African Petrochemicals Nov/Dec Edition 14.6 {2017}

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

IN THIS EDITION<br />

SASOL UNVEILS STRATEGY TO DRIVE FUTURE VALUE-BASED GROWTH<br />

<strong>Edition</strong> <strong>14.6</strong><br />

Transnet and OTGC Make Headway on New Ngqura Liquid Bulk Terminal <strong>Nov</strong>ember / <strong>Dec</strong>ember <strong>2017</strong>

FENNER DRIVE ALIGNMENT LASER<br />

pulley and sprocket alignment<br />

BMG’s extensive range of Fenner power transmission components encompasses the<br />

Fenner Drive Alignment Laser instrument, designed for accurate pulley and sprocket<br />

alignment, to reduce wear on belts and pulleys and ensure drive efficiency.<br />

“The portable Fenner Drive Alignment Laser system - suitable for both vertical<br />

and horizontal mounted machines - is quick and easy to use for accurate results,”<br />

explains Carlo Beukes, general manager, power transmission, BMG. “The laser line<br />

of this compact and lightweight tool, allows rapid adjustment to perfect alignment.<br />

Conventional alignment methods, which often require difficult, lengthy<br />

positioning of components, can prolong downtime and affect<br />

efficiency.<br />

“The Fenner alignment system shows parallel and angular<br />

misalignment and as a result, drive efficiency is improved<br />

and energy savings are increased. With minimal friction and<br />

vibration, the service life of chain, sprockets, shafts and bearings<br />

is significantly extended and the costs of maintenance, repair and<br />

downtime are reduced.”<br />

For maximum accuracy, the mounting unit is magnetised to attach firmly<br />

to sheaves or pulleys. It is also possible to attach this instrument to nonmagnetic<br />

sheaves using double sided adhesive tape.<br />

BMG’s Fenner range also includes synchronous transmission belts, pulleys<br />

and accessories, as well as shaft fixings, chain drives and couplings. BMG also<br />

supplies Fenner shaft mounted speed reducers (SMSRs).<br />

For further information:<br />

Carlo Beukes, General Manager, Power Transmission, BMG<br />

Tel: (011) 620 1500<br />

Email: carlob@bmgworld.net<br />

Web: www.bmgworld.net<br />

BMG’s new<br />

Fenner Drive Alignment<br />

Laser instrument,<br />

designed for quick,<br />

easy and accurate pulley<br />

and sprocket alignment,<br />

improves drive efficiency,<br />

reduces wear<br />

and enhances energy<br />

savings.<br />

FIRST HIGH PRESSURE VALVES SUPPLIED TO EGYPT<br />

The company already has decades of<br />

operational experience with almost<br />

all of the effective principles and<br />

assemblies used. As such the SHP can<br />

be considered ‘Proven Equipment’.<br />

The individual system components<br />

have simply been modified and<br />

innovatively combined, as such that<br />

they enhance the dependable and<br />

low-wear area of application of the<br />

existing technology to meet the<br />

increased requirements. Thus, the new<br />

SHP-series automatic recirculation<br />

valve enables and promotes the<br />

energy-efficient operation of modern<br />

power plant facilities.<br />

Schroeder Valves is among the suppliers for the world’s biggest gas-fired combined-cycle power plant<br />

complex currently built in Egypt. The first of a total of 36 Schroeder High Pressure Valves (SHP) have<br />

already been delivered. The automatic recirculation valve is suited for the high and maximum pressure<br />

range as well as for situations involving highly fluctuating pump loads and long periods of operation<br />

under extreme partial load conditions – exactly the features needed for the protection of the pumps<br />

in the Egyptian complex.<br />

The Schroeder High Pressure Valve SHP is an automatic recirculation valve which was developed to<br />

protect pumps and equipment from damage that can occur due to the flow rate falling below the<br />

permissible minimum. Thus the SHP is suited primarily for customers in the field of power plant and<br />

plant construction and the offshore industry. The SHP builds on existing Schroeder Valves technology.<br />

For more information on Schroeder<br />

products and services please visit our<br />

website www.valve.co.za<br />

Contact:<br />

Desmond Delport<br />

Valve & Automation (PTY) Ltd<br />

Vereeniging<br />

sales@valve.co.za or<br />

call +27 – 11 – 397 2833<br />

Durban<br />

sales@valve.co.za or<br />

call +27 – 31 – 579 2593<br />

2

<strong>African</strong> <strong>Petrochemicals</strong> is published bi-monthly by Direct Publications cc<br />

<strong>Edition</strong> <strong>14.6</strong> <strong>Nov</strong>ember / <strong>Dec</strong>ember <strong>2017</strong><br />

Direct Publications<br />

Publisher<br />

Richard Scott<br />

richard@africanpetrochemicals.co.za<br />

Accounts and Admin<br />

Ashni Padiachie<br />

accounts@africanpetrochemicals.co.za<br />

Sales<br />

Annelize Arrow<br />

sales@africanpetrochemicals.co.za<br />

Graphic Designer<br />

Linda Graae<br />

production@africanpetrochemicals.co.za<br />

CONTENTS<br />

Fenner Drive Alignment Laser - pulley and<br />

sprocket alignment ................................................... 2<br />

First High Pressure Valves supplied to Egypt .... 2<br />

EMERSON collaborates with exida to reduce<br />

complexity and time required for safety system<br />

setup ............................................................................... 4<br />

BBF Safety Group recognises the Bright Stars .... 5<br />

Hytec Engineers ‘Fluid Power Fitter’<br />

Qualification ................................................................ 6<br />

Rockwell Automation to showcase its Digital<br />

Oilfield and ConnectedProduction TM Solutions<br />

for increased profitability in the Oil & Gas<br />

Sector at ADIPEC <strong>2017</strong> ............................................. 8<br />

20 Years with NACE as standard construction<br />

of JC Ball Valves ........................................................... 8<br />

Sasol Khanyisa approved by Sasol<br />

Shareholders .............................................................. 10<br />

Specialised Industrial Electronics ....................... 11<br />

Emerson extends industrial IOT application<br />

portfolio for improved operations and<br />

maintenance .............................................................. 12<br />

FDA and EU food approved JC Valves .............. 12<br />

Automation - creating the worker of<br />

tomorrow .................................................................... 13<br />

Instrumentation and measurement solutions<br />

for the South <strong>African</strong> water industry ................ 14<br />

thyssenkrupp Service Centre capabilities<br />

showcased at Copperbelt Mining & Trade Expo<br />

<strong>2017</strong>, Zambia ............................................................. 15<br />

Renewable energy, critical to meeting Africa’s<br />

energy needs by 2040 ............................................ 16<br />

Photos of the recent Durban Petrochemical<br />

Roadshow ................................................................... 18<br />

Preferred work-at-height, confined-space<br />

service provider in Africa ...................................... 20<br />

Entrepreneurs key to addressing South Africa’s<br />

desperate jobs crisis ............................................... 21<br />

Sasol signs US$3,9 billion five-year revolving<br />

credit facility .............................................................. 21<br />

Sasol unveils strategy to drive future valuebased<br />

growth ............................................................ 22<br />

Zwick Triple Eccentric Valve with superior<br />

operating characteristics ...................................... 23<br />

RTS Africa Engineering provides accurate,<br />

reliable hydrogen detection solutions ............ 25<br />

SEW-EURODRIVE confirms its presence at<br />

BAUMA CONEXPO Africa 2018 ........................... 26<br />

The new age of digitisation and the impact on<br />

the <strong>African</strong> energy sector ..................................... 26<br />

The compEAct series guarantee fast and<br />

simple analysis of compressed and liquefied<br />

pressurized gases .................................................... 27<br />

Transnet and OTGC make headway on new<br />

Ngqura Liquid Bulk Terminal .............................. 28<br />

“Refueling” of Electric Vehicles in “No Time”.... 29<br />

Sulzer appoints US Sales Manager for high<br />

voltage coils .............................................................. 30<br />

