0-#12 AWG AL<br />

1Ó DIA BY 5 7/8Ó<br />

TLN<br />

TR-R<br />

R200A1BE<br />

R200A3BE<br />

1<br />

3<br />

200 Polyester<br />

250 MCM-<br />

#6 AWG CU AL<br />

1 1/2Ó DIA BY<br />

7 1/8Ó<br />

R400A1B<br />

R400A3B<br />

R<strong>600</strong>A1B<br />

R<strong>600</strong>A3B<br />

N/A<br />

1<br />

3<br />

1<br />

3<br />

400<br />

<strong>600</strong><br />

Phenolic<br />

(2) 350 MCM-<br />

#6 AWG CU AL<br />

(2) 500 MCM-<br />

#4 AWG CU AL<br />

2 13/32Ó DIA BY<br />

8 5/8Ó<br />

2 29/32Ó DIA BY<br />

10 3/8Ó<br />

*UL Recognized File No. E35113<br />

Contact Factory for Stud Options<br />

11<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:21 AM Page 12<br />

Fuseholders<br />

Specifications:<br />

Class R Fuse Holders - <strong>600</strong> <strong>Volt</strong><br />

¥ Have Been Tested & Approved for 200,000 Amp Interrupting Capacity<br />

¥ Patented Cool Clip¨ Design<br />

¥ UL Listed File No. E35113<br />

¥ CSA Certified File No. LR21455<br />

¥<br />

30 & 60 Amp:<br />

¥ Clip, Copper Alloy, Tin Plated, with Patented Reject Member<br />

100 Amp:<br />

200 Amp:<br />

400 & <strong>600</strong> Amp:<br />

Catalog#:<br />

¥ Clip, Copper Alloy, Tin Plated<br />

¥ Clip, One Piece Aluminum, Tin Plated, with Reject Pin<br />

¥ Clip, Copper Alloy, Tin Plated, with Reject Pin<br />

Base Wire Fuse<br />

Std. Reinforced Poles Amp Materials Range Size Fuses<br />

6R30A1S 1<br />

6R30A2S 2 #10-#22 AWG CU<br />

6R30A3S 3<br />

6R30A1SP 1<br />

6R30A2SP 2 30 Phenolic #10-#14 AWG CU 13/16Ó DIA BY 5Ó A6D-R<br />

6R30A3SP 3 A6K-R<br />

6R30A1B 1 DLS-R<br />

6R30A2B 2 #6-#14 AWG CU FLSR<br />

6R30A3B 3 FLSR_ID<br />

6R60A1B<br />

6R60A2B<br />

6R60A3B<br />

6R100A1B<br />

6R100A2B<br />

6R100A3B<br />

SAME 1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

60<br />

100<br />

Phenolic<br />

#2-#14 AWG CU<br />

#2-#12 AWG AL<br />

#2/0-#14 AWG CU<br />

#2/0-#12 AWG AL<br />

1 1/16Ó<br />

DIA BY<br />

5 1/2Ó<br />

1 11/32Ó DIA BY<br />

7 7/8Ó<br />

FRS-R<br />

IDSR<br />

KLSR<br />

KTS-R<br />

LLSRK<br />

LLSRK_ID<br />

6R200A1BE<br />

6R200A3BE<br />

1<br />

3<br />

200 Polyester<br />

250 MCM-<br />

#6 AWG CU AL<br />

1 3/4Ó DIA BY<br />

9 5/8Ó<br />

LPS-RK<br />

TRS-R<br />

6R400A1B<br />

6R400A3B<br />

6R<strong>600</strong>A1B<br />

6R<strong>600</strong>A3B<br />

N/A<br />

1<br />

3<br />

1<br />

3<br />

400<br />

<strong>600</strong><br />

Phenolic<br />

(2) 350 MCM-<br />

#6 AWG CU AL<br />

(2) 500 MCM-<br />

#4 AWG CU AL<br />

2 29/32Ó DIA BY<br />

11 5/8Ó<br />

3 7/16Ó DIA BY<br />

13 3/8Ó<br />

Contact Factory for Stud Options<br />

12

5-37.Fuseholders 11/20/03 11:21 AM Page 13<br />

Class H and R Fuse Holder Dimensions<br />

Figure A B C D E F G H I J K L<br />

F30A 1 POLE<br />

RF30A 2 POLE<br />

SEE FIGURE #1<br />

R30A 3 POLE<br />

F60A 1 POLE 1.48<br />

RF60A 2 POLE FIG2 4.83 2.86 2.01 1.24 1.8 .50 .49 1.33 N/A N/A .218 DIA THRU .11<br />

R60A 3 POLE 4.23 .40 DIA X. 63 CÕBORE<br />

RF100A<br />

R100A<br />

1 POLE<br />

2 POLE<br />

3 POLE<br />

FIG 2 6.12<br />

1.93<br />

3.49<br />

5.05<br />

2.44 2.37 1.87 .62 .61 1.56 N/A N/A .28 DIA THRU<br />

.53 DIA X .59 CÕBORE<br />

.36<br />

F200A<br />

R200A<br />

1 POLE<br />

3 POLE<br />

FIG 4 7.13<br />

3.00<br />

9.00<br />

3.01 3.00 2.06 2.00 .50 8.00 N/A N/A<br />

.28 DIA THRU<br />

.63 DIA X .38 CÕBORE<br />

.26<br />

RF400A<br />

R400A<br />

1 POLE<br />

3 POLE<br />

FIG 5 11.5<br />

3.5<br />

10.5<br />

3.31 4.00 3.75<br />

2.25<br />

9.25<br />

.62 N/A N/A 5/16 HEX<br />

.28 DIA THRU<br />

.56 DIA X .44 CÕBORE<br />

.19<br />

F<strong>600</strong>A<br />

R<strong>600</strong>A<br />

1 POLE<br />

3 POLE<br />

FIG 5 14.00<br />

4.5<br />

12.5<br />

4.31 5.00 4.50<br />

3.00<br />

11.00<br />

.75 N/A N/A 3/8 HEX<br />

.28 DIA THRU<br />

.56 DIA X .44 CÕBORE<br />

.19<br />

6F30A<br />

R6F30A<br />

6R30A<br />

1 POLE<br />

2 POLE<br />

3 POLE<br />

FIG 3 6.25<br />

1.63<br />

2.94<br />

4.25<br />

1.69 3.13 1.56<br />

.31<br />

N/A<br />

N/A<br />

.62<br />

.51<br />

.38<br />

.25<br />

N/A<br />

1.56<br />

3.13<br />

.34<br />

N/A<br />

N/A<br />

.28 DIA THRU<br />

.50 DIA X .44 CÕBORE<br />

.25<br />

6F60A<br />

R6F60A<br />

6R60A<br />

1 POLE<br />

2 POLE<br />

3 POLE<br />

FIG 3 6.75<br />

1.95<br />

3.51<br />

5.08<br />

2.12 3.12 1.81 N/A .62 .66<br />

N/A<br />

1.56<br />

3.12<br />

N/A<br />

.28 DIA THRU<br />

.50 DIA X .50 CÕBORE<br />

.33<br />

1 POLE<br />

R6F100A<br />

2 POLE<br />

6R100A<br />

3 POLE<br />

FIG 3 8.12<br />

2.1<br />

3.91<br />

5.73<br />

2.60 4.26 1.94 N/A .87 .61<br />

N/A<br />

1.81<br />

3.62<br />

N/A<br />

.28 DIA THRU<br />

.59 DIA X .64 CÕBORE<br />

.23<br />

6F200A<br />

6R200A<br />

1 POLE<br />

3 POLE<br />

FIG 4 9.63<br />

3.00<br />

9.00<br />

3.01 3.00 3.31 2.00 .5 8.00 N/A N/A<br />

.33 DIA THRU<br />

.73 DIA X .44 CÕBORE<br />

