UKIVA Vision in Action Autumn 2017

Industry updates from the UK Industrial Vision Association: Vision in Action Autumn 2017

Industry updates from the UK Industrial Vision Association: Vision in Action Autumn 2017

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

17<br />

SWIR<br />

Short wavelength <strong>in</strong>frared (SWIR)<br />

Short wavelength <strong>in</strong>frared (SWIR) imag<strong>in</strong>g takes place <strong>in</strong> the<br />

0.9 µm - 1.7 µm wavelength range. SWIR imag<strong>in</strong>g can measure<br />

temperatures above 250°C and up to 800°C. Although <strong>in</strong>frared<br />

radiation <strong>in</strong> the short wave <strong>in</strong>frared region is not visible to the<br />

human eye, it <strong>in</strong>teracts with objects <strong>in</strong> a similar manner as visible<br />

wavelengths. Therefore, images from an SWIR sensor are<br />

comparable to visible light images <strong>in</strong> resolution and detail although<br />

they are only displayed <strong>in</strong> monochrome. SWIR radiation, like NIR<br />

radiation will pass through glass. This means that special and<br />

expensive lenses are generally unnecessary. SWIR cameras are<br />

available for a wide variety of applications and <strong>in</strong>dustries. S<strong>in</strong>ce<br />

silicon is transparent to these wavelengths SWIR cameras are useful<br />

<strong>in</strong> semiconductor applications where they can ‘look through’ silicon<br />

layers. Water, however, strongly absorbs <strong>in</strong>frared light <strong>in</strong> this region,<br />

mak<strong>in</strong>g it appear opaque <strong>in</strong> the image.<br />

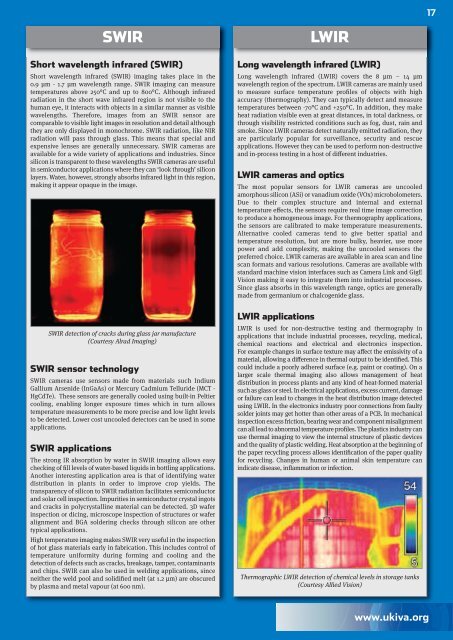

SWIR detection of cracks dur<strong>in</strong>g glass jar manufacture<br />

(Courtesy Alrad Imag<strong>in</strong>g)<br />

SWIR sensor technology<br />

SWIR cameras use sensors made from materials such Indium<br />

Gallium Arsenide (InGaAs) or Mercury Cadmium Telluride (MCT -<br />

HgCdTe). These sensors are generally cooled us<strong>in</strong>g built-<strong>in</strong> Peltier<br />

cool<strong>in</strong>g, enabl<strong>in</strong>g longer exposure times which <strong>in</strong> turn allows<br />

temperature measurements to be more precise and low light levels<br />

to be detected. Lower cost uncooled detectors can be used <strong>in</strong> some<br />

applications.<br />

SWIR applications<br />

The strong IR absorption by water <strong>in</strong> SWIR imag<strong>in</strong>g allows easy<br />

check<strong>in</strong>g of fill levels of water-based liquids <strong>in</strong> bottl<strong>in</strong>g applications.<br />

Another <strong>in</strong>terest<strong>in</strong>g application area is that of identify<strong>in</strong>g water<br />

distribution <strong>in</strong> plants <strong>in</strong> order to improve crop yields. The<br />

transparency of silicon to SWIR radiation facilitates semiconductor<br />

and solar cell <strong>in</strong>spection. Impurities <strong>in</strong> semiconductor crystal <strong>in</strong>gots<br />

and cracks <strong>in</strong> polycrystall<strong>in</strong>e material can be detected. 3D wafer<br />