CID 510 – Cetane Ignition Delay ......................... 30<br />

Visit <strong>African</strong> <strong>Petrochemicals</strong> online:<br />

www.africanpetrochemicals.co.za<br />

<strong>African</strong> <strong>Petrochemicals</strong> IOS App is now available<br />

for download on your iPhone!<br />

The views and opinions expressed in this<br />

magazine are those of the respective authors<br />

and do not necessarily express the views and<br />

opinions of Direct Publications cc. We do not<br />

endorse any of the products , services or<br />

expertise offered by any of our advertisers or<br />

contributors. No liability will be accepted for<br />

artwork supplied incorrectly or slight colour<br />

deviations. Editorial contributions relevant<br />

to any section of the magazine are more than<br />

welcome. Email submissions to<br />

production@africanpetrochemicals.co.za<br />

Direct Publications reserves the right to cut and<br />

alter editorials received for publication.<br />

Reproduction<br />

No part of this magazine may be reproduced<br />

without written permission from the editor or<br />

publisher.<br />

Subscription Service<br />

For address changes, subscriptions or missed<br />

issues, please call 011 083 5125 or<br />

email: accounts@africanpetrochemicals.co.za<br />

<strong>African</strong> <strong>Petrochemicals</strong><br />

Magazine<br />

<strong>African</strong><br />

Petrochemical Mag...<br />

Direct Publications t/a...<br />

+<br />

GET<br />

Magazine Overview<br />

All the latest industry related news on one page!<br />

CONNECT WITH US<br />

3

EMERSON<br />

COLLABORATES WITH<br />

EXIDA TO REDUCE<br />

COMPLEXITY AND TIME<br />

REQUIRED FOR SAFETY<br />

SYSTEM SETUP<br />

Project teams can avoid delays and<br />

eliminate errors by automating SIS<br />

configuration<br />

Emerson and exida announce<br />

the release of the DeltaV safety<br />

instrumented system (SIS) configurator,<br />

an exida exSILentia® tool that<br />

automatically generates DeltaV SIS<br />

configurations. By pairing built-in<br />

DeltaV functionality with exida’s<br />

comprehensive software tools for<br />

functional safety, users can develop<br />

safety logic configurations much faster<br />

and in fewer steps. Project teams can<br />

not only decrease time and effort of<br />

safety system configuration, but also<br />

deliver more consistent configurations<br />

with fewer errors, requiring less rework.<br />

4<br />

In traditional SIS configuration, project teams<br />

use the safety requirements specification<br />

(SRS), along with custom-built cause and<br />

effect matrices (CEM) as the basis for system<br />

configuration. The CEM data is manually<br />

interpreted and coded into the safety logic<br />

to configure the system. This configuration<br />

model requires multiple stages of data<br />

entry, taking too much time and presenting<br />

opportunities for human error. The new<br />

DeltaV SIS configurator leverages data<br />

structures created during the conceptual<br />

safety instrumented function (SIF) design,<br />

safety instrumented level (SIL) verification,<br />

and the SRS to automatically generate the<br />

safety system configuration.<br />

“With the DeltaV SIS Configurator,<br />

programming the logic only takes a fraction<br />

of the time, so the SIS conceptual design can<br />

be finalized before programming begins.<br />

This eliminates any rework due to changing<br />

requirements and dramatically impacts<br />

project schedule,” said Iwan van Beurden,<br />

chief technology officer and director of<br />

product development at exida.<br />

With automated SIS configuration, there is<br />

no need for entering data in multiple tools;<br />

everything is entered once into exSILentia,<br />

and an automated tool translates the<br />

information into the DeltaV safety logic<br />

configuration. The SRS data, SIF definition,<br />

and the associated SIL verification data are<br />

included.<br />

“Using automatic SIS configuration, project<br />

teams can deliver accurate safety logic with<br />

minimal programming,” said Sergio Diaz,<br />

DeltaV SIS product marketing manager,<br />

Emerson Automation Solutions. “Less data<br />

entry means more consistency between<br />

engineers, leading to less validation time and<br />

faster startups.”<br />

“By minimizing the need for manually entered<br />

data and automating other critical steps,<br />

this jointly developed solution addresses<br />

some key pain points and should be able<br />

to help end users design and implement<br />

safer systems more efficiently, maintain<br />

these systems, and ensure compliance with<br />

pertinent regulations and standards,” says<br />

Mark Sen Gupta, research director with ARC<br />

Advisory Group.<br />

For more information on DeltaV SIS, visit<br />

Emerson.com/DeltaVSIS<br />

For more information on the DeltaV SIS<br />

configurator for exida exSILentia, visit http://<br />

www.exida.com/exSILentia/exSILentia-<br />

DeltaV-Config<br />

Monitor exida ExSILentia tool.<br />

About exida<br />

exida is a global leader in functional<br />

safety tools, consulting and assessments<br />

specializing in safety critical/high availability<br />

automation systems, control system<br />

cybersecurity, and alarm management.<br />

exida’s main offices located in: Sellersville,<br />

PA, USA and Munich, Germany and has<br />

worldwide operations with service centers in<br />

Brazil, Canada, Mexico, Netherlands, and New<br />

Zealand, Singapore, Japan, South Africa, and<br />

the United Kingdom. For more information,<br />

exida.com<br />

About Emerson<br />

Emerson (NYSE: EMR), headquartered<br />

in St. Louis, Missouri (USA), is a global<br />

technology and engineering company<br />

providing innovative solutions for customers<br />

in industrial, commercial, and residential<br />

markets. Our Emerson Automation Solutions<br />

business helps process, hybrid, and discrete<br />

manufacturers maximize production, protect<br />

personnel and the environment while<br />

optimizing their energy and operating costs.<br />

Our Emerson Commercial and Residential<br />

Solutions business helps ensure human<br />

comfort and health, protect food quality<br />

and safety, advance energy efficiency, and<br />

create sustainable infrastructure. For more<br />

information visit Emerson.com.<br />

Further information is available from:<br />

Rob Smith, Sales Manager<br />

South & East Africa Emerson Automation<br />

Solutions<br />

Tel: 011 451 3700<br />

Email: Rob.Smith@emerson.com<br />

Web: www.Emerson.com

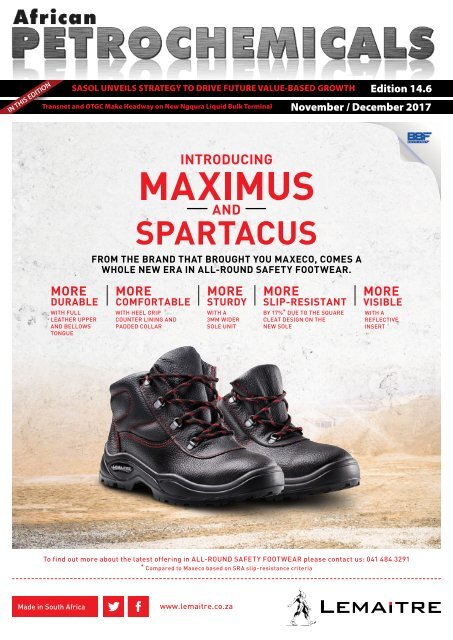

FRONT COVER STORY<br />

BBF SAFETY GROUP RECOGNISES THE BRIGHT STARS<br />

On 9 <strong>Nov</strong>ember <strong>2017</strong>, BBF Safety Group hosted customers in Johannesburg for its annual year-end celebration.<br />