.26<br />

R6F400A 1 POLE<br />

6R400A 3 POLE<br />

FIG 5 14.50<br />

3.50<br />

10.50<br />

3.31 7.00 3.75<br />

2.25<br />

9.25<br />

.62 N/A N/A 5/16 HEX<br />

.28 DIA THRU<br />

.56 DIA X .44 CÕBORE<br />

.19<br />

6F<strong>600</strong>A<br />

6R<strong>600</strong>A<br />

1 POLE<br />

3 POLE<br />

FIG 5 17.0<br />

4.50<br />

12.50<br />

4.31 8.00 4.50<br />

3.00<br />

11.00<br />

.75 N/A N/A 3/8 HEX<br />

.28 DIA THRU<br />

.56 DIA X .44 CÕBORE<br />

.19<br />

MM = Dim X 25.4<br />

1 Pole 2 Pole 3 Pole<br />

Figure 1:<br />

13<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:21 AM Page 14<br />

Fuseholders<br />

Class H and R Fuse Holder Dimensions<br />

1 Pole 2 Pole 3 Pole<br />

Figure 2:<br />

1 Pole 2 Pole 3 Pole<br />

Figure 3:<br />

14

5-37.Fuseholders 11/20/03 11:21 AM Page 15<br />

Class H and R Fuse Holder Dimensions<br />

1 Pole 3 Pole<br />

Figure 4:<br />

1 Pole 3 Pole<br />

Figure 5:<br />

15<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:21 AM Page 16<br />

Fuseholders<br />

Specifications:<br />

Class T Fuse Holders - 300 <strong>Volt</strong><br />

¥ Have Been Tested & Approved for<br />

200,000 Amp Interrupting Capacity<br />

¥ Patented Cool Clip¨ Design<br />

¥ UL Listed File No. E35113<br />

¥ CSA Certified File No. LR21455<br />

¥<br />

30 & 60 Amp:<br />

¥ Clip, Copper Alloy, Tin Plated, with Patented<br />

Reject Member<br />

100 Amp:<br />

¥ Connector, One Piece Aluminum with<br />

Integral Heat Sink, Tin Plated Bolt<br />

¥ 1/4Ó-20 X 1/2Ó, 1/4Ó Belleville Washer<br />

200 Amp:<br />

400 & <strong>600</strong> Amp:<br />

Catalog#:<br />

¥ Connector, One Piece Aluminum with<br />

Integral Heat Sink, Tin Plated Bolt,<br />

5/16Ó-18 X 3/4Ó Hex Head, 5/16Ó Belleville<br />

Washer<br />

¥ Connector, One Piece Aluminum with<br />

Integral Heat Sink, Tin Plated Bolt,<br />

3/8Ó-16 X 3/4Ó Hex Head<br />

Base Wire Fuse<br />

Std. Reinforced Poles Amp Materials Range Size Fuses<br />

T30A2B<br />

T30A3B<br />

RT30A2B<br />

RT30A3B<br />

2<br />

3<br />

30<br />

#2-#14 AWG CU<br />

13/32Ó DIA BY<br />

7/8Ó<br />

T60A2B<br />

T60A3B<br />

RT60A2B<br />

RT60A3B<br />

2<br />

3<br />

60<br />

#2-#12 AWG AL 9/16Ó DIA BY<br />

7/8Ó<br />

T100A1B<br />

T100A3B<br />

T200A1B<br />

T200A3B<br />

T400A1B<br />

T<strong>600</strong>A1B<br />

N/A<br />

1<br />

3<br />

1<br />

3<br />

1<br />

100<br />

200<br />

400<br />

<strong>600</strong><br />

Phenolic<br />

#2/0-#14 AWG CU<br />

#2/0-#12 AWG AL<br />

250 MCM<br />

#6 AWG CU AL<br />

(2) 250 MCM-<br />

#6 AWG CU AL<br />

(2) 500 MCM-<br />

#6 AWG CU AL<br />

13/16Ó DIA BY<br />

2 5/32Ó<br />

1 1/16Ó DIA BY<br />

2 7/16Ó<br />

1 11/32Ó DIA BY<br />

2 3/4Ó<br />

1 39/64Ó DIA BY<br />

3 1/16Ó<br />

A3T<br />

JJN<br />

JLLN<br />

16

5-37.Fuseholders 11/20/03 11:21 AM Page 17<br />

Class T Fuse Holders - <strong>600</strong> <strong>Volt</strong><br />

Specifications:<br />

¥ Have Been Tested & Approved for<br />

200,000 Amp Interrupting Capacity<br />

¥ Patented Cool Clip¨ Design<br />

¥ UL Listed File No. E35113<br />

¥ CSA Certified File No. LR21455<br />

¥<br />

30 & 60 Amp:<br />

¥ Clip, Copper Alloy, Tin Plated, with Patented<br />

Reject Member<br />

100 Amp:<br />

¥ Connector, One Piece Aluminum with<br />

Integral Heat Sink, Tin Plated Bolt<br />

¥ 1/4Ó-20 X 1/2Ó Bolt<br />

¥ 1/4Ó Belleville Washer<br />

200 Amp:<br />

Catalog#:<br />

¥ Connector, One Piece Aluminum with<br />

Integral Heat Sink, Tin Plated Bolt<br />

¥ 5/16Ó-18 X 3/4Ó Hex Head<br />

¥ 5/16Ó Belleville Washer<br />

17<br />

400 & <strong>600</strong> Amp:<br />

¥ Connector, One Piece Aluminum with<br />

Integral Heat Sink, Tin Plated Bolt<br />

¥ 3/8Ó-16 X 3/4Ó Hex Head<br />

¥ 3/8Ó Belleville Washer<br />

Base Wire Fuse<br />

Std. Reinforced Poles Amp Materials Range Size Fuses<br />

6T30A2S<br />

6T30A3S<br />

R6T30A2S<br />

R6T30A3S<br />

2<br />

3<br />

#10-#22 AWG CU<br />

6T30A2SP<br />

6T30A3SP<br />

R6T30A2SP<br />

R6T30A3SP<br />

2<br />

3<br />

30 #10-#14 AWG CU<br />

9/16Ó DIA BY<br />

1 1/2Ó<br />

6T30A2B R6T30A2B 2<br />

6T30A3B R6T30A3B 3 #2-#14 AWG CU<br />

R6T60A2B<br />

R6T60A3B<br />

6T100A1B<br />

6T100A3B<br />

SAME<br />

2<br />

3<br />

1<br />

3<br />

60<br />

100<br />

Phenolic<br />

#2-#12 AWG AL<br />

#2/0-#14 AWG CU<br />

#2/0-#12 AWG AL<br />

13/16Ó DIA BY<br />

1 9/16Ó<br />

13/16Ó DIA BY<br />

2 61/64Ó<br />

A6T<br />

JJS<br />

JLLS<br />

6T200A1B<br />

6T200A3B<br />

6T400A1B<br />

6T<strong>600</strong>A1B<br />

N/A<br />

1<br />

3<br />

1<br />

200<br />

400<br />

<strong>600</strong><br />

250 MCM-<br />

#6 AWG CU AL<br />

(2) 250 MCM-<br />

#6 AWG CU AL<br />

(2) 500 MCM-<br />

#6 AWG CU AL<br />

1 1/16Ó DIA BY<br />

3 1/4Ó<br />

1 39/64Ó DIA BY<br />

3 5/8Ó<br />

2 5/64Ó DIA BY<br />

3 63/64Ó<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:21 AM Page 18<br />

