6. Nov-Dec 2010

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PANCHAKANYA GROUP<br />

INFOCUS<br />

7 questions to ask before using<br />

Ready Mix Concrete<br />

Text: Ar. Bansri Pandey<br />

Concrete is the largest consumed material in the<br />

world after water. As of a 2006 study conducted by<br />

United States Geographic Service, about 7.5 cubic<br />

kilometres of concrete is made each year – more<br />

than one cubic meter for every person on Earth.<br />

To meet this large demand of concrete, it needs to<br />

be produced in bulk. Thus, taking the advantage of<br />

scale and efficiency of mechanical mixing. Ready<br />

Mix Concrete was patented in 1903 in Germany. But<br />

due to the lack of transporting means, the concept<br />

was not sufficiently exploited till 1926 when the<br />

first transit-mixer was born. The first delivery of<br />

ready mix concrete was made in1931 in Baltimore.<br />

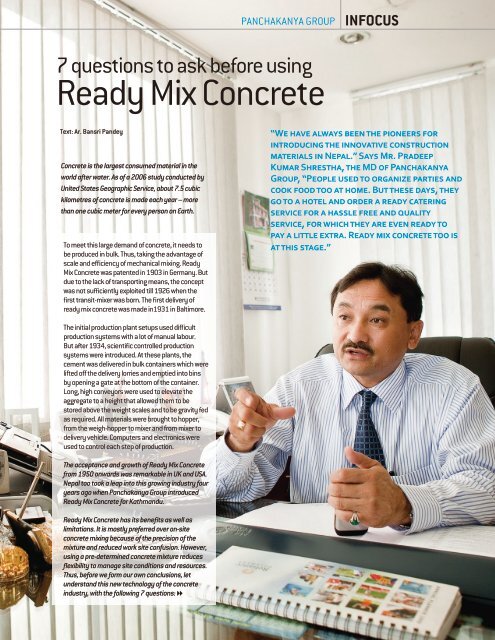

“We have always been the pioneers for<br />

introducing the innovative construction<br />

materials in Nepal.” Says Mr. Pradeep<br />

Kumar Shrestha, the MD of Panchakanya<br />

Group, “People used to organize parties and<br />

cook food too at home. But these days, they<br />

go to a hotel and order a ready catering<br />

service for a hassle free and quality<br />

service, for which they are even ready to<br />

pay a little extra. Ready mix concrete too is<br />

at this stage.”<br />

The initial production plant setups used difficult<br />

production systems with a lot of manual labour.<br />

But after 1934, scientific controlled production<br />

systems were introduced. At these plants, the<br />

cement was delivered in bulk containers which were<br />

lifted off the delivery lorries and emptied into bins<br />

by opening a gate at the bottom of the container.<br />

Long, high conveyors were used to elevate the<br />

aggregate to a height that allowed them to be<br />

stored above the weight scales and to be gravity fed<br />

as required. All materials were brought to hopper,<br />

from the weigh-hopper to mixer and from mixer to<br />

delivery vehicle. Computers and electronics were<br />

used to control each step of production.<br />

The acceptance and growth of Ready Mix Concrete<br />

from 1950 onwards was remarkable in UK and USA.<br />

Nepal too took a leap into this growing industry four<br />

years ago when Panchakanya Group introduced<br />

Ready Mix Concrete for Kathmandu.<br />

Ready Mix Concrete has its benefits as well as<br />

limitations. It is mostly preferred over on-site<br />

concrete mixing because of the precision of the<br />

mixture and reduced work site confusion. However,<br />

using a pre-determined concrete mixture reduces<br />

flexibility to manage site conditions and resources.<br />

Thus, before we form our own conclusions, let<br />

understand this new technology of the concrete<br />

industry, with the following 7 questions:8<br />

<strong>Nov</strong>ember-<strong>Dec</strong>ember <strong>2010</strong><br />

29<br />

www.spacesnepal.com