Brand Captain Award<br />

The Brand Captain Award was presented to the distributors who<br />

achieved the highest volume sales for an individual brand within<br />

a calendar year, amongst all regions. The brands are: Bova, Frams,<br />

Lemaitre, Sisi and Wayne.<br />

• <strong>2017</strong> winner – Bova: Select PPE<br />

• <strong>2017</strong> winner – Frams: Pienaar Bros. North<br />

• <strong>2017</strong> winner – Lemaitre: Cattell’s Industrial Footwear<br />

• <strong>2017</strong> winner – Sisi: Cattell’s Industrial Footwear<br />

• <strong>2017</strong> winner – Wayne: Select PPE<br />

(L-R) Silvio Ceriani CEO BBF Safety Group.<br />

On the evening, themed “The Future is Bright”, the BBF Safety Group<br />

leadership team set the agenda for a 2018 characterised by growth,<br />

diversification and a bullish outlook on the workplace safety market.<br />

BBF Safety Group also recognised and rewarded its top achieving<br />

customers through an awards ceremony. Awards were presented in<br />

four categories, honouring the distributors that performed at the top<br />

of their game in <strong>2017</strong>.<br />

Major Award<br />

This award was presented to the distributor that achieved the highest<br />

combined turnover on BBF Safety Group brands within a calendar<br />

year, across all regions.<br />

<strong>2017</strong> winner: Select PPE<br />

Lieutenant Award<br />

The Lieutenant Award was presented to the distributor who achieved<br />

the highest combined turnover on BBF brands in a calendar year, within<br />

a respective region. The regions are: Inland North, Inland East, Inland<br />

Central, Inland West, KwaZulu Natal, Western Cape and Eastern Cape.<br />

• <strong>2017</strong> winner – KwaZulu Natal: FTS Safety Group<br />

• <strong>2017</strong> winner – Eastern Cape: Vanguard Fire and Safety<br />

• <strong>2017</strong> winner – Western Cape: Pienaar Bros. South<br />

• <strong>2017</strong> winner – Inland North: Pienaar Bros. North<br />

• <strong>2017</strong> winner – Inland East: Cattel’s Industrial Footwear<br />

• <strong>2017</strong> winner – Inland Central: Halsted and Co.<br />

• <strong>2017</strong> winner – Inland West: Moostart<br />

Select PPE Accepting the Major award.<br />

Export Distributor of the Year<br />

<strong>2017</strong> winner: Deekay<br />

CSD Consultant of the Year<br />

This award was presented to a member of the BBF Safety Group<br />

Customer Service Department (CSD) who has gone above and<br />

beyond the call of duty to provide outstanding customer service, as<br />

rated by both customers and staff.<br />

<strong>2017</strong> winner: Natasja Strydom<br />

Entertainment<br />

from the Muses.<br />

5

HYTEC ENGINEERS ‘FLUID POWER FITTER’ QUALIFICATION<br />

The Hytec Group has become South Africa’s first company to receive<br />

full accreditation as a training provider to qualify ‘Fluid Power Fitters’.<br />

The Hytec Group, a hydraulics, pneumatics and automation specialist<br />

company, received full accreditation with program approval from<br />

the industry sector education and training authority – merSETA<br />

– to provide theoretical and practical training for the National<br />

Certificate Mechanical Engineering: Fitting (Fluid Power); and the<br />

National Certificate Mechanical Engineering: Fitting (Manufacturing,<br />

Engineering and Related Industries), both at NQF level II.<br />

Registered with SAQA – the South <strong>African</strong> Qualifications Authority –<br />

the two qualifications comprise 49 individual unit standards (short<br />

courses) each with theoretical and practical components clustered<br />

into a learnership, which has a one year duration per NQF level. As the<br />

in South Africa trained by a South <strong>African</strong> training provider. This is an<br />

achievement that the South <strong>African</strong> fluid power industry has been<br />

striving to achieve since 2 009 when the qualification was originally<br />

registered with SAQA,” van Gent asserts.<br />

According to the SAQA qualification documentation, this qualification<br />

is comparable with many other countries, such as New Zealand,<br />

Australia, the United Kingdom, Zambia, Zimbabwe, Kenya, Tanzania<br />

and the United States, to name a few.<br />

The National Certificate Mechanical Engineering Level 2 is the first in<br />

a learning path of three consecutive qualifications which culminate in<br />

a Further Education and Training Certificate: Mechanical engineering,<br />

NQF Level 4, within the context of a traditional designated trade<br />

specialisation.<br />

The importance of the certification cannot be underestimated,<br />

according to van Gent who admits to there being numerous<br />

mechanical fitters with hydraulics industry experience. “It is the formal<br />

recognition of the specific training that’s important,” he points out.<br />

Essentially, the scope of training that we are accredited to provide<br />

encompasses every aspect that a ‘fluid power fitter’ needs to know<br />

in order to conduct his day-to-day activities within the fluid power<br />

industry. It is believed that qualified ‘fluid power fitters’ will save their<br />

respective companies, or clients, hours in downtime and reduce their<br />

spare parts expenditure.”<br />

Currently Hytec’s training facilities provide for theoretical and<br />

practical learning of 36 learners. However, once housed in the new<br />

Hytec facility, due to open in 2018, three dedicated training rooms will<br />

be able to accommodate a combined capacity of 120 people. “One of<br />

the great training advantages of our new premises is the proximity<br />

of the theoretical training venues and the practical on-site location<br />

being in the same building,” van Gent says. “This means that learners<br />

are exposed to all facets of the qualification within the fluid power<br />

industry under one roof.”<br />

Fait accompli. Allen van Gent, Hytec Group Training Manager (left) with<br />

John Wingrove, Hytec CEO pictured with the certificate recognising Hytec<br />

as fully accredited training provider for ‘Fluid Power Fitters’.<br />

Another part of the learning experience will be a state-of-the-art<br />

WS290 hydraulic and pneumatic training workstation donated by<br />

Bosch Rexroth Germany. The hydraulic power unit, with a loud sensing<br />

double pump, can accommodate four to six trainees simultaneously. It<br />

is perfectly suited for training sessions with respect to on/off, electro,<br />

unit standards are dedicated<br />

to specific learning areas,<br />

learners may opt to qualify by<br />

following the full learnership<br />

route or undergo training for<br />

selected unit standards only.<br />

“This provides the flexibility<br />

for learners to complete<br />

the qualification in a unit<br />

standards format over a longer<br />

period if they are unable<br />

to complete a continuous<br />

learning programme,” says<br />

Allen van Gent, Hytec Group<br />

Training Manager and the<br />

driver behind the successful<br />

reinstatement of the fluid<br />

power qualification, the<br />

company’s accreditation and<br />

the programme approval.<br />

6<br />

There are currently four learners<br />

undergoing training at Hytec<br />

for the National Certificate:<br />

Mechanical Engineering:<br />

Fitting (Fluid Power) who,<br />

once qualified, will be the first<br />

Certified ‘Fluid Power Fitters’<br />

Making history. The four learners currently undergoing training will be the first in South Africa to be certified fluid<br />

power fitters trained by a South <strong>African</strong> training provider. They are (from l): Juan Hartzenberg, Daiyaan Naidoo,<br />

Group Training Manager Allen van Gent, Innocent Mthanti and Sydney Scrooby.

proportional and closed-loop control hydraulics topics and on/off,<br />

electro pneumatics and PLCs which incorporate modular mechatronics<br />

systems. “This provides the type of training that is required to deem<br />

competency with respect to the qualification,” van Gent says. “We’ll use<br />

this state-of-the-art training workstation in our theoretical training and<br />

practical simulation to ensure that all learners gain hands-on experience<br />

in a controlled, practical learning environment.”<br />

The full accreditation and programme approval process was a long<br />

and arduous one, beginning in 2016 as far as Hytec’s involvement is<br />

concerned, which was to maintain the existence of the qualification.<br />

However, the process has a history dating as far back as 2006. It was<br />

in this year that the South <strong>African</strong> Fluid Power Association (SAFPA)<br />

began designing and developing a curriculum for a National Certificate<br />

Mechanical Engineering: Fluid Power, a process which took them three<br />

years to finalise. There was no associated specification as a ‘Fluid Power<br />

Fitter’ or Technician in the legacy qualification prior to 2006.<br />

“During the qualification design phase, SAFPA registered the curriculum<br />

and associated learning material with SAQA,” van Gent explains.<br />

“Unfortunately, post 2009 no learners were registered against the<br />

qualification and, because of this, SAQA deregistered it in 2015.”<br />

merSETA then replaced the qualification with the Quality Council for<br />

Trades & Occupations (QTCO) Tool Maker Occupational Qualification.<br />

Subsequently, SAFPA attempted to reinstate the original qualification as<br />

it planned to introduce a pilot programme for the fluid power industry.<br />

The pilot programme did not gain approval as the entire qualification<br />

had already been deregistered.<br />

m3⁄h<br />

l/h<br />

fact<br />

m/s<br />

“SAQA required proof that industry faced a shortage of ‘fluid power<br />

fitters’ and that there would be definitive interest and uptake<br />

in the qualification,” van Gent states. During the course of 2016,<br />

SAFPA enrolled six learners onto the NQF level II pilot programme<br />

administered by TVET College JFa² Technical Training Institute, an East<br />

Rand-based TVET college. The college focused on the theoretically<br />

driven Core and Fundamental Unit Standards.<br />

JFa² Technical Training Institute was endorsed by SAFPA in 2016 to<br />

provide the theoretical components of the qualification. “However,”<br />

van Gent asserts, “a company accredited to provide practical training<br />

was needed and at this stage as there was no hydraulics company<br />

accredited to do so.” It was at about this time that Hytec, concerned over<br />

the existing training gap for ‘Fluid Power Fitters’, for which there is a<br />

legitimate industry need, got involved.<br />

Thus began the long and convoluted interactions between the relevant<br />

stakeholders, all doing their best to get the NQF qualification reinstated<br />

as it was prior to it being linked to the QTCO qualification. “Our goal was<br />

