Institute of Production Management, Technology and Machine

Institute of Production Management, Technology and Machine

Institute of Production Management, Technology and Machine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

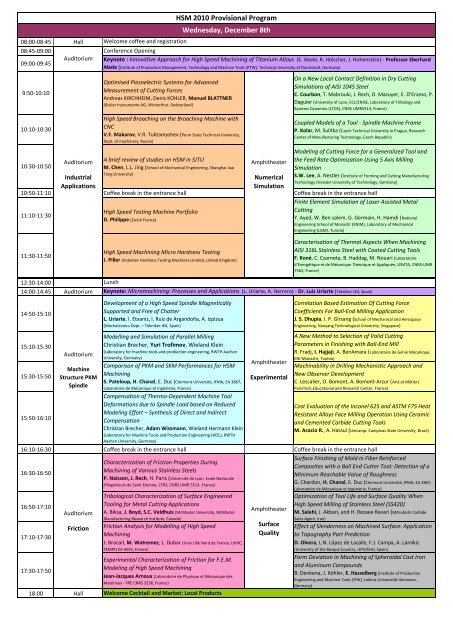

08:00-08:45 Hall<br />

08:45-09:00<br />

09:00-09:45<br />

9:50-10:10<br />

10:10-10:30<br />

10:30-10:50<br />

Optimised Piezoelectric Systems for Advanced<br />

Measurement <strong>of</strong> Cutting Forces<br />

Andreas KIRCHHEIM, Denis KOHLER, Manuel BLATTNER<br />

(Kistler Instrumente AG, Winterthur, Switzerl<strong>and</strong>)<br />

High Speed Broaching on the Broaching <strong>Machine</strong> with<br />

CNC<br />

V.F. Makarov, V.R. Tuktamyshev (Perm State Technical University,<br />

Dept. <strong>of</strong> machinery, Russia)<br />

A brief review <strong>of</strong> studies on HSM in SJTU<br />

M. Chen, L.L. Jing (School <strong>of</strong> Mechanical Engineering, Shanghai Jiao<br />

Tong University)<br />

On a New Local Contact Definition in Dry Cutting<br />

Simulations <strong>of</strong> AISI 1045 Steel<br />

C. Courbon, T. Mabrouki, J. Rech, D. Mazuyer, E. D’ Eramo, P.<br />

Daguier (University <strong>of</strong> Lyon, ECL/ENISE, Laboratory <strong>of</strong> Tribology <strong>and</strong><br />

Systems Dynamics (LTDS), CNRS UMR5513, France)<br />

Coupled Models <strong>of</strong> a Tool - Spindle <strong>Machine</strong> Frame<br />

P. Kolar, M. Sulitka (Czech Technical University in Prague, Research<br />

Center <strong>of</strong> Manufacturing <strong>Technology</strong>, Czech Republic)<br />

Modeling <strong>of</strong> Cutting Force for a Generalized Tool <strong>and</strong><br />

the Feed Rate Optimization Using 5 Axis Milling<br />

Simulation<br />

S.W. Lee, A. Nestler (<strong>Institute</strong> <strong>of</strong> Forming <strong>and</strong> Cutting Manufacturing<br />

<strong>Technology</strong> Dresden University <strong>of</strong> <strong>Technology</strong>, Germany)<br />

Industrial<br />

Numerical<br />

Applications<br />

Simulation<br />

10:50-11:10 C<strong>of</strong>fee break in the entrance hall C<strong>of</strong>fee break in the entrance hall<br />

Finite Element Simulation <strong>of</strong> Laser Assisted Metal<br />

11:10-11:30<br />

High Speed Testing <strong>Machine</strong> Portfolio<br />

D. Philippe (Zwick France)<br />

Cutting<br />

Y. Ayed, W. Ben salem, G. Germain, H. Hamdi (National<br />

Engineering School <strong>of</strong> Monastir (ENIM), Laboratory <strong>of</strong> Mechanical<br />

