African Petrochemicals- 16.1 2019

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Quarterly Edition <strong>16.1</strong><br />

IN THIS EDITION<br />

ACHIEVING GREATER ENERGY EFFICIENCY WITH THERMAL SOLAR<br />

GAS ANALYSIS AND THE 4th INDUSTRIAL REVOLUTION

ZWICK FOR MOLTEN SULPHUR OR SULPHUR TAIL GAS<br />

If you work with Molten Sulphur or Sulphur Tail gas, please take time to read more.<br />

Design engineers at Zwick in Germany have looked at solving on-going problems being<br />

experienced with valves on sulphur units.<br />

Typical valve problems on large bore line sizes range from seizing of the packing to severe<br />

seat damage when valve need to be operated after long periods of time of inactivity.<br />

Valves should be specified as steam jacketed valves as this is a standard mandatory type of<br />

valve requirement.<br />

Generally a standard valve may be suitable in an ideal line were<br />

there are never any shutdowns or upset conditions as once the<br />

valves body temperature has reached that of the hot sulphur or<br />

tail gas passing through it will not allow for any solidification,<br />

however in an upset condition were the valve body cools down<br />

with sulphur cooling also, then this will solidify in the bearing /<br />

shaft areas which will consequently generate a seizure of these<br />

elements.<br />

Based on international experience, Zwick engineers recommend the use<br />

of steam jacketed valves as these would maintain the critical areas under a<br />

constant temperature, thus eliminating any potential seizure.<br />

Zwick are capable of supplying valves in both wafer and double flanged style<br />

with steam jackets, and we can also apply a steam traced trim (stem and disc).<br />

Zwick Tri-Con series valves come with bearing protectors, which<br />

reduce the ingress of the medium into the critical areas, which<br />

coupled with the bearing flush purge ports constitute a true<br />

cleansing and protection of these critical areas.<br />

The following explanation highlights the technical differences<br />

between the Zwick Tri-Con valve and other manufacturers of valves ranging<br />

from double eccentric to unjacketed valves which will fail in this type of application.<br />

2<br />

The Zwick Tri-Con series valve is a specially designed process isolation, on/off and control<br />

valve, which has a wide range of application uses limited only by that of the actual<br />

materials used, in fact Zwick manufacture valves for applications which range from -196ºC<br />

up to +815ºC. Valves can be manufactured in any machinable form of alloy available on<br />

the market for specific client requirements.<br />

The Zwick Tri-Con series valve is a triple offset valve with true cone in cone design which<br />

totally eliminates any rubbing of the seats, hence eliminates any wear and tear which<br />

would generate leakages across the seat, this is technically not possible for other typical<br />

high performance valves, which means it is limited to a double eccentric design, rubbing<br />

sealing in the last 15-18º which will generate leakage as the time goes by.<br />

The other standard double eccentric are not designed for these severe applications<br />

therefore any attempt to use it for particular process applications may result in a<br />

problematic outcome.<br />

Self Centering disc<br />

With it’s unique self centering temperature compensating disc, the Tri-Con series<br />

construction guarantees the optimal position of the laminated seal against the seat.<br />

Jamming due to thermal expansion is therefore eliminated.<br />

The torque transmission with keys<br />

The disc is keyed to the shaft and not pinned, providing equal torque transmission and<br />

eliminating the danger of pins sheering off.<br />

Ideal lamination and disc design<br />

The strong disc with it’s elliptical supporting surface offers the best fixing of the<br />

lamination. The zero leakage is achieved by the special machining of thre lamination.<br />

Supporting bearing bushing<br />

The optimal position of the bearing reduces the bending of the shaft. This guarantees<br />

bi-directional tightness under maximum pressure.<br />

General characteristics<br />

• Triple eccentric design<br />

• Metal seating<br />

• Zero leakage<br />

• Pressure classes<br />

• Full bi-directional shutoff tp<br />

API & DIN, ZERO Leakage<br />

• Temperature range -196ºC up<br />

to +815ºC<br />

• Size range 2” to 72” (DN50 to<br />

DN1800)<br />

• Friction free opening and<br />

closing<br />

• Vacuum tight<br />

• Laminated seal and seat made<br />

of stainless steel<br />

• Anti blow-out shaft to API 609<br />

• Steel casting, stainless steel<br />

and special alloys<br />

• Fire-safe acc. To BD 6755 and<br />

API 607 for both flow directions<br />

• Fugitive emission control acc.<br />

To “TA-Luft II”