Fuseholders<br />

MM = Dim X 25.4<br />

18<br />

Class T Dimensions<br />

Figure A B C D E F G H I J<br />

T30A<br />

RT30A<br />

2 POLE<br />

3 POLE<br />

FIG 1 1.12<br />

T60A<br />

RT60A<br />

2 POLE<br />

3 POLE<br />

FIG 1 1.28<br />

T100A 1 POLE 3 POLE<br />

FIG 2 5.25<br />

1.37<br />

4.12<br />

1.87 4.50 0.38 0.69<br />

N/A<br />

2.75<br />

0.20 THRU<br />

0.37 X .44 CÕBORE<br />

3/16<br />

HEX<br />

0.19<br />

T200A 1 POLE FIG 2 7.00<br />

1.50<br />

4.50<br />

2.25 6.25 0.38 0.75<br />

N/A<br />

3.00<br />

0.28 THRU<br />

0.50 X .44 CÕBORE<br />

5/16<br />

HEX<br />

0.19<br />

T400A 1 POLE FIG 3 8.12 2.25 2.37 7.37 0.38 1.12 N/A<br />

0.28 THRU<br />

0.50 X .44 CÕBORE<br />

N/A 0.19<br />

T<strong>600</strong>A 1 POLE FIG 4 8.75 2.75 2.62 8.06 0.34 0.38 2.00<br />

0.28 THRU<br />

0.50 X .44 CÕBORE<br />

N/A 0.19<br />

6T30A<br />

R6T30A<br />

2 POLE<br />

3 POLE<br />

FIG 5 1.28<br />

6T60A<br />

R6T60A<br />

2 POLE<br />

3 POLE<br />

FIG 5 1.74<br />

6T100A 1 POLE 3 POLE<br />

FIG 2 6.06<br />

1.37<br />

4.12<br />

1.87 5.31 0.38 0.69<br />

N/A<br />

2.75<br />

0.20 THRU<br />

0.37 X .44 CÕBORE<br />

3/16<br />

HEX<br />

0.19<br />

6T200A 1 POLE SEE FIGURE #1<br />

SEE FIGURE #1<br />

SEE FIGURE #5<br />

SEE FIGURE #5<br />

3 POLE<br />

FIG 2 7.75<br />

1.50<br />

4.50<br />

2.25 7.00 0.38 0.75<br />

N/A<br />

3.00<br />

0.28 THRU<br />

0.50 X .44 CÕBORE<br />

5/16<br />

HEX<br />

0.19<br />

6T400A 1 POLE FIG 3 9.00 2.25 2.37 8.25 0.38 1.12 N/A<br />

0.28 THRU<br />

0.50 X .44 CÕBORE<br />

N/A 0.19<br />

6T<strong>600</strong>A 1 POLE FIG 4 9.75 2.75 2.62 9.00 0.38 0.38 2.00<br />

0.28 THRU<br />

0.50 X .44 CÕBORE<br />

N/A 0.19

5-37.Fuseholders 11/20/03 11:21 AM Page 19<br />

Class T Dimensions<br />

2 Pole 3 Pole<br />

Figure 1:<br />

1 Pole 3 Pole<br />

Figure 2:<br />

19<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:21 AM Page 20<br />

Fuseholders<br />

20<br />

Class T Dimensions<br />

Figure 3: Figure 4:<br />

2 Pole 3 Pole<br />

Figure 5:

5-37.Fuseholders 11/20/03 11:22 AM Page 21<br />

Class J Fuse Holders - <strong>600</strong> <strong>Volt</strong><br />

Specifications:<br />

¥ Have Been Tested & Approved for<br />

200,000 Amp Interrupting Capacity<br />

¥ Patented Cool Clip¨ Design<br />

¥ UL Listed File No. E35113<br />

¥ CSA Certified File No. LR21455<br />

¥<br />

30 & 60 Amp:<br />

¥ Clip, Copper Alloy, Tin Plated<br />

30 Amp:<br />

100 Amp:<br />

200 Amp:<br />

400-<strong>600</strong> Amp:<br />

Catalog#:<br />

¥ Integral DIN Rail Mount<br />

¥ Expander Block<br />

¥ Clip, Copper Alloy, Tin Plated<br />

¥ Clip, One Piece Aluminum, Tin Plated<br />

¥ Clip, Copper Alloy, Tin Plated<br />

Base Wire Fuse<br />

Std. Reinforced Poles Amp Materials Range Size Fuses<br />

6J30A1S R6J30A1S 1<br />

6J30A2S<br />

6J30A3S<br />

R6J30A2S<br />

R6J30A3S<br />

2<br />

3<br />

#10-#22 AWG CU<br />

6J30AES R6J30AES Expander<br />

6J30A1SP R6J30A1SP 1<br />

6J30A2SP<br />

6J30A3SP<br />

6J30AESP<br />

R6J30A2SP<br />

R6J30A3SP<br />

R6J30AESP<br />

2<br />

3<br />

Expander<br />

30<br />

Thermoplastic<br />

#10-#14 AWG CU 13/16Ó DIA BY 2 1/4Ó<br />

6J30A1B R6J30A1B 1 A4J<br />

6J30A2B<br />

6J30A3B<br />

R6J30A2B<br />

R6J30A3B<br />

2<br />

3<br />

#6-#14 AWG CU<br />

AJT<br />

JKS<br />

6J30AEB R6J30AEB Expander JLS<br />

6J60A1B R6J60A1B 1 JTD<br />

6J60A2B R6J60A2B 2 60 #2-#14 AWG CU AL 1 1/16Ó DIA BY 2 3/8Ó JTD_ID<br />

6J60A3B R6J60A3B 3 LPJ<br />

6J100A1B<br />

6J100A3B<br />

1<br />

3<br />

100<br />

#2/0-#14 AWG CU<br />

#2/0-#12 AWG AL<br />

1 1/8Ó DIA BY 4 5/8Ó<br />

6J200A1B<br />

6J200A3B<br />

6J400A1B<br />

6J400A3B<br />

SAME<br />

1<br />

3<br />

1<br />

3<br />

200<br />

400<br />

Phenolic<br />

250 MCM-<br />

#6 AWG CU AL<br />

(2) 350 MCM-<br />

#6 AWG CU AL<br />

1 1/2Ó DIA BY 5 3/4Ó<br />

2Ó DIA BY 3 3/8Ó<br />

6J<strong>600</strong>A1B<br />

6J<strong>600</strong>A3B<br />

1<br />

3<br />

<strong>600</strong><br />

(2) 500 MCM-<br />

#4 AWG CU AL<br />

2 1/2Ó DIA BY 3 3/4Ó<br />

Contact Factory for Stud Options<br />

21<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:22 AM Page 22<br />

Fuseholders<br />

Specifications:<br />

Catalog#:<br />

M Fuse Holders - <strong>600</strong> <strong>Volt</strong><br />

¥ Have Been Tested & Approved for 100,000 Amp Interrupting Capacity<br />

¥ Clip, Copper Alloy, Tin Plated<br />

¥ Quick Connect Standard with Screw (S) or<br />

Sems Pressure (SP)<br />

¥ UL Recognized File No. E35113<br />

¥ CSA Certified File No. LR21455<br />

¥<br />

Base Wire Fuse<br />

Std. Reinforced Poles Amp Materials Range Size Fuses<br />

6M30A1SQ 1 A13X-2, A25Z-2,<br />

6M30A2SQ 2 #10-#22 AWG CU A60Q-2, A6Y-2B,<br />

6M30A3SQ 3 AGU, ATM,<br />

6M30A1SPQ 1 ATQ, BAF,<br />

6M30A2SPQ<br />

6M30A3SPQ<br />

6M30A1B<br />

N/A<br />

2<br />

3<br />

1<br />

30 Thermoplastic<br />

#10-#14 AWG CU<br />

13/32Ó DIA BY<br />

1 1/2Ó<br />

BAN, BLF,<br />

BLN, BLS,<br />

FLA, FLM,<br />

6M30A2B 2 FLQ, FNM,<br />

6M30A3B<br />

6M30A1BCU<br />

3<br />

1<br />

#6-#14 AWG AL<br />

FNQ, GFN,<br />

GGO, KLK,<br />

6M30A2BCU 2 KLKD, KLQ,<br />

6M30A3BCU 3 KTK, OTM, TRM<br />

22

5-37.Fuseholders 11/20/03 11:22 AM Page 23<br />

Midget Enclosed Fuse Holders - <strong>600</strong> <strong>Volt</strong><br />

Specifications:<br />

¥ Has Been Tested & Approved for<br />

100,000 Amp Interrupting Capacity<br />

¥ Touchsafe Design IEC Type IP2<br />

¥ DIN Rail Mount (35mm)<br />

¥ Blown Fuse Indication Available<br />

¥ Handle Allows Quick Easy Fuse Change<br />

¥ Ventilated Design for Cooler Operation<br />

¥ UL Recognized File No. E35113<br />

¥ IEC Type IP2 Protection<br />

¥ CSA Certified File No. LR21455<br />

¥<br />

Catalog# Indicating Poles Amp Base Material Wire Range Fuse Size Fuses<br />

6SM30A1 1 A13X-2, A25Z-2, A60Q-2,<br />

6SM30A2<br />

6SM30A3<br />

No<br />

2<br />

3<br />

A6Y-2B, AGN, ATM,<br />

ATQ, BAF, BAN,<br />

6SM30A4<br />

6SM30A1l<br />

4<br />

1<br />

30 Thermoplastic #6 - #14 AWG CU 13/32Ó DIA BY 1 1/2Ó<br />

BLF, BLN, BLS,<br />

FLA, FLM, FLQ,<br />

6SM30A2l<br />

6SM30A3l<br />

Yes<br />

2<br />

3<br />

FNM, FNQ, GFN,<br />

GGO, KLK, KLKD,<br />

6SM30A4l 4 KLQ, KTK, OTM, TRM<br />

Dimensions mm Inches<br />

A 17.8 0.70<br />

B 35.6 1.40<br />

C 53.3 2.10<br />

D 71.1 2.80<br />

E 43.2 1.70<br />

F 61.0 2.40<br />

G 9.9 0.39<br />

H 78.2 3.08<br />

23<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:22 AM Page 24<br />

Fuseholders<br />

30 Amp<br />

Sectional Version<br />

<strong>600</strong> <strong>Volt</strong>s<br />

Specifications:<br />

Midget Fuse Holder - <strong>600</strong> <strong>Volt</strong><br />

¥ Have Been Tested & Approved for<br />

100,000 Amp Interrupting Capacity<br />

¥ Base, White Nylon, 105¡ C Connector, Box<br />

Type, Accepts up to #10 Awg Wire, either<br />

Terminated or Non-Terminated<br />

¥ Clip, Copper Alloy, Tin Plated<br />

¥ UL Recognized File No. E35113<br />

¥ CSA Certified File No. LR21455<br />

¥<br />

Catalog# Description Std. Pack Wire Range Fuse Size Fuses<br />

6W30A1F<br />

6W30A1C<br />

6WE-F<br />

6WE-C<br />

MC<br />

MPC-6<br />

MPC-3<br />

GR-2<br />

Flat Mount<br />

Channel Mount<br />

End Piece-Flat<br />

End Piece-Channel<br />

Channel Clamp<br />

6 Foot Channel<br />

3 Foot Channel<br />

1/8Ó Diameter X 2Ó<br />

Long Nylon Rod<br />

10<br />

25<br />

-<br />

#10-#14 Awg<br />

CU Stranded<br />

13/32Ó DIA BY<br />

1 1/2Ó LONG<br />

A13X-2, A25Z-2, A60Q-2,<br />

A6Y-2B, AGN, ATM,<br />

ATQ, BAF, BAN,<br />

BLF, BLN, BLS,<br />

FLA, FLM, FLQ,<br />

FNM, FNQ, GFN,<br />

GGO, KLK, KLKD,<br />

KLQ, KTK, OTM, TRM<br />

24<br />

Flat Mount<br />

L = 0.88 + (0.68 X N)<br />

C = 0.48 + (0.68 X N)<br />

N = No. of Poles<br />

Channel Dimensions<br />

LCH = L + 2.25

5-37.Fuseholders 11/20/03 11:22 AM Page 25<br />

CC Fuse Holders - <strong>600</strong> <strong>Volt</strong><br />

Specifications:<br />

30 Amp:<br />

¥ Have Been Tested & Approved for<br />

200,000 Amp Interrupting Capacity<br />

¥ Clip, Copper Alloy, Tin Plated with Patented<br />

Reject Member<br />

¥ Quick Connect Standard with Screw (S)<br />

or Sems Pressure (SP)<br />

¥ UL Listed File No. E35113<br />

¥ CSA Certified File No. LR21455<br />

¥<br />

60 Amp:<br />

¥ Have Been Tested & Approved for<br />

200,000 Amp Interrupting Capacity<br />

¥ Patented Cool Clip¨ Design<br />

¥ Clip, Copper Alloy, Tin Plated with<br />

Patented Reject Member<br />

¥ Integral DIN Rail Mount<br />

¥ Expander Block Available<br />

¥ UL Listed File No. E35113, Class CD<br />

¥ CSA Certified File No. LR21455-91<br />

¥<br />

Catalog#:<br />

Base Wire Fuse<br />

Std. Reinforced Poles Amp Materials Range Size Fuses<br />

6CC30A1SQ 1<br />

6CC30A2SQ 2 #10-#22 AWG CU<br />

6CC30A3SQ 3<br />

6CC30A1SPQ 1 ATDR<br />

6CC30A2SPQ 2 #10-#14 AWG CU ATMR<br />

6CC30A3SPQ<br />

6CC30A1B<br />

N/A<br />

3<br />

1<br />

30<br />

13/32Ó DIA BY<br />

1 1/2Ó<br />

ATQR<br />

CCMR<br />

6CC30A2B 2 Thermoplastic FRQ-R<br />

6CC30A3B<br />

6CC30A1BCU<br />

3<br />

1<br />

#6-#14 AWG CU<br />

KLDR<br />

KLKR<br />

6CC30A2BCU 2 KTK-R<br />

6CC30A3BCU 3 LP-CC<br />

R6CC60A1B SAME 1<br />

R6CC60A2B<br />

R6CC60A3B<br />

SAME<br />

SAME<br />

2<br />

3<br />

60<br />

#2-#14 AWG CU<br />

#2-#12 AWG AL<br />

0.70Ó DIA BY<br />

1.85Ó<br />

R6CC60AEB EXPANDER<br />

25<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:22 AM Page 26<br />

Fuseholders<br />

Class CC Enclosed Fuse Holders - <strong>600</strong> <strong>Volt</strong><br />