two-fold,” points out van Gent. “We needed the qualification reinstated<br />

and we aimed to get Hytec fully accredited as a training provider with<br />

programme approval for the full qualification”. Hytec and JFa² worked<br />

closely with the merSETA to get the qualification reinstated. Once SAQA<br />

approval had finally been obtained, Hytec employed and registered the<br />

learners who had completed theoretical training and wanted to continue<br />

with the qualification. Of the original six learners, only four remain.<br />

Liquid flow measurement<br />

up to 600 °C or 490 bar<br />

OPTISONIC 4400 –<br />

technology driven by KROHNE<br />

• Ultrasonic flowmeter for<br />

high temperature and high pressure<br />

liquids, e. g. in vacuum distillation,<br />

visbreaking or coker unit<br />

• HT version: 45…+600 °C,<br />

DN25…1000<br />

• HP version: ≤490 bar, DN25…200<br />

• Flow range 0,5…20 m/s,<br />

bi-directional<br />

• Communication options<br />

with NAMUR NE 107 diagnostics<br />

After many negotiations and a lot of work carried out by Hytec Group’s<br />

Training Department, Hytec received full accreditation as a training<br />

provider with programme approval.<br />

“We were subsequently informed that, as of 2019, all Legacy SAQA<br />

qualifications will be realigned or replaced by a QCTO occupational<br />

qualification,” van Gent says. “Subsequent to receiving this notification,<br />

relevant stakeholders in the fluid power industry are in the process of<br />

applying to register a QCTO Qualification: Fluid Power Fitter, and both<br />

SAFPA and industry will be kept up-to-date regarding the progress as it<br />

unfolds.”<br />

At the time of writing, Hytec was awaiting feedback from its submission<br />

for registration with the Department of Higher Education.<br />

Companies seeking further information can contact Hytec Group’s<br />

training department on tel: +27 (0) 11 979 4630.<br />

KROHNE South Africa<br />

8 Bushbuck Close, Corporate Park South<br />

Randjiespark, Midrand, Tel.: +27 113141391<br />

Fax: +27 113141681, Clayton Duckworth,<br />

c.duckworth@krohne.com, www.za.krohne.com<br />

7

ROCKWELL AUTOMATION TO SHOWCASE ITS DIGITAL<br />

OILFIELD AND CONNECTEDPRODUCTION TM SOLUTIONS<br />

for Increased Profitability in the Oil & Gas Sector at ADIPEC <strong>2017</strong><br />

Rockwell Automation to demonstrate how knowledge-driven solutions are the key to<br />

improving oil and gas businesses’ operational efficiency and bottom-line productivity.<br />

Rockwell Automation, the world’s largest<br />

company dedicated to industrial automation<br />

and information, will showcase its Digital<br />

Oilfield and ConnectedProductionTM<br />

solutions at the booth 1230 in Hall 1 of<br />

the Abu Dhabi International Petroleum<br />

Exhibition and Conference (ADIPEC) from<br />

<strong>Nov</strong>ember 13-16, <strong>2017</strong>.<br />

At the world’s leading oil and gas exhibition<br />

and conference, Rockwell Automation will<br />

demonstrate how the automation, control<br />

and safety systems can help producers<br />

improve nearly all aspects of oil and gas<br />

production, from maximizing equipment<br />

performance and meeting production<br />

targets to lowering operating costs.<br />

“Leveraging data and turning that into<br />

real-time knowledge is the lifeblood of the<br />

digital oilfield,” said Pankaj Shrivastava, field<br />

business leader architecture and software,<br />

Rockwell Automation. “Digital Oilfield and<br />

Connected Production solutions of Rockwell<br />

Automation bring value to our customers<br />

in the form of cost reduction, production<br />

optimization, asset utilization and wellhead<br />

optimization, and support network and cyber<br />

security and production risk mitigation.”<br />

Visitors to the Rockwell Automation booth<br />

will see how harnessing knowledge-driven<br />

solutions is the key to improving operational<br />

efficiency and bottom-line productivity<br />

in the oil and gas sector. Rockwell<br />

Automation experts will showcase how the<br />

ConnectedProduction environment brings<br />

the digital oil field to life in three key ways:<br />

• Connecting production equipment,<br />

devices and systems.<br />

• Integrating all of the data seamlessly.<br />

• Transforming that data into useful<br />

operational intelligence.<br />

ConnectedProduction enables operators<br />

to capture data from any number of third<br />

party sources through standard open source<br />

technologies, and then making it available to<br />

a number of applications – such as real time<br />

visualization and historical logging - within a<br />

single information environment.<br />

It allows operators to run short-term Artificial<br />

Lift Systems (ALS) production optimization<br />

loops, asset management systems and to<br />

connect to advance optimization modules<br />

that can help the producer to reduce<br />

operational costs, increase efficiency,<br />

raise profit margins and have a stable<br />

infrastructure to reap the rewards of further<br />

Industrial Internet of Things (IIoT) benefits as<br />

they come online.<br />

ADIPEC <strong>2017</strong> Exhibiton Details<br />

Booth Number: 1230, Hall 1<br />

When: <strong>Nov</strong>ember 13-16, <strong>2017</strong><br />

Where: Abu Dhabi National Exhibition<br />

Center (ADNEC)<br />

Khaleej Al Arabi Street, Abu Dhabi, United<br />

Arab Emirates<br />

Website: www.adipec.com<br />

Media are invited to join Rockwell<br />

Automation product managers, industry<br />

experts and leadership team at the stand<br />

for interviews upon request and by<br />

appointment.<br />

For more information about Rockwell<br />

Automation at ADIPEC <strong>2017</strong>, please visit<br />

http://www.rockwellautomation.com<br />

About Rockwell Automation<br />

Rockwell Automation Inc. (NYSE: ROK),<br />

the world’s largest company dedicated to<br />

industrial automation and information,<br />

makes its customers more productive and<br />

the world more sustainable. Headquartered<br />

in Milwaukee, Wis., Rockwell Automation<br />

employs approximately 22,000 people<br />

serving customers in more than 80 countries.<br />

20 YEARS WITH NACE AS STANDARD CONSTRUCTION<br />

OF JC BALL VALVES<br />

One of our main objectives is taking care of our customer’s requirements and listen to their<br />

needs. This close communication with them allow us to do things better and improve the<br />

quality of our products and services. One example of this is that, to facilitate the inventory<br />

management by our distributors and avoid errors in the supply of ex-stock valves, JC has<br />

been manufacturing all ASME/API ball valves in accordance with NACE MR0175 / ISO 15156<br />

as a STANDARD feature for more than 20 years now. This is an added value we offer to all our<br />

customers without any extra cost.<br />

Valve & Automation are the exclusive agents for JC Valves.<br />

8<br />

For more information please contact:<br />

Desmond Delport, Valve & Automation Tel: +27(0) 11 397 2833 Email: sales@valve.co.za

