Compact Air-Conditioning Unit - Weiss Klimatechnik GmbH

Compact Air-Conditioning Unit - Weiss Klimatechnik GmbH

Compact Air-Conditioning Unit - Weiss Klimatechnik GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

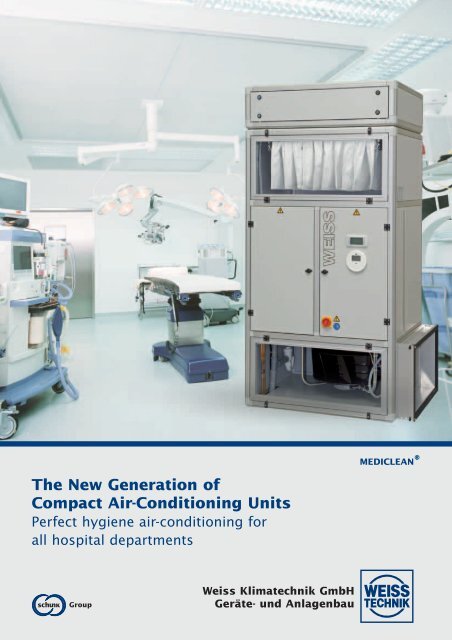

The New Generation of<br />

<strong>Compact</strong> <strong>Air</strong>-<strong>Conditioning</strong> <strong>Unit</strong>s<br />

Perfect hygiene air-conditioning for<br />

all hospital departments<br />

<strong>Weiss</strong> <strong>Klimatechnik</strong> <strong>GmbH</strong><br />

Geräte- und Anlagenbau<br />

MEDICLEAN ®

2<br />

The new generation of compact<br />

air-conditioning units<br />

The new generation of compact air-conditioning<br />

units has been developed for<br />

universal use in all hospital departments<br />

and meets the requirements of DIN<br />

1946-4.<br />

<strong>Compact</strong> construction and innovative<br />

technology ensure operating cost benefits<br />

extending well into the future. The<br />

optimised arrangement of mechanical<br />

and dynamic-flow components ensure<br />

low speeds and internal pressure losses.<br />

Maximum ease of servicing<br />

Very little outlay is needed for start-up,<br />

maintenance and service. Thanks to<br />

the compact housing and variable duct<br />

connections, the units can even be set<br />

up under unfavourable installation conditions.<br />

The type designations reflect the field<br />

of use of the air-conditioning units.<br />

Performance features<br />

Complies with DIN 1946-4<br />

Nominal volume flow from<br />

2.000 to 22.000 m3 /h<br />

Full air-conditioning function with<br />

heating, cooling, humidifying and<br />

dehumidifying<br />

<strong>Compact</strong>, single-module<br />

construction<br />

Filter class: F7 standard,<br />

F9 optional<br />

Two filter stages possible<br />

<strong>Compact</strong><br />

<strong>Air</strong>-<strong>Conditioning</strong> <strong>Unit</strong>s

1 Housing<br />

Double-shell wall construction with<br />

45 mm thick insulation produces a<br />

high degree of housing rigidity and<br />

optimum sound absorption.<br />

All-sided detachable housing lining<br />

in keeping with DIN 1946-4<br />

Interior of housing powder-coated,<br />

bottom of housing as stainless<br />

steel tub<br />

Stable, low-maintenance and flexible<br />

profile frame structure<br />

Optional: vision panels for fan/filter<br />

unit. They allow fans and filters to<br />

be checked under operating conditions.<br />

Electrical section, regulation, all-in<br />

refrigeration components, humidifier,<br />

PKW (Pumped Cold Water) or<br />

PWW (Pumped Hot Water) valves<br />

sealed off on the air side from the<br />

air purification section – thus inspection<br />

and maintenance possible<br />

when the unit is running.<br />

2 Fan motor unit<br />

Efficiency of optimised heavy-duty<br />

radial fan without spiral housing,<br />

with blades bent backwards, aspirating<br />

at one end<br />

Drive motor as external impeller<br />

integrated in the rotor – compact<br />

design<br />

Variable fan arrangement for maximum<br />

blowoff position diversity<br />

The fan speed is controlled via EC or<br />

frequency converter in keeping with<br />

individual pressure and volume flow.<br />

Support-structured fan/motor unit<br />

easily extractable from the front<br />

3 Filter<br />

F7/F9 Filter Class as cassette filter<br />

Optional: bag filters possible with<br />

downflow design<br />

Filter change from the front<br />

4a Refrigeration cycle<br />

Scroll compressor: low-on-wear and<br />

economical<br />

<strong>Compact</strong> <strong>Air</strong>-<strong>Conditioning</strong> <strong>Unit</strong><br />

