MEM38

Marine Engineers Messenger Volume 2 Issue 38

Marine Engineers Messenger Volume 2 Issue 38

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The Cathelco impressed current cathodic protection<br />

(ICCP) systems will protect the underwater surfaces of the<br />

ship’s hulls from corrosion in the most demanding Arctic<br />

conditions.<br />

Unlike sacrificial anodes which may have to be changed<br />

at every drydocking the ICCP anodes have a life in excess<br />

of 15 years. This reduces maintenance costs as well as<br />

ensuring that the hull receives reliable protection.<br />

“This is one of a number of projects where we have<br />

worked in close collaboration with Vyborg Shipyard to<br />

provide a technical solution which will work effectively in<br />

Arctic waters”, said Anna Siodlak who has supervised the<br />

project at Cathelco.<br />

The purpose of the ICCP system is to neutralise the<br />

corrosive activity which occurs on the surface of the hull<br />

by enveloping it in a small, but effective impressed<br />

electrical current. The system consists of an arrangement<br />

of hull mounted anodes and reference electrodes which<br />

are wired to a control panel. The reference electrodes<br />

measure the electrical potential at the hull/seawater<br />

interface and send a signal to the control panel which<br />

raises or lowers the output to the anodes accordingly.<br />

“Systems for fishing vessels are easily installed and<br />

usually consist of two aft mounted anodes and reference<br />

electrodes, therefore the number of hull penetrations are<br />

kept to a minimum”, Anna Siodlak explained.<br />

Cathelco are world leading suppliers of ICCP systems<br />

for vessels of every size ranging from workboats and<br />

fishing vessels to cruise vessels and container ships with a<br />

record of more than 20,000 installations. They also<br />

produce marine growth prevention systems (MGPS)<br />

which prevent blockages in seawater pipework caused by<br />

bio-fouling.<br />

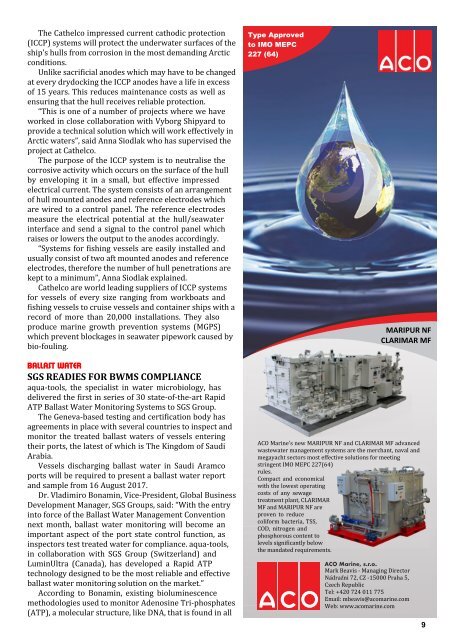

Type Approved<br />

to IMO MEPC<br />

227 (64)<br />

MARIPUR NF<br />

CLARIMAR MF<br />

BALLAST WATER<br />

SGS READIES FOR BWMS COMPLIANCE<br />

aqua-tools, the specialist in water microbiology, has<br />

delivered the first in series of 30 state-of-the-art Rapid<br />

ATP Ballast Water Monitoring Systems to SGS Group.<br />

The Geneva-based testing and certification body has<br />

agreements in place with several countries to inspect and<br />

monitor the treated ballast waters of vessels entering<br />

their ports, the latest of which is The Kingdom of Saudi<br />

Arabia.<br />

Vessels discharging ballast water in Saudi Aramco<br />

ports will be required to present a ballast water report<br />

and sample from 16 August 2017.<br />

Dr. Vladimiro Bonamin, Vice-President, Global Business<br />

Development Manager, SGS Groups, said: “With the entry<br />

into force of the Ballast Water Management Convention<br />

next month, ballast water monitoring will become an<br />

important aspect of the port state control function, as<br />

inspectors test treated water for compliance. aqua-tools,<br />

in collaboration with SGS Group (Switzerland) and<br />

LuminUltra (Canada), has developed a Rapid ATP<br />

technology designed to be the most reliable and effective<br />

ballast water monitoring solution on the market.”<br />

According to Bonamin, existing bioluminescence<br />

methodologies used to monitor Adenosine Tri-phosphates<br />

(ATP), a molecular structure, like DNA, that is found in all<br />

ACO Marine's new MARIPUR NF and CLARIMAR MF advanced<br />

wastewater management systems are the merchant, naval and<br />

megayacht sectors most effective solutions for meeting<br />

stringent IMO MEPC 227(64)<br />

rules.<br />

Compact and economical<br />

with the lowest operating<br />

costs of any sewage<br />

treatment plant, CLARIMAR<br />

MF and MARIPUR NF are<br />

proven to reduce<br />

coliform bacteria, TSS,<br />

COD, nitrogen and<br />

phosphorous content to<br />

levels significantly below<br />

the mandated requirements.<br />

Mark Beavis - Managing Director<br />

Nádrazňi 72, CZ -15000 Praha 5,<br />

Czech Republic<br />

Tel: +420 724 011 775<br />

Email: mbeavis@acomarine.com<br />

Web: www.acomarine.com<br />

9