Pottery in Australia Vol 17 No 1 Autumn 1978

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

EDITORIAL COMMITTEE<br />

Editor<br />

Janet Mansfield<br />

Derek Smith Margaret Tuckson<br />

Janet DeBoos Doug Alexander Penny Riley<br />

Bus<strong>in</strong>ess Manager<br />

State Correspondents<br />

Dulce Herd (Vic)<br />

Jean Rob<strong>in</strong>s (WA)<br />

Joyce Scott (SA)<br />

Margaret McNaught (Old)<br />

Penny Smith (Tas)<br />

President of the Potters' Society<br />

of A ustralia Dennis Pile<br />

PhilHpa Southwell-Keeley<br />

Please address all correspondence to<br />

The Editor 0/ "Pollery <strong>in</strong> <strong>Australia</strong>"<br />

48 Burton Street, Darl<strong>in</strong>ghu"t, N.S.W. 2010<br />

Telephone: (02) 31-3151. Private: (02)44-6396<br />

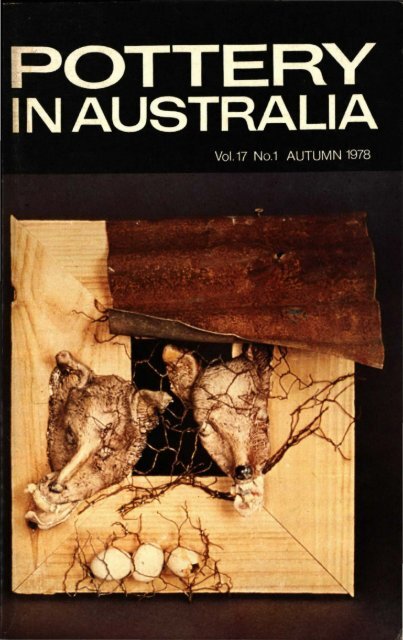

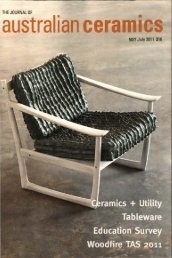

COVER : PETER HOOK, "Don'! count your chickens": porcela<strong>in</strong> slip with low-fired<br />

enamels, iron, wood and wire. 45 cm x 40 cm. From the Exhibition of <strong>Australia</strong>n Crafts <strong>1978</strong>.<br />

Photograph by lohn Deloeollr lor the Cra/ls Board, A IIstralia Council

POTTERY<br />

IN AUSTRALIA<br />

Published by the Potters' Society of <strong>Australia</strong><br />

<strong>Vol</strong>. <strong>17</strong>, <strong>No</strong>.1, <strong>1978</strong><br />

Three Dollars Filty Cell/J<br />

CONTENTS<br />

Editorial<br />

Time for Re-assessment<br />

Peter Travis<br />

Haruo Shimada, Master Potter<br />

Janet Mansfield<br />

Faenza 1977<br />

Ceramic Fibre Kilns-Dawn of a New Age Joe Davis<br />

A New Energy-sav<strong>in</strong>g Kiln for Potters Max Murray<br />

Leonie Ryan and Cheryl Small<br />

Harry Memmott<br />

<strong>Australia</strong>n <strong>Pottery</strong> J 900-1950<br />

Peter Timms<br />

Lyrebird Ridge <strong>Pottery</strong><br />

Erro/ Barnes<br />

An Air<strong>in</strong>g about De-air<strong>in</strong>g Pugmills<br />

Doug Alexander<br />

A Clay Mixer<br />

Leonard Smith<br />

Recent Work<br />

Leadless Insoluble Low-temperature Glazes Leigh Roberts<br />

<strong>Pottery</strong> <strong>in</strong> Crete<br />

Penny Riley<br />

Some Thoughts on Cracks and Textures Stephen Skillitzi<br />

College Courses<br />

Compiled by Janet DeBoos<br />

Bendigo College 1977 Graduate Exhibition<br />

Ceramic Toxicology<br />

William Alexander<br />

The Craftsman Potters' Association of Brita<strong>in</strong> Beryl Barton<br />

Acquisitions<br />

Exhibition Reviews<br />

Book and Magaz<strong>in</strong>e Reviews<br />

The Potters' Society of <strong>Australia</strong><br />

Competitions and Exhibitions<br />

News<br />

<strong>No</strong>tice to Subscribers and Subscription Forms<br />

page 2<br />

3<br />

5<br />

8<br />

11<br />

13<br />

20<br />

22<br />

23<br />

27<br />

31<br />

33<br />

40<br />

43<br />

47<br />

49<br />

50<br />

52<br />

55<br />

58<br />

61<br />

68<br />

70<br />

72<br />

74<br />

108

EDITORIAL<br />

The publication date of this issue of<br />

<strong>Pottery</strong> <strong>in</strong> A ustralia co<strong>in</strong>cides with the open<strong>in</strong>g of<br />

the first National Ceramic Conference for<br />

Potters. This conference, which many of the lead<strong>in</strong>g<br />

potters <strong>in</strong> <strong>Australia</strong> are attend<strong>in</strong>g, will have<br />

sessions allocated to the technical, educational<br />

and philosophical aspects of ceramics. A four- or<br />

five-day conference cannot possibly hope to<br />

cover <strong>in</strong> any detail such a wide field but the<br />

greatest ga<strong>in</strong> will be, I'm sure, the meet<strong>in</strong>g together<br />

of the pottery community of <strong>Australia</strong>. To mark<br />

the occasion of the Conference, <strong>Pottery</strong> <strong>in</strong> <strong>Australia</strong><br />

has reproduced a colour photograph for the<br />

cover of this issue. In future issues of the<br />

magaz<strong>in</strong>e we hope to <strong>in</strong>troduce more and more<br />

colour and possibly a change <strong>in</strong> layout.<br />

Peter Hook's cover piece may be apt, however,<br />

warn<strong>in</strong>g us "Don't count your chickens".<br />

2

TIME FOR RE-ASSESSMENT<br />

An Introduction to the National Ceramic Conference<br />

Peter Travis<br />

From the first moment that the National Ceramic Conference for Potters was<br />

suggested it showed the possibility of be<strong>in</strong>g the most excit<strong>in</strong>g event <strong>in</strong> the <strong>Australia</strong>n<br />

ceramic scene. Enthusiasm spontaneously illum<strong>in</strong>ated everyone contacted<br />

with the news.<br />

<strong>Australia</strong> has now possibly more than 20,000 people actively tak<strong>in</strong>g part <strong>in</strong><br />

pottery mak<strong>in</strong>g. With such a large number <strong>in</strong>volved one immediately asks :<br />

"What sort of people are they?"<br />

"For what reasons are they do<strong>in</strong>g it?"<br />

Recent surveys have compiled much <strong>in</strong>formation but the process<strong>in</strong>g of this<br />

material is almost out-dated s<strong>in</strong>ce the growth of the craft has escalated yearly to<br />

an almost unknown po<strong>in</strong>t. The potter with his long hours of devoted labour probably<br />

has less opportunity to discover where he fits <strong>in</strong>to the fabric of the contemporary<br />

scene.<br />

The first National Ceramic Conference for Potters gives the excit<strong>in</strong>g prospect<br />

of potters meet<strong>in</strong>g other potters, f<strong>in</strong>d<strong>in</strong>g by social contact a sense of identity and<br />

a relief to that feel<strong>in</strong>g of isolation imposed upon them by the physical demands<br />

of the craft. The social contact is the essence of the conference, the diverse<br />

technical and aesthetic papers secondary.<br />

Twenty-two years ago four Sydney polters founded the Potters' Society of<br />

<strong>Australia</strong>. Barely anyone knew they existed, or even thought there was such a<br />

th<strong>in</strong>g as local handmade ceramics. But from this small group, and a few isolated<br />

others, grew the vigorous pottery scene of today that has expanded <strong>in</strong>to a diverse<br />

range of styles removed from its <strong>in</strong>itial aesthetic stimulu~. <strong>Australia</strong>, without<br />

ceramic traditions, or a ceramic heritage from its <strong>in</strong>digenous people, stepped off<br />

with the <strong>in</strong>spiration of Bernard Leach where<strong>in</strong> the great periods of Ch<strong>in</strong>ese and<br />

Japanese ceramics became the criteria. Traces of mediaeval England and other<br />

small personal eclectic predilections were absorbed and the <strong>in</strong>fluences were spread<br />

as this small core of potters taught and exhibited.<br />

<strong>No</strong>w a generation has passed and the new craftsman, a product of today's<br />

complex society, is open to the overall <strong>in</strong>fluences of media and education. His<br />

work should become more relevant to the time as it reveals the conscious or subconscious<br />

<strong>in</strong>fluence of his environment. He has the opportunity to choose his own<br />

vocation and not have his future determ<strong>in</strong>ed by <strong>in</strong>herit<strong>in</strong>g a trade passed down from<br />

father to son or by I iv<strong>in</strong>g <strong>in</strong> a specialised community from which he fears to leave. A<br />

temperament that leans toward aesthetic response and the ability to express it<br />

manually assists his choice and the acceptance of the craftsman's lifestyle implies<br />

his need for an alternative to that offered by present society.<br />

The craft revival was a reaction aga<strong>in</strong>st the n<strong>in</strong>eteenth century <strong>in</strong>dustrialization<br />