9

SASOL KHANYISA APPROVED BY<br />

SASOL SHAREHOLDERS<br />

On the 17 <strong>Nov</strong>ember <strong>2017</strong> in Johannesburg,<br />

formal approval of Sasol Khanyisa, Sasol’s new R21<br />

billion Broad-Based Black Economic Empowerment<br />

ownership structure, was granted by Sasol<br />

shareholders at a General Meeting that followed<br />

its Annual General Meeting of shareholders. Sasol<br />

Khanyisa will see 25% ownership of Sasol South<br />

Africa in the hands of Black South <strong>African</strong>s.<br />

10<br />

“We are delighted with this outcome as it marks<br />

a significant milestone in Sasol’s transformation<br />

journey. Sasol Khanyisa will be implemented<br />

from June 2018 and we believe Sasol Khanyisa<br />

will realise sustainable and long-term value for<br />

Black South <strong>African</strong> shareholders,” said Bongani<br />

Nqwababa, Joint President and Chief Executive<br />

Officer of Sasol Limited.<br />

“We recognise that our valuable stakeholders<br />

have walked a significant journey with us,<br />

which will continue as we redefine our<br />

empowerment landscape and accelerate<br />

transformation across Sasol. Once Sasol<br />

Khanyisa is effective, our existing Sasol Inzalo<br />

shareholders will realise value creation on<br />

day two of Sasol Khanyisa next year,” said<br />

Stephen Cornell, Joint President and Chief<br />

Executive Officer of Sasol Limited.<br />

Sasol Khanyisa is intended to achieve<br />

effective direct and indirect B-BBEE<br />

ownership of at least 25% in Sasol South<br />

Africa, a wholly-owned subsidiary of Sasol.<br />

Sasol South Africa houses Sasol’s most cash<br />

generative assets, which include its synthetic<br />

fuels, chemicals and gas businesses.<br />

Through two invitations eligible existing<br />

Sasol inzalo Groups and Public shareholders<br />

will receive bonus Sasol BEE ordinary shares<br />

(SOLBE1), that trade on the BEE segment of<br />

the JSE, at no additional cost to them. These<br />

bonus SOLBE1 and additional SOLBE1 shares<br />

issued to shareholders are tradeable on 2<br />

June 2018, realising upfront and immediate<br />

value creation for shareholders.<br />

Sasol Inzalo, which was created in 2008, comes<br />

to an end in 2018. Eligible participants in<br />

Sasol Khanyisa will comprise Sasol’s qualifying<br />

employees, existing Sasol Inzalo Public and<br />

Groups shareholders, and existing Black Sasol<br />

shareholders that own shares listed on the<br />

empowerment segment of the JSE.<br />

Black members of the public participated<br />

in Sasol Inzalo through 54 different groups.<br />

In addition, more than 200 000 members of<br />

the South <strong>African</strong> Black public participated<br />

in the Inzalo Public Funded element and<br />

Sasol Limited has more than 50 000 SOLBE1<br />

shareholders. Approximately 23 000 Sasol<br />

employees participated in the Sasol Inzalo<br />

employee trusts.<br />

In February 2018, eligible participants will<br />

be invited to keep Sasol BEE Ordinary<br />

(SOLBE1) shares on the empowerment<br />

segment of the JSE, instead of converting<br />

to Sasol ordinary shares, and receive the<br />

following should they elect to keep the<br />

SOLBE1 designation:<br />

• Receive one bonus SOLBE1 share for every<br />

four SOLBE1 shares owned; and<br />

• Be invited to participate in Sasol Khanyisa.<br />

Thereafter, in April 2018, eligible Sasol<br />

BEE Ordinary shareholders (SOLBE1) and<br />

Sasol Inzalo Groups and Public funded<br />

shareholders will be invited to participate in<br />

Sasol Khanyisa and receive the following:<br />

• One Sasol Khanyisa Public share for every<br />

Sasol Inzalo share held; and<br />

• One Sasol BEE Ordinary share for every 10<br />

Sasol Khanyisa Public shares held.<br />

These bonus SOLBE1 and additional SOLBE1<br />

shares issued to shareholders are tradeable<br />

from the date of issue.<br />

At the end of the 10 year period and once<br />

the vendor funding has been settled, Sasol<br />

Khanyisa Public shares will be exchanged<br />

for SOLBE1 shares listed the empowerment<br />

segment of the JSE. This will lead to longlasting,<br />

unencumbered ownership of Sasol<br />

Limited by Black South <strong>African</strong>s.<br />

Participants in the Sasol Khanyisa employee<br />

share ownership plan will receive a debt-free<br />

share grant of Sasol ordinary shares and<br />

Sasol shares listed on the empowerment<br />

segment of the JSE worth R100 000. These<br />

shares, subject to taxation, will become theirs<br />

to keep or sell at the end of a three-year<br />

period, in 2021. Participating employees will<br />

also receive a pro rata portion of dividends<br />

received by the Sasol Khanyisa trust during<br />

the three-year period.<br />

The Sasol Inzalo Foundation will be renamed<br />

and will continue as a public benefit<br />

organisation, driving excellence in science,<br />

technology, engineering and mathematics<br />

(STEM) education at all levels of the education<br />

value chain. The Sasol Inzalo Foundation<br />

benefitted over 20 million learners in South<br />

<strong>African</strong> public schools by way of 118 natural<br />

science, technology and mathematics school<br />

work books that were developed. In addition,<br />

more than 800 bursaries and fellowships have<br />

been awarded to students at 16 South <strong>African</strong><br />

universities, to name but a few examples.<br />

Comprehensive additional information is<br />

available on our website:<br />

www.sasol.com

SKY004.qxp_Layout 1 <strong>2017</strong>/10/24 3:17 PM Page 1<br />

SPECIALISED INDUSTRIAL ELECTRONICS<br />

GHM Messtechnik South Africa supplies<br />

industrial electronics that meet the<br />

ever increasing requirements<br />

by industry for all systems and<br />

components involved in the<br />

production process. Their<br />

precision instrumentation<br />

reduces downtime whilst<br />

maximising process efficiencies.<br />

“The cost savings and<br />

associated competitive ability<br />

of our industrial electronics<br />

plays an important role when<br />

our customers are considering<br />

the modernisation of existing<br />

machinery or processes.<br />

We believe that GHM<br />

Messtechniek’s specialised<br />

instrumentation easily<br />

addresses these concerns<br />

as a result of our continued<br />

investment into state-of-theart<br />

research and development<br />

methodology and production<br />

processes” said Jan Grobler,<br />

Managing Director for GHM<br />

Messtechnik based in Alberton,<br />

The upcoming Industry 4.0<br />

industry programme requires a<br />

deeper focus on better integration<br />

of customer requirements. Throughout the<br />

value chain process values in production<br />

processes will have to be combined without<br />

any loss of information that is relevant<br />

to users on site. Grobler added “Through<br />

in-depth knowledge of our customer’s ever<br />

evolving requirements, GHM Messtechnik<br />

constantly enhances its ranges of<br />

specialised industrial instrumentation in<br />

