UW Schallschutzkonzepte 3. Baltic Future 04 05 2011 - Wind Energy ...

UW Schallschutzkonzepte 3. Baltic Future 04 05 2011 - Wind Energy ...

UW Schallschutzkonzepte 3. Baltic Future 04 05 2011 - Wind Energy ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Unterwasser <strong>Schallschutzkonzepte</strong> bei der<br />

Fundamentinstallation von Offshore- Offshore<br />

<strong>Wind</strong>energieanlagen<br />

(Underwater Noise Mitigation Concepts for Offshore <strong>Wind</strong>turbine<br />

Foundations)<br />

Martin Ros (MENCK GmbH) GmbH<br />

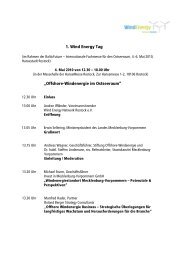

2. <strong>Wind</strong> <strong>Energy</strong> Tag im Rahmen der <strong>3.</strong> <strong>Baltic</strong> <strong>Future</strong>, <strong>04</strong> Mai <strong>2011</strong>; Rostock

Overview<br />

•Why Piling – Foundations – Hammer – airborne piling noise (mitigation)<br />

•Aspects and Basic Data of Underwater Piling Noise (<strong>UW</strong>) Mitigation<br />

•Research projects: (Little) Bubble Curtain<br />

•Concepts for Tripods/ Jackets :, Inflatable Hose Concept, Hydro Dampers<br />

and Incorporated Foundation design concepts<br />

•Noise Mitigation Concepts <strong>UW</strong> for Monopiles (MENCK Patents):<br />

Telescopic (sandwich) Tube & Piling Frame combined liftable Noise Curtain<br />

•Status of Discussion - Conclusion

Why PILING?(Noise)<br />

Offshore <strong>Wind</strong> Foundation Concepts (shallow)<br />

Gravity<br />

Gravity<br />

Monopile Monopile Suction Suction Caisson Caisson<br />

Caisson<br />

Tri Tri-/Tetrapod<br />

Tri Tetrapod<br />

driven driven pile<br />

pile<br />

Tri Tri-/Tetrapod<br />

Tri Tetrapod Tetrapod<br />

suction suction caisson<br />

caisson

Offshore <strong>Wind</strong> Foundation Concepts<br />

[suction, gravity, drilling (3-G), (3 G), floating]<br />

Driven pile proven / reliable foundation practice)<br />

Learning from Offshore Oil & Gas

Facilities<br />

Headquartered in<br />

Kaltenkirchen, Germany<br />

since March 2002<br />

Piling hammers<br />

Powerpacks (on-deck and<br />

underwater)<br />

Winches, hoses, umbilicals<br />

Followers<br />

Accessories<br />

Noise protection systems above &<br />

under water

MENCK Offshore<br />

Houston, TX – Office<br />

Amelia, LA - Storage<br />

Kaltenkirchen, Germany<br />

Headquaters<br />

Singapore<br />

Storage

MHU Hammer Design

Reduction of above water noise<br />

CT4 Terminal / Bremerhaven<br />

(20<strong>05</strong>) / GER<br />

Driving of H-Beams<br />

Manufacturing possible up to<br />

6.0m OD<br />

> 60dB in 1500m distance

Noise Measurements of Hydraulic<br />

Hammer Underwater from Various Projects<br />

Project/Year<br />

North Hoyle / 2003<br />

Metmast Amrumbank<br />

West, 20<strong>05</strong><br />

Q7/NL, 2006/2007<br />

Metmast FINO 3” /<br />

Ger, 2008<br />

Alpha Ventus –<br />

Tripod, 2009<br />

Pile OD (m)/<br />

Hammer-<strong>Energy</strong><br />

4.0m/MHU 500T<br />

(max. 600kJ)<br />

<strong>3.</strong>5m bottom - 2.0m<br />

top / MHU 800S<br />

(max. 800kJ)<br />

4.0m (very stiff pilehigh<br />

wallthicknesses)<br />

/ MHU 800S & MHU<br />

1900S (max. energy<br />

800kJ)<br />

4.5m bottom – <strong>3.</strong>0m<br />

top / MHU 800S<br />

(max. energy 800kJ)<br />

2.48m / MHU 500T<br />

(max. energy 550kJ)<br />

Noise Level (dB)/<br />

Distance from<br />

Source<br />

180 dB / 955m<br />

180 db / 750m<br />

195 – 198 dB /<br />

1600m<br />

180 db / 750m<br />

170 dB / 750m<br />

Noise at Source –<br />

correlated (dB)<br />

200 – 2<strong>05</strong> dB<br />

200 – 2<strong>05</strong> dB<br />

213 db (36m<br />

distance)<br />

200 dB – 2<strong>05</strong> dB<br />

180 dB<br />

Betke, K.: Minderung von Unterwassergeräuschen beim Bau von OWEA, FINO3 Workshop, Okt. 2008.