. But many <strong>in</strong>volved felt the need to preserve the past. Consequently, some<br />

perpetuated traditions that f<strong>in</strong>ally became mere exercises <strong>in</strong> virtuosity no longer<br />

relevant to the present society. Others, more concerned with creative process,<br />

allowed evolution to adapt to society's needs and today the new craftsman is concerned<br />

that the materials make statements communicat<strong>in</strong>g his personal aesthetic<br />

response to the world around him. His higher education, toward creative th<strong>in</strong>k<strong>in</strong>g,<br />

rejects the rout<strong>in</strong>e of the early craftsman. He tries to make each object a new<br />

3

statement, even the repetition of one form is a series of fresh possibilities no<br />

matter how subtle or m<strong>in</strong>ute the difference. His attitude shows his self-awareness<br />

and it is comparable to that of the f<strong>in</strong>e artist. His statements reflect with equal<br />

right that of the pa<strong>in</strong>ter and sculptor. His work is seen and becom<strong>in</strong>g known; and<br />

the world is be<strong>in</strong>g enriched aga<strong>in</strong> by a consciousness of the special qualities of<br />

handmade objects.<br />

But how many people <strong>in</strong>volved <strong>in</strong> craft mak<strong>in</strong>g fit this image? Certa<strong>in</strong>ly there<br />

are some very beautiful, excit<strong>in</strong>g and imag<strong>in</strong>ative craft objects be<strong>in</strong>g made that<br />

are unique to this period; and they are executed by the dedicated few who are<br />

artists as well as craftsmen. How many such craftsmen are <strong>in</strong> <strong>Australia</strong>? How<br />

much handmade pottery <strong>in</strong> <strong>Australia</strong> has a special quality that justifies its existence?<br />

The truth is that craft shops everywhere are filled with crafty junk. Most is<br />

designless and crudely made and even domestic pottery is non-functional-plates<br />

that are too heavy, casseroles with awkward handles, jars with ill-fitt<strong>in</strong>g .1 ids,<br />

glazes that are overfired or underfired, shapes ugly, colours depress<strong>in</strong>g, touch<br />

horrid, orig<strong>in</strong>ality nil. Even the attempted traditional, for which one has guidel<strong>in</strong>es,<br />

is bad but the contrived efforts from those try<strong>in</strong>g to f<strong>in</strong>d novelty is much<br />

worse. <strong>No</strong> doubt the creator enjoyed the mak<strong>in</strong>g or did he? Was it merely the<br />

result of a hurried rout<strong>in</strong>e, not reviewed by any k<strong>in</strong>d of critical eye <strong>in</strong> order to<br />

supply quickly someth<strong>in</strong>g to the local craft shop? After all someone might buy it.<br />

The Craft Revival of the n<strong>in</strong>eteenth century was not just a rejection of the<br />

mach<strong>in</strong>e made, it was an objection to the banality and poor design of mass produced<br />

products. Many accepted the cballenge. The Great Arts and Crafts Exhibition<br />

of 1888 <strong>in</strong> London saw works of the craftsmen acclaimed. Each decade<br />

s<strong>in</strong>ce has produced new masters as the <strong>in</strong>terest <strong>in</strong> the crafts cont<strong>in</strong>ued. But only<br />

s<strong>in</strong>ce the last World War has craft consciousness escalated <strong>in</strong>to the explosion of<br />

craft activity today with millions of people <strong>in</strong> the Western world, and thousands<br />

<strong>in</strong> <strong>Australia</strong> f<strong>in</strong>d<strong>in</strong>g pleasure <strong>in</strong> mak<strong>in</strong>g.<br />

Why then is there so much tbat is bad? Realis<strong>in</strong>g that very few people have<br />

the natural ability to relate the elements of a work to each other so that a unified<br />

design results and that most people practis<strong>in</strong>g crafts have had very little design<br />

tra<strong>in</strong><strong>in</strong>g, if any, it is not surpris<strong>in</strong>g. However, tbe pleasure of mak<strong>in</strong>g is open to<br />

all of us and should not be denied. But just how many of the results that will<br />

become permanent is what we need to worry about. And this is of the greatest<br />

importance to pottery, an almost <strong>in</strong>destructible medium which will allow the bad<br />

and the good to survive time, both becom<strong>in</strong>g a record of their day.<br />

This Conference through its social contact and dialogue, I hope, will help<br />

the potters of <strong>Australia</strong>:<br />

1. understand their significance <strong>in</strong> society <strong>in</strong> human and aesthetic terms;<br />

2. realise that it is the responsibility of each potter to advance his manual<br />

technique, his technical knowledge and his aesthetic awareness <strong>in</strong> order<br />

to execute his ideas with excellence;<br />

3. to become more self-critical of his work and be able to reject what is<br />

<strong>in</strong>ferior before and not just after fir<strong>in</strong>g makes it permanent;<br />

4. to hold on to the joy of mak<strong>in</strong>g and never lose it to the joy of sell<strong>in</strong>g.<br />

The future of the potter's craft lies not <strong>in</strong> the depth of his creativity, s<strong>in</strong>ce<br />

the biggest volume of potters will be makers not <strong>in</strong>novators, but <strong>in</strong> the <strong>in</strong>tegrity<br />

of each potter to attempt honestly to make each object as best he can.<br />

PETER TRAVIS is a well-known ceramic artist who toured for the Crafts Council <strong>in</strong> 1977. He<br />

has just returned from be<strong>in</strong>g guest lecturer <strong>in</strong> ceramics at Banff School of F<strong>in</strong>e Arts, Canada.<br />

He is a past president of the Potters' Society and chairman of the National Ceramic Conference<br />

for Potters.<br />

4

HARUO SHIMADA, MASTER POTTER<br />

Janet Mansfield<br />

Photographs: Andrew Halford<br />

Haruo Shimada, master potter, is one of the few rema<strong>in</strong><strong>in</strong>g Japanese potters still<br />

mak<strong>in</strong>g the large jars used for storage of water and gra<strong>in</strong>. As the demand for these<br />

jars is no longer sufficient for economic viability, Shimada san has developed an<br />

extended range of ware to keep the pottery <strong>in</strong> full production. Today it is very<br />

busy with twelve people employed and a constant demand for all the workshop<br />

output.<br />

Andrew Halford, an <strong>Australia</strong>n potter, has been apprenticed to Shimada san<br />

for some time and together they will visit <strong>Australia</strong> later this year, giv<strong>in</strong>g demonstrations<br />

and workshops.<br />

The Shimada <strong>Pottery</strong> is just outside Gotsu city <strong>in</strong> Shimane prefecture on the<br />

side of a mounta<strong>in</strong> which overlooks the Sea of Japan. Clay for the pottery is dug<br />

5

6

locally. For the large pots, it is put three times through a rough mixer with rollers.<br />

For the smaller pots, the cl ay is further ref<strong>in</strong>ed, us<strong>in</strong>g a blunger and pugmill.<br />

Everyth<strong>in</strong>g <strong>in</strong> the pottery is thrown and the range extends from the smallest sauce<br />

bowls to teapots, platters, umbrella stands and the six-foot-high jars. Much of the<br />

ware is slip decorated with iron oxide and sgraffito decoration. Glazes <strong>in</strong>clude a<br />

clear, an iron glaze and an opaque copper green. A large thirteen-chamber climb<strong>in</strong>g<br />

kiln is fired every two months, although often only the first six chambers are<br />

used. The large jars go <strong>in</strong>to this kiln , the doorways be<strong>in</strong>g enlarged to allow their<br />

entry. A large gas kiln is used to fire the smaller pieces and this is fired every<br />

three days.<br />

The large jars are made by a coil and throw method. The base is thrown up<br />

to a height of fourteen or more <strong>in</strong>ches and then coils "as thick as a man's wrist"<br />

are added and thrown until the pot is complete. Several pots are made simultaneously<br />

on Korean-type wheels.<br />

As President of the Gotsu branch of the Bussankan, a national organization<br />

which sells and promotes the work of craftsmen, Shimada san is constantly he<strong>in</strong>g<br />

called upon to advise and mediate. Sometimes artists from Tokyo come to the<br />

pottery to decorate large platters which Shimada san has thrown for them and<br />

there is a feel<strong>in</strong>g of purpose and progress <strong>in</strong> the workshop. Shimada san is a<br />

traditional craftsman with a modern attitude and a broad and generous outlook,<br />

adapt<strong>in</strong>g his work to the needs of the community.<br />

JANET MANSFIELD visited the Shimada <strong>Pottery</strong> while on a study tour of Ja pan <strong>in</strong> 1977 on a<br />

grant from the <strong>Australia</strong>-Japan Foundation.<br />

HAMADA<br />

Shoji Hamada was not only a great potter, like Bernard Leach he was a "builder of the<br />

bridge between East and West"--as Leach described tbeir activities-a pioneer <strong>in</strong> the development<br />

of an <strong>in</strong>ternational community of potters and an <strong>in</strong>ternational c.eramic idiom. We are<br />

all deeply <strong>in</strong>debted to him.<br />

Older members of the pott<strong>in</strong>g communilY <strong>in</strong> Sydney will have happy memories of<br />