1<br />

4a<br />

High compressor efficiency<br />

Future-proof, environmentally-compatible<br />

R407c refrigerant; optional<br />

R417a<br />

4b - Pumped cold water (optional)<br />

Large –surface Cu/Al heat exchanger,<br />

completely tubed internally,<br />

incl. 3-way valve<br />

5 Heat exchanger<br />

Large-surface Cu/Al heat exchanger<br />

with 2.5 mm multi-plate spacing,<br />

easy to access for cleaning<br />

Low passage speed – thus only<br />

slight pressure losses<br />

Aluminium condensate tray – easily<br />

removable and cleanable<br />

6 Electrical section<br />

Regulation system and control and<br />

power section are in the basic appliance<br />

Standardised contactor/motor protection<br />

combination for fusing the<br />

fitted components<br />

Easily accessible main switch on the<br />

outer housing<br />

3<br />

2<br />

6<br />

7 5<br />

Front view Side view<br />

7 Humidifier<br />

8a<br />

4b<br />

8b<br />

Electrode steam humidifier for automatic<br />

generation and output of<br />

mineral-free, odourless and sterile<br />

steam<br />

The humidifier has a micro-processor<br />

control and automatically<br />

adjusts to the water conductivity<br />

present (auto adaptive).<br />

Direct connection to all the usual<br />

water supply grids<br />

8a Electrical heating<br />

Stainless steel smooth-bore heating<br />

rods<br />

Threefold fusing against short-circuits<br />

and overheating by means of automatic<br />

circuit-breaker, protective circuit-breaker<br />

and safety thermostat –<br />

constantly controlled.<br />

8b- Pumped hot water (optional)<br />

Large –surface Cu/Al heat exchanger,<br />

completely tubed internally,<br />

incl. 3-way valve<br />

2<br />

3

4<br />

Maximum quality in k<br />

Housing profiles<br />

Housing profiles connected with fibreglass<br />

reinforced plastic corner joints<br />

complete with flame protection<br />

High degree of housing rigidity<br />

Anodised aluminium profiles<br />

Corrosion-proof<br />

Functional setup<br />

Innovative design<br />

Refrigeration cycle and<br />

electrical equipment (VDI 6022)<br />

Refrigeration cycle and electrical<br />

equipment can be serviced under<br />

ongoing operations (without intervention<br />

in the air stream)<br />

Clear arrangement of all components<br />

Filter (VDI 6022)<br />

Standard-dimensioned external air<br />

bag filter<br />

Easy-to-get to and be seen<br />

F7/F9 filter quality, large dust<br />

storage capacity<br />

Filter frame seal replaced with<br />

filter change<br />

Vision panel optional

<strong>Compact</strong> <strong>Air</strong>-<strong>Conditioning</strong> <strong>Unit</strong><br />

eeping with VDI 6022<br />

Control and sensor (VDI 6022)<br />

Clearly readable digital readings<br />

indicator<br />

Filter pressure sensor autonomously<br />

for control according<br />

to VDI 6022<br />

Preheater<br />

For outer air proportion > 50 %<br />

Preheater in the top-mounted box<br />

4 mm multi-plate spacing in accordance<br />

with DIN 1946-4<br />

Can be easily extracted for cleaning<br />

Fans (VDI 6022)<br />

Suspended fans easily removable<br />

Safe, easy handling<br />

Can be easily cleaned<br />

Vision panel optional<br />

5

6<br />

Technical data<br />

SERIES 35.3 55.3 75.3 90.3 120.3 160.3 220.3<br />

NOMINAL VOLUME FLOW<br />

Volume flow at max. ext. pressure loss m3 /h 3.500 5.500 7.500 9.000 12.000 16.000 22.000<br />

