POLY-CRETE CF - Dur-A-Flex

POLY-CRETE CF - Dur-A-Flex

POLY-CRETE CF - Dur-A-Flex

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

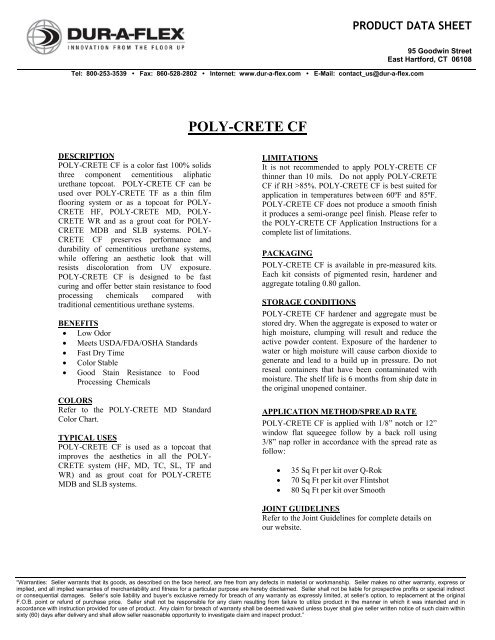

DESCRIPTION<br />

<strong>POLY</strong>-<strong>CRETE</strong> <strong>CF</strong> is a color fast 100% solids<br />

three component cementitious aliphatic<br />

urethane topcoat. <strong>POLY</strong>-<strong>CRETE</strong> <strong>CF</strong> can be<br />

used over <strong>POLY</strong>-<strong>CRETE</strong> TF as a thin film<br />

flooring system or as a topcoat for <strong>POLY</strong>-<br />

<strong>CRETE</strong> HF, <strong>POLY</strong>-<strong>CRETE</strong> MD, <strong>POLY</strong>-<br />

<strong>CRETE</strong> WR and as a grout coat for <strong>POLY</strong>-<br />

<strong>CRETE</strong> MDB and SLB systems. <strong>POLY</strong>-<br />

<strong>CRETE</strong> <strong>CF</strong> preserves performance and<br />

durability of cementitious urethane systems,<br />

while offering an aesthetic look that will<br />

resists discoloration from UV exposure.<br />

<strong>POLY</strong>-<strong>CRETE</strong> <strong>CF</strong> is designed to be fast<br />

curing and offer better stain resistance to food<br />

processing chemicals compared with<br />

traditional cementitious urethane systems.<br />

BENEFITS<br />

• Low Odor<br />

• Meets USDA/FDA/OSHA Standards<br />

• Fast Dry Time<br />

• Color Stable<br />

• Good Stain Resistance to Food<br />

Processing Chemicals<br />

COLORS<br />

Refer to the <strong>POLY</strong>-<strong>CRETE</strong> MD Standard<br />

Color Chart.<br />

TYPICAL USES<br />

<strong>POLY</strong>-<strong>CRETE</strong> <strong>CF</strong> is used as a topcoat that<br />

improves the aesthetics in all the <strong>POLY</strong>-<br />

<strong>CRETE</strong> system (HF, MD, TC, SL, TF and<br />

WR) and as grout coat for <strong>POLY</strong>-<strong>CRETE</strong><br />

MDB and SLB systems.<br />

<strong>POLY</strong>-<strong>CRETE</strong> <strong>CF</strong><br />

LIMITATIONS<br />

It is not recommended to apply <strong>POLY</strong>-<strong>CRETE</strong> <strong>CF</strong><br />

thinner than 10 mils. Do not apply <strong>POLY</strong>-<strong>CRETE</strong><br />

<strong>CF</strong> if RH >85%. <strong>POLY</strong>-<strong>CRETE</strong> <strong>CF</strong> is best suited for<br />

application in temperatures between 60ºF and 85ºF.<br />

<strong>POLY</strong>-<strong>CRETE</strong> <strong>CF</strong> does not produce a smooth finish<br />

it produces a semi-orange peel finish. Please refer to<br />

the <strong>POLY</strong>-<strong>CRETE</strong> <strong>CF</strong> Application Instructions for a<br />

complete list of limitations.<br />

PACKAGING<br />

<strong>POLY</strong>-<strong>CRETE</strong> <strong>CF</strong> is available in pre-measured kits.<br />