Hamada's visit to Sydney <strong>in</strong> 1964. He was scheduled for about a week <strong>in</strong> Sydney. and we<br />

had planned a full program of visits and excursions, and some demonstrations. On arrival,<br />

however, on be<strong>in</strong>g shown the wheel, clay, and raw-dip glazes that had been prepared for his<br />

demonstrations, he said he felt he could make a better contribution to pott<strong>in</strong>g <strong>in</strong> Sydney<br />

by sitt<strong>in</strong>g down <strong>in</strong> the one place and mak<strong>in</strong>g pots. And this is just what he did, topp<strong>in</strong>g it<br />

off with his two most memorable demonslrations at the University of New South Wales.<br />

He will be remembered-and missed-by those who got to koow him not only as a<br />

good potter, but as a friendly, generous and humble person.<br />

/ VO II M cMeekill<br />

One of the greatest Japanese potters of the twentieth century, Shoji Hamada, who perfected<br />

Mashiko ware, died on the 5th of January, <strong>1978</strong>.<br />

When he returned to Japan from England <strong>in</strong> 1924, Shoji Hamada went to li ve at a littleknown<br />

village ca ll ed Mashiko, where he cont<strong>in</strong>ued develop<strong>in</strong>g what is known today as<br />

Mashiko ware, us<strong>in</strong>g clay from around that vi llage <strong>in</strong> his work.<br />

The beauty of Mashiko ware comes from its simple yet unique design. Shoji Hamada<br />

taught and gave demonstrations of his art <strong>in</strong> many countries, and def<strong>in</strong>itely contributed to<br />

the current world-wide boom <strong>in</strong> pottery.<br />

In 1965 Hamada came to <strong>Australia</strong>, where he taught at the University of New South<br />

Wales, us<strong>in</strong>g a stick wheel provided by the university. Many people <strong>in</strong> <strong>Australia</strong> were deepl y<br />

impressed by this artist and his work, and recall particula rl y the beauty of hIS hand move.<br />

ments while throw<strong>in</strong>g.<br />

The Japanese Travell<strong>in</strong>g Ceramic Exhibition, which toured <strong>Australia</strong> <strong>in</strong> 1976, <strong>in</strong>cluded<br />

a large bowl made by Shoji Hamada with a magnificently dynamic and free feel<strong>in</strong>g.<br />

, believe that Shoji Hamada was one of the truly great purely Ja panese potters, and<br />

hi s death is like the go<strong>in</strong>g out of a great light <strong>in</strong> the East.<br />

Shigeo Shiga<br />

7

FAENZA 1977<br />

The 35th International Exhibition of Contemporary Ceramics Arts presented the<br />

work of 190 artists from 30 countries, at Faenza, Italy, <strong>in</strong> October 1977. Sandra<br />

Taylor of Sydney received a gold medal for her piece, "Gucci Handbag", made<br />

from porcela<strong>in</strong> with lustre decoration. Seven <strong>Australia</strong>n potters have now<br />

received gold medals from Faenza. Altogether seventeen awards were made at<br />

Faenza's 1977 exhibition.<br />

TLDICO POLGAR (Hungary) : "Idols", 33 x 48 cm. Gold Medal. (above)<br />

BAN KAJlTANI (USA): "Canyon Spirit"; partially wedged and thrown stoneware<br />

<strong>in</strong> three colours; 28 cm. Gold Medal. (opp., lOp)<br />

BATTISTA VALENTINT ( Jtaly): "Rotation", 80 x 46 cm. Tnternational Gold Medal.<br />

(opp., below)<br />

8

ARTS VICTORIA 78; CRAFTS FESTIVAL<br />

The long-awaited crafts festival, Arts Victoria 78, was officially opened at the Myer Music<br />

Bowl on Sunday, 5th February, by the Premier and M<strong>in</strong>ister of the Arts, the Hon. R. J.<br />

Hamer.<br />

There were 10,000 uDglazed ceramic tiles <strong>in</strong> the gardens and the Premier <strong>in</strong>vited every·<br />

one present to decorate a tile and lay it on a pathway marked out under the trees. These<br />

tiles were taken away and fired and many of them will be <strong>in</strong>corporated <strong>in</strong>to a permanent<br />

ceramic pathway <strong>in</strong> ODe of Melbourne's public gardens.<br />

American ceramist, Ela<strong>in</strong>e Katzer, the first of the <strong>in</strong>ternational craftsmen to arrive <strong>in</strong><br />

Victoria to take up residence for six months dur<strong>in</strong>g festival year, was present to advise and<br />

assist. At a later date, when a garden venue has been selected, Ela<strong>in</strong>e Katzer will be <strong>in</strong>volved<br />

<strong>in</strong> the design and construction of a permanent pathway to commemorate the Arts Victoria 78<br />

festival.<br />

The first exhibition of the festival, "Collection Pieces", was held at the National Gallery.<br />

"Colleclion Pieces", an exhibition drawn from public and corporate collections all over <strong>Australia</strong>,<br />

was sponsored by The Age newspaper.<br />

The other major exhibition will be later <strong>in</strong> the year (October) and will centre around<br />

Victorian Colonial Crafts, from early settlement to post-Federation 1920.<br />

Six overseas craftsmen have been chosen to work <strong>in</strong> Victoria next year <strong>in</strong> an <strong>in</strong>stitution,<br />

school, or suitable workshop area. Each will rema<strong>in</strong> <strong>in</strong> Victoria for a period of six<br />

months.<br />

Applications were received from 150 craftsmen from 23 different countries. The six<br />

craftsmen who have been chosen to work here are Eva Almeberg, a Swedish glassworker;<br />

<strong>No</strong>el Dyrenforth, an English Batik craftsman; Ela<strong>in</strong>e Katzer, an American ceramist; Christ<strong>in</strong>e<br />

O'Loughl<strong>in</strong>, an <strong>Australia</strong>n ceramist who has been work<strong>in</strong>g <strong>in</strong> Japan for the past two<br />

years; David Poston, an English jeweller; and Hiroshi Seto, a Japanese potter. All bave an<br />

outstand<strong>in</strong>g record of achievement, <strong>in</strong> tbeir own country and <strong>in</strong>ternationally.<br />

The Premier bas approved expenditure of $40,000 to be spent on a Festival Collection<br />

which will be a last<strong>in</strong>g record of the <strong>1978</strong> festival.<br />

Work was purchased for <strong>in</strong>clusion <strong>in</strong> tbis Collection from the Purchas<strong>in</strong>g Exhibition and<br />

Craft Fair at the Metropolitan Meat Market <strong>in</strong> <strong>No</strong>rth Melbourne at Easter. The Metropolitan<br />

Meat Market will be the new home of the crafts <strong>in</strong> Victoria and the Festival Collection will<br />

eventually be permanently housed there.<br />

Myer Melbourne will be stag<strong>in</strong>g an exhibition/ workshop <strong>in</strong> the Myer Gallery for two<br />

weeks, open<strong>in</strong>g at tbe time of tbe Queen's Birthday weekend (3rd June), and exhibits will<br />

<strong>in</strong>clude work by six craftsmen-<strong>in</strong>-residence.<br />

Regional galleries are co-operat<strong>in</strong>g and will feature craft exhibitions throughout the year.<br />

The craft sections at tbe Royal Show will be extended to attract professional craftsmen<br />

with prizes rang<strong>in</strong>g from $500 to $ 1500. The craftsman judged as "Craftsman of the Show"<br />

will be flown to Japan to attend the World Craft Council Conference <strong>in</strong> Kyoto. All prizew<strong>in</strong>ners'<br />

exhibits will be displayed <strong>in</strong> the new Government Pavilion at the Royal Showgrounds.<br />

A Festival Handbook has been produced. This will be a last<strong>in</strong>g record of the festival<br />

and will also act as an on-go<strong>in</strong>g reference book for several years ahead, list<strong>in</strong>g craft shops,<br />

courses, organisations, workshops, etc. The handbook has been sponsored by Rothmans of<br />

Pall Mall.<br />

ELAINE KATZER pictured witb her "Sea Chanty"-a stoneware ceramic wall<br />

designed for tbe Chula Vista Public Library, California.<br />

10

CERAMIC FIBRE KILNS <br />

THE DAWN OF A NEW AGE<br />

Joe Davis<br />

At the outset it must be stated that the ceramic fibre kiln was not <strong>in</strong>itiated by<br />

people who were, first and foremost, ceramists.<br />

Our many years of association with all aspects of ceramic and refractories<br />

production had highlighted the technological shortcom<strong>in</strong>gs of established clay<br />

fir<strong>in</strong>g procedures.<br />

On the large-scale commercial level, and particularly <strong>in</strong> the heavy clay side<br />

of ceramics production-that is the production of build<strong>in</strong>g bricks, tiles, sewer<br />

pipes, etc., some attempt has been made to br<strong>in</strong>g modern technology <strong>in</strong>to play.<br />

But the typical small traditional kiln used by the <strong>in</strong>dividual potter is, from the<br />

technological viewpo<strong>in</strong>t, at best, an anachronism left over from the Middle Ages.<br />

To illustrate this, let us look really critically at the manner <strong>in</strong> which the<br />

heat<strong>in</strong>g energy put <strong>in</strong>to that unit is actually dissipated.<br />

For tbis exercise we can take a fairly typical LPG-fired down-draft kiln of<br />

about 10 cu ft sett<strong>in</strong>g with a 9 <strong>in</strong> overall wall thickness, us<strong>in</strong>g fire-brick on the<br />