<strong>in</strong>spection or dic<strong>in</strong>g, microscope <strong>in</strong>spection of structures or wafer<br />

alignment and BGA solder<strong>in</strong>g checks through silicon are other<br />

typical applications.<br />

High temperature imag<strong>in</strong>g makes SWIR very useful <strong>in</strong> the <strong>in</strong>spection<br />

of hot glass materials early <strong>in</strong> fabrication. This <strong>in</strong>cludes control of<br />

temperature uniformity dur<strong>in</strong>g form<strong>in</strong>g and cool<strong>in</strong>g and the<br />

detection of defects such as cracks, breakage, tamper, contam<strong>in</strong>ants<br />

and chips. SWIR can also be used <strong>in</strong> weld<strong>in</strong>g applications, s<strong>in</strong>ce<br />

neither the weld pool and solidified melt (at 1.2 µm) are obscured<br />

by plasma and metal vapour (at 600 nm).<br />

LWIR<br />

Long wavelength <strong>in</strong>frared (LWIR)<br />

Long wavelength <strong>in</strong>frared (LWIR) covers the 8 µm – 14 µm<br />

wavelength region of the spectrum. LWIR cameras are ma<strong>in</strong>ly used<br />

to measure surface temperature profiles of objects with high<br />

accuracy (thermography). They can typically detect and measure<br />

temperatures between -70°C and +250°C. In addition, they make<br />

heat radiation visible even at great distances, <strong>in</strong> total darkness, or<br />

through visibility restricted conditions such as fog, dust, ra<strong>in</strong> and<br />

smoke. S<strong>in</strong>ce LWIR cameras detect naturally emitted radiation, they<br />

are particularly popular for surveillance, security and rescue<br />

applications. However they can be used to perform non-destructive<br />

and <strong>in</strong>-process test<strong>in</strong>g <strong>in</strong> a host of different <strong>in</strong>dustries.<br />

LWIR cameras and optics<br />

The most popular sensors for LWIR cameras are uncooled<br />

amorphous silicon (ASi) or vanadium oxide (VOx) microbolometers.<br />

Due to their complex structure and <strong>in</strong>ternal and external<br />

temperature effects, the sensors require real time image correction<br />

to produce a homogeneous image. For thermography applications,<br />

the sensors are calibrated to make temperature measurements.<br />

Alternative cooled cameras tend to give better spatial and<br />

temperature resolution, but are more bulky, heavier, use more<br />

power and add complexity, mak<strong>in</strong>g the uncooled sensors the<br />

preferred choice. LWIR cameras are available <strong>in</strong> area scan and l<strong>in</strong>e<br />

scan formats and various resolutions. Cameras are available with<br />

standard mach<strong>in</strong>e vision <strong>in</strong>terfaces such as Camera L<strong>in</strong>k and GigE<br />

<strong>Vision</strong> mak<strong>in</strong>g it easy to <strong>in</strong>tegrate them <strong>in</strong>to <strong>in</strong>dustrial processes.<br />

S<strong>in</strong>ce glass absorbs <strong>in</strong> this wavelength range, optics are generally<br />

made from germanium or chalcogenide glass.<br />

LWIR applications<br />

LWIR is used for non-destructive test<strong>in</strong>g and thermography <strong>in</strong><br />

applications that <strong>in</strong>clude <strong>in</strong>dustrial processes, recycl<strong>in</strong>g, medical,<br />

chemical reactions and electrical and electronics <strong>in</strong>spection.<br />

For example changes <strong>in</strong> surface texture may affect the emissivity of a<br />

material, allow<strong>in</strong>g a difference <strong>in</strong> thermal output to be identified. This<br />

could <strong>in</strong>clude a poorly adhered surface (e.g. pa<strong>in</strong>t or coat<strong>in</strong>g). On a<br />

larger scale thermal imag<strong>in</strong>g also allows management of heat<br />

distribution <strong>in</strong> process plants and any k<strong>in</strong>d of heat-formed material<br />

such as glass or steel. In electrical applications, excess current, damage<br />

or failure can lead to changes <strong>in</strong> the heat distribution image detected<br />

us<strong>in</strong>g LWIR. In the electronics <strong>in</strong>dustry poor connections from faulty<br />

solder jo<strong>in</strong>ts may get hotter than other areas of a PCB. In mechanical<br />

<strong>in</strong>spection excess friction, bear<strong>in</strong>g wear and component misalignment<br />

can all lead to abnormal temperature profiles. The plastics <strong>in</strong>dustry can<br />

use thermal imag<strong>in</strong>g to view the <strong>in</strong>ternal structure of plastic devices<br />

and the quality of plastic weld<strong>in</strong>g. Heat absorption at the beg<strong>in</strong>n<strong>in</strong>g of<br />

the paper recycl<strong>in</strong>g process allows identification of the paper quality<br />

for recycl<strong>in</strong>g. Changes <strong>in</strong> human or animal sk<strong>in</strong> temperature can<br />

<strong>in</strong>dicate disease, <strong>in</strong>flammation or <strong>in</strong>fection.<br />

Thermographic LWIR detection of chemical levels <strong>in</strong> storage tanks<br />

(Courtesy Allied <strong>Vision</strong>)<br />

www.ukiva.org