Max. external pressure loss (standard*)<br />

*more powerful fan/motor unit on request<br />

Pa 300 470 360 210 450 320 390<br />

COOLING/REFRIGERATING CYCLE, EXTERNALLY AIR-COOLED<br />

Refrigerating capacity (tc=50°C) acc. to EUROVENT<br />

Intake temp. +27 °C/46 % r.h. - total/sens. kW 13.4/11.5 18.4/17.9 29.2/26.2 34.9/31.4 45.4/41.7 54.4/52.3 73.1/71.0<br />

Type SCROLL compressor<br />

Quantity pc(s) 1 1 2 2 3 3 4<br />

Refrigerant R407C<br />

Electrical connected load kVA 8.8 9 2 x 8.8 2 x 9 3 x 8.8 3 x 9 4x 9<br />

Part type code (DX=direct evaporator) DX DX DX DX DX DX DX<br />

COOLING/COLD WATER 7/12,5*<br />

Refrigerating capacity acc. to EUROVENT<br />

Intake temp. +27 °C/46 % r.h. - total/sens. kW 11.6/9.8 26.1/20.4 36.6/28.5 42.9/33.5 60.6/46.8 75/58.9 106/82.7<br />

Cold water flow rate m3 /h 1.8 4.1 5.7 6.7 9.5 11.7 16.5<br />

Water-sided pressure loss - cooler kPa 11.1 10 15.6 10.1 15.5 14.2 12.8<br />

Cold water valve DN 25 25 25 25 25 32 40<br />

Water-sided pressure loss kPa 16 17 31 18 33 23 27<br />

Part type code (CW=cold water)<br />

*other temperatures on request<br />

CW CW CW CW CW CW CW<br />

FAN MOTOR UNIT*<br />

Type Brushless DC motor, directly driven, freely running<br />

Number Quantity 1 1 1 1 2 2 3<br />

Motor mounting form External impeller<br />

Rotor diameter mm 450 560 560 560 560 560 560<br />

Motor control Internal commutation unit<br />

Motor rated output kW 1.1 3.1 3.1 3.1 2 x 3.1 2 x 3.1 3 x 3.1<br />

Current input - max. A 2.4 4.9 4.9 4.9 2 x 4.9 2 x 4.9 3 x 4.9<br />

Electrical connected load kVA 1.1 3.1 3.1 3.1 2 x 3.1 2 x 3.1 3 x 3.1<br />

Speed 1/min 1.620 1.510 1.510 1.510 1.510 1.510 1.510<br />

Protection class IP F 54<br />

Part type code (D=Downflow/U=Upflow)<br />

* more powerful fan motor on request<br />

D D D D D D D<br />

We reserve the right to effect technical engineering modifications in the cause of progress.<br />

Clarification of the type code – Example<br />

MEDICLEAN ® 75. 3 DX D 13. 8 H/N<br />

Type of unit:<br />

H = „Hygiene“<br />

N = Standard<br />

<strong>Unit</strong> depth:<br />

e.g. 850 mm<br />

<strong>Unit</strong> width:<br />

e.g. 1,355 mm<br />

<strong>Air</strong> direction through cooler:<br />

D = Downflow<br />

U = Upflow<br />

Kind of cooling:<br />

DX = Direct evaporator<br />

CW = Cold water<br />

Version number:<br />

Version 3<br />

Series:<br />

e.g. 75 = 7500 m3 /h<br />

Field of application:<br />

MEDICLEAN®: for all hospital departments

<strong>Compact</strong> <strong>Air</strong>-<strong>Conditioning</strong> <strong>Unit</strong><br />