Specifications:<br />

¥ Has Been Tested & Approved for<br />

200,000 Amp Interrupting Capacity<br />

¥ Touchsafe Design IEC Type IP2<br />

¥ DIN Rail Mount (35mm)<br />

¥ Blown Fuse Indication Available<br />

¥ Handle Allows Quick Easy Fuse Change<br />

¥ Ventilated Design for Cooler Operation<br />

¥ UL Listed File No. E35113<br />

¥ IEC Type IP2 Protection<br />

¥ Certified File No. LR21455<br />

¥<br />

Base Wire Fuse<br />

Catalog # Indicating Poles Amp Materials Range Size Fuses<br />

6SC30A1 1 ATDR<br />

6SC30A2<br />

6SC30A3<br />

NO<br />

2<br />

3<br />

ATMR<br />

ATQR<br />

6SC30A4<br />

6SC30A1l<br />

4<br />

1<br />

30 Thermoplastic #6-#14 AWG CU<br />

13/32Ó DIA BY<br />

1 1/2Ó<br />

CCMR<br />

FRQ-R<br />

6SC30A2l<br />

6SC30A3l<br />

YES<br />

2<br />

3<br />

KLDR<br />

KLKR<br />

6SC30A4l 4 KTK-R, LP-CC<br />

Dimensions mm inches<br />

A 17.8 0.70<br />

B 35.6 1.40<br />

C 53.3 2.10<br />

D 71.1 2.80<br />

E 43.2 1.70<br />

F 61.0 2.40<br />

G 9.90 0.39<br />

H 78.2 3.08<br />

26

5-37.Fuseholders 11/20/03 11:22 AM Page 27<br />

Class G Fuse Holders<br />

Specifications:<br />

¥ Have Been Tested & Approved for<br />

100,000 Amp Interrupting Capacity<br />

¥ Clip, Copper Alloy, Tin Plated with Patented<br />

Reject Member<br />

¥ Quick Connect Standard with Screw (S)<br />

or Sems Pressure (SP)<br />

¥ UL Listed File No. E35113<br />

¥ CSA Certified File No. LR21455<br />

¥<br />

1/2 - 15 Amps (<strong>600</strong> <strong>Volt</strong>)<br />

Catalog #: Base Wire Fuse<br />

Std. Reinforced Poles Amp Materials Range Size Fuses<br />

G15A1SQ RG15A1SQ 1<br />

G15A2SQ RG15A2SQ 2 #10-#22 AWG CU<br />

G15A3SQ RG15A3SQ 3<br />

G15A1SPQ RG15A1SPQ 1<br />

G15A2SPQ RG15A2SPQ 2 #10-#14 AWG CU<br />

G15A3SPQ<br />

G15A1B<br />

RG15A3SPQ<br />

RG15A1B<br />

3<br />

1<br />

15 Thermoplastic<br />

13/32Ó DIA BY<br />

1 5/16Ó<br />

G15A2B RG15A2B 2<br />

G15A3B<br />

G15A1BCU<br />

RG15A3B<br />

RG15A1BCU<br />

3<br />

1<br />

#6-#14 AWG CU<br />

G15A2BCU RG15A2BCU 2<br />

G15A3BCU RG15A3BCU 3<br />

20 Amps (<strong>600</strong> <strong>Volt</strong>)<br />

Catalog #: Base Wire Fuse<br />

Std. Reinforced Poles Amp Materials Range Size Fuses<br />

G20A1SQ RG20A1SQ 1<br />

G20A2SQ RG20A2SQ 2 #10-#22 AWG CU<br />

G20A3SQ RG20A3SQ 3<br />

G20A1SPQ RG20A1SPQ 1<br />

G20A2SPQ RG20A2SPQ 2 #10-#14 AWG CU<br />

G20A3SPQ<br />

G20A1B<br />

RG20A3SPQ<br />

RG20A1B<br />

3<br />

1<br />

20 Thermoplastic<br />

13/32Ó DIA BY<br />

1 13/32Ó<br />

G20A2B RG20A2B 2<br />

G20A3B<br />

G20A1BCU<br />

RG20A3B<br />

RG20A1BCU<br />

3<br />

1<br />

#6-14 AWG CU<br />

G20A2BCU RG20A2BCU 2<br />

G20A3BCU RG20A3BCU 3<br />

25 - 30 Amps (480 <strong>Volt</strong>)<br />

Catalog #: Base Wire Fuse<br />

Std. Reinforced Poles Amp Materials Range Size Fuses<br />

G30A1SQ RG30A1SQ 1<br />

G30A2SQ RG30A2SQ 2 #10-#22 AWG CU<br />

G30A3SQ RG30A3SQ 3<br />

G30A1SPQ RG30A1SPQ 1<br />

G30A2SPQ RG30A2SPQ 2 #10-#14 AWG CU<br />

G30A3SPQ<br />

G30A1B<br />

RG30A3SPQ<br />

RG30A1B<br />

3<br />

1<br />

30 Thermoplastic<br />

13/32Ó DIA BY<br />

1 5/8Ó<br />

G30A2B RG30A2B 2<br />

G30A3B<br />

G30A1BCU<br />

RG30A3B<br />

RG30A1BCU<br />

3<br />

1<br />

#6-#14 AWG CU<br />

G30A2BCU RG30A2BCU 2<br />

G30A3BCU RG30A3BCU 3<br />

27<br />

AG<br />

SC<br />

SLC<br />

AG<br />

SC<br />

SLC<br />

AG<br />

SLC<br />

SC<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:22 AM Page 28<br />

Fuseholders<br />

Class J, G, M, CC Fuse Holder Dimensions<br />

MM = Dim X 25.4<br />

Figure A B C D E F G H I J K L M EXPANDER<br />

6J30A<br />

R6J30A<br />

1 POLE<br />

2 POLE<br />

3 POLE<br />

FIG 1 3.38<br />

1.16<br />

2.20<br />

3.25<br />

1.95 1.69 1.04 0.30 0.57<br />

.22 X .79<br />

SLOT<br />

N/A N/A N/A N/A 0.24 YES<br />

6J60A<br />

R6J60A<br />

1 POLE<br />

2 POLE<br />

3 POLE<br />

R6J100A 1 POLE FIG 2 5.06 2.25 2.06 2.53 1.50 0.38 3 POLE FIG 2A 5.13 5.36 2.65 2.56 1.93<br />

N/A N/A N/A N/A<br />

0.28 THRU<br />

0.53 CÕBORE<br />

N/A N/A N/A<br />

6J200A 1 POLE 3 POLE<br />

FIG 2 6.13<br />

3.00<br />

8.00<br />

2.68 3.06 2.00 0.50<br />

N/A N/A N/A<br />

N/A<br />

2.22<br />

N/A<br />

1.69<br />

N/A N/A<br />

0.50 7.00<br />

N/A<br />

0.34 THRU<br />

0.75 X .40 CÕBORE<br />

0.23 NO<br />

6M30A<br />

6CC30A<br />

G30A<br />

1 POLE<br />

2 POLE<br />

3 POLE<br />

FIG 1 3.13<br />

0.85<br />

1.60<br />

2.35<br />

1.29 1.56 0.75 0.24 0.38<br />

.18 X .59<br />

SLOT<br />

N/A N/A N/A N/A 0.09 NO<br />

1 POLE<br />

R6CC60A 2 POLE<br />

3 POLE<br />

FIG 1 3.35<br />

1.11<br />

2.12<br />

3.12<br />

1.89 1.68 1.01 0.27 0.57<br />

.18 X .74<br />

SLOT<br />

N/A N/A N/A N/A 0.09 YES<br />

6J400A 1 POLE 3 POLE<br />

FIG 4<br />

3.00<br />

10.00<br />

9.32<br />

2.00<br />

3.31 2.00 4.00<br />

6.00<br />

0.50<br />

1.66<br />

N/A N/A<br />

0.28 THRU<br />

N/A<br />

.56 X .44 CÕBORE<br />

.19 Ñ NO<br />

6J<strong>600</strong>A 1 POLE SEE FIGURE #3<br />

3 POLE<br />

FIG 5<br />

4.00 1.75 1.13<br />

11.75 4.38 2.38 4.69<br />

12.00 11.00 1.50<br />

N/A N/A<br />

.291 THRU<br />

N/A<br />

.58 X .19 CÕBORE<br />

.19 Ñ NO<br />

EXPANDER 1 Pole 2 Pole 3 Pole<br />

Figure 1:<br />

28

5-37.Fuseholders 11/20/03 11:22 AM Page 29<br />

Class J, G, M, CC Fuse Holder Dimensions<br />

3/16 HEX SOCKET<br />

D<br />

I<br />

H<br />

G<br />

F E F E<br />

B<br />

1 Pole 3 Pole<br />

J<br />

B<br />

Figure 2: Figure 2A:<br />

1 Pole 2 Pole 3 Pole<br />

K<br />

L<br />

A<br />

C-1015<br />

M<br />

C<br />

Figure 3:<br />

29<br />

C<br />

K<br />

A<br />

D<br />

F<br />

B<br />

E<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:22 AM Page 30<br />

Fuseholders<br />

Class J, G, M, CC Fuse Holder Dimensions<br />

1 Pole 3 Pole<br />

Figure 4:<br />

1 Pole 3 Pole<br />

Figure 5:<br />

30

5-37.Fuseholders 11/20/03 11:22 AM Page 31<br />

Semi Conductor Fuse Holder<br />

Box Version - Specifications:<br />

¥ Insulator Base, General Purpose Phenolic,<br />

150¡ C<br />

¥ Hex-Head Bolts and Belleville Washers<br />

Provided Unassembled<br />

¥ Connector-Aluminum, Tin Plated<br />

¥ 1MS101 has dove-tail interlocking feature<br />

¥ Two-piece modular design<br />

¥ UL <strong>600</strong>V<br />

Catalog#: Maximum Amperage: Wire Range:<br />