Engineering (LGM), Tunisia)<br />

11:30-11:50<br />

12:30-14:00<br />

14:00-14:45 Auditorium<br />

14:50-15:10<br />

15:10-15:30<br />

15:30-15:50<br />

15:50-16:10<br />

High Speed Machining Micro Hardness Testing<br />

J. Piller (Indentec Hardness Testing <strong>Machine</strong>s Limited, United Kingdom)<br />

Development <strong>of</strong> a High Speed Spindle Magnetically<br />

Supported <strong>and</strong> Free <strong>of</strong> Chatter<br />

L. Uriarte, I. Etxaniz, I. Ruiz de Arg<strong>and</strong>oña, A. Izpizua<br />

(Mechatronics Dept. – Tekniker-IK4, Spain)<br />

Modelling <strong>and</strong> Simulation <strong>of</strong> Parallel Milling<br />

Christian Brecher, Yuri Tr<strong>of</strong>imov, Wiel<strong>and</strong> Klein<br />

(Laboratory for machine tools <strong>and</strong> production engineering, RWTH Aachen<br />

University, Germany)<br />

Comparison <strong>of</strong> PKM <strong>and</strong> SKM Performances for HSM<br />

Machining<br />

S. Pateloup, H. Chanal, E. Duc (Clermont Université, IFMA, EA 3867,<br />

Laboratoire de Mécanique et Ingénierie, France)<br />

Compensation <strong>of</strong> Thermo-Dependent <strong>Machine</strong> Tool<br />

Deformations due to Spindle Load based on Reduced<br />

Modeling Effort – Synthesis <strong>of</strong> Direct <strong>and</strong> Indirect<br />

Compensation<br />

Christian Brecher, Adam Wissmann, Wiel<strong>and</strong> Hermann Klein<br />

(Laboratory for <strong>Machine</strong> Tools <strong>and</strong> <strong>Production</strong> Engineering (WZL), RWTH<br />

Aachen University, Germany)<br />

Caracterisation <strong>of</strong> Thermal Aspects When Machining<br />

AISI 316L Stainless Steel with Coated Cutting Tools<br />

F. Koné, C. Czarnota, B. Haddag, M. Nouari (Laboratoire<br />

d’ Energétique et de Mécanique Théorique et Appliquée, LEMTA, CNRS-UMR<br />

7563, France)<br />

Correlation Based Estimation Of Cutting Force<br />

Coefficients For Ball-End Milling Application<br />

J. S. Dhupia, I. P. Girsang (School <strong>of</strong> Mechanical <strong>and</strong> Aerospace<br />

Engineering, Nanyang Technological University, Singapore)<br />

A New Method to Selection <strong>of</strong> Valid Cutting<br />

Parameters in Finishing with Ball-End Mill<br />

R. Fradj, I. Hajjaji, A. BenAmara (Laboratoire de Génie Mécanique,<br />

ENI-Monastir, Tunisia)<br />

Machinability in Drilling Mechanistic Approach <strong>and</strong><br />

New Observer Development<br />

C. Lescalier, O. Bomont, A. Bomont-Arzur (Arts et Métiers<br />

ParisTech,Educational <strong>and</strong> Research Center, France)<br />

Cost Evaluation <strong>of</strong> the Inconel 625 <strong>and</strong> ASTM F75 Heat<br />

Resistant Alloys Face Milling Operation Using Ceramic<br />

<strong>and</strong> Cemented Carbide Cutting Tools<br />

M. Acacio R., A. Hassui (Unicamp. Campinas State University, Brazil)<br />

16:10-16:30 C<strong>of</strong>fee break in the entrance hall C<strong>of</strong>fee break in the entrance hall<br />

16:30-16:50<br />

16:50-17:10<br />

17:10-17:30<br />

17:30-17:50<br />

Auditorium<br />

Auditorium<br />

Auditorium<br />

<strong>Machine</strong><br />

Structure PKM<br />

Spindle<br />

Auditorium<br />

Friction<br />

18:00 Hall<br />

Welcome c<strong>of</strong>fee <strong>and</strong> registration<br />

HSM 2010 Provisional Program<br />

Wednesday, December 8th<br />

Conference Opening<br />

Keynote : Innovative Approach for High Speed Machining <strong>of</strong> Titanium Alloys (E. Abele, R. Hölscher, J. Hohenstein) - Pr<strong>of</strong>essor Eberhard<br />