<strong>in</strong>side and <strong>in</strong>sulat<strong>in</strong>g brick outside th is.<br />

It is not unusual for a kiln of this capacity to use up to 150 Ibs of gas for a<br />

stoneware fir<strong>in</strong>g. A well-packed glost kiln will on average have about 10 Ibs of<br />

pottery per cubic foot of space, so that the kiln we are discuss<strong>in</strong>g will hold about<br />

100 Ibs of ware.<br />

The only reason we are putt<strong>in</strong>g heat <strong>in</strong>to the kiln is to mature the clay and<br />

glazes on this 100 Ibs of pottery. Consequently, it is true to say that <strong>in</strong> fact the<br />

only really useful heat is that which is be<strong>in</strong>g absorbed by the pottery itself. When<br />

we calculate this theoretical amount of heat, we f<strong>in</strong>d an almost unbelievable<br />

situation.<br />

The amount of heat required to raise the temperature of J 00 Jbs of pottery<br />

to 1280°C is no more than that released by burn<strong>in</strong>g approximately 21bs of gas!<br />

Before comment<strong>in</strong>g further on this, it is necessary to <strong>in</strong>vestigate where the<br />

heat from the other 148 Ibs of gas goes to. The kiln structure itself, consist<strong>in</strong>g of<br />

some 500 bricks, will weigh about 3000 Ibs. Only the <strong>in</strong>side face of the kiln<br />

reaches top temperature, but it is quite straightforward to calculate an average<br />

temperature for the whole structure. These calculations show that someth<strong>in</strong>g over<br />

30 Ibs of gas will be used to heat up the structure.<br />

On basic design, this type of high temperature equipment will never have<br />

an efficiency over 25-30% , that is, 25-30% of the total beat <strong>in</strong>put is the<br />

maximum that can be used for actual heat<strong>in</strong>g. This efficiency is an <strong>in</strong>herent<br />

thermodynamic characteristic of all kilns. Because of it, the 32-35 Ibs of gas will<br />

be but 25-30% of the total at best.<br />

This accounts fo r the rema<strong>in</strong><strong>in</strong>g 100 Ibs or so be<strong>in</strong>g used <strong>in</strong> the kiln.<br />

So, summ<strong>in</strong>g up, we have a piece of equipment which uses 150lbs of gas each<br />

time it is fired, yet we are obta<strong>in</strong><strong>in</strong>g a heat<strong>in</strong>g benefit from only 32-35 Ibs of gas,<br />

and it is a cold hard fact that we are really only <strong>in</strong>terested <strong>in</strong> the effects of a<br />

mere 2 Ibs of this fuel!<br />

If this proposition is now transferred to a solid or liquid fuel-fired kiln, we<br />

f<strong>in</strong>d that the efficiency is reduced to about half that shown above, and we f<strong>in</strong>ish up<br />

II

with a umt In which less than I % of the total fuel <strong>in</strong>put is be<strong>in</strong>g used for the<br />

actual job for which it was <strong>in</strong>tended.<br />

It is now nearly a decade s<strong>in</strong>ce we first checked out these calculations, and<br />

it appeared glar<strong>in</strong>gly obvious that one of the major disadvantages of a brick kiln<br />

of this general capacity was that while both kiln and contents required to be<br />

heated, <strong>in</strong> effect 15 times more heat was be<strong>in</strong>g absorbed by the structure, or<br />

deadload, than was be<strong>in</strong>g absorbed by the payload.<br />

The solution was quite simple-get rid of the deadload. Theoretically, if<br />

you br<strong>in</strong>g the dead load down to, say, 3001bs, you are heat<strong>in</strong>g up only one-tenth<br />

of the structure that you were heat<strong>in</strong>g previously.<br />

Let us just look aga<strong>in</strong> at the figures for a conventional kiln .... Total heat<br />

absorbed = 351bs gas (33 Ibs kiln and 2lbs ware) . With 25% efficiency this is<br />

equivalent to 140 Ibs gas total.<br />

<strong>No</strong>w for a super light-weight kiln .... Total heat absorbed = 5.3 lbs gas<br />

(3.3Ibs kiln and 21bs ware). Aga<strong>in</strong>, with 25 % efficiency, this is equivalent to<br />

22 Ibs gas. Of course, ten years ago, such a proposal was quite preposterous. The<br />

mathematics were quite straightforward-perhaps too straightforward-and they<br />

were only figures. <strong>No</strong>where <strong>in</strong> the world had it been done.<br />

The prototype models showed immediately that the fuel sav<strong>in</strong>gs anticipate

A NEW ENERGY - SAVING KILN<br />

FOR POTTERS<br />

Max J. Murray<br />

Summary<br />

Details are given of the design and construction of a 1300°C ceramic fibre<br />

<strong>in</strong>sulated pottery kiln with 0.75 cu m (27 cu ft) of ware capacity. Gas-fired<br />

burners draw pre-heated air for combustion through the hollow roof and wall<br />

panels, thus achiev<strong>in</strong>g low fuel usage.<br />

Introduction<br />

Follow<strong>in</strong>g the article on kiln design which appeared <strong>in</strong> the <strong>Autumn</strong> 1976<br />

issue of <strong>Pottery</strong> <strong>in</strong> A ustralia, numerous requests were received from potters for<br />

a kiln design which would use ceramic fibre as the ma<strong>in</strong> <strong>in</strong>sulation material. In<br />

response to the requests, I spent six months <strong>in</strong> assess<strong>in</strong>g what the majority of<br />

potters wanted from a kiln and 1 am <strong>in</strong>debted to many good pott<strong>in</strong>g friends for<br />

their comments and patience.<br />

From this assessment it became apparent tbat most potters have common<br />

requirements when it comes to kilns. I then set to work to try to design a kiln<br />

which might go some way to satisfy<strong>in</strong>g their demands.<br />

There were three ma<strong>in</strong> aims to beg<strong>in</strong> with, to f<strong>in</strong>d an optimum size or capacity,<br />

to improve thermal efficiency and thereby reduce fuel usage and to achieve<br />

better temperature uniformity than is often achieved with exist<strong>in</strong>g kilns. It seems<br />

that a majority of potters have experienced a similar pattern of development.<br />

They <strong>in</strong>itially buy or build a .small kiln and then quickly outgrow its capabilities.<br />

The ideal size accord<strong>in</strong>g to many potters is between 20 and 30 cu ft (0.4-0.6 cu m)<br />

<strong>in</strong> volume, yet there has been a shortage of designs for kilns of this size.<br />

This then established a size for the new kiln; it would be just under 30 cu ft<br />

<strong>in</strong> volume. The shape would be of a cubic geometry, because this has a m<strong>in</strong>imum<br />

surface area to volume ratio and as requested the ma<strong>in</strong> <strong>in</strong>sulation would bc<br />

formed from layers of ceramic fibre blanket or felt.<br />

Three different ceramic fibre materials were chosen to form the ma<strong>in</strong> <strong>in</strong>sulation.<br />

The <strong>in</strong>side or hot-face of the kiln required a fibre blanket capable of withstand<strong>in</strong>g<br />

temperatures up to 1340°C; however, this type of fibre is expensive and<br />

has to be kept to a m<strong>in</strong>imum. The hot-face layer was followed with several overlapp<strong>in</strong>g<br />

layers of less costly fibre blanket with an upper temperature limit of<br />

1260°C. On the cooler outer layer, low temperature rockwool <strong>in</strong>sulation would be<br />

used.<br />

Numerous calculations were then required to determ<strong>in</strong>e an economically<br />

suitable comb<strong>in</strong>ation of these <strong>in</strong>sulation layers. The <strong>in</strong>sulation thickness was found<br />

to be optimum at 125 mm and was made up of a 25 mm thick layer of "Fiberfrax<br />

H", 3 x 25 mm thick layers of "Locon" and a 25 mm layer of rockwool. A<br />

greater thickness than this would obviously reduce heat losses still further but<br />

it was considered that the <strong>in</strong>creased cost did not warrant the use. Even so the<br />

125 mm thick layer of fibres is equivalent to over 250 mm of refractory fire-brick<br />

<strong>in</strong>sulation.<br />

Calculations to determ<strong>in</strong>e the heat storage capacity of the fibre comb<strong>in</strong>ation<br />

showed that 15 000 kilocalories would be lost th rough storage <strong>in</strong> the fibre <strong>in</strong>sulated<br />

walls and roof, compared to 180 000 kilocalories lost, every fir <strong>in</strong>g, <strong>in</strong> a<br />

13

Kiln <strong>in</strong> the raised position,<br />

show<strong>in</strong>g freedom of access.<br />

Shelv<strong>in</strong>g and ware has<br />

just been removed after<br />

fir<strong>in</strong>g.<br />

Kiln <strong>in</strong> the closed position.<br />

H<strong>in</strong>ged cover is open, ready<br />

for light<strong>in</strong>g the burners.

efractory fire-brick structure of the same size. On this basis it would not take<br />

many fir<strong>in</strong>gs to pay for the higher cost of the ceramic fibre with sav<strong>in</strong>gs <strong>in</strong> fuel.<br />