1MS101 100 #2/0 - #14<br />

1MS102 400 (2) 250 MCM - #6<br />

1MS103 400 (2) 250 MCM - #6<br />

1MS104 <strong>600</strong> (2) 500 MCM - #6<br />

Note: Order two blocks per fuse.<br />

Request “Semi-Conductor Fuse Holders” Brochure for more information.<br />

1MS101 1MS103<br />

1MS102 1MS104<br />

31<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:22 AM Page 32<br />

Fuseholders<br />

Semi Conductor Fuse Holder - 1,000 <strong>Volt</strong><br />

Stud Version - Specifications:<br />

¥ Base, General Purpose Phenolic, 150¡ C<br />

¥ Stud, Steel Zinc Plated<br />

¥ Nuts and Washers Provided Unassembled<br />

¥ UL Recognized File No. E35113<br />

¥<br />

Catalog#: Maximum Amperage: Fuse Size:<br />

Note: Order two blocks per fuse.<br />

ST 14 400 1Ó DIA<br />

ST 38 800 3Ó DIA<br />

ST14 ST38<br />

32

5-37.Fuseholders 11/20/03 11:22 AM Page 33<br />

Fuse Holders with BD<br />

(Box Distribution) Connectors<br />

30 and 60 Amp<br />

250 and <strong>600</strong> <strong>Volt</strong><br />

Specifications:<br />

¥ Available on Class H, R, and J Holders<br />

¥ Connectors, High Conductive Aluminum, Tin Plated<br />

¥ Reinforcing Member Available, Standard on Class R<br />

¥ UL Recognized File No. E35113<br />

¥ CSA Certified File No. LR21455<br />

Class H Fuse Holders (For Class R Replace F With R in Catalog Number)<br />

Class J Fuse Holders<br />

X - Denotes Number of Poles<br />

* - Class R and J - No Agency<br />

Catalog #: <strong>Volt</strong>s Amp Line Wire Range Load Wire Range<br />

F60AXBD<br />

F60AXBD-D<br />

250 60 (1) #2-#10 AWG<br />

6F30AXBD-D 30 (1) #6-#14 AWG<br />

6F60AXBD <strong>600</strong><br />

6F60AXBD-D<br />

60 (1) #2-#10 AWG<br />

33<br />

(1) #2-#10 AWG<br />

(1) #6-#14 AWG<br />

(1) #6-#14 AWG<br />

(2) #10-#18 AWG<br />

(1) #2-#10 AWG<br />

(1) #6-#14 AWG<br />

(1) #2-#10 AWG<br />

(2) #6-#14 AWG<br />

Catalog #: <strong>Volt</strong>s Amp Line Wire Range Load Wire Range<br />

6J60AXBD<br />

6J60AXBD-D<br />

<strong>600</strong> 60 (1) #2-#10 AWG<br />

(1) #2-#10 AWG<br />

(1) #6-#14 AWG<br />

(1) #2-#10 AWG<br />

(2) #6-#14 AWG<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:22 AM Page 34<br />

Fuseholders<br />

STSF Forklift/Semi Conductor Fuse Holder<br />

Specifications:<br />

Applications:<br />

¥ Base, High Strength Thermoplastic<br />

¥ Temperature Rating of 170¡ C<br />

¥ Studs, Stainless Steel (Nuts and Washers Provided)<br />

¥ 130V AC/DC, 1 to 400 Amps<br />

¥ UL Recognized File No. E35113<br />

This holder is found in direct current (DC) Applications: forklifts,<br />

golf carts, custom high-end car stereo systems, heavy equipment,<br />

marine aircraft, etc.<br />

STSF:<br />

A #10 flat or conventional pan head screw head is acceptable.<br />

34

5-37.Fuseholders 11/20/03 11:22 AM Page 35<br />

Fuse Holder Covers<br />

Specifications:<br />

¥ Material, Thermoplastic<br />

¥ Thermal Rating, 125¡ C (RT1, per UL 746)<br />

¥ Flammability, VO (per UL 94)<br />

¥ UL Listed Accessories Under File No. E181825<br />

¥ In Application, Protection is Consistent With IEC Standard 529,<br />

Designation IP2 (finger safe)*<br />

¥ Opening Allows View of Self-Indicating Fuses<br />

¥ Holes for Test Probes and Re-tightening of Wire Terminations<br />

¥ Covers Fit Most Fuse Holder Brands<br />

Catalog#: For Use W/Fuse Holder#: Fuse Type: <strong>Volt</strong>age: Amp:<br />

CHR230 F30A/R30A H/R 250 30<br />

CHR260 F60A/R60A H/R 250 60<br />

CHR2100 RF100A/R100A H/R 250 100<br />

CHR630 6F30A/6R30A H/R <strong>600</strong> 30<br />

CHR660 6F60A/6R60A H/R <strong>600</strong> 60<br />

CHR6100 R6F100A/6R100A H/R <strong>600</strong> 100<br />

CJ630 6J30A J <strong>600</strong> 30<br />

CJ660 6J60A J <strong>600</strong> 60<br />

CC630 6CC30 CC <strong>600</strong> 30<br />

CC660 6CC60 CD <strong>600</strong> 60<br />

CCM630** 6M30A/6CCM30A MISC <strong>600</strong> 30<br />

* Applications involving fuse holders other than Marathon may not provide IP2 finger protection.<br />

** Covers are recognized if used with recognized fuses.<br />

35<br />

Fuseholders

5-37.Fuseholders 11/20/03 11:22 AM Page 36<br />

Fuseholders<br />

36<br />

Fuse Holder Covers<br />

Catalog Name Figure A B C D E F<br />

CHR230 Fig 1 3.76 1.67 0.86 2.54 0.40 0.30<br />

CHR260 Fig 1 5.80 2.16 1.07 3.66 0.47 0.42<br />

CHR2100 Fig 2 7.38 2.41 1.49 4.90 0.38 0.46<br />

CHR630 Fig 1 7.56 1.71 1.10 5.58 0.47 0.42<br />

CHR660 Fig 1 8.30 2.37 1.35 6.32 0.35 0.42<br />

CHR6100 Fig 2 9.34 2.45 1.49 6.90 0.38 0.46<br />

CJ630 Fig 1 4.30 1.95 0.90 2.66 0.35 0.30<br />

CJ660 Fig 1 5.04 2.07 1.35 3.10 0.35 0.42<br />

CC630 Fig 3 3.83 1.69 0.74 2.34 0.34 0.30<br />

CC660 Fig 1 4.58 1.95 0.90 2.66 0.35 0.42<br />

CCM630 Fig 3 3.83 1.69 0.74 2.34 0.34 0.30<br />

MM = Dim X 25.4<br />

Figure 1:<br />

Figure 2:<br />

Figure 3:

5-37.Fuseholders 11/20/03 11:22 AM Page 37<br />

Class CC, G and Midget<br />

Fuse Holder Accessories<br />

DIN Rail Adapter (Catalog# DIN R-2)<br />

This adapter is for use with the Class CC (30A), Midget and Class G fuse holders. The DIN R-2 snaps<br />

securely to the Marathon fuse holders and to DIN rails without tools. This permits the holders to mount<br />

directly to standard and low profile 35mm symmetrical and 32mm asymmetrical DIN rails. They may be<br />

removed from rails by lifting the disconnect tab.<br />

Cover/Puller (Catalog# CVR-MCC)<br />

MarathonÕs Cover/Puller was designed for use with the Class CC (30A), Midget and Class G (15 & 20 amp<br />

only) fuse holders. Once installed, the Cover/Puller provides an easy and safe way to remove fuses. In<br />

application, protection is consistent with IEC Standard 529, designation IP2 (finger safe).<br />

37<br />

Fuseholders

38-50.power blocks 11/20/03 11:24 AM Page 38<br />

Power Blocks<br />

General Information:<br />

Power Terminal Blocks<br />

Power Terminal Blocks are available in seven molding sizes. They are identified by the first three digits of the catalog number.<br />

The 140, 142, 143, 144 and 145 series are manufactured with general purpose phenolic rated at 150¡ C. The 141 and 132<br />

series are manufactured of high impact thermoplastic rated at 125¡ C.<br />

All Power Terminal Blocks are UL recognized file number E62806 and CSA certified file number LR19766, unless noted.<br />

