UKIVA Vision in Action Autumn 2017

Industry updates from the UK Industrial Vision Association: Vision in Action Autumn 2017

Industry updates from the UK Industrial Vision Association: Vision in Action Autumn 2017

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

18<br />

UV imag<strong>in</strong>g<br />

UV<br />

UV light is <strong>in</strong>visible to the human eye (and most CCD/CMOS<br />

cameras). It has wavelengths <strong>in</strong> the range between 400 nm and 10<br />

nm which is shorter than that of visible light but longer than X-rays.<br />

Direct UV imag<strong>in</strong>g<br />

Standard imag<strong>in</strong>g techniques us<strong>in</strong>g visible light make it possible<br />

to recognise and resolve features down to approx. 0.5µm (500nm).<br />

To accurately visualise smaller features, however, the visible light<br />

spectrum is no longer sufficient. To resolve smaller structures, the<br />

reduction of the wavelength is the most practical and effective<br />

solution. Us<strong>in</strong>g ultraviolet illum<strong>in</strong>ation <strong>in</strong> conjunction with a UV<br />

sensitive camera/sensor allows ultraf<strong>in</strong>e resolution images to be<br />

captured <strong>in</strong> applications where submicron features need to be<br />

resolved. UV <strong>in</strong>dustrial cameras typically have either glassless CCD<br />

or CMOS imagers to enable sensitivity below 400 nm, or quartzcovered<br />

sensors to provide both extended sensitivity and better<br />

protection aga<strong>in</strong>st damage. However, to detect wavelengths below<br />

320 nm, special imagers such as specially th<strong>in</strong>ned sensors or<br />

sensors coated with a wavelength-shift<strong>in</strong>g layer are required. For<br />

shorter wavelengths, special lenses made of materials such as<br />

sapphire (Al2O3) or magnesium fluoride are needed. High<br />

brightness, high current LEDS that emit at 365 or 395 nm are<br />

available as UV illum<strong>in</strong>ation sources. These provide sufficient<br />

power for the longer work<strong>in</strong>g distances to be used than with the<br />

more traditional gas discharge UV lights. Appropriate safety<br />

precautions must be taken when work<strong>in</strong>g with UV radiation.<br />

Typical applications for direct UV imag<strong>in</strong>g <strong>in</strong>clude detection of<br />

scratches and digs on optical surfaces such as lenses or w<strong>in</strong>dows or<br />

detection of small amounts of surface contam<strong>in</strong>ation s<strong>in</strong>ce the<br />

shorter UV wavelengths tend to scatter more strongly off surface<br />

features. UV light also tends to be absorbed by organic materials,<br />

mak<strong>in</strong>g it possible to detect traces of oil or grease on many surfaces,<br />

especially us<strong>in</strong>g shorter UV wavelengths.<br />

Fluorescence imag<strong>in</strong>g<br />

A completely different approach to UV imag<strong>in</strong>g is fluorescence<br />

imag<strong>in</strong>g. Here, a UV sensitive dye is used to mark a component.<br />

These mark<strong>in</strong>gs cannot be seen under visible light<strong>in</strong>g, but when<br />

they are illum<strong>in</strong>ated <strong>in</strong> the UV, the dye fluoresces, giv<strong>in</strong>g a strong<br />

emission <strong>in</strong> the visible region of the spectrum which can be readily<br />

imaged us<strong>in</strong>g a conventional mach<strong>in</strong>e vision camera and lens. This<br />

is particularly useful when the aesthetic design of a component<br />

requires visible mark<strong>in</strong>g to be kept to a m<strong>in</strong>imum.<br />

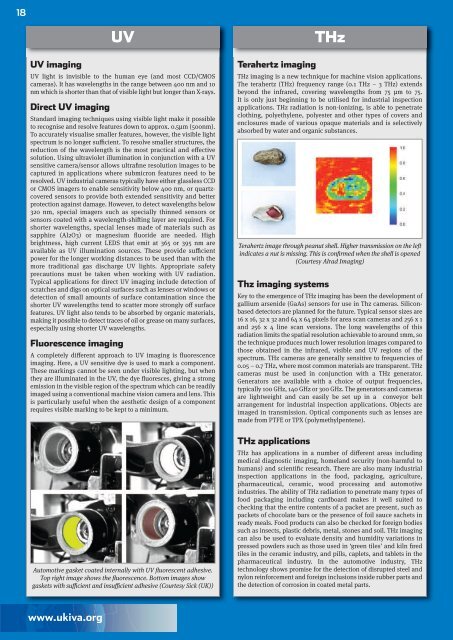

Automotive gasket coated <strong>in</strong>ternally with UV fluorescent adhesive.<br />