As the kiln design evolved, a new approach was found to several previously<br />

accepted methods of kiln construction. The first of these changes was achieved<br />

with the kiln frame. In conventional construction techniques <strong>in</strong> which refractory<br />

bricks are used the support<strong>in</strong>g framework and outer cladd<strong>in</strong>g is generally formed<br />

from heavy steel structural elements. This method of construction, however,<br />

becomes redundant when light-weight fibre <strong>in</strong>sulation is utilized. Instead lightgauge<br />

metal panels can be used.<br />

A re<strong>in</strong>forced hollow panel fabricated from sheet metal was developed for this<br />

purpose. Ribs were <strong>in</strong>corporated <strong>in</strong> the panel for stiffen<strong>in</strong>g purposes. By modify<strong>in</strong>g<br />

the panels, channels could be created through which cool<strong>in</strong>g air would be<br />

circulated when the kiln was <strong>in</strong> operation. The circulated air, which is preheated<br />

by this operation, could then be directed to the burners as the ma<strong>in</strong> air supply for<br />

combustion.<br />

This would have a three-fold advantage. Firstly, by rais<strong>in</strong>g the temperature<br />

of the <strong>in</strong>com<strong>in</strong>g combustion air the efficiency of combustion would <strong>in</strong>crease,<br />

thereby reduc<strong>in</strong>g the fuel usage. Secondly, rais<strong>in</strong>g the start<strong>in</strong>g temperature of the<br />

<strong>in</strong>com<strong>in</strong>g air would enable a higher ceil<strong>in</strong>g temperature to be atta<strong>in</strong>ed and permit<br />

the use of simple burners. Thirdly, by provid<strong>in</strong>g a mov<strong>in</strong>g air stream over the kiln<br />

outer surfaces, less <strong>in</strong>sulation could be used without risk of overheat<strong>in</strong>g.<br />

The anchor<strong>in</strong>g p<strong>in</strong>s used for support<strong>in</strong>g the fibre <strong>in</strong>sulation are generally <strong>in</strong><br />

the form of threaded sta<strong>in</strong>less steel rods. Most fibre-kiln manufacturers fix the<br />

rods to the steel back<strong>in</strong>g plate by spot weld<strong>in</strong>g, but a number of failures have<br />

.. resulted from this technique. A more reliable fix<strong>in</strong>g method was therefore sought<br />

; for this kiln design. The result is that rods pass through the panels and are fixed<br />

on either side with nuts. A nut-shaped recess was punched <strong>in</strong>to the outer face of<br />

the panels to prevent the outer nuts from protrud<strong>in</strong>g, and a spac<strong>in</strong>g tube <strong>in</strong>serted<br />

over each rod with<strong>in</strong> the duct cavity. The rods therefore pass through two layers<br />

of the panell<strong>in</strong>g, 25 mm apart, and when clamped up they are completely rigid<br />

and <strong>in</strong>capable of be<strong>in</strong>g tom out. The outer surface is covered with a metal sheet,<br />

hid<strong>in</strong>g. the recessed nuts from view and provid<strong>in</strong>g further strength and rigidity.<br />

Figure 1 shows the technique which was used.<br />

The sta<strong>in</strong>less steel rods which are fitted to the panels are used to support<br />

flanged refractory tubes which <strong>in</strong> turn clamp the fibre <strong>in</strong> place. Because of the<br />

permeable nature of ceramic fibre, kiln gases can penetrate and condense on the<br />

surface of the metal support<strong>in</strong>g panel. The condensate is generally acidic and as a<br />

result corrosion can quickly set <strong>in</strong>. The <strong>in</strong>side faces of the support<strong>in</strong>g panels were<br />

therefore coated with a heat- and acid-resistant polyester acrylic before the fibre<br />

l<strong>in</strong><strong>in</strong>g was <strong>in</strong>stalled.<br />

The panels bolt together to form the four sides and top of the kiln and are<br />

designed to sit on a rigid hearth conta<strong>in</strong><strong>in</strong>g the burners and flue. The panels are<br />

extremely light <strong>in</strong> weight, each complete side of the kiln weigh<strong>in</strong>g only 29 kg. This<br />

feature then led to another break from conventional kiln design. The light-weight<br />

panels have elim<strong>in</strong>ated the need for a heavy h<strong>in</strong>ged-door, or the primitive wicket<br />

door which has to be built up and dismantled with each fir<strong>in</strong>g. Instead the whole<br />

side of the kiln can be lifted aside by one person. This means that access can be<br />

made through the front, side, back or top of the kiln, or through two sides if<br />

necessary. The kiln can even be used as a top hat structure by lift<strong>in</strong>g the whole of<br />

the fibre <strong>in</strong>sulated top section aside, by us<strong>in</strong>g a simple hoist. This enables the<br />

advantages of a top hat kiln to be achieved at a fraction of the usual cost.<br />

15

25"" .... .<br />

'L~ -CO'"<br />

VlQa~~r -----=--------·--~~--------------~R~c-C~k-~--OC-r\-<br />

~p"ti~ ' ''be.<br />

DETAILS OF PANEL CONSTRUCTION<br />

The hearth is ma<strong>in</strong>ly constructed from conventional <strong>in</strong>sulat<strong>in</strong>g refractory<br />

bricks. It was required to be rigid, strong and flat and to <strong>in</strong>corporate the flue<br />

channels and chimney. Most potters, if they are rebuild<strong>in</strong>g a kiln, like to re-use<br />

their old bricks. The hearth and chimney of this kiln therefore provide a useful<br />

application for these recycled materials.<br />

The base slab of the kiln was formed from light-weight vermiculite concrete.<br />

Ducts were <strong>in</strong>corporated <strong>in</strong> the base for the passage of cool<strong>in</strong>g air. The <strong>in</strong>sulat<strong>in</strong>g<br />

bricks were laid over this base and the floor of the kiln chamber given additional<br />

<strong>in</strong>sulation with a s<strong>in</strong>gle layer of ceramic fibre.