SERIES 35.3 55.3 75.3 90.3 120.3 160.3 220.3<br />

FILTER F7 IN THE INTAKE *<br />

Type Cassette filter<br />

Quantity pc(s) 1 1 1 1 2 3 3<br />

Filter class acc. to DIN EN 779 F7<br />

Recommended final pressure<br />

* also available as bag filter (only downflow)<br />

Pa 200 200 200 200 200 200 200<br />

HOUSING DIMENSIONS<br />

Width mm 1.090 1.090 1.355 1.610 2.140 2.405 2.405<br />

Depth mm 650 850 850 850 850 1.100 1.100<br />

Height mm 1.950 1.950 1.950 1.950 1.950 1.950 1.950<br />

Part type code (width, depth) 10.6 10.8 13.8 16.8 21.8 24.11 24.11<br />

BASIC APPLIANCE - COMPLETE<br />

Weight complete DX/CW<br />

Acoustic output level at nominal volume<br />

kg 325/286 384/312 534/471 628/523 890/778 1153/1038 1284/1086<br />

flow and ext. pressure loss Pa 50 50 50 50 50 50 50<br />

Waste air sleeve db (A) 74 70 76 83 76 84 86<br />

Supply air sleeve db (A) 81 77 83 90 83 91 93<br />

Housing radiation db (A) 68 58 64 71 64 70 72<br />

Free zone noise level (1 m spacing) db (A) 64 54 59 66 59 66 68<br />

Supply voltage V/Ph/Hz 400/3/50<br />

Electrical connected load* kVA 9.9 12.1 20.7 21.1 32.6 33.2 45.3<br />

Overall type code (Bsp.)<br />

* without condenser<br />

35.3DXD10.6H 55.3DXD10.8H 75.3DXD13.8H 90.3DXD16.8H 120.3DXD21.8H 160.3DXD24.11H 220.3DXD24.11H<br />

OPTIONS<br />

FILTER F9 IN THE INTAKE *<br />

Type Cassette filter<br />

Quantity pc(s) 1 1 1 1 2 3 3<br />

Filter class acc. to DIN EN 779 F9<br />

Recommended final pressure<br />

* also available as bag filter (only downflow)<br />

and as second filter stage<br />

Pa 300 300 300 300 300 300 300<br />

HUMIDIFYING - STEAM GENERATOR<br />

Type Electrode steam humidifier<br />

Max. quantity pc(s) 1 1 1 1 1 1 1<br />

Current input A 4.7 7.4 10 11.9 15.9 21.1 29.1<br />

Input power kW 3.2 5 6.8 8.1 10.8 14.4 19.8<br />

Electrical connected load kVA 3.2 5 6.8 8.1 10.8 14.4 19.8<br />

Max. steam output kg/h 4.2 6.6 9 10.8 14.4 19.2 26.4<br />

Water supply bar 1 - 10 1 - 10 1 - 10 1 - 10 1 - 10 1 - 10 1 - 10<br />

Water conductivity μS/cm 125-900 125-900 125-900 125-900 125-900 125-900 125-900<br />

HEATING - ELECTRICAL HEATING<br />

Type Smooth bore radiator<br />

Max. quantity of heating rods pc(s) 3 6 6 6 6 6 12<br />

Max. heating output kW 7.5 15 15 21 21 21 30<br />

Max. stages constant<br />

Current input A 10.8 21.7 21.7 30.3 30.3 30.3 43.4<br />

Electrical connected load kVA 7.5 15 15 21 21 21 30<br />

HEATING - HOT WATER 70/50<br />

Heating output at intake temp. 15 °C kW 15.9 23.9 32.4 36.2 49.2 66.5 79.2<br />

Hot water flow rate m3 /h 0.7 1 1.4 1.6 2.2 2.9 3.5<br />

Water-sided pressure loss kPa 9.1 6.9 9.5 6.8 6.9 8.6 8.2<br />

PWW valve DN 15 15 15 15 25 25 25<br />

Water-sided pressure loss - valve kPa 11 12 16 18 27 16 17<br />

We reserve the right to effect technical engineering modifications in the cause of progress.<br />

7

8<br />

Technical data<br />

SERIES 35.3 55.3 75.3 90.3 120.3 160.3 220.3<br />

HEATING - HOT WATER 70/50(VE)*<br />

Heating output at intake temp. -15 °C kW 22 34.7 47.2 57.6 79 114.6 138.5<br />

Hot water flow rate m3 /h 1 1.5 2.1 2.5 3.5 5 6.1<br />

Water-sided pressure loss kPa 12.9 14.7 14.3 13 12 8.5 11.8<br />

PWW valve DN 15 15 15 15 25 25 25<br />

Water-sided pressure loss - valve kPa 16 20 26 38 22 26 35<br />

* VE=Preheater in the top-mounted box (only downflow)<br />

CONDENSER, AIR-COOLED, EXTERN, TYPE KLDR (Field of application with outside temperature up to +35°C)<br />