Abele (<strong>Institute</strong> <strong>of</strong> <strong>Production</strong> <strong>Management</strong>, <strong>Technology</strong> <strong>and</strong> <strong>Machine</strong> Tools (PTW), Technical University <strong>of</strong> Darmstadt, Germany)<br />

Lunch<br />

Keynote: Micromachining: Processes <strong>and</strong> Applications (L. Uriarte, A. Herrero) - Dr. Luis Uriarte (Tekniker-IK4, Spain)<br />

Characterization <strong>of</strong> Friction Properties During<br />

Machining <strong>of</strong> Various Stainless Steels<br />

P. Naisson, J. Rech, H. Paris (Université de Lyon, Ecole Nationale<br />

d’ Ingénieurs de Saint Etienne, LTDS, CNRS UMR 5513, France)<br />

Tribological Characterization <strong>of</strong> Surface Engineered<br />

Tooling for Metal Cutting Applications<br />

A. Biksa, J. Boyd, S.C. Veldhuis (McMaster University, McMaster<br />

Manufacturing Research <strong>Institute</strong>, Canada)<br />

Friction Analysis for Modelling <strong>of</strong> High Speed<br />

Machining<br />

J. Brocail, M. Watremez, L. Dubar (Univ Lille Nord de France; UVHC,<br />

TEMPO EA 4542, France)<br />

Experimental Characterization <strong>of</strong> Friction for F.E.M.<br />

Modeling <strong>of</strong> High Speed Machining<br />

Jean-Jacques Arnoux (Laboratoire de Physique et Mécanique des<br />

Matériaux - FRE CNRS 3236, France)<br />

Welcome Cocktail <strong>and</strong> Market: Local Products<br />

Amphitheater<br />

Amphitheater<br />

Experimental<br />

Amphitheater<br />

Surface<br />

Quality<br />

Surface Finishing <strong>of</strong> Mold in Fiber Reinforced<br />

Composites with a Ball End Cutter Tool: Detection <strong>of</strong> a<br />

Minimum Reachable Value <strong>of</strong> Roughness<br />

G. Chardon, H. Chanal, E. Duc (Clermont Université, IFMA, EA 3867,<br />

Laboratoire de Mécanique et Ingénierie, France)<br />

Optimization <strong>of</strong> Tool Life <strong>and</strong> Surface Quality When<br />

High Speed Milling <strong>of</strong> Stainless Steel (SS420)<br />

M. Salehi, J. Akbari, <strong>and</strong> H. Rezaee Ravari (Mitsubishi Carbide<br />

Sales Agent, Iran)<br />

Effect <strong>of</strong> Slenderness on <strong>Machine</strong>d Surface: Application<br />

to Topography Part Prediction<br />

D. Olvera, L.N. López de Lacalle, F.J. Campa, A. Lamikiz<br />

(University <strong>of</strong> the Basque Country, UPV/EHU, Spain)<br />

Form Deviation in Machining <strong>of</strong> Spheroidal Cast Iron<br />

<strong>and</strong> Aluminum Compounds<br />

B. Denkena, J. Köhler, E. Hasselberg (<strong>Institute</strong> <strong>of</strong> <strong>Production</strong><br />

Engineering <strong>and</strong> <strong>Machine</strong> Tools (IFW), Leibniz Universität Hannover,<br />

Germany)

09:00-09:45 Auditorium<br />

9:50-10:10<br />

10:10-10:30<br />

10:30-10:50<br />

HSM 2010 Provisional Program<br />

Antifriction Action <strong>of</strong> Cooling <strong>and</strong> Lubrication Mediums<br />

on Ti6Al4v/Wc-Co<br />

Li Liang, Qi Baoyun, He Ning (Nanjing University <strong>of</strong> Aeronautics <strong>and</strong><br />

Astronautics, China)<br />

Effects <strong>of</strong> Lubrication Mode on Friction <strong>and</strong> Heat<br />

Partition Coefficients at the Tool-Workmaterial<br />

Interface in Machining<br />

C. Claudin, A. Mondelin, F. Dumont, J. Rech (Université de Lyon,<br />

Ecole Nationale d'Ingénieurs de Saint Etienne, Laboratoire de Tribologie et<br />