I<br />

UO:::!*-<br />

I<br />

, 70

~~~r:--~<br />

~ ~~------,<br />

~ ~<br />

r:-:-<br />

r:-:.-<br />

r-:- , ~<br />

r.--;<br />

b.<br />

r-- ~<br />

~ I':-'::'<br />

~ r77.<br />

r:--:-<br />

r:""<br />

r-- ~<br />

~ r'-':-<br />

r::::-<br />

~.<br />

;: :, ·:r ~<br />

L .

should enable potters to be more imag<strong>in</strong>ative with the size and shape of their<br />

products.<br />

The kiln can also be used as a small <strong>in</strong>dustrial unit. The top hat version is<br />

particularly suitable for <strong>in</strong>dustrial use. In this situation more than one hearth<br />

could be built, possibly us<strong>in</strong>g a back-to-back configuration and shar<strong>in</strong>g a common<br />

chimney. The ware could then be loaded on to one hearth while the other hearth<br />

was fir<strong>in</strong>g. Upon completion of the first fir<strong>in</strong>g the canopy would be lifted on to<br />

the loaded hearth and immediately fired, m<strong>in</strong>imis<strong>in</strong>g delays caused by sett<strong>in</strong>g and<br />

unload<strong>in</strong>g. The two-hearth system would also lend itself to the use of a second<br />

simple canopy as a drier. The green ware could then be loaded directly on to the<br />

kiln shelves, dried and fi.red without further handl<strong>in</strong>g.<br />

The ma<strong>in</strong> disadvantage with this new kiln is the cost. Ceramic fibre <strong>in</strong>sulation<br />

is more expensive than refractory bricks, although when bricklay<strong>in</strong>g charges are<br />

<strong>in</strong>cluded the more easily <strong>in</strong>stalled ceramic fibre comes out about equal. The<br />

simple panelised construction has enabled for the first time a kiln of this size to<br />

be portable. It can be rapidly dismantled, transported and re-assembled without<br />

any lift<strong>in</strong>g equipment. Two sides of the kiln will fit <strong>in</strong>to the boot of the average<br />

family car and the top will neatly fit on a pack rack, enabl<strong>in</strong>g potters to take their<br />

kiln with them whenever they move house or just decide to re-arrange their studio.<br />

In design<strong>in</strong>g this kiln an attempt was made to use the most up-to-date technology<br />

and materials. I hope this has been achieved.<br />

Pott<strong>in</strong>g colleagues are welcome to any help or advice that I can give should<br />

they be <strong>in</strong>terested <strong>in</strong> build<strong>in</strong>g a similar kiln.<br />

MATERIALS LIST<br />

The Base<br />

I bag of Ciment Fondu<br />

4 bags of Vermiculite<br />

I drum of Air-set Mortar<br />

190 approx. RI-26 Insulat<strong>in</strong>g Bricks. (Newbold General Refractories)<br />

210 approx. "Litebrik" (South Yarra Firebrick Co.)<br />

The Sides and Roof<br />

4 Ducted wall panels (1280 x 1000 mrn)<br />

I Ducted roof (1310 x 1310 mm )<br />

12 Bats of 25 mm Rockwool (900 x 750 mm) . (Bradford Insulation)<br />

22 Pieces of 25 mm " LoCon" (600 x 1200 mm). (Carborundum Co.)<br />

9 Pieces of 25 mm "LoCon" (600 x 900 mm). (Carborundum Co.)<br />

2 Pieces of 25 mm "Fiberfrax H" (600 x 1200 mm) . (Carborundum Co.)<br />

8 Pieces of 25 mm "Fiberfrax H" (600 x 900 mm) . (Carborundum Co.)<br />

110 Ceramic Anchors<br />

130 Sta<strong>in</strong>less steel rods with 3 nuts each<br />

Accessories<br />

4 Gas burner/ mixer sets 1 <strong>in</strong> . SSP<br />

M~X .MURRA Y. is an . electrical and mechanic~l e~g<strong>in</strong>eer ~ith tbe CSIRO Build<strong>in</strong>g Research<br />

D,v,s,on at HIghet! In Melbourne. He speclahses In ceramIC materials and processes.<br />

BILL REID CENTERING ARM-Available from Ihe Polters' Gallery,<br />

48 Burton 51., Darl<strong>in</strong>ghurst 2010. Ph. (02) 31 31 51.<br />

19

LEONIE RYAN and CHERYL SMALL<br />

Harry Memmott<br />

Leonie Ryan and Cheryl Small are honours graduates from Prahran College of<br />

Advanced Education.<br />

Both these potters have received grants from the Craft Board of the <strong>Australia</strong><br />

Council-a unique achievement for two students <strong>in</strong> the same year of tra<strong>in</strong><strong>in</strong>g.<br />

Leonie works <strong>in</strong> genre scenes depict<strong>in</strong>g the environs of the shear<strong>in</strong>g shed and<br />

the cocky farmer, as she recalls the area where she spent her childhood.<br />

She identifies very strongly with this life, and believes the <strong>in</strong>fluence of the<br />

country ways is still a powerful force <strong>in</strong> <strong>Australia</strong>. Bush music will be played at<br />

her exhibition.<br />

Leonie has carried out exhaustive research <strong>in</strong> her subject. All aspects of<br />

country life are depicted <strong>in</strong> authentic detail. This regard for detail extends further<br />

than just the material-to the curiosity of sheep, the tiredness of a work horse,<br />

and the care of a farmer for his animals. The movement of people and animals<br />

and the sag of the shear<strong>in</strong>g shed roof are described vividly.<br />

Leonie will be show<strong>in</strong>g her work <strong>in</strong> her first exhibition, dur<strong>in</strong>g April <strong>1978</strong>,<br />

<strong>in</strong> the town hall of her home town, Pyalong, <strong>in</strong> Victoria.<br />

LEONIE RYAN: "Shear<strong>in</strong>g Shed"<br />

20

CHERYL SMALL:<br />

"Peter the hot<br />

bread roll conta<strong>in</strong>er" :<br />

matt glaze <strong>in</strong>side.<br />

engobe and matt dry<br />

glaze outside. All<br />

local materials.<br />

Cheryl Small works <strong>in</strong> a style loosely based on the Greek Classic.<br />

Upon strong shapes she uses a sgraffito l<strong>in</strong>e through coloured engobe. She<br />

glazes the <strong>in</strong>side of the functional ware with soft matt glazes. The outside of these<br />

pots has a "dug-up" look, the result of the discreet use of almost dry glaze and<br />

subtle application of oxides.<br />

Cheryl will be exhibit<strong>in</strong>g at the Craft Centre <strong>in</strong> Melbourne dur<strong>in</strong>g late <strong>1978</strong>.<br />

Both of these artists use clay <strong>in</strong>tuitively, work<strong>in</strong>g on their own creative<br />

themes with strength of design and clear visual approach.<br />

In this world, where humanity follows the natural urge to create, these two<br />

potters are contribut<strong>in</strong>g to its enrichment.<br />

HARRY M EMMOTT, potter and author, is <strong>in</strong> cbarge of the Ceramics Department of the Prahran<br />

College of Advanced Education.<br />

2 1

AUSTRALIAN POTTERY 1900-1950<br />

Although a great deal of work has been done on the history of <strong>Australia</strong>n pa<strong>in</strong>t<strong>in</strong>g early<br />

pottery <strong>in</strong> this country bas received very little attention. Merric Boyd is well know~ as a<br />

pioneer potter, hav<strong>in</strong>g established what is generally regarded as <strong>Australia</strong>'s first artist-potters'<br />

studio, at Murrumbeena (Victoria) <strong>in</strong> 191 I. But one suspects that it is his family name which<br />

has secured his reputation rather than a familiarity or understand<strong>in</strong>g of his impressive body<br />

of work. Even today good Boyd pieces rema<strong>in</strong> unnoticed <strong>in</strong> junk shops.<br />

But what of the artist-potters who followed Boyd? People such as Anne Dangar, Gladys<br />

Reynell, Marguerite Mahood, Maude Poynter, Klytie Pate, F. E. Cox and others establisbed<br />

a strong tradition which tended to be cut off with the <strong>in</strong>troduction of stoneware pottery and<br />

tbe Japanese <strong>in</strong>fluence <strong>in</strong> the fifties, a tradition which had strong l<strong>in</strong>ks with the modernist<br />

movement and echoed its <strong>in</strong>terest <strong>in</strong> establish<strong>in</strong>g a nationalistic <strong>Australia</strong>n art.<br />

There are isolated examples <strong>in</strong> public collections, most acquired <strong>in</strong> the early days and<br />

now tucked away <strong>in</strong> basement cupboards. Only the National Gallery of Victoria and the<br />

Shepparton Arts Centre (<strong>in</strong> north·east Victoria) are now systematically collect<strong>in</strong>g early Aus.<br />

tralian pottery, although the <strong>Australia</strong>n National Gallery has acquired some f<strong>in</strong>e examples<br />

over tbe past few years.<br />

The Shepparton Arts Centre is now prepar<strong>in</strong>g a survey exhibition, <strong>Australia</strong>n <strong>Pottery</strong><br />

1900-1950, to be sbown <strong>in</strong> August-September this year, and which will thereafter tour two<br />

or three other venues. One important aspect of this show will be a comprehensive catalogue,<br />

collat<strong>in</strong>g much of the available <strong>in</strong>formation on this period for the first time.<br />

The exhibition will not, at this early stage, be def<strong>in</strong>itive. It is <strong>in</strong>tended primarily to<br />

establish public <strong>in</strong>terest and as a basis for further work. It will comprise about 100 pieces.<br />

Anyone with <strong>in</strong>formation which might assist <strong>in</strong> the preparation of the show, <strong>in</strong> particular<br />

biograpbical <strong>in</strong>formation, is <strong>in</strong>vited to contact Shepparton Arts Centre, Civic Centre, 3630.<br />

Illustrated is a vase by Klytie Pate (about 1941) from Shepparton's collection.<br />

Peter Timms,<br />

Director,<br />

Shepparton Arts Centre.<br />

22

L YREBIRD RIDGE POTTERY<br />

A BEGINNING<br />

Errol Barnes<br />

This workshop is located at Spr<strong>in</strong>gbrook <strong>in</strong> the h<strong>in</strong>terland of Queensland's Gold<br />

Coast. Brisbane is two hours' driv<strong>in</strong>g time away to the north-west. Spr<strong>in</strong>gbrook<br />

is part of the McPherson Ranges that lie east-west and form the border between<br />

Queensland and the <strong>No</strong>rthern Rivers District of New South Wales. Elevated,<br />

rugged country, it is an eroded plateau, the result of Mount Warn<strong>in</strong>g's ancient<br />

volcanic eruptions.<br />

The workshop gets its name from the ridge it cl<strong>in</strong>gs to where the Pr<strong>in</strong>ce Albert<br />

lyrebirds' beautiful caBs can be heard, mostly dur<strong>in</strong>g the w<strong>in</strong>ter months. I use<br />