order to supply highly efficient devices and<br />

systems for the next industrial revolution”.<br />

Specialised Industrial Electronic Range<br />

The range of industrial electronics extends<br />

from process value detection to signal<br />

processing, display, control and regulation,<br />

to actuators for intervening<br />

in the process. The GHM Messtechnik<br />

range includes temperature measurement<br />

transducers, universal transmitters,<br />

universal isolating amplifiers, switch<br />

amplifiers, limit value switches and<br />

thermal limiters. All highly specialised,<br />

quality instruments with high accuracy<br />

performance.<br />

High operating efficiency is achieved<br />

through-out all areas of the product life cycle<br />

via:<br />

• space-saving assembly<br />

• quick and uncomplicated integration<br />

• short wiring times<br />

• simple commissioning without software<br />

• use of intuitively operated configuration<br />

software<br />

• clear process information for operators in<br />

order to minimise downtimes<br />

• fulfilment of necessary regulations such<br />

as EN 14597 or SIL<br />

• long service life<br />

“The quality of our instrumentation<br />

and their successful application across<br />

industries such as food and beverage, plant<br />

and machinery construction, industrial and<br />

laboratory furnace construction, oil and<br />

gas, ship construction, plastics, chemical<br />

and pharmaceutical is well documented. It<br />

is German precision, reliability and accuracy<br />

at its best” said Grobler.<br />

GHM Messtechnik SA is part of GHM<br />

Messtechnik GmbH, an amalgamation of<br />

globally renowned companies comprising:<br />

Greisinger Electronic, Honsberg<br />

Instruments, Martens Elektronik, Imtron,<br />

T & A (Telemetry & Automation), Delta<br />

Ohm (Italy) and Valco.<br />

Further information is available from:<br />

Jan Grobler<br />

Managing Director<br />

GHM Messtechnik South Africa<br />

Tel: 011 902 0158<br />

Email: info@ghm-sa.co.za<br />

11

EMERSON EXTENDS INDUSTRIAL IOT APPLICATION PORTFOLIO<br />

for improved Operations and Maintenance<br />

Plantweb Insight for heat exchanger<br />

monitoring enables quick ROI through<br />

a secure, affordable app alerts viewable<br />

anytime, anywhere<br />

Emerson today announced an extension<br />

of its Plantweb digital ecosystem with the<br />

new Plantweb Insight Heat Exchanger<br />

app, an affordable, easy-to-use analytics<br />

and asset alert predictive intelligence tool,<br />

which provides maintenance staffs real-time<br />

access to critical heat exchanger diagnostics<br />

anytime, anywhere to improve operations in<br />

chemical, oil and gas and refining operations.<br />

Providing quick return on investment<br />

through reduced slowdowns and shutdowns,<br />

Emerson’s Plantweb Insight apps leverage<br />

Emerson’s Pervasive Sensing Strategies<br />

to help users instantly make sense of plant<br />

data and drive overall enterprise profitability.<br />

Emerson’s Plantweb Insight Heat Exchanger<br />

app joins the previously announced apps for<br />

pumps, steam traps and pressure gauges.<br />

“The web interface with Plantweb Insight<br />

is very intuitive. It is easy to get useful<br />

information about our steam traps without<br />

requiring a lot of user training. This makes it<br />

easy for operators and engineers to benefit<br />

from the system.” said Michael Sowell, regional<br />

manager of energy distribution, Evonik.<br />

The Plantweb Insight apps employ pre-built<br />

algorithms based on decades of process<br />

experience and industry-vetted analytics<br />

to deliver predictive diagnostics, enabling<br />

maintenance prioritization. The easy to use<br />

interface allows maintenance and operations<br />

to take instant action within a browser from<br />

any laptop, tablet, smartphone or other<br />

device connected to the network.<br />

Plantweb Insight monitors shell and tube<br />

heat exchangers to provide real-time status<br />

and alerts including fouling, heat duty<br />

and heat transfer coefficient. It does not<br />

require integration with the plant’s existing<br />

monitoring and control system. It can operate<br />

completely independent of existing or legacy<br />

control systems. The app can also leverage<br />

existing data points if desired, using OPC UA<br />

to collect data stored in the control system,<br />

historian or data base if access is available.<br />

Plantweb Insight apps paired with wireless<br />

instrumentation lower the cost to entry<br />

for customers looking to implement an<br />

Industrial IoT strategy. Emerson’s Plantweb<br />

digital ecosystem is a next-generation<br />

Industrial IoT portfolio that extends the<br />

power of automation beyond process control<br />

to the entire enterprise.<br />

For more information on Plantweb Insight for<br />

Heat Exchangers, please visit: www.Emerson.<br />

com/HeatExchangerInsight<br />

About Emerson<br />

Emerson (NYSE: EMR), headquartered<br />

in St. Louis, Missouri (USA), is a global<br />

technology and engineering company<br />

providing innovative solutions for customers<br />

in industrial, commercial, and residential<br />

markets. Our Emerson Automation Solutions<br />

business helps process, hybrid, and discrete<br />

manufacturers maximize production, protect<br />

personnel and the environment while<br />

optimizing their energy and operating costs.<br />

Our Emerson Commercial and Residential<br />

Solutions business helps ensure human<br />

comfort and health, protect food quality<br />

and safety, advance energy efficiency, and<br />

create sustainable infrastructure. For more<br />

information visit Emerson.com.<br />

Further information is available from:<br />

Rob Smith, Sales Manager<br />

South & East Africa Emerson Automation<br />

Solutions<br />

Tel: 011 451 3700<br />

Email: Rob.Smith@emerson.com<br />

Web: www.Emerson.com<br />

FDA AND EU FOOD APPROVED JC VALVES<br />

JC Valves is constantly investing in innovation and products as an engine for growth and leadership in the<br />

valve industry. Our latest development is the manufacture and supply of valves for special applications,<br />

mainly in the food and pharmaceutical industry. For that, we have invested in a new FDA & EC-1935/2004<br />

Compliant Clean Room in our facilities, a space with a controlled atmosphere for the specific treatment of<br />

these valves. This room has a demanding action protocol, provided with a special equipment for cleaning,<br />

testing and monitoring of the valves that ensure an environment free from impurities and a special<br />

production area for valves with very strict requirements for the above-mentioned sectors. Our valves<br />

meet Food approvals: EU 10/2011 and F.D.A. 21 CFR Ch.I (<strong>Edition</strong> 4-1-12) §177.2600, section E and F. JC<br />

Valves takes a further step to meet the most demanding needs of our market.<br />

Valve & Automation are the exclusive agents for JC Valves.<br />

12<br />

For more information please contact:<br />

Desmond Delport, Valve & Automation Tel: +27(0) 11 397 2833 Email: sales@valve.co.za