Type Axial fan condenser<br />

Quantity at ta=35 °C / tc=50 °C pc(s) 1 1 1 1 1 1 2<br />

Cooling air volume flow, constant, max. m3 /h 8.500 8.500 18.000 18.000 18.400 18.400 18.000/18.000<br />

Max. noise level at 5 m spacing db(A) 56 56 59 59 62 62 59/59<br />

Number of motors pc(s) 1 1 2 2 2 2 2/2<br />

Supply voltage V 230 230 230 230 230 230 230<br />

Output kW 27 27 47 47 71 71 47/47<br />

Current input A 3.3 3.3 2x3.3 2x3.3 2x3.3 2x3.3 2x3.3/2x3.3<br />

Electrical connected load kVA 1.3 1.3 2.6 2.6 2.6 2.6 2x2.6<br />

Length (A+C) mm 1.408 1.408 2.115 2.115 2.665 2.665 2.115/2.115<br />

Width vertical (B1) mm 1.050 1.050 1.050 1.050 1.050 1.050 1.050/1.050<br />

Width horizontal (B2) mm 540 540 540 540 540 540 540/540<br />

Height vertical (D) mm 1.105 1.105 1.105 1.105 1.105 1.105 1.105/1.105<br />

Height horizontal (E) mm 1.615 1.615 1.615 1.615 1.615 1.615 1.615/1.615<br />

Weight kg 109 109 160 160 217 217 160/160<br />

CONDENSER, AIR-COOLED, EXTERN, TYPE KLI (Field of application with outside temperature up to +45°C)<br />

Type Axial fan condenser<br />

Quantity at ta=45 °C / tc=52 °C pc(s) 1 1 1 1 1 1 2<br />

Cooling air volume flow, constant, max. m3 /h 18.360 18.360 27.000 27.000 44.064 44.064 27.000/27.000<br />

Max. noise level at 5 m spacing db(A) 58 58 60 60 56 56 60/60<br />

Number of motors pc(s) 2 2 3 3 3 3 3/3<br />

Supply voltage V 400 400 400 400 400 400 400<br />

Output kW 26.4 26.4 49.7 49.7 72.9 72.9 49.7/49.7<br />

Current input A 2x1.25 2x1.25 3x1.25 3x1.25 3x3.1 3x3.1 3x1.25/3x1.25<br />

Electrical connected load kVA 1.73 1.73 2.6 2.6 6.4 6.4 2.6/2.6<br />

Length (A+C) mm 2.490 2.490 3.640 3.640 3.908 3.908 3.640/3.640<br />

Width vertical (B1) mm 980.5 980.5 980.5 980.5 1.158 1.158 980.5/980.5<br />

Width horizontal (B2) mm 800 800 800 800 1.225 1.225 800/800<br />

Height vertical (D) mm 870 870 870 870 1.225 1.225 870/870<br />

Height horizontal (E) mm 920.5 920.5 920.5 920.5 1.158 1.158 920.5/920.5<br />

Weight kg 155 155 235 235 490 490 235/235<br />

We reserve the right to effect technical engineering modifications in the cause of progress.<br />

Design (V)<br />

blowing vertically<br />

Design (H)<br />

blowing horizontally

Front view of unit<br />

Options<br />

All dampers can also be designed<br />

as sleeves.<br />

300 – 840 mm high top-mounted<br />

and base boxes can be supplied.<br />

150 to 650 mm high base frames<br />

can be supplied.<br />

Supply connections<br />

Side view from left side<br />

<strong>Compact</strong> <strong>Air</strong>-<strong>Conditioning</strong> <strong>Unit</strong><br />

