IJTCS Vol.-1 Issue-1 March-May, 2017

The Indian Journal of Textile and Clothing Science (IJTCS) is a peer reviewed (refereed) national journal (India). Which is aimed at providing platform to exchange information pertaining to all sectors of textile and the clothing industry among researchers, textile technocrats, fashion designers and industrial experts. The journal focuses on scientific, technical, economical, managerial and all other aspects of textile activity at theoretical and experimental level. IJTCS is aimed at publishing original research articles, review papers, short communications, and letters to the editor and book reviews catering the needs of both industry and academia.

The Indian Journal of Textile and Clothing Science (IJTCS) is a peer reviewed (refereed) national journal (India). Which is aimed at providing platform to exchange information pertaining to all sectors of textile and the clothing industry among researchers, textile technocrats, fashion designers and industrial experts.

The journal focuses on scientific, technical, economical, managerial and all other aspects of textile activity at theoretical and experimental level. IJTCS is aimed at publishing original research articles, review papers, short communications, and letters to the editor and book reviews catering the needs of both industry and academia.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Indian Journal of Textile and Clothing Science<br />

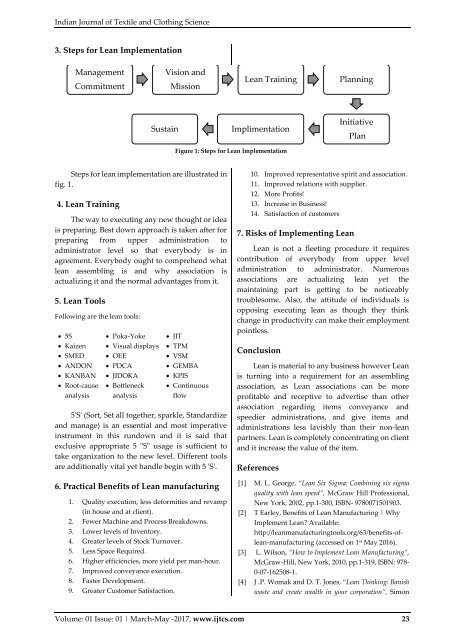

3. Steps for Lean Implementation<br />

Management<br />

Commitment<br />

Vision and<br />

Mission<br />

Lean Training<br />

Planning<br />

Sustain<br />

Implimentation<br />

Initiative<br />

Plan<br />

Figure 1: Steps for Lean Implementation<br />

Steps for lean implementation are illustrated in<br />

fig. 1.<br />

4. Lean Training<br />

The way to executing any new thought or idea<br />

is preparing. Best down approach is taken after for<br />

preparing from upper administration to<br />

administrator level so that everybody is in<br />

agreement. Everybody ought to comprehend what<br />

lean assembling is and why association is<br />

actualizing it and the normal advantages from it.<br />

5. Lean Tools<br />

Following are the lean tools:<br />

5S Poka-Yoke JIT<br />

Kaizen Visual displays TPM<br />

SMED OEE VSM<br />

ANDON PDCA GEMBA<br />

KANBAN JIDOKA KPIS<br />

Root-cause<br />

analysis<br />

Bottleneck<br />

analysis<br />

Continuous<br />

flow<br />

5'S' (Sort, Set all together, sparkle, Standardize<br />

and manage) is an essential and most imperative<br />

instrument in this rundown and it is said that<br />

exclusive appropriate 5 "S" usage is sufficient to<br />

take organization to the new level. Different tools<br />

are additionally vital yet handle begin with 5 'S'.<br />

6. Practical Benefits of Lean manufacturing<br />

1. Quality execution, less deformities and revamp<br />

(in house and at client).<br />

2. Fewer Machine and Process Breakdowns.<br />

3. Lower levels of Inventory.<br />

4. Greater levels of Stock Turnover.<br />

5. Less Space Required.<br />

6. Higher efficiencies, more yield per man-hour.<br />

7. Improved conveyance execution.<br />

8. Faster Development.<br />

9. Greater Customer Satisfaction.<br />

10. Improved representative spirit and association.<br />

11. Improved relations with supplier.<br />

12. More Profits!<br />

13. Increase in Business!<br />

14. Satisfaction of customers<br />

7. Risks of Implementing Lean<br />

Lean is not a fleeting procedure it requires<br />

contribution of everybody from upper level<br />

administration to administrator. Numerous<br />

associations are actualizing lean yet the<br />

maintaining part is getting to be noticeably<br />

troublesome. Also, the attitude of individuals is<br />

opposing executing lean as though they think<br />

change in productivity can make their employment<br />

pointless.<br />

Conclusion<br />

Lean is material to any business however Lean<br />

is turning into a requirement for an assembling<br />

association, as Lean associations can be more<br />

profitable and receptive to advertise than other<br />

association regarding items conveyance and<br />

speedier administrations, and give items and<br />

administrations less lavishly than their non-lean<br />

partners. Lean is completely concentrating on client<br />

and it increase the value of the item.<br />

References<br />

[1] M. L. George, “Lean Six Sigma: Combining six sigma<br />

quality with lean speed”, McGraw Hill Professional,<br />

New York, 2002, pp.1-300, ISBN- 9780071501903.<br />

[2] T Earley, Benefits of Lean Manufacturing | Why<br />

Implement Lean? Available:<br />

http://leanmanufacturingtools.org/63/benefits-oflean-manufacturing<br />

(accessed on 1 st <strong>May</strong> 2016).<br />

[3] L. Wilson, “How to Implement Lean Manufacturing”,<br />

McGraw-Hill, New York, 2010, pp.1-319, ISBN: 978-<br />

0-07-162508-1.<br />

[4] J .P. Womak and D. T. Jones, “Lean Thinking: Banish<br />

waste and create wealth in your corporation”, Simon<br />

<strong>Vol</strong>ume: 01 <strong>Issue</strong>: 01 | <strong>March</strong>-<strong>May</strong> -<strong>2017</strong>, www.ijtcs.com 23