Connector Wire Hole Size:<br />

Conductor Opening Diameter of Opening<br />

#10-18 . . . . . . . . . . . . . . . . . . . . . . . . . .158Ó<br />

#4-14 . . . . . . . . . . . . . . . . . . . . . . . . . . .250Ó<br />

#2-14 . . . . . . . . . . . . . . . . . . . . . . . . . . .312Ó<br />

#2/0-14 . . . . . . . . . . . . . . . . . . . . . . . . . .438Ó<br />

#250MCM-6 . . . . . . . . . . . . . . . . . . . . . .630Ó<br />

#315MCM-6 . . . . . . . . . . . . . . . . . . . . . .718Ó<br />

#400MCM-6 . . . . . . . . . . . . . . . . . . . . . .769Ó<br />

#500MCM-4 . . . . . . . . . . . . . . . . . . . . . .875Ó<br />

Wire hole openings are designed to accept stranded conductors with the number of strands specified in UL 486. Consult factory<br />

for other diameters.<br />

Ratings and Standards:<br />

The voltage ratings of terminal blocks are based upon the minimum spacing between electrically conductive parts line to line<br />

through air and over surface and line to ground through air and over surface.<br />

Class A<br />

Service equipment including deadfront switchboards, panel boards, service entrance devices.<br />

Class B<br />

Commercial appliances including business equipment, electronic data processing equipment and the like.<br />

Class C<br />

General industrial and machine tool controls which can be further defined as equipment falling under UL 508.<br />

Ratings based on UL 1059 may be higher in some cases depending on application.<br />

Spacing Requirements*:<br />

<strong>Volt</strong>age Thru Air Over Surface<br />

51-150 .500 .750<br />

Class A 151-300 .750 1.250<br />

301-<strong>600</strong> 1.000 2.000<br />

51-150 .063 .063<br />

Class B 151-300 .094 .094<br />

301-<strong>600</strong> .375 .500<br />

51-150 .125 .250<br />

Class C 151-300 .250 .375<br />

*In Inches<br />

301-<strong>600</strong> .375 .500<br />

Applications:<br />

Designed for use with heating, air conditioning and refrigeration, elevator systems, material handling equipment, control<br />

panels, motor control, switchgear, and any area where power needs to be distributed to more than one load.<br />

38

38-50.power blocks 11/20/03 11:24 AM Page 39<br />

Power Distribution Blocks<br />

<strong>600</strong> <strong>Volt</strong>s<br />

Specifications:<br />

Catalog #<br />

1411403<br />

1412403<br />

1413403<br />

1414403<br />

1411400<br />

1412400<br />

1413400<br />

1414400<br />

1421570<br />

1422570<br />

1423570<br />

1402402<br />

1403402<br />

1402401<br />

1403401<br />

1402404<br />

1403404<br />

1441401<br />

1442401<br />

1443401<br />

1431552<br />

1432552<br />

1433552<br />

1431553<br />

1432553<br />

1433553<br />

1441560<br />

1442560<br />

1443560<br />

1431555<br />

1432555<br />

1433555<br />

1441551<br />

1442551<br />

1443551<br />

¥ Connector, High Conductive Aluminum, Tin Plated<br />

¥ Amp Rating Based on NEC Table 310-16 Using 75¡ C Copper Wire<br />

¥ *Wire Connector Rated 90¡ C<br />

¥ UL Recognized File No. E62806<br />

¥ CSA Certified File No. LR19766<br />

¥<br />

** Openings rated for #4-14 AWG are multiple wire rated:<br />

(2) #10 CU Str, (2 to 4) #12 CU Str, and (2 to 4) #14 CU Str.<br />

Poles<br />

1<br />

2<br />

3<br />

4<br />

1<br />

2<br />

3<br />

4<br />

1<br />

2<br />

3<br />

2<br />

3<br />

2<br />

3<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

Amps<br />

60<br />

115<br />

175<br />

175<br />

175<br />

310<br />

335<br />

335<br />

335<br />

335<br />

350<br />

380<br />

Connector<br />

Configuration<br />

*<br />

*<br />

*<br />

*<br />

Line Openings Connector<br />

Load<br />

Wire Range per pole Configuration Wire Range<br />

#2-#14AWG<br />

#2-#14AWG<br />

2/0-#14AWG<br />

2/0-#14AWG<br />

2/0-#14AWG<br />

350MCM-#6AWG<br />

400MCM-#6AWG<br />

400MCM-#6AWG<br />

400MCM-#6AWG<br />

400MCM-#6AWG<br />

2/0-#14AWG<br />

500MCM-#4AWG<br />

39<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

2<br />

1<br />

#10-#18AWG<br />

#10-#18AWG<br />

** #4-#14AWG<br />

** #4-#14AWG<br />

** #4-#14AWG<br />

** #4-#14AWG<br />

#2-#14AWG<br />

#2-#14AWG<br />

#2-#14AWG<br />

#2-#14AWG<br />

** #4-#14AWG<br />

#2-#14AWG<br />

Openings<br />

per pole<br />

2<br />

4<br />

4<br />

4<br />

6<br />

6<br />

6<br />

4<br />

6<br />

8<br />

6<br />

6<br />

Power Blocks

38-50.power blocks 11/20/03 11:25 AM Page 40<br />

Power Blocks<br />

<strong>600</strong> <strong>Volt</strong>s<br />

Catalog #<br />

1451579<br />

1452579<br />

1453579<br />

1431587<br />

1432587<br />

1433587<br />

1451594<br />

1452594<br />

1453594<br />

1451552<br />

1452552<br />

1453552<br />

1451592<br />

1452592<br />

1453592<br />

1451587<br />

1452587<br />

1453587<br />

1451586<br />

1452586<br />

1453586<br />

1451411<br />

1452411<br />

1453411<br />

1421970<br />

1422970<br />

1423970<br />

1431953<br />

1432953<br />

1433953<br />

1431955<br />

1432955<br />

1433955<br />

1451992<br />

1452992<br />

1453992<br />

1451986<br />

1452986<br />

1453986<br />

1453401<br />

Poles<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

2<br />

3<br />

1<br />

Power Distribution Blocks (Cont.)<br />

Amps<br />

380<br />

380<br />

380<br />

380<br />

760<br />

665<br />

760<br />

840<br />

175<br />

380<br />

350<br />

760<br />

760<br />

2280<br />

Specifications:<br />

Connector<br />

Configuration<br />

CU<br />

CU<br />

¥ Connector, High Conductive Aluminum, Tin Plated<br />

¥ Amp Rating Based on NEC Table 310-16 Using 75¡ C, Copper Wire<br />

¥ CU-Connector, High Conductive Copper, Tin Plated<br />

(Meets Copper Only Automotive Standard)<br />

¥ UL Recognized File No. E62806<br />

¥ CSA Certified File No. LR19766<br />

¥<br />

** Openings rated for #4-14 AWG are multiple wire rated:<br />

(2) #10 CU Str, (2 to 4) #12 CU Str, and (2 to 4) #14 CU Str.<br />

Line Openings Connector<br />

Load<br />

Wire Range per pole Configuration Wire Range<br />

500MCM-#4AWG<br />

500MCM-#4AWG<br />

500MCM-#4AWG<br />

500MCM-#4AWG<br />

500MCM-#4AWG<br />

500MCM-#4AWG<br />

350MCM-#4AWG<br />

500MCM-#4AWG<br />

<strong>600</strong>MCM-#2AWG<br />

2/0-#14AWG<br />

500MCM-#4AWG<br />

2/0-#14AWG<br />

500MCM-#4AWG<br />

500MCM-#4AWG<br />

500MCM-#6AWG<br />

40<br />

1<br />

1<br />

1<br />

1<br />

2<br />

1<br />

2<br />

2<br />

1<br />

1<br />

2<br />

2<br />

2<br />

6<br />

CU<br />

CU<br />

CU<br />

CU<br />

CU<br />

2/0-#14AWG<br />

350MCM-#6AWG<br />

#2-14AWG<br />

#2-#14AWG<br />

#2-#14AWG<br />

** #4-#14AWG<br />

2/0-#14AWG<br />

2/0-#14AWG<br />

3/0-#6AWG<br />

** #4-#14AWG<br />

** #4-#14AWG<br />

#2-#14AWG<br />

** #4-#14AWG<br />

#2-#14AWG<br />

2/0-#14AWG<br />

2/0-#14AWG<br />

Openings<br />

per pole<br />

6<br />

1<br />

3<br />

1<br />

3<br />

1<br />

3<br />

8<br />

12<br />

12<br />

4<br />

8<br />

4<br />

4<br />

6<br />

6<br />

12<br />

8<br />

18

38-50.power blocks 11/20/03 11:25 AM Page 41<br />

Power Blocks (Splicer)<br />

<strong>600</strong> <strong>Volt</strong>s<br />

Specifications:<br />

¥ Connector, High Conductive Aluminum, Tin Plated<br />

¥ CU-Connector, High Conductive Copper, Tin Plated<br />

(Meets Copper Only Automotive Standard)<br />

¥ Amp Rating Based on NEC Table 310-16 Using 75¡ C Copper Wire<br />

¥ *Wire Connector Rated 90¡ C<br />

¥ UL Recognized File No. E62806<br />

¥ CSA Certified File No. LR19766<br />

¥<br />

Connector<br />

Line Openings Connector<br />

Load Openings<br />

Catalog# Poles Amps Configuration Wire Range Per Pole Configuration Wire Range Per Pole<br />