Dynamique des Systèmes, CNRS UMR 5513, France)<br />

Towards a New Process <strong>of</strong> Internal Micro-Lubrification<br />

by Internal Channels for Carbide Tools. Numerical<br />

Validation on Some Examples <strong>of</strong> Geometries<br />

Arnaud Duchosal, René Leroy, David Bonhoure (CEROC - LMR,<br />

France)<br />

Establishment <strong>of</strong> High Speed Lapping Using the New<br />

Lapping Tool with Linear Motor<br />

T. Iyama, I. Tanae, R. Kondo, T. Kondo (Nagaoka University <strong>of</strong><br />

<strong>Technology</strong>, Japan)<br />

Cutting Behavior <strong>and</strong> Process Monitoring During<br />

Grinding <strong>of</strong> Ceramics<br />

H.-W. H<strong>of</strong>fmeister, M. Rüggeberg (Technische Universität<br />

Braunschweig, <strong>Institute</strong> <strong>of</strong> <strong>Machine</strong> Tools <strong>and</strong> <strong>Production</strong> <strong>Technology</strong> (IWF),<br />

Germany)<br />

Improving Grinding Infeed Cycle Configuration by<br />

means <strong>of</strong> Continuous Variable Feed Rate<br />

J. Álvarez, D. Barrenetxea, J.I. Marquínez, I. Gallego (Ideko IK4,<br />

Spain)<br />

10:50-11:10 C<strong>of</strong>fee break in the entrance hall C<strong>of</strong>fee break in the entrance hall<br />

11:10-11:30<br />

11:30-11:50<br />

12:30-14:00<br />

14:00-14:45 Auditorium<br />

14:45-15:00<br />

15:00-15:20<br />

15:20-15:40<br />

Auditorium<br />

Lubrification<br />

Auditorium<br />

Composites<br />

Keynote: Pr<strong>of</strong>essor I.S. Jawahir (University <strong>of</strong> Kentucky, USA)<br />

Regenerative Chatter Of Composites<br />

R. Rusinek, J. Warminski, K. Kecik (Lublin University <strong>of</strong> <strong>Technology</strong>,<br />

Pol<strong>and</strong>)<br />

Effects <strong>of</strong> High-Speed Machining on Aluminum,<br />

Reinforced by Composite Rods<br />

H. Rezaee, J. Akbari (Islamic Azad University, Iran)<br />

Lunch<br />

Thursday, December 9th<br />

An ALE Model to Study the Depth <strong>of</strong> Cut Influence on<br />

Chip Formation in Orthogonal Cutting<br />

F. Ducobu, E. Rivière-Lorphèvre, E. Filippi (University <strong>of</strong> Mons<br />

(UMONS), FPMs, Belgium)<br />

2D Numerical Simulation <strong>of</strong> Orthogonal Metal Cutting<br />

Based on Advanced Constitutive Equations with<br />

Damage <strong>and</strong> Fully Adaptive Numerical Procedure<br />

M. Issa, C. Labergère, K. Saanouni, A. Rassineux (ICD/LASMIS,<br />

FRE 2848 CNRS University <strong>of</strong> <strong>Technology</strong> <strong>of</strong> Troyes, France)<br />

Fe Modeling <strong>of</strong> Orthogonal Cutting Process, Assuming<br />

Chip Segmentation Frequency<br />

V. Gyliene, V. Ostasevicius (Kaunas University <strong>of</strong> <strong>Technology</strong> (KTU),<br />

Lithuania)<br />

Numerical Analysis <strong>of</strong> the Cutting Parameters<br />

Influence during Machining Aluminum Alloy A2024-<br />

T351<br />

S. Atlati, B. Haddag, M. Nouari, C. Barlier, M. Zenasni<br />

(Laboratoire d’ Énergétique et de Mécanique Théorique et Appliquée, LEMTA<br />

CNRS-UMR 7563 – InSIC-27, France)<br />

Amphitheater<br />

Grinding<br />

Keynote: Pr<strong>of</strong>essor Tomasz Lodygowski (Poznan University <strong>of</strong> <strong>Technology</strong>, Pol<strong>and</strong>)<br />