View of unit from left side<br />

(symmetrical arrangement of the sleeves)<br />

Max. air volume for each lateral connection:<br />

9.000 m3 /h<br />

Media connections: on the left side<br />

(top, bottom or at the side)<br />

Electrical connections: on the right<br />

side (top, bottom or at the side)<br />

Side view from right side<br />

Operating side<br />

Maintenance<br />

envelope<br />

min. unit depth<br />

<strong>Unit</strong> L B L1 L2 L3 L4 B1 B2 H2<br />

35.3 1.090 650 765 1.000 177 147 550 550 150-650<br />

55.3 1.090 850 765 1.000 177 147 750 750 150-650<br />

75.3 1.355 850 1.030 1.255 172 152 750 750 150-650<br />

90.3 1.610 850 1.260 1.505 192 157 750 750 150-650<br />

120.3 2.140 850 1.790 2.035 192 157 710* 750 150-650<br />

160.3 2.405 1.100 2.035 2.300 212 157 (1000) 960* 1.000 150-650<br />

220.3 2.405 1.100 2.035 2.300 212 157 (1000) 960* 1.000 150-650<br />

Top view of unit<br />

Intake/blowoff honeycomb grid possible<br />

at the side and front when no<br />

duct system needed and appliance is<br />

directly in the room.<br />

Partial top and bottom view<br />

1. PWW reheater supply flow<br />

2. PWW reheater return flow<br />

3. Humidifier supply<br />

4. Humidifier discharge<br />

5. PKW supply/<br />

Refrigerant liquid line<br />

6. PKW return/<br />

Refrigerant hot gas line<br />

7. Electric line inlets<br />

8. Condensate discharge<br />

9

10<br />

EC fan technology -<br />

The best solution<br />

We use modern EC fans in our compact<br />

air-conditioning units. In contrast to<br />

the usual AC fans, they have an EC<br />

permanent magnet direct-current<br />

motor.<br />

Commutation with this new technology<br />

involves semi-conductor modules -<br />

thus electronic and non-wearing.<br />

EC fan technology benefits:<br />

High degree of efficiency<br />

30 % saving in energy over AC fans<br />

Vibration-free (oscillation-free<br />

mounting)<br />

Extremely quiet when running<br />

Long service life<br />

Infinitely adjustable speeds<br />

Control/Regulation<br />

with „pcs+"“<br />

<strong>Weiss</strong> Klima compact air-conditioning<br />

units are fitted as standard with a pcs+<br />

control. Other control types on request.<br />

Operating terminal<br />

LCD display, 8 lines, 22 characters<br />

6 keys with LED feedback<br />

Warning horn<br />

Front installation<br />

IP 65 protection class<br />

Integrated monitoring functions protect<br />

both motor and electrical equipment<br />

from the effects of blockage, phasing<br />

failure and excess temperature and<br />

thus ensure reliable operations and<br />

long service life. Internal electrical<br />

equipment continuously regulates the<br />

air volume.<br />

Controller<br />

Microprocessor 16 bit, 16 MHz,<br />

256 kB RAM<br />

Clock , battery-buffered<br />

RS485 interface for pLAN<br />

Display connection<br />

Programme storage on non-volatile<br />

flash memory<br />

Inputs and outputs<br />

8/14/18 digital inputs<br />

8/13/18 digital outputs<br />

2/2/4 sensor inputs<br />

3/6/6 universal inputs<br />

4/4/6 analogue outputs

Universal use<br />

Made in Germany<br />

F7/F9 cassette<br />

and bag filters<br />

Complies with VDI 6022<br />

Complies with DIN 1946-4<br />

<strong>Compact</strong> <strong>Air</strong>-<strong>Conditioning</strong> <strong>Unit</strong><br />

Benefits<br />

of <strong>Weiss</strong><br />

<strong>Compact</strong> <strong>Unit</strong>s<br />

Incl. <strong>Weiss</strong> partner package:<br />

Support from planning to after-<br />

sales-service<br />

Ultra-modern EC fan technology<br />

Ease of service and maintenance<br />

11

Competence immediate information<br />

Hygiene Technology Centre<br />

<strong>Weiss</strong> <strong>Klimatechnik</strong> <strong>GmbH</strong><br />

Geräte- und Anlagenbau<br />

Greizer Straße 41– 49<br />

D-35447 Reiskirchen-Lindenstruth<br />

Telefon: +49 (6408) 84 71<br />

Telefax: +49 (6408) 84 87 20<br />

info@wkt.com<br />

www.wkt.com<br />

We would be glad to advise you on:<br />

The new MEDICLEAN® system units<br />

<strong>Weiss</strong> ULA and FFA clean air canopies<br />

Circulating air wall modules<br />

System concepts<br />

Media bridges<br />

Data transmission<br />

Installation, service and maintenance<br />

Do visit us at our Hygiene Technology<br />

Centre (HTZ) in Reiskirchen-Lindenstruth.<br />

D-Nr. RK 4.0.0.122e/2 0508.1