Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Tech <strong>Tune</strong><br />

BLOW<br />

OFF<br />

VALVE<br />

Our Tech <strong>Tune</strong> segment for this issue concerns that wonderful noise-unleashing contraption turbo lovers can’t get enough off – blow off valve. Never mind<br />

that its namesake might take on a rather ‘naughty’ connotation, a blow off valve is an important part to any turbocharged or supercharged vehicle.<br />

These valves save our forced induction components in a way that most users may over look. Other terms you may hear or read about that are essentially<br />

the same thing to Blow Off Valve, are recirc (re-circulating) valves, diverter valve, bypass valves, or the chic ‘stylized’ abbreviated BOV.<br />

A blowoff valve (BOV) is similar to a wastegate, except it works on the intake side of the turbocharger. Once a certain level of pressure is reached, the<br />

inlet air opens a spring, allowing for the intake air downstream of the turbocharger to either vent to the atmosphere or be redirected back into the<br />

turbo. Blowoff valves which open to the atmosphere give the iconic “pssshh” sound, which is heard when you let off the throttle. Instead of the high<br />

pressure air trying to work its way back through the compressor (surge), a BOV allows it to escape.<br />

Why we have blow off valves?<br />

Blow off valves are important in helping with<br />

the longevity of turbochargers and centrifugal<br />

superchargers. These valves open whenever<br />

there is enough boost pressure in the intake<br />

pipes, and vacuum from the intake manifold.<br />

Essentially, these valves operate every time<br />

the throttle is opening enough to create boost<br />

pressure, and then backed off to create vacuum.<br />

When this valve opens it releases the pressurized<br />

air in the intake piping either back to the turbo<br />

intake piping or vents it to the atmosphere.<br />

The reason this is important is because if that<br />

pressurized air is not allowed to escape once<br />

the throttle buttery closes, then the air will<br />

apply pressure on the turbo or superchargers<br />

compressor wheel putting un-wanted stress on<br />

it. While this stress is very small, over time it<br />

can cause added wear to the bearings and cause<br />

the unit to fail prematurely.<br />

Another great benet of a BOV, other than adding<br />

longevity and reliability to your set-up, is that<br />

it can help maintain turbine speeds in-between<br />

shifts adding a performance enhancement as well<br />

to the vehicle. There are not many modications<br />

one can do to an engine that can give them<br />

reliability and POWER, so a BOV should be an<br />

essential component on your list if running a<br />

turbocharger or centrifugal blower.<br />

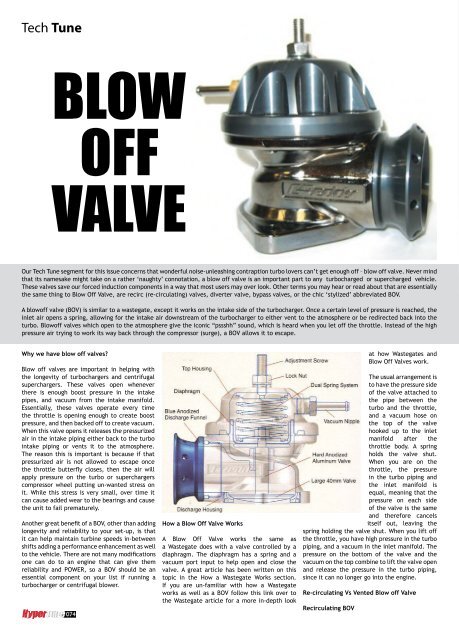

How a Blow Off Valve Works<br />

A Blow Off Valve works the same as<br />

a Wastegate does with a valve controlled by a<br />

diaphragm. The diaphragm has a spring and a<br />

vacuum port input to help open and close the<br />

valve. A great article has been written on this<br />

topic in the How a Wastegate Works section.<br />

If you are un-familiar with how a Wastegate<br />

works as well as a BOV follow this link over to<br />

the Wastegate article for a more in-depth look<br />

at how Wastegates and<br />

Blow Off Valves work.<br />

The usual arrangement is<br />

to have the pressure side<br />

of the valve attached to<br />

the pipe between the<br />

turbo and the throttle,<br />

and a vacuum hose on<br />

the top of the valve<br />

hooked up to the inlet<br />

manifold after the<br />

throttle body. A spring<br />

holds the valve shut.<br />

When you are on the<br />

throttle, the pressure<br />

in the turbo piping and<br />

the inlet manifold is<br />

equal, meaning that the<br />

pressure on each side<br />

of the valve is the same<br />

and therefore cancels<br />

itself out, leaving the<br />

spring holding the valve shut. When you lift off<br />

the throttle, you have high pressure in the turbo<br />

piping, and a vacuum in the inlet manifold. The<br />

pressure on the bottom of the valve and the<br />

vacuum on the top combine to lift the valve open<br />

and release the pressure in the turbo piping,<br />

since it can no longer go into the engine.<br />

Re-circulating Vs Vented Blow off Valve<br />

Recirculating BOV