1411300 1<br />

1412300<br />

1413300<br />

2<br />

3<br />

115 *<br />

#2-#14AWG 1 #2-#14AWG 1<br />

1414300 4<br />

1421552 1<br />

1422552 2 115 *<br />

#2-#14AWG 1 #2-#14AWG 1<br />

1423552 3<br />

1421572 1<br />

1422572 2 175 *<br />

2/0-#14AWG 1 2/0-#14AWG 1<br />

1423572 3<br />

1402801<br />

1403801<br />

2<br />

3<br />

255 250MCM-#6AWG 1 250MCM-#6AWG 1<br />

1431123 1<br />

1432123 2 255 250MCM-#6AWG 1 250MCM-#6AWG 1<br />

1433123 3<br />

1402303<br />

1403303<br />

2<br />

3<br />

310 350MCM-#6AWG 1 350MCM-#6AWG 1<br />

1431126 1<br />

1432126 2 310 350MCM-#6AWG 1 350MCM-#6AWG 1<br />

1433126 3<br />

1441557 1<br />

1442557 2 420 <strong>600</strong>MCM-#4AWG 1 <strong>600</strong>MCM-#4AWG 1<br />

1443557 3<br />

1451129 1<br />

1452129 2 620 350MCM-#4AWG 2 350MCM-#4AWG 2<br />

1453129 3<br />

1451301 1<br />

1452301 2 760 500MCM-#4AWG 2 500MCM-#4AWG 2<br />

1453301 3<br />

1421121<br />

1422121<br />

1423121<br />

1<br />

2<br />

3<br />

175<br />

*<br />

CU<br />

2/0-#14AWG 1<br />

CU<br />

2/0-#14AWG 1<br />

1431124 1<br />

1432124 2 255 250MCM-#6AWG 1 250MCM-#6AWG 1<br />

1433124 3<br />

41<br />

Power Blocks

38-50.power blocks 11/20/03 11:25 AM Page 42<br />

Power Blocks<br />

<strong>600</strong> <strong>Volt</strong>s<br />

Specifications:<br />

¥ Connector, High Conductive Copper, Tin Plated<br />

¥ Stud, Brass, Tin Plated<br />

¥ Amp Rating Based on NEC Table 310-16 Using 75¡ C Copper Wire<br />

¥ UL Recognized File No. E62806<br />

¥ CSA Certified File No. LR19766<br />

¥<br />

42<br />

Power Stud Blocks<br />

Connector<br />

Line Openings Connector<br />

Load Openings<br />

Catalog# Poles Amps Configuration Wire Range Per Pole Configuration Wire Range Per Pole<br />

1421123 1<br />

1422123<br />

1423123<br />

2<br />

3<br />

200 1/4-20 Screw 1 1/4-20 Screw<br />

1<br />

1421122 1<br />

1422122 2 200 1/4-20 X 9/16 Stud 1 1/4-20 X 9/16 Stud 1<br />

1423122 3<br />

1431563 1<br />

1432563 2 230 3/8-16 X1 3/16 Stud 1 3/8-16 X1 3/16 Stud 1<br />

1433563 3<br />

1431561 1<br />

1432561 2 230 3/8-16 X1 3/16 Stud 1 1/4-20 X1 3/16 Stud 1<br />

1433561 3<br />

1441122 1<br />

1442122 2 260 3/8-16 X1 7/16 Stud 1 1/4-20 X 9/16 Stud 2<br />

1443122 3<br />

1441553 1<br />

1442553 2 230 3/8-16 X1 7/16 Stud 1 3/8-16 X1 7/16 Stud 1<br />

1443553 3<br />

1451606 1<br />

1452606 2 410 1/2-13 X1 7/16 Stud 1 1/2-13 X1 7/16 Stud 1<br />

1453606 3<br />

1451573<br />

1452573<br />

1<br />

2 360 3/8-16 X1 7/16 Stud 1 3/8-16 X1 7/16 Stud<br />

2<br />

1453573 3<br />

1451583 1<br />

1452583 2 360 3/8-16 X1 7/16 Stud 1 1/4-20 X1 7/16 Stud 2<br />

1453583 3<br />

1441614 1<br />

1442614 2 840 3/8-16 X 1 Stud 1 3/8-16 X 1 Stud 1<br />

1443614 3

38-50.power blocks 11/20/03 11:25 AM Page 43<br />

Power/Splicer Stud Blocks<br />

<strong>600</strong> <strong>Volt</strong>s<br />

Specifications:<br />

¥ Connector, High Conductive Aluminum, Tin Plated<br />

¥ Stud, Brass, Tin Plated<br />

¥ Quick Connect, Brass, Tin Plated<br />

¥ 10-32 Screw, Brass, Nickel Plated<br />

¥ Amp Rating Based on NEC Table 310-16 Using 75¡ C Copper Wire<br />

¥ *Wire Connector Rated 90¡ C<br />

¥ UL Recognized File No. E62806<br />

¥ CSA Certified File No. LR19766<br />

¥<br />

Connector<br />

Line Openings Connector<br />

Load Openings<br />

Catalog# Poles Amps Configuration Wire Range Per Pole Configuration Wire Range Per Pole<br />

1411200 1<br />

1412200<br />

1413200<br />

2<br />

3<br />

115<br />

#2-#14AWG 1 10-32 Screw 1<br />

1414200 4<br />

1411201 1<br />

1412201<br />

1413201<br />

2<br />

3<br />

115<br />

#2-#14AWG 1 10-32 Tapped Hole 1<br />

1414201 4<br />

1411202 1<br />

1412202<br />

1413202<br />

2<br />

3<br />

115<br />

#2-#14AWG 1 .25X.032 Qk Cnct 4<br />

1414202 4<br />

1411203 1<br />

1412203<br />

1413203<br />

2<br />

3<br />

115<br />

#2-#14AWG 1 10-32 X .60 Stud 1<br />

1414203 4<br />

1411205 1<br />

1412205<br />

1413205<br />

2<br />

3<br />

115<br />

#2-#14AWG 1 #10-32 Hole & (2) QC 1<br />

1414205 4<br />

1411301 1<br />

1412301<br />

1413301<br />

2<br />

3<br />

115<br />

#2-#14AWG 1 #2-#14AWG & (1) QC 1<br />

1414301 4<br />

1431559 1<br />

1432559 2 310 350MCM-#6AWG 1 3/8-16 X 11/8 Stud 1<br />

1433559 3<br />

1421411<br />

1422411<br />

1<br />

2 175 *<br />

2/0-#14AWG 1 M6 Hole 1<br />

1423411 3<br />

1421553<br />

1422553<br />

1<br />

2 175 *<br />

2/0-#14AWG 1 1/4-20 Tapped Hole 1<br />

1423553 3<br />

43<br />

Power Blocks

38-50.power blocks 11/20/03 11:25 AM Page 44<br />

Power Blocks<br />

<strong>600</strong> <strong>Volt</strong>s<br />

Specifications:<br />

Power Splicer/Stud Blocks (Cont.)<br />