AUTOMATION - CREATING THE WORKER<br />

OF TOMORROW<br />

Job Simulator is a virtual reality game<br />

set in the future, where machines<br />

have replaced all human jobs. In this<br />

game, players can relive the “glory<br />

days” when people did regular work,<br />

such as being a chef, or working a 9-5,<br />

caffeine-fueled desk job. If research is<br />

to be believed, we are in the midst of a<br />

massive workforce transformation, and<br />

the world envisioned in Job Simulator<br />

isn’t too far off.<br />

and a new vista is presented. One<br />

where more and more business is<br />

conducted digitally, at any time of the<br />

day, with very little human interaction<br />

or intervention thanks to automated<br />

and integrated sourcing, manufacturing,<br />

distribution and sales processes. Where<br />

employees may work from anywhere, at<br />

any time. Where communication is via<br />

group chat and managers have never<br />

met their staff members face-to-face.<br />

One of the largest takeaways from<br />

the predictions such as the claim that<br />

47% of American jobs today will be<br />

automated by 2037, and PwC’s findings<br />

that 37% of today’s workforce are<br />

concerned about automation putting<br />

their jobs at risk, is that there exists a<br />

very strong likelihood that today’s jobs<br />

won’t exist some twenty years from now.<br />

So, what jobs will be in existence and,<br />

more importantly, what skills will be<br />

required in order to do them and how<br />

can organisations and individuals begin<br />

planning for the skills required to power<br />

their businesses in the not-too-distant<br />

future?<br />

Tomorrow’s workplace is already<br />

emerging<br />

Automation, particularly in<br />

manufacturing and production, is not<br />

a new concept, and technological<br />

advancements are fast absorbed<br />

into work environments to increase<br />

productivity and improve efficiency.<br />

However, technology can also open the<br />

door to new business opportunities.<br />

Rapid developments in Artificial<br />

Intelligence (AI), cloud computing and<br />

data analytics have made it possible to<br />

take automation beyond operational<br />

improvement. We live in a world of<br />

instant gratification and the faster things<br />

happen, the faster we expect them to.<br />

As customer and business expectations<br />

evolve, technology rises to meet this<br />

evolution.<br />

Omni-channel engagement and<br />

automation strategies are enabling<br />

consistent, real-time interactions<br />

and transactions, and have become<br />

business imperatives rather than<br />

competitive advantages. The concepts<br />

of business hours and location have<br />

all but evaporated. Technology is<br />

briskly nudging us through the door<br />

of workplace transformation, new job<br />

requirements and the host of new skills<br />

required to meet them.<br />

Add urbanisation, increasing congestion,<br />

and rapidly improving connectivity<br />

A world of new jobs and skills<br />

Any job where productivity, efficiency<br />

or quality is constrained by the ability<br />

of a human to perform that task is a<br />

natural target for automation. What<br />

has changed though is that not only<br />

can machines work harder, faster and<br />

longer than people, now they can<br />

also work “smarter”, making decisions<br />

based on complex “thought processes”<br />

which opens up the opportunity to<br />

automate tasks currently performed<br />

by “knowledge workers”. However,<br />

automation doesn’t spell out the<br />

eradication of jobs but, rather, the<br />

creation of new career opportunities.<br />

Automated processes need to be<br />

designed, developed, monitored and<br />

improved. This means a likely increase<br />

in demand for automation experts,<br />

business process specialists, subject<br />

matter experts, enterprise architects,<br />

process modelers, testing specialists,<br />

integration specialists, network and<br />

communication specialists, software<br />

developers, business analysts, etc.<br />

The common thread here is one of<br />

specialisation, either in a business field<br />

or in technology.<br />

The requirement for human interaction<br />

will always be there and customers or<br />

partners expect to be able to contact a<br />

person if required. Very often, this will<br />

be when something goes wrong so<br />

communication skills, conflict handling<br />

and decision making remain valuable<br />

skills.<br />

Anywhere, anytime operations require an<br />

advanced support infrastructure. Business,<br />

operational and technical roles will still<br />

be required, along with the prerequisite<br />

skills in people management, logistical<br />

support, operational management, HR,<br />

Finance etc.<br />

Lastly, a great deal of technological<br />

awareness, flexibility and adaptability<br />

from staff will be required as the tempo<br />

of change increases. Knowledge, ideas,<br />

people skills and creativity is - and will<br />

be - of more value than the ability to do<br />

Andrew Hoseck – Chief Operating<br />

Officer at In2IT Technologies<br />

manual work, crunch numbers or shuffle<br />

papers.<br />

Merging today and tomorrow<br />

The current workforce spans multiple<br />

generations, is geographically dispersed<br />

and has varying degrees of technological<br />

enablement. Businesses need to adapt<br />

accordingly.<br />

Instant gratification and immediacy<br />

extends internally as well. The business<br />

of the future will need to ensure<br />

that employee communication and<br />

engagement takes place consistently<br />

across multiple channels and should<br />

make use of automation to speed up<br />

traditional employee support processes.<br />

Tomorrow’s workforce will require a<br />

flexible approach with respect to policy,<br />

process, communication, work hours,<br />

working environment, etc. Changing<br />

customer demands will inevitably fuel a<br />

change in employee demands, especially<br />

in an anywhere, anytime organisation.<br />

Employee support processes will be the<br />

glue that holds this together.<br />

The future workplace is not one<br />

comprised entirely of robots and<br />

empty desks. Rather, it is an exciting<br />

collaboration of human creativity,<br />

thinking and innovation, enabled by<br />

technology and automation. Best we<br />

prepare ourselves, discard our human<br />

tendency to cling to the familiar, and<br />

embrace an evolving world of emerging,<br />

ever-shifting skills where specialised<br />

knowledge carries gravitas.<br />

13

m 3 /h<br />

fact<br />

Liquid flow measurement<br />

up to 600 °C or 490 bar<br />

OPTISONIC 4400 –<br />

technology driven by KROHNE<br />

l/h<br />

m/s<br />

• Ultrasonic flowmeter for high temperature and high pressure liquids,<br />

e. g. in vacuum distillation, visbreaking or coker unit<br />

• HT version: 45…+600 °C, DN25…1000<br />

• HP version: ≤490 bar, DN25…200<br />

• Flow range 0,5…20 m/s, bi-directional<br />

• Communication options with NAMUR NE 107 diagnostics<br />

products solutions services<br />

KROHNE South Africa<br />

8 Bushbuck Close, Corporate Park South, Randjiespark, Midrand<br />

Tel.: +27 113141391,Fax: +27 113141681, Clayton Duckworth,<br />

c.duckworth@krohne.com, www.za.krohne.com

INSTRUMENTATION AND MEASUREMENT<br />

SOLUTIONS FOR THE SOUTH AFRICAN<br />

WATER INDUSTRY<br />

KROHNE has been active in water markets for over 60 years. In fact,<br />

the Duisburg, German-based company was the first to introduce<br />

an electromagnetic flowmeter (magmeter) for water, wastewater,<br />

additives and sludge in 1961. Since then, KROHNE has not only<br />

developed a complete portfolio for flow measurement, including<br />

partially filled pipes, but also level, pressure, temperature as well as<br />

process analytics to equip waterworks, sewage treatment plants and<br />

all networks in between.<br />

Since magmeters remain the standard in water measurement,<br />

KROHNE has widened its OPTIFLUX portfolio over the years with<br />

many different liners for applications from clean water to sludge<br />

with high solid content. However, the development of standalone,<br />

battery-powered electromagnetic water meters has mostly taken<br />

place in the last 10 years. Although it was demanded by customers<br />

as an alternative to mechanical meters at points where no mains<br />

power is available, the development of these meters depended on<br />

a special design of the measuring tube. Introduced in 2009, the<br />

WATERFLUX battery-powered water meter (certified to MID<br />

MI001 and OIML R49) has been a very successful product<br />

in the drinking / clean water market. It features a unique<br />

rectangular measuring tube design. Because inlet or<br />

outlet sections are not required, the sensor allows<br />

for a compact installation and a small overall<br />

installation footprint. Even better, there is no<br />

need for grounding rings because, as standard,<br />

the flow sensor has a reference electrode<br />

for grounding and a special coating allows<br />

for subsoil (IP 68) installation. To leave out<br />

grounding rings is also available as an<br />

option for the OPTIFLUX series (virtual<br />

reference option).<br />

As water meters are often installed in<br />

remote locations, reducing the frequency<br />

of visits to the sites, the time spent on setup<br />

and maintenance is crucial. This relies<br />

on aspects such as a simplified installation,<br />

integrated diagnostics, a long battery lifetime,<br />

remote communication options and low overall<br />

maintenance requirements of the meters. The<br />

features and options of WATERFLUX contribute to<br />

these targets and the device is continuously updated<br />

to keep up with modern requirements.<br />

In terms of installation, the polycarbonate converter housing<br />

with protection class IP68 rating is now standard for both the<br />

compact and the remote version, that is, for temporarily flooded<br />

measuring pits. It features IP68 Mil connectors that do not require<br />

wiring on site, and a small installation footprint to fit into electrical<br />

cabinets. For locations where mains power is available, WATERFLUX<br />

is now available with an external FlexPower unit to connect the<br />

meter to a power source on site, e.g. electrical grid, solar panel or a<br />

small windmill.<br />

The integrated pressure and temperature sensor allows the use of<br />

WATERFLUX for various tasks in drinking water networks: Flow and<br />

pressure measurement data are an important input for pressure<br />

monitoring, maintaining the water balance, district zoning (DMA),<br />

and for leak detection in drinking water networks when comparison<br />

of pressure and flow values are used as methods. Eliminating the<br />

installation and wiring of external pressure sensors, the integrated<br />

pressure sensor can provide an alarm when a programmed upper<br />

or lower limit is reached. The same applies for the integrated<br />

WATERFLUX 3070 C battery-powered<br />

electromagnetic water meter.<br />

temperature sensor that can serve for quality monitoring of potable<br />

water, also without the need to open the line a second time. Alarms<br />

can be generated via the status output or via Modbus when critical<br />

limits for pressure and or temperature are exceeded.<br />

Current communication options meet water companies’ increasing<br />

demand for more measurement and status data. The Modbus RTU<br />

output offers an alternative to the two-pulse and two-status outputs.<br />

Transferred data includes measurement data (sum, forward and<br />

reverse counters, flow rate), status data (battery lifetime, meter status),<br />

actual values for pressure and temperature, and alarms. In addition,<br />

remote data communication solutions are also available off-the-shelf.<br />

Contact:<br />

Email: C.Duckworth@KROHNE.com<br />

Web: www.za.krohne.com<br />

Tel: 011 314 1391<br />

14

THYSSENKRUPP SERVICE CENTRE EXHIBITED<br />

ITS PRODUCT PORTFOLIO AND CAPABILITIES<br />

to customers at the Copperbelt Mining and Trade Expo and Conference<br />

(CBM-TEC) held from 6 to 8 June <strong>2017</strong> in Kitwe, Zambia<br />

Hosted exclusively within the Copperbelt, CBM-TEC is Zambia’s<br />

professional attendance technical supplies and equipment trade expo<br />

for the Copperbelt region. Zambia’s mining sector contributes over<br />

70% to the country’s foreign exchange earnings. The Expo provides<br />

an exclusive and unique opportunity for equipment and service<br />

companies to engage directly with the regional mining operations in<br />

one convenient place over a three-day period.<br />

“We invited all our customers from across the <strong>African</strong> continent to visit<br />