Enhancement <strong>of</strong> the New <strong>Technology</strong> “ Speed Stroke<br />

Grinding” by High Speed Grinding<br />

M. Duscha, B. Linke, F. Klocke (Laboratory <strong>of</strong> <strong>Machine</strong> Tools <strong>and</strong><br />

<strong>Production</strong> Engineering (WZL) at Aachen University, Germany)<br />

Energetic <strong>and</strong> Dynamic Problems <strong>of</strong> Peripheral<br />

Smoothing<br />

Tadeusz Hryniewicz, Zdzislaw Pluta (Politechnika Koszalinska,<br />

Pol<strong>and</strong>)<br />

New Advances in the Machining <strong>of</strong> Hard Metals Using<br />

Physics-Based Modeling<br />

T. Marusich, S. Usui, L. Zamorano, K. Marusich, J. Leopold<br />

(Third Wave Systems, Inc., USA.)<br />

A Force Model for Superfinish Turning <strong>of</strong> Pure Copper<br />

with Rounded Edge Tools at Low Feed Rate<br />

D. Germain, G. Fromentin, G. Poulachon, <strong>and</strong> S.<br />

Bissey– Breton (CEA, DAM, Valduc, France)<br />

Stress <strong>and</strong> Heat Flux Distribution in Rake Face<br />

Analytical <strong>and</strong> Experimental Approaches<br />

J. Artozoul, C. Lescalier, A. D’ Acunto, A. Bomont-Arzur (Arts et<br />

Métiers ParisTech, Educational <strong>and</strong> Research Center, France)<br />

Auditorium<br />

FEM Analysis <strong>of</strong> Chip Formation <strong>and</strong> Crater Wear at<br />

High Speed Machining<br />

15:40-16:00<br />

Amphitheater Abdenbi Bouthiche, Gautier List, Guy Sutter, Jean-Jacques<br />

Constitutive<br />

Arnoux (Laboratoire de Physique et Mécanique des Matériaux - FRE CNRS<br />

Relations <strong>and</strong><br />

Modelling 3236, University Paul Verlaine - Metz, France)<br />

16:00-16:30 Simulation C<strong>of</strong>fee break in the entrance hall<br />

On Modeling the Peak Temperature on the Tool-Chip<br />

C<strong>of</strong>fee break in the entrance hall<br />

Interface During High-Speed Machining <strong>of</strong> AISI 1045<br />

Correction <strong>of</strong> Trajectory Execution Errors in HSM Using<br />

16:30-16:50<br />

Steel<br />

T. J. Burns, S. P. Mates, R. L. Rhorer, E. P. Whitenton, D.<br />

a Mirror Approach<br />

D. Prévost, S. Lavernhe, C. Latigue (LURPA, ENS Cachan, Université<br />

Basak (Information <strong>Technology</strong> Laboratory; National <strong>Institute</strong> <strong>of</strong> St<strong>and</strong>ards<br />

<strong>and</strong> <strong>Technology</strong> (NIST), USA)<br />

Paris Sud 11, France)<br />

16:50-17:10<br />

Compression Tests <strong>of</strong> Tantalum Over a Wide Range <strong>of</strong><br />

Strain Rates<br />

W. Moćko, Z.L. Kowalewski (Motor Transport <strong>Institute</strong>, Pol<strong>and</strong>)<br />

Smoothness Optimization <strong>of</strong> 5-Axis High-Speed Flank<br />

Milling Tool Paths<br />

P-Y. Pechard, X. Beudaert, C. Tournier, C. Lartigue (LURPA, ENS<br />

Cachan, Université Paris Sud 11, France)<br />

Modelling <strong>of</strong> High Strain Rate Behaviour <strong>of</strong> Metals<br />

Offline Adaptive Control – Empirical Approach<br />

17:10-17:30<br />

Accounting for Micro-Shear B<strong>and</strong>ing<br />

Ryszard B. Pecherski (<strong>Institute</strong> <strong>of</strong> Fundamental Technological<br />

M. Shah, S. Mangal, K.P. Karunakaran, P. Bidare, A.<br />

Tripathi, Abdulrahman M. Al-Ahmari<br />

Research, Polish Academy <strong>of</strong> Sciences, Pol<strong>and</strong>)<br />