Top right image shows the fluorescence. Bottom images show<br />

gaskets with sufficient and <strong>in</strong>sufficient adhesive (Courtesy Sick (UK))<br />

Terahertz imag<strong>in</strong>g<br />

THz<br />

THz imag<strong>in</strong>g is a new technique for mach<strong>in</strong>e vision applications.<br />

The terahertz (THz) frequency range (0.1 THz – 3 THz) extends<br />

beyond the <strong>in</strong>frared, cover<strong>in</strong>g wavelengths from 75 µm to 75.<br />

It is only just beg<strong>in</strong>n<strong>in</strong>g to be utilised for <strong>in</strong>dustrial <strong>in</strong>spection<br />

applications. THz radiation is non-ioniz<strong>in</strong>g, is able to penetrate<br />

cloth<strong>in</strong>g, polyethylene, polyester and other types of covers and<br />

enclosures made of various opaque materials and is selectively<br />

absorbed by water and organic substances.<br />

Terahertz image through peanut shell. Higher transmission on the left<br />

<strong>in</strong>dicates a nut is miss<strong>in</strong>g. This is confirmed when the shell is opened<br />

(Courtesy Alrad Imag<strong>in</strong>g)<br />

Thz imag<strong>in</strong>g systems<br />

Key to the emergence of THz imag<strong>in</strong>g has been the development of<br />

gallium arsenide (GaAs) sensors for use <strong>in</strong> Thz cameras. Siliconbased<br />

detectors are planned for the future. Typical sensor sizes are<br />

16 x 16, 32 x 32 and 64 x 64 pixels for area scan cameras and 256 x 1<br />

and 256 x 4 l<strong>in</strong>e scan versions. The long wavelengths of this<br />

radiation limits the spatial resolution achievable to around 1mm, so<br />

the technique produces much lower resolution images compared to<br />

those obta<strong>in</strong>ed <strong>in</strong> the <strong>in</strong>frared, visible and UV regions of the<br />

spectrum. THz cameras are generally sensitive to frequencies of<br />

0.05 – 0.7 THz, where most common materials are transparent. THz<br />

cameras must be used <strong>in</strong> conjunction with a THz generator.<br />

Generators are available with a choice of output frequencies,<br />

typically 100 GHz, 140 GHz or 300 GHz. The generators and cameras<br />

are lightweight and can easily be set up <strong>in</strong> a conveyor belt<br />

arrangement for <strong>in</strong>dustrial <strong>in</strong>spection applications. Objects are<br />

imaged <strong>in</strong> transmission. Optical components such as lenses are<br />

made from PTFE or TPX (polymethylpentene).<br />

THz applications<br />

THz has applications <strong>in</strong> a number of different areas <strong>in</strong>clud<strong>in</strong>g<br />

medical diagnostic imag<strong>in</strong>g, homeland security (non-harmful to<br />

humans) and scientific research. There are also many <strong>in</strong>dustrial<br />

<strong>in</strong>spection applications <strong>in</strong> the food, packag<strong>in</strong>g, agriculture,<br />

pharmaceutical, ceramic, wood process<strong>in</strong>g and automotive<br />

<strong>in</strong>dustries. The ability of THz radiation to penetrate many types of<br />

food packag<strong>in</strong>g <strong>in</strong>clud<strong>in</strong>g cardboard makes it well suited to<br />

check<strong>in</strong>g that the entire contents of a packet are present, such as<br />

packets of chocolate bars or the presence of foil sauce sachets <strong>in</strong><br />

ready meals. Food products can also be checked for foreign bodies<br />

such as <strong>in</strong>sects, plastic debris, metal, stones and soil. THz imag<strong>in</strong>g<br />

can also be used to evaluate density and humidity variations <strong>in</strong><br />

pressed powders such as those used <strong>in</strong> ‘green tiles’ and kiln fired<br />

tiles <strong>in</strong> the ceramic <strong>in</strong>dustry, and pills, caplets, and tablets <strong>in</strong> the<br />

pharmaceutical <strong>in</strong>dustry. In the automotive <strong>in</strong>dustry, THz<br />

technology shows promise for the detection of disrupted steel and<br />

nylon re<strong>in</strong>forcement and foreign <strong>in</strong>clusions <strong>in</strong>side rubber parts and<br />

the detection of corrosion <strong>in</strong> coated metal parts.<br />

www.ukiva.org