the word "cl<strong>in</strong>g" because it best describes the way the workshop is situated gn<br />

the steep ra<strong>in</strong> forest slope. We look east and north out over the Gold Coast strip<br />

to the Moreton Bay islands.<br />

Our choice of Spr<strong>in</strong>gbrook as a site for the pottery was due ma<strong>in</strong>ly to our<br />

love of the high, ra<strong>in</strong> forest country. The basalts give us beautiful red soil but<br />

no usable clays.<br />

This br<strong>in</strong>gs one to the question of whether or not a pottery should be set up<br />

close to the materials source. I argue it is preferable to be <strong>in</strong> a good market area<br />

and transport the clays. The amount of clay any studio-workshop uses is so little<br />

compared to the <strong>in</strong>come it generates that transport costs are not a real concern.<br />

This south-east corner of Queensland is develop<strong>in</strong>g fast and the market potential<br />

is good.<br />

I was tra<strong>in</strong>ed as a teacher, then spent two years at the Technical College Art<br />

School <strong>in</strong> Brisbane. Here I met Carl McConnell and Milton Moon and my<br />

<strong>in</strong>volvement <strong>in</strong> pottery began; that was 1962. A spot of teach<strong>in</strong>g art <strong>in</strong> high<br />

school, then <strong>in</strong> December of 1964 I began full-time pott<strong>in</strong>g. For ten years 1<br />

worked mostly on my own. Dur<strong>in</strong>g these years I saw myself as an artist-potter<br />

primarily concerned with mak<strong>in</strong>g <strong>in</strong>dividual pieces. For a while I made and<br />

exhibited ceramic sculptures but gradually recognised the trap I was gett<strong>in</strong>g <strong>in</strong>toa<br />

no-man's-land somewhere between be<strong>in</strong>g a potter and be<strong>in</strong>g a sculptor but<br />

be<strong>in</strong>g neither. The year was 1971 and for me it was a turn<strong>in</strong>g po<strong>in</strong>t. I was at last<br />

gett<strong>in</strong>g myself together. I could see my limitations and the all-too-obvious limitations<br />

of my primitive workshop-but no regrets. The preced<strong>in</strong>g years had given<br />

me time. Time to learn and time to th<strong>in</strong>k of how th<strong>in</strong>gs might be.<br />

How does an <strong>Australia</strong>n potter survive? Does he live off the earn<strong>in</strong>gs of his<br />

craft or does he have a second job? A lot teach-some make pots. The teach<strong>in</strong>g<br />

doesn't appeal to me though I see myself as a teacher. I choose to produce<br />

domestic wares for my liv<strong>in</strong>g and I take tra<strong>in</strong>ees <strong>in</strong>to my workshop. Teach<strong>in</strong>g <strong>in</strong><br />

the work situation is different from what takes place <strong>in</strong> an <strong>in</strong>stitution. It is a natural<br />

process-immediate and obvious. The workshop-tra<strong>in</strong>ed potter is be<strong>in</strong>g equipped<br />

for survival as a craftsperson.<br />

I am first a craftsman and if by chance ] am also an artist then that is a<br />

bonus. But if J am only a craftsman then that is enough. My craft provides me<br />

with a lifestyle of <strong>in</strong>terest<strong>in</strong>g mak<strong>in</strong>g; it allows me to live <strong>in</strong> the environment of<br />

my choice and it feeds me.<br />

There is a develop<strong>in</strong>g market for handmade domestic pottery that is of a<br />

consistently good quality, reasonably priced and cont<strong>in</strong>ually available. A potter

ERROL BARNES<br />

at Lyrebird Ridge<br />

work<strong>in</strong>g alone is at a disadvantage should he decide to meet this market demand.<br />

He cannot possibly make a wide enough range without fragment<strong>in</strong>g his work<strong>in</strong>g<br />

week and besides it doesn't pay to make pots <strong>in</strong> short runs. Prepar<strong>in</strong>g for five<br />

potters takes little extra time than prepar<strong>in</strong>g for one. A large kiln fires <strong>in</strong> the<br />

same time as a small one. From the retailer's po<strong>in</strong>t of view he can hardly be<br />

expected to pay you a visit to pick up a handful of pots. He needs voLume and<br />

he needs to select from a reasonable range of wares.<br />

With these sorts of attitudes the plann<strong>in</strong>g of the workshop began. It would<br />

be a workshop for five potters-a good number. Big enough to manage without<br />

my be<strong>in</strong>g a manager. For the first three or four years I would put aside my own<br />

work and concentrate on develop<strong>in</strong>g a range and style of domestic wares. We<br />

would wholesale our pots, wherever and to whomever we could. Consignment<br />

sell<strong>in</strong>g is out of the question. That is no way to run a bus<strong>in</strong>ess, particularly when<br />

there are wages to meet at the end of each week.<br />

In May ) 975 I began the build<strong>in</strong>g of the first workshed. I had demolished<br />

an old build<strong>in</strong>g on the mounta<strong>in</strong> that had fallen <strong>in</strong>to absolute disrepair. It provided<br />

me with most of the milled timber I needed. An old dairy went the same<br />

way. This was built of hand-split hardwoods and the old slabs were beautifully<br />

weathered and grey. With a farmer neighbour I exchanged a few days of labour<br />

for tallow-wood logs from his forest to use as my ma<strong>in</strong> uprights and cross-ties.<br />

Months of work<strong>in</strong>g with adze and mortise chisel and I had a pottery that felt<br />

good to be <strong>in</strong>. As a potter friend whose prefabricated shed went up <strong>in</strong> a matter<br />

of days said, "You must have really wanted to take that trip."<br />

24

Mart<strong>in</strong> Kelly was the first tra<strong>in</strong>ee <strong>in</strong> the new workshop-a school teacher,<br />

twenty-one years of age. He heard 1 was look<strong>in</strong>g for a tra<strong>in</strong>ee <strong>in</strong> June 1975 and<br />

started with me <strong>in</strong> J anuary 1976. A true pottery "freak" who gave up his secure<br />

job with a future to settle for a doubtful one on a tra<strong>in</strong>ee's wage. He is now <strong>in</strong><br />

his third and f<strong>in</strong>al year. Mart<strong>in</strong> has received Crafts Board assistance for each of<br />

his three years of tra<strong>in</strong><strong>in</strong>g.<br />

rt ra<strong>in</strong>s a Jot on Spr<strong>in</strong>gbrook. We can spend days at a time drift<strong>in</strong>g <strong>in</strong> and<br />

out of low, saturat<strong>in</strong>g cloud that reduces the landscape to a series of greyed backdrops-one<br />

fad<strong>in</strong>g beh<strong>in</strong>d another. For this reason at least we have to build<br />

enclosed workrooms. The workshop was up but not enclosed when Mart<strong>in</strong> arrived.<br />

I was build<strong>in</strong>g the kiln and he had to put <strong>in</strong> his five hours a day practis<strong>in</strong>g on the<br />

wheel. After that he helped with the kiln. It was the wet season, everyth<strong>in</strong>g was<br />

damp. The kiln's foundations filled with water seep<strong>in</strong>g down from the mounta<strong>in</strong>side.<br />

The mildew was rampant. Eventually the kiln was completed with the help<br />

of a local, Barry Walsh, who would wander <strong>in</strong> and put <strong>in</strong> a few hours' work. Two<br />

fir<strong>in</strong>gs before the year's end and then without a break headlong <strong>in</strong>to the new<br />

year. Barry jo<strong>in</strong>ed us as the new tra<strong>in</strong>ee. He was a wood jo<strong>in</strong>er by trade but had<br />

become disillusioned by the way his trade was los<strong>in</strong>g all its hand skills and<br />

quality of product. Th<strong>in</strong>gs weren't so good. We didn't have sufficient outlets for<br />

our wares and we were gett<strong>in</strong>g a certa<strong>in</strong> amount of reaction aga<strong>in</strong>st what we were<br />

do<strong>in</strong>g. We were be<strong>in</strong>g " knocked" for produc<strong>in</strong>g a "workshop article". <strong>No</strong>body, it<br />

seemed to us then, wanted to know about Lyrebird Ridge <strong>Pottery</strong>. They would<br />

have much preferred to sell the <strong>in</strong>dividual personality of Errol Barnes. All wares<br />

The workshop at Lyrebird Ridge <strong>Pottery</strong>.<br />

25

made <strong>in</strong> the pottery bear the workshop seal no matter who makes the pot. <strong>No</strong><br />

<strong>in</strong>dividual marks appear on workshop pieces. Comments like "Oh! Hasn't Errol's<br />

work changed" were to be heard.<br />

We survived and th<strong>in</strong>gs improved. Our first major show<strong>in</strong>g of workshop<br />

pieces was held <strong>in</strong> Brisbane at the Potters' Gallery <strong>in</strong> September 1977. The<br />

volume of work on display impressed some and dismayed others. This wasn't a<br />

one-man show but a sell<strong>in</strong>g exhibition of a workshop's domestic wares. It sold<br />

very well. S<strong>in</strong>ce then we have reached the stage where we cannot fully meet the<br />

demand.<br />

The kiln is large--too large for our present needs. Fir<strong>in</strong>g is every eight<br />

weeks whereas I prefer to fire each month. Once the build<strong>in</strong>g program is completed<br />

and with the <strong>in</strong>troduction of another experienced potter I believe the oncemonthly<br />

target will be achieved. The bogey-hearth kiln is fuelled with drip-fed<br />

distillate and holds between 800 and 1000 pots of mixed sizes per fir<strong>in</strong>g. The<br />

natural draught is provided by 26 feet of stack. We fire for 22 hours to 1280°C<br />

and the evenness of the fir<strong>in</strong>g is quite remarkable for such a large chamber. The<br />

materials for this kiln were purchased with the assistance of a Crafts Board grant.<br />

Monica Breedon, our third tra<strong>in</strong>ee, started this year. I am very careful <strong>in</strong><br />

my selection of tra<strong>in</strong>ees. When I decided to take tra<strong>in</strong>ees <strong>in</strong>to the new workshop<br />

I gave the matter a great deal of thought. As I see it the motives for a young<br />

person select<strong>in</strong>g the craft as an occupation are varied. Anyone person's decision<br />

is a comb<strong>in</strong>ation of factors-aside from any desire to be an artist: a desire to<br />