Indian <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong> Bombay, India<br />

CNC Milling <strong>of</strong> Complex Surfaces by Nurbs<br />

17:30-17:50<br />

Interpolation in High Speed Machining<br />

H. Ameddah, M. Assas (Laboratoire de Recherche en Productique<br />

(LRP), Université de Batna, Algeria)<br />

19:30<br />

Gala dinner

08:30-09:15 Auditorium<br />

09:20-09:40<br />

09:40-10:00<br />

10:00-10:20<br />

HSM 2010 Provisional Program<br />

Manufacturing Process Planning under a Product<br />

Lifecycle <strong>Management</strong> Approach<br />

R. Mejía-Gutiérrez, S. Ruiz-Arenas, C.M. Echeverri (Design<br />

Engineering Research Group (GRID), EAFIT University, Colombia)<br />

The Method <strong>of</strong> Vibration Surveillance During High<br />

Speed Milling with the Use <strong>of</strong> Variable Spindle Speed<br />

Krzyszt<strong>of</strong> J. Kaliński, Marek Galewski (Gdańsk University <strong>of</strong><br />

<strong>Technology</strong>, Pol<strong>and</strong>)<br />

Safe <strong>and</strong> Efficient Trajectory Generation While<br />

Avoiding Multi-Axis <strong>Machine</strong> Tool Collision by Image<br />

Processing<br />

Rafiq Ahmad, Stephane Tichadou, Jean-Yves Hascoet<br />

(IRCCyN, UMR-CNRS 6597 (Team MO2P), France)<br />

High Speed Milling Vibration Surveillance with the Use<br />

<strong>of</strong> the Map <strong>of</strong> Optimal Spindle Speeds<br />

Krzyszt<strong>of</strong> J. Kaliński, Michał Mazur, Marek Galewski<br />

(Gdańsk University <strong>of</strong> <strong>Technology</strong>, Pol<strong>and</strong>)<br />

Tchebyshev Collocation Method for Vibration<br />

Avoidance in Turning <strong>of</strong> Flexible Parts<br />

G. Urbicain, A. Fernández, F. Campa, L.N. López de Lacalle<br />

(University <strong>of</strong> the Basque Country, UPV/EHU, Spain)<br />

Torsional Chatter in Twist Drills: Stability Analysis,<br />

Influence <strong>of</strong> Ploughing<br />

D. Bondarenko, H. Paris, A. Gouskov (University <strong>of</strong> Grenoble,<br />

Laboratory G-SCOP, France)<br />

Modeling Cutting Forces <strong>and</strong> Stability for Generalized<br />

Milling Tools in 5 Axis Operations<br />

O. M. Ozkirimli, E. Budak (Sabanci University, Turkey)<br />

Experimental Verification <strong>of</strong> Stability Lobes <strong>of</strong> Titanium<br />

Superalloys Milling<br />

K. Kecik, R. Rusinek, J. Warminski (Lublin University <strong>of</strong> <strong>Technology</strong>,<br />

Pol<strong>and</strong>)<br />

10:20-10:40<br />

Dynamic<br />

Analysis<br />

10:40-11:10 C<strong>of</strong>fee break in the entrance hall C<strong>of</strong>fee break in the entrance hall<br />

11:10-11:30<br />

11:30-11:50<br />

11:50-12:10<br />

12:10-12:30<br />

12:30-12:50<br />

12:50-13:10<br />

13:30<br />

14:30<br />

Auditorium<br />

PLM /<br />

Monitoring<br />

Auditorium<br />

Wear<br />

Keynote: Xavier Fouger (Dassault Systèmes, France)<br />

Friday, December 10th<br />

Application <strong>of</strong> Acoustic Emission <strong>and</strong> Force Sensing<br />

Techniques in Tool Condition Monitoring During<br />

Turning<br />

M.S.H. Bhuiyan, I.A. Choudhury, Y. Nukman (Department <strong>of</strong><br />

Engineering Design <strong>and</strong> Manufacture, University <strong>of</strong> Malaya, Malaysia)<br />