Each kit consists of pigmented resin, hardener and<br />

aggregate totaling 0.80 gallon.<br />

STORAGE CONDITIONS<br />

<strong>POLY</strong>-<strong>CRETE</strong> <strong>CF</strong> hardener and aggregate must be<br />

stored dry. When the aggregate is exposed to water or<br />

high moisture, clumping will result and reduce the<br />

active powder content. Exposure of the hardener to<br />

water or high moisture will cause carbon dioxide to<br />

generate and lead to a build up in pressure. Do not<br />

reseal containers that have been contaminated with<br />

moisture. The shelf life is 6 months from ship date in<br />

the original unopened container.<br />

APPLICATION METHOD/SPREAD RATE<br />

<strong>POLY</strong>-<strong>CRETE</strong> <strong>CF</strong> is applied with 1/8” notch or 12”<br />

window flat squeegee follow by a back roll using<br />

3/8” nap roller in accordance with the spread rate as<br />

follow:<br />

• 35 Sq Ft per kit over Q-Rok<br />

• 70 Sq Ft per kit over Flintshot<br />

• 80 Sq Ft per kit over Smooth<br />

PRODUCT DATA SHEET<br />

Tel: 800-253-3539 • Fax: 860-528-2802 • Internet: www.dur-a-flex.com • E-Mail: contact_us@dur-a-flex.com<br />

95 Goodwin Street<br />

East Hartford, CT 06108<br />

JOINT GUIDELINES<br />

Refer to the Joint Guidelines for complete details on<br />

our website.<br />

“Warranties: Seller warrants that its goods, as described on the face hereof, are free from any defects in material or workmanship. Seller makes no other warranty, express or<br />

implied, and all implied warranties of merchantability and fitness for a particular purpose are hereby disclaimed. Seller shall not be liable for prospective profits or special indirect<br />

or consequential damages. Seller’s sole liability and buyer’s exclusive remedy for breach of any warranty as expressly limited, at seller’s option, to replacement at the original<br />

F.O.B. point or refund of purchase price. Seller shall not be responsible for any claim resulting from failure to utilize product in the manner in which it was intended and in<br />

accordance with instruction provided for use of product. Any claim for breach of warranty shall be deemed waived unless buyer shall give seller written notice of such claim within<br />

sixty (60) days after delivery and shall allow seller reasonable opportunity to investigate claim and inspect product.”

MOISTURE CONCERNS<br />

Please refer to the Floor Evaluation Flow Chart in the<br />

Contractor’s Center of our website for a step-by-step<br />

process to determine the condition of the concrete.<br />

DRAWINGS AND DETAILS<br />

Standard CAD drawings and details are available for<br />

coves, drains, breaches, transitions, etc. Please refer<br />

to the master Drawings and Details guide for actual<br />

drawings.<br />

<strong>POLY</strong>-<strong>CRETE</strong> <strong>CF</strong><br />

PRODUCT PROPERTIES<br />

Weight Solids, % (Resin/Hardener/Powder) 100%<br />

Volatile Organic Compounds Content (VOC) 0 g/l<br />

Mix Ratio 3 Component Kit<br />

<strong>Flex</strong>ural Strength (ASTM D790) 1000 psi<br />

Compressive Strength (ASTM C579) 7,800 psi<br />

Tensile Strength (ASTM D638) 4,200 psi<br />

Taber Abrasion Resistance (ASTM D4060)<br />

45 mg loss<br />

ASTM D 4060, 1000g load, 1000 cycles, CS-17 wheel<br />

Impact, in.–lbs. (ASTM D1709): Direct<br />

Reverse<br />

Recommended Applied Thickness and Spread Rate<br />

Q-Rok<br />

Flintshot<br />

Smooth<br />

CLEANING<br />

This product is considered a low maintenance<br />

flooring solution, however, certain textures and<br />

service environments do require certain procedures.<br />

Please refer to the master Cleaning Guide on our<br />

website.<br />

CAUTION<br />

Follow the Hazardous Materials Identification<br />

System labeling guide for proper personal<br />

protective equipment to use when handling this<br />

product. Use only as directed. KEEP OUT OF<br />

REACH OF CHILDREN.<br />

Before using any DUR-A-FLEX, Inc. product, be sure the Material Safety Data Sheet is read and understood.<br />

160<br />

160<br />

35 Sq Ft per kit<br />

70 Sq Ft per kit<br />

80 Sq Ft per kit @ 12mils<br />

Shore D Hardness (ASTM D2240) 65 D<br />

Gloss (ASTM D523) 60º 40-50 Satin Appearance<br />

Pot Life at 70ºF, 50%RH<br />

20 minutes<br />

Working Time at 70ºF,50%RH<br />

Dry Time for Full Service Traffic<br />

15 minutes<br />

70ºF<br />

16 hours<br />

60ºF<br />

24 hours<br />

50ºF<br />

44 hours<br />

CHEMICAL RESISTANCE (8 HOURS COVERED SPOT TEST – ASTM D1308)<br />

30% Nitric Acid Good<br />

30% Acetic Acid Good<br />

50% Lactic Acid Good<br />

CIP Cleaning Solutions AC 55-5 Good<br />

066. Poly-Crete <strong>CF</strong> Product Data Sheet4/30/2012