make pots, the lifestyle pott<strong>in</strong>g affords, <strong>in</strong>come earn<strong>in</strong>g, social stand<strong>in</strong>g.<br />

1 take on tra<strong>in</strong>ees for a period of three to five years depend<strong>in</strong>g on age and<br />

education. Mart<strong>in</strong> is here for three. Monica, who is sixteen, is here for five. With<br />

each tra<strong>in</strong>ee I have an <strong>in</strong>dividual agreement that states the conditions of our<br />

work<strong>in</strong>g together. We have compulsory discussions at six-monthly <strong>in</strong>tervals when<br />

tHis agreement can be reviewed. Sometimes a compromise is required. The work<br />

load <strong>in</strong> the workshop is spread as evenly as possible with no specialisation. All<br />

aspects of workshop procedure are covered with one exception-l take sale control<br />

of fir<strong>in</strong>gs. They observe and to a limited degree assist, but too much is at stake<br />

to allow a tra<strong>in</strong>ee to take charge of a fir<strong>in</strong>g. When a planned small kiln is<br />

<strong>in</strong>stalled they will then be able to have fir<strong>in</strong>gs of their own.<br />

We don't "victimise" new tra<strong>in</strong>ees. They corne here to make pots and the<br />

sooner they do the better. This means the workshop loses on a tra<strong>in</strong>ee until his<br />

mak<strong>in</strong>g reaches an acceptable standard. For each mak<strong>in</strong>g cycle the tra<strong>in</strong>ee is set<br />

a program to follow. This program repeats known skills and <strong>in</strong>troduces one or<br />

two new ones. The teach<strong>in</strong>g is aimed at the development of skills and the transfer<br />

of technical knowledge. Simple bus<strong>in</strong>ess pr<strong>in</strong>ciples and practice are also dealt with.<br />

While a tra<strong>in</strong>ee is <strong>in</strong> my workshop he rema<strong>in</strong>s with<strong>in</strong> the discipl<strong>in</strong>e of function al<br />

pott<strong>in</strong>g.<br />

I do not th<strong>in</strong>k it is possible to ma<strong>in</strong>ta<strong>in</strong> a traditional employer-employee<br />

relationship <strong>in</strong> a workshop of this size. There has to be room for friendship.<br />

There can never be any doubt where the f<strong>in</strong>al decision-mak<strong>in</strong>g lies but suggestions<br />

from the tra<strong>in</strong>ees are sought and considered.<br />

I have taken a major step <strong>in</strong> my career as a potter by accept<strong>in</strong>g tra<strong>in</strong>ees<br />

<strong>in</strong>to the workshop. Obviously I believe on-the-job tra<strong>in</strong><strong>in</strong>g for young potters is a<br />

good th<strong>in</strong>g. There has to be a future for the shared workshop.<br />

26

AN AIRING ABOUT DE-AIRING<br />

PUGMILLS<br />

Doug Alexander<br />

Let me be rather adamant and state that I th<strong>in</strong>k that a de-air<strong>in</strong>g pugmill is only<br />

secondary <strong>in</strong> importance to the kiln on the full-time potter's equipment list. To<br />

qualify this statement I will expla<strong>in</strong> the pr<strong>in</strong>ciple and benefits of de-air<strong>in</strong>g clay,<br />

and how the potter can justify the f<strong>in</strong>ancial outlay for this piece of equipment <strong>in</strong><br />

terms of creativity and <strong>in</strong>creased productivity.<br />

Firstly it is important to understand the action of de-air<strong>in</strong>g on plastic clay<br />

and the method of achiev<strong>in</strong>g this. Basically the clay is fed by hand <strong>in</strong>to the hopper<br />

at the beg<strong>in</strong>n<strong>in</strong>g of the pugmill, a series of blades chop the clay and move it forward<br />

along the barrel, then augers force the clay through a screen <strong>in</strong>to the<br />

vacuum chamber; <strong>in</strong> a shredded state, the air pockets explode due to the vacuum<br />

and the air is removed. The clay is then further mixed by blades and is f<strong>in</strong>ally<br />

re-united and compressed by augers at the tapered exit nozzle of the pugmill.<br />

It is a misconception on the part of many potters that de-air<strong>in</strong>g improves<br />

plasticity; this is not so. A good de-air<strong>in</strong>g pugmill neither impairs nor improves<br />

plasticity. Its action <strong>in</strong>creases workability by br<strong>in</strong>g<strong>in</strong>g the clay particles <strong>in</strong>to closer<br />

contact, with a greater overall friction, without affect<strong>in</strong>g their capacity to slide,<br />

that is their plasticity. What is ga<strong>in</strong>ed is an <strong>in</strong>crease <strong>in</strong> strength. Thus "workability"<br />

on the potter's wheel, pull<strong>in</strong>g handles, mak<strong>in</strong>g slabs, etc., are greatly<br />

improved with the denser and more uniform clay that de-air<strong>in</strong>g pugmills produce<br />

<strong>in</strong> contrast to hand-wedged clay.<br />

If we accept that plasticity is improved by sour<strong>in</strong>g and age<strong>in</strong>g, I would<br />

suggest that the potter only pugs the clay once prior to us<strong>in</strong>g it for the mak<strong>in</strong>g<br />

process, after lett<strong>in</strong>g it sour and age after the primary mix<strong>in</strong>g.<br />

One aspect that should be clarified at this po<strong>in</strong>t is that pugmills are only<br />

secondary clay mixers. The primary mix<strong>in</strong>g of the clay should be done by blung<strong>in</strong>g,<br />

then filter press<strong>in</strong>g or dry<strong>in</strong>g beds, dough mixer, z-arm or whatever favourite<br />

form of primary mix<strong>in</strong>g one chooses to employ.<br />

This br<strong>in</strong>gs us to the benefits of the de-air<strong>in</strong>g pugmill <strong>in</strong> relation to productivity.<br />

Given one is us<strong>in</strong>g a pugmill with a capacity of say 500 kg per hour,<br />

it is easy to say that productivity will <strong>in</strong>crease because the potter will greatly<br />

reduce the time spent wedg<strong>in</strong>g, and with better de-aired and compressed clay<br />

used straight from the pug, will have more time to make pots. Thus with a<br />

mach<strong>in</strong>e perform<strong>in</strong>g one of the semi-skilled labour <strong>in</strong>tensive areas <strong>in</strong> a more<br />

efficient and quicker manner, there will be more pots at the end of the day, thus<br />

more money which will quickly pay for the pugmill.<br />

The facility to re-cycle scraps and turn<strong>in</strong>gs is also a most important feature<br />

of a de-air<strong>in</strong>g pugmill, especially for the potter who makes a lot of flat ware; and<br />

it does allow the more critical potter to discard those nasty shapes before they<br />

reach the kiln, with the knowledge that there will not be much effort <strong>in</strong>volved<br />

to re-cycle the clay. Plus there are such th<strong>in</strong>gs as tiles and other extrusions which<br />

a pugmill makes possible, that could be potentially creative areas for exploration.<br />

The two basic designs of de-air<strong>in</strong>g pugmi1ls are two-stage barrels and the<br />

s<strong>in</strong>gle-barrel type. The two-stage barrel type is common to <strong>in</strong>dustry. The reason<br />

for the two stages is that the action of the vacuum has a tendency to pull the clay<br />

back towards the vacuum source. By us<strong>in</strong>g gravity to counteract this action, the<br />

27

1<br />

\I~c-uum<br />

(;.\lAt"n!!>F.9..<br />

....<br />

PUCsMILL<br />

rwo:rrAGE BARREL PUGMILL<br />

SINGLE-BARREL PUGMll.L<br />

shredded clay falls to the lower level, keep<strong>in</strong>g the vacuum chamber from becom<strong>in</strong>g<br />

blocked with clay. The problem with this design is not one of performance<br />

but the cost of manufacture. A new mach<strong>in</strong>e of this design is far beyond the<br />

average potter's budget.<br />

The s<strong>in</strong>gle-barrel design is simpler to make with less eng<strong>in</strong>eer<strong>in</strong>g, thus a<br />

lower f<strong>in</strong>al cost. Harry Davis, a potter well known to most <strong>in</strong> the pottery world,<br />

produced a plan several years ago which went a long way towards reduc<strong>in</strong>g the<br />

problem of the vacuum pull<strong>in</strong>g clay <strong>in</strong>to the vacuum chamber. He overcame this<br />

by us<strong>in</strong>g a s<strong>in</strong>gle shaft with blades set at differential pitches and what he termed<br />

a breather valve <strong>in</strong> the vacuum chamber. A number of potters built these<br />

mach<strong>in</strong>es and they have given good service, except for two problems: the mild<br />

steel blades pit and corrode badly over a period of time, and the h<strong>in</strong>ged breather<br />

valve needs constant ma<strong>in</strong>tenance.<br />

Dur<strong>in</strong>g 1975 Geoff Hill, who manufactures Yenco wheels, approached Harry<br />

Davis to enquire if he could use Harry's design with some modifications. This was<br />

agreed upon, so Geoff set about re-design<strong>in</strong>g the orig<strong>in</strong>al pugmill and it is now<br />

available on the market. The ma<strong>in</strong> modifications were the use of a split alum<strong>in</strong>ium<br />

barrel (easier to clean) , a sta<strong>in</strong>less steel shaft and blades (less resistance so a<br />

smaller motor needed to power the pug) , a plunger on the hopper, which makes<br />

the mach<strong>in</strong>e safer and also enables turn<strong>in</strong>gs and slops to be more easily fed <strong>in</strong>to<br />

the pug, a high-capacity piston vacuum pump with water trap and a vacuum<br />

read<strong>in</strong>g of 26 <strong>in</strong>-28 <strong>in</strong> mercury. One notices an appreciable difference when the<br />

vacuum reads above 22 <strong>in</strong> mercury. Milk<strong>in</strong>g mach<strong>in</strong>e vacuum pumps are not<br />

very suitable because they are designed to operate at 15 <strong>in</strong> mercury. ln theory<br />

and practice, the higher the vacuum the better quality clay produced. There are<br />

28

other m<strong>in</strong>or <strong>in</strong>novations on the Venco pug, such as a heavy perspex cover on top<br />

of the vacuum chamber, which is quickly removed for clean<strong>in</strong>g. But the most <strong>in</strong>novative<br />