our stand at the Expo which we shared with EC Mining,” comments, John<br />

Stapelberg, the Sales Manager of the thyssenkrupp Service Division.<br />

John confirms that this was a very successful event for thyssenkrupp.<br />

“The Expo presented us with the perfect opportunity to meet and<br />

share our capabilities with customers we do not always get to see. The<br />

excellent contact established during the expo necessitates our return<br />

to the region to engage with the various companies.”<br />

John recommends that thyssenkrupp attends the next CBM-TEC in<br />

2019, and adds that “even more emphasis must be placed on our<br />

equipment and capabilities.”<br />

Some other prominent companies that exhibited at CBM-TEC<br />

included METSO, Hitachi, Murray & Roberts Cementation Zambia,<br />

KOMATSU Zambia as well as several smaller companies with Ndola<br />

Lime Company, Mopani Copper Mine and Zeco Electricity Company of<br />

special interest to thyssenkrupp.<br />

The show attracted a high quality audience with over 4 300 visitors<br />

attending over the three days and was an ideal opportunity for<br />

networking, exchanging of ideas, building relationships and<br />

developing business partnerships for exhibitors and visitors alike.<br />

thyssenkrupp team at Copperbelt Expo. Back left to right: Demitri<br />

Kokoroyanis, Igor Zuvela, Gerhard van Wyk & Koos Smit. Front left to<br />

right: Natasha Minny (thyssenkrupp) with Andrew Kansamba from EC<br />

Mining, a distributor in Zambia.<br />

About thyssenkrupp Industrial Solutions:<br />

The Industrial Solutions business area at thyssenkrupp is a leading<br />

partner for the engineering, construction and service of industrial<br />

plants and systems. Based on more than 200 years of experience we<br />

supply tailored, turnkey plants and components for customers in the<br />

chemical, fertilizer, cement, mining and steel industries. As a system<br />

partner to the automotive, aerospace and naval sectors we develop<br />

highly specialized solutions to meet the individual requirements of<br />

our customers. More than 21,000 employees at over 70 locations<br />

form a global network with a technology portfolio that guarantees<br />

maximum productivity and cost-efficiency.<br />

For more information visit:<br />

www.thyssenkrupp-industrial-solutions.co.za<br />

Company blog:<br />

https://engineered.thyssenkrupp.com<br />

15

RENEWABLE ENERGY, CRITICAL<br />

TO MEETING AFRICA’S ENERGY<br />

NEEDS BY 2040<br />

Africa, filled with many developing<br />

nations, provides the ideal opportunity<br />

for the application of renewable energy<br />

solutions and technologies.<br />

About 635 million <strong>African</strong>s still live without electricity and demand for<br />

energy is rising rapidly. Given the lack of power supply, especially in the<br />

rural regions of the continent, the growth and demand for applications<br />

of small-scale solar, wind and geothermal technologies providing power<br />

to people and business, is rapidly expanding. The use of renewable<br />

technologies is especially useful in the further and outlying areas as it is<br />

easier to install a more cost-effective solution in order to be less reliant<br />

on transporting electricity from power plants via transmission lines,<br />

which becomes very expensive. Renewable energy has the potential<br />

to substantially assist many <strong>African</strong> countries and their people to have<br />

access to energy, essential for the reduction of poverty and to ensure<br />

economic growth.<br />

The <strong>African</strong> Development Bank (AfDB) is stepping up the pace by<br />

focusing on five priorities that are crucial for accelerating Africa’s<br />

economic transformation. The Bank calls them the “High 5s”: Light up<br />

and power Africa, Feed Africa, Industrialise Africa, Integrate Africa, and<br />

Improve the quality of life for the people of Africa. The AfDB President,<br />

Akinwumi Adesina, describes energy as “the lifeblood of any society<br />

and the passport to economic transformation”. As such, energy is at the<br />

top of the bank’s “High 5” priorities and its new Energy Strategy aims to<br />

increase energy production and access, improve affordability, reliability<br />

and energy efficiency.<br />

According to the International Energy Agency (IEA), the global energy<br />

demand will be 30 per cent higher with renewable energy facilitating<br />

almost half of sub-Saharan Africa’s power generation growth by 2040.<br />

Africa’s demand for electricity is expected to increase by more than<br />

two-thirds between 2016 and 2040. Herein lies the business opportunity<br />

for the private sector participation. Added to this, renewable energy<br />

reduces carbon emissions, has the potential to supply cheaper electricity,<br />

and is becoming more affordable while coal and nuclear are likely to be<br />

more expensive. The IEA states that solar PV is expected to lead capacity<br />

additions as it has become the cheapest source of electricity generation.<br />

Research by McKinsey indicated that Africa’s potential energy generation<br />

capacity is up to 1.2 terawatts excluding solar, and more than 10<br />

terawatts including solar. Africa has solar in abundance and can provide<br />

almost 10 terawatts of new energy. By 2040, it has been estimated that<br />

more than 25% or Africa’s total energy will originate from geothermal,<br />

hydro, solar and wind, indicating a more than four-fold increase from<br />

only 5% in 2013.<br />

The opportunity for private sector involvement and access to renewable<br />

energy projects in Africa will be a focused feature of the 10th <strong>African</strong><br />

Energy Indaba (AEI) which is set take place on 20-21st February 2018<br />

at the Sandton Convention Centre in Johannesburg, South Africa and is<br />

set to unpack these critical issues pertinent to <strong>African</strong> renewable energy<br />

implementation.<br />

ABOUT AFRICA ENERGY INDABA<br />

An <strong>African</strong> Energy event for <strong>African</strong>s and by <strong>African</strong>s<br />

Africa is the continent of opportunity for the serious energy investor.<br />

With vast natural energy resources ranging from coal, oil, gas, hydro,<br />

solar, wind and geothermal, there is ample choice for the discerning<br />

energy entrepreneur. Lack of access to electricity means that there is an<br />

opportunity for regional governments, energy businesses, organisations<br />

and investors to unlock electricity access to millions of people who have<br />

don’t have power.<br />

The Africa Energy Indaba is the continent’s premier energy conference and<br />

exhibition: bringing together leading <strong>African</strong> and global energy players<br />

to unlock energy and business opportunities across the <strong>African</strong> continent.<br />

The Africa Energy Indaba has strategic partnerships with the World Energy<br />

Council (WEC), the South <strong>African</strong> National Energy Association (SANEA) and<br />

the NEPAD Planning & Coordinating Agency (NPCA).<br />

16<br />

For more information:<br />

www.africaenergyindaba.com

SECUNDA PETROCHEMICAL ROADSHOW<br />

proudly hosted by<br />

15 March 2018<br />

Sasol Recreation Club<br />

Nelson Mandela Drive, Secunda<br />

10am - 4pm<br />

FREE<br />

ENTRY<br />

Pre-register online to<br />

stand a chance to win<br />

Book your stand today!<br />

Email sales@africanpetrochemicals.co.za<br />

or call 011 083 5125<br />

Mystery prize<br />

give away<br />

Dates are subject to change<br />

17

DURBAN PETROCHEMICAL ROADSHOW<br />

The recent<br />

Durban Petrochemical<br />

Roadshow<br />

was held on the<br />

2 nd <strong>Nov</strong>ember <strong>2017</strong><br />

at the Amanzimtoti Civic Centre<br />

18

Thank you<br />

to all our<br />

exhibitors<br />

and visitors<br />

for all your<br />

support<br />

Bookings are<br />

now open for 2018<br />

www.africanpetrochemicals.co.za<br />

NOVEMBER <strong>2017</strong>, AMANZIMTOTI CIVIC CENTRE<br />

19

PREFERRED WORK-AT-HEIGHT, CONFINED-SPACE<br />

SERVICE PROVIDER IN AFRICA<br />

Skyriders Access Specialists (Pty) Ltd. aims to become the preferred work-at-height<br />

and confined-space service provider on the <strong>African</strong> continent. It offers various<br />

solutions to all heavy industrial sectors, including mining.<br />

A particular achievement of the company<br />

to date is its zero-fatality rate, in line<br />

with OHSAS 18001:2007 and Institute<br />

for Work at Height best practice. “Safety<br />

is paramount in any industry. Mining,<br />

for example, is an inherently dangerous<br />

environment, as it encompasses both workat-height<br />

and confined spaces,” Skyriders<br />

Marketing Manager Mike Zinn comments.<br />

“Mines often select the more traditional<br />

means of access for inspection purposes,<br />

maintenance projects, and shutdowns.<br />

This means they pay a premium, and end<br />

up using a large portion of the project<br />

programme to erect and break down<br />

these access systems. Rope access offers a<br />

safer, quicker means of carrying out many<br />

of these tasks, resulting in significant<br />

time- and cost-savings,” Zinn elaborates.<br />

Skyriders employs teams of highly<br />

experienced and trained rope-access<br />

technicians. “The career path of a ropeaccess<br />

technician is ongoing from a skills’<br />

development point of view. One needs<br />

to bear in mind that rope access is just a<br />

means of moving from one work point<br />

to another work point. This requires<br />

renewal every three years, which poses<br />

the challenge of progressing from Level<br />

1 to Level 2 and, ultimately, to Level 3,<br />

depending on the experience in the form<br />

of hours logged,” Zinn stresses.<br />

Apart from the rope-access discipline<br />

itself, Skyriders’ technicians also<br />

require trade skills such as welding,<br />

Non-Destructive Testing (NDT) and<br />