Sound Pressure Levels of different piles<br />

(under water, Betke-ITAP<br />

Betke ITAP)<br />

SEL, 1/3 octave, dB re 1 µPa<br />

180<br />

170<br />

160<br />

150<br />

140<br />

130<br />

120<br />

110<br />

FINO1, 400 m Amrumbank, 850 m Port construction, 340 m FINO2, 530 m<br />

16 31.5 63 125 250 500 1000 2000 4000 8000 16000<br />

Frequency, Hz

Spectral impact noise of hydraulic<br />

hammer underwater<br />

Important frequency range: 50 Hz – 2000 Hz; Peaks: 100 Hz – 300 Hz<br />

Betke, K.: Minderung von Unterwassergeräuschen beim Bau von OWEA, FINO3 Workshop, Okt. 2008.

Involvement in Research Projects

Reduction of under water noise<br />

To date no state-of-the-art<br />

(Stand der Technik) uw noise<br />

existing; only concepts<br />

Basic test on MENCK <strong>Baltic</strong> Sea<br />

testpile 2006: Rubber curtain, steel<br />

caising & foam coated steel tube

Test Results <strong>Baltic</strong> Sea:<br />

Reduction of under water noise<br />

Air (Foam) Isolation/Barrier is most effective<br />

(especially in high freqency band)

<strong>UW</strong> Noise Bubble Curtains:<br />

Experiences Worldwide<br />

Illingsworth & Rodkin, Inc. (2001) / Reyff (2003)<br />

Vagle (20<strong>05</strong>)<br />

Reyff (2003)<br />

Petrie (20<strong>05</strong>)

Bubble curtain: curtain:<br />

How Effective in<br />

marine environment?<br />

Unprotected bubble curtain –<br />

bubble shift (Betke ( Betke-ITAP) ITAP)<br />

Protected bubble curtain

Research Project Little Bubble Curtain -<br />

Tripods Alpha Ventus funded by German<br />

BMU / PTJ<br />

Located 30km north of Borkum (FINO 1)<br />

6 Tripods for 6 Areva-Multibrid M5000 turbines<br />

Pile OD 2.48m, 46 – 56 m length<br />

Water depth 26 -28m

<strong>UW</strong> Noise Mitigation Research Project –<br />

Little Bubble Curtain;<br />

funded by German BMU / PTJ<br />

Involved parties:<br />

Doti / Multibrid-Areva /<br />

Prokon Nord<br />

MENCK / Hydro Technik<br />

ISD / ITAP / DEWI

Alpha Ventus: Ventus:<br />

Lower part Design<br />

Tripod AV– Little Bubble Curtain with hammer application designed by<br />

MENCK / Lower and upper Part

Noise Protection underwater – Tripod AV<br />

Tripod AV – Little Bubble<br />

Curtain: Upper Part with<br />

bouyancy tanks

Little Bubble Curtain<br />

MHU500T-<strong>3.</strong>2m short sleeve Alpha Ventus – start<br />

of Tripod pile driving without bubble curtain

Little Bubble Curtain<br />

MHU500T-<strong>3.</strong>2m short<br />

sleeve Alpha Ventus – pile<br />

driving with lower bubble<br />

curtain (tested on two pile<br />

sleeves)<br />

12 dB reduction possible!

Measurement results AV 09: Little Bubble Curtain<br />

Opposite direction of current only 1-2 2 dBa reduction-<br />

reduction<br />

Effect of (missing ( missing) ) upper part LBC ??? To be clarified/tested<br />

SEL (1/3-Oktav), dB re 1 µPa<br />

180<br />

170<br />

160<br />

150<br />

140<br />

130<br />

120<br />

110<br />

100<br />

Messposition "Arne Tiselius", Entfernung = 520...560 m, Richtung = 270°<br />

10 100 1 000 10 000<br />

Frequenz, Hz<br />

21:15 Blasen aus<br />

20:55 Blasen ein<br />

22:10 Blasen aus<br />

22:15 Blasen ein<br />

Ramme aus

Noise Protection underwater<br />

Large Bubble Curtain –<br />

FINO 3 / 10-12 dBa<br />

reduction, costs could be<br />

reduced in serial<br />

foundation installation

Noise Reduction Bubble Curtains<br />

Bubble curtains very effective at high frequencies/ average -12 dB<br />

Betke, K.: Minderung von Unterwassergeräuschen beim Bau von OWEA, FINO3 Workshop, Okt. 2008.<br />

Reyff, JA.:Underwater sound pressures associated with the restrike of the PIDP pile; Illingw.& Rodk., 200<strong>3.</strong><br />

Würsig,B, Greene,GR, Jefferson,TA: Development of an air bubble curtain, Mar. Environ. Res.,49,79-93,2000.