Machinability <strong>of</strong> Al-SiC Metal Matrix Composites Using<br />

WC, PCD <strong>and</strong> MCD Inserts<br />

J. Beristain, O. Gonzalo (Fundación Tekniker - IK4, Spain)<br />

Nanocomposite Coated PcBN for Hard Turning<br />

Processes<br />

E. Uhlmann, J.A. Oyanedel Fuentes, H. Frank (<strong>Institute</strong> for<br />

<strong>Machine</strong> Tools <strong>and</strong> Factory <strong>Management</strong> (IWF), Germany)<br />

Dry High Speed Milling <strong>of</strong> Inconel 718 Superalloy<br />

M. Benghersallah, L. Boulanouar, G. Lecoz, D. Dudzinski<br />

(Laboratoire de mécanique des matériaux et maintenance industrielle<br />

(LR3MI), Université Badji Mokhtar, Algeria)<br />

Influence <strong>of</strong> Surface Inclination Angle on the<br />

Distribution <strong>of</strong> Ball-End Mill Wear<br />

I. Hajjaji, R. Fradj, A. BenAmara (Laboratoire de Génie Mécanique,<br />

ENI-Monastir, Tunisia)<br />

Tool Life <strong>and</strong> Wear Mechanism <strong>of</strong> PVD Coated Carbide<br />

Tool When Dry Turning <strong>of</strong> Inconel 718<br />

C.H. Che Haron, J.A.Ghani, H.S. Yunn, M.S. Kasim, M.A.<br />

Sulaiman (Faculty <strong>of</strong> Engineering <strong>and</strong> Build Environment, Universiti<br />

Kebangsaan Malaysia)<br />

Lunch Buffet<br />

Visit <strong>of</strong> the Christmas market in Metz<br />

Amphitheater<br />

Amphitheater<br />

Non-<br />

Conventional<br />

Machining<br />

Envelope Dynamic Analysis for Cutting Milling Tool<br />

CF. Bisu¹, M. Zapciu, A. Gérard², V. Vijelea, M. Anica<br />

(1. University Politehnica <strong>of</strong> Bucharest, Laboratory <strong>Machine</strong>s <strong>and</strong> <strong>Production</strong><br />

Systems, Romania<br />

2. University Bordeaux 1, Mechanical <strong>and</strong> Physics Laboratory, France)<br />

Dynamic Absorbers for High Speed Machining<br />

Applications<br />

Aitor Olarra (Fundación Tekniker - IK4, Spain)<br />

Dynamic Response Analysis <strong>of</strong> Thin Wall Part<br />

Machining Using Moving Loadfinite Element Model<br />

Tao Ye, Cai-Hua Xiong (State Key Lab <strong>of</strong> Digital Manufacturing<br />

Equipment <strong>and</strong> <strong>Technology</strong>, Huazhong University <strong>of</strong> Science <strong>and</strong> <strong>Technology</strong>,<br />

P.R. China)<br />

<strong>Production</strong> <strong>of</strong> Graphite Electrodes with Thin Bars for<br />

Sinking-EDM Using Wire-EDM<br />

F. Klocke, S. Kamenzky, J. Dieckmann (RWTH Aachen University,<br />

Laboratory for <strong>Machine</strong> Tools <strong>and</strong> <strong>Production</strong> Engineering (WZL), Germany)<br />

Experimental Study on the Influence <strong>of</strong> Micro Abrasive<br />

Jet Machining for the Generation <strong>of</strong> Rounded Cutting<br />

Edges on Cemented Carbide Tools<br />

Carl-Frederik Wyen, Konrad Wegener (<strong>Institute</strong> <strong>of</strong> <strong>Machine</strong> Tools<br />

<strong>and</strong> Manufacturing (IWF), ETH Zurich, Switzerl<strong>and</strong>)<br />

Adaptation <strong>of</strong> Cutting Tools by Eroding Miscellaneous<br />

Purging Ducts <strong>and</strong> Nozzles<br />

F. Klocke, J. Dieckmann, M. Garzón, S. Kamenzky<br />

(RWTH Aachen University, Laboratory for <strong>Machine</strong> Tools <strong>and</strong> <strong>Production</strong><br />

Engineering (WZL), Germany)