Integrated in Foundation Design<br />

New Tripod Concept – Driving through noise<br />

dampened/insulated leg: foam and<br />

rubber/wood/kevlar liners

Noise Protection <strong>UW</strong> – Long Leg tripod<br />

New Tripod Concept –<br />

Driving through legs

Noise Protection <strong>UW</strong> – LL Tripod<br />

Tipod – Driving through noise insulated leg: foam and<br />

rubber/wood/kevlar liners

Jacket Installation – MHU Slender and Pre-<br />

pile installation by using a template<br />

(with integrated <strong>UW</strong> Noise protection)

Noise Protection underwater<br />

Double Wall (sandwich) Protection pipe for Tripods/Jackets<br />

and Monopiles

Noise Protection underwater<br />

Inflatable Airhose Mitigation for<br />

Monopiles and Tripod/Jackets with<br />

bubble curtain for bracing slot – high<br />

resistance to current

Noise Protection <strong>UW</strong> – Monopiles<br />

Various Piling Frames for<br />

Monopiles – necessary tool to be<br />

combined with noise mitigation<br />

system

Noise Protection <strong>UW</strong> - Monopiles<br />

Different Concepts:<br />

Cofferdam / Pile Guide<br />

Hydro Dampers<br />

BeKa Shales (incl. BC)<br />

Solid Steel Protection pile (incl. BC)<br />

TST – Telescopic Sandwich Tube<br />

Foldable BC or Airhoses connected<br />

to piling frame

Noise Protection<br />

Hydro Sound Damper (HSD, Elmer 2010)<br />

- using gas filled envelope bodies (balloons) instead of free bubbles<br />

- scattering, absorption and additional material damping effects<br />

- allow extreme resonant effects in decisive frequency range 100 – 300 Hz<br />

- fully controlled elast. Balloons<br />

- fixed to fishing nets or frames<br />

- number, size, damping rate<br />

and distribution are controlled<br />

/ designed<br />

- reduced resistance to current<br />

- no supply with compressed<br />

air needed<br />

- easy adaptable to different<br />

applications

Noise Protection underwater (HSD)<br />

Hydro Sound Damper (HSD) Applications Offshore<br />

(Elmer, 2010)<br />

Elmer, 2010

Reduction of <strong>UW</strong> Noise – Telescopic Tube<br />

Telescopic noise mitigation<br />

tube (sandwich principle, schematically,<br />

not to scale)<br />

- Supposed to be very effective in<br />

noise reduction (> 20 dB) but<br />

additional handling time and stability<br />

to be solved

Bubble Curtain or Air Hoses/Piling Frame<br />

Combination<br />

Draft designs of large scale under<br />

water noise mitigation systems<br />

(patent pending) either bubble<br />

curtain or inflatable hoses<br />

(patents as stated and described in the COWRIE<br />

Study “Assessment and costs of potential<br />

engineering solutions for the mitigation of the<br />

impacts of underwater noise arising from the<br />

construction of offshore windfarms)

Anwendungmöglichkeiten<br />

Anwendungm glichkeiten Blasenschleier<br />

Unter Piling Frame hängen und Ballast<br />

entsprechend gestalten

Conclusion<br />

• Underwater piling noise restricted to max. 160 dBa by law<br />

(hammered into stone unless political approach changes – increase of noise<br />

level limit)<br />

• No state-of-the-art noise mitigation existing so far for serial pile installation<br />

• Bubble Curtain principle in test phases for offshore application<br />

•Test results for Bubble curtain offshore indicates reduction of 10 -15 dB,<br />

optimization tests ongoing<br />

and for double wall pile (TST) approx. 20 -25 dBA<br />

• Alternative method (sandwich pile/air hose, red. potential approx. 20 -25<br />

dBA) limited in application offshore due to high loads (currents, waves) and<br />

relatively complicated/time consuming handling – system has to be robust<br />

and user friendly

Conclusion (con ( con’t)<br />

• Hydro Dampers in initial test phase, first laboratory results expected July<br />

2010 – in case of succesful testing MENCK to adopt Hydrodampers instead<br />

of LBC for Frame-Noise Mitigation concept<br />

•Cofferdam-, Beka Shales concepts in design phase<br />

• alternative foundation concepts (suction, gravity, drilled, floating) are not<br />

yet mature for OWG requirements<br />

• New or alternative mitigation proposals for piling noise from everywhere<br />

appriciated<br />

• MENCK prefers handling friendly concepts (e.g. combine Noise Mitigation<br />

System with existing tools)<br />

• Ongoing projects have to provide/implement piling noise reduction system<br />

for construction approval and into construction phase

Thank you !<br />

Please ask<br />

questions !