<strong>African</strong> <strong>Petrochemicals</strong> is published bi-monthly by Direct Publications cc<br />

Quarterly Edition <strong>16.1</strong><br />

Direct Publications<br />

Publisher<br />

Richard Scott<br />

richard@africanpetrochemicals.co.za<br />

Accounts and Admin<br />

Ashni Padiachie<br />

accounts@africanpetrochemicals.co.za<br />

Sales<br />

Sales Team<br />

sales@africanpetrochemicals.co.za<br />

Graphic Designer<br />

Linda Graae<br />

production@africanpetrochemicals.co.za<br />

The views and opinions expressed in this<br />

magazine are those of the respective authors<br />

and do not necessarily express the views and<br />

opinions of Direct Publications cc. We do not<br />

endorse any of the products , services or<br />

expertise offered by any of our advertisers or<br />

contributors. No liability will be accepted for<br />

artwork supplied incorrectly or slight colour<br />

deviations. Editorial contributions relevant<br />

to any section of the magazine are more than<br />

welcome. Email submissions to<br />

production@africanpetrochemicals.co.za<br />

Direct Publications reserves the right to cut and<br />

alter editorials received for publication.<br />

Reproduction<br />

No part of this magazine may be reproduced<br />

without written permission from the editor or<br />

publisher.<br />

Subscription Service<br />

For address changes, subscriptions or missed<br />

issues, please call 011 083 5125 or<br />

email: accounts@africanpetrochemicals.co.za<br />

CONTENTS<br />

Zwick for Molten Sulphur or Sulphur<br />

Tail Gas 2<br />

It’s all systems go with SKF System 24<br />

Lubrication Solution 4<br />

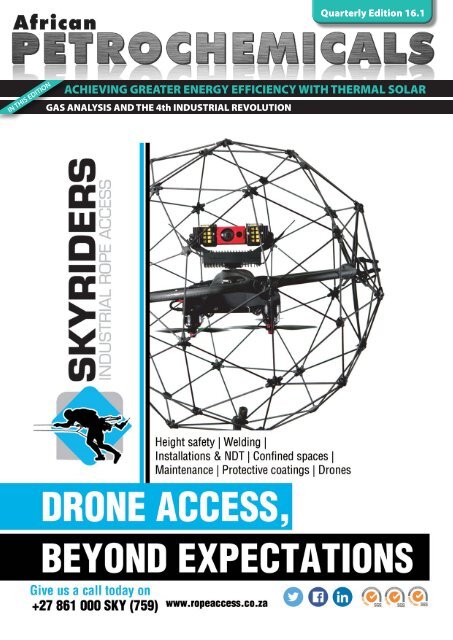

Skyriders Elios SkyEye Drone powers up<br />

emergency tube-leak inspection 5<br />

Achieving greater energy efficiency with<br />

Thermal Solar 6<br />

Afrox Advances Cylinder Tracking 7<br />

Bosch Rexroth South Africa Group hosts<br />

customers at the Rexroth HUBB 8<br />

New Sensors and Languages for Ventis<br />

Pro Series Gas Monitors 9<br />

thyssenkrupp combines Standard<br />

Engineering with Software Development<br />

to offer a Holistic Liquid Fuel Storage<br />

Solution 10<br />

Creating a force for the future of<br />

Resources and Energy 12<br />

Vert Energy’s Leroy-Somer LSK Direct<br />

Current (DC) Motors provide cost-<br />

Effective Solutions for Variable Speed<br />

Applications 14<br />

BMG Fluid Technology - Industrial Slurry<br />

Valves for Harsh Conditions 15<br />

Skyriders Consults on Fall-Protection<br />

Plan for Platinum-Smelter Project 16<br />

NATREF fuels Document Management<br />

improvements with Datacentrix 18<br />

Speedy, reliable mA Loop Valve Testing 19<br />

RTS Africa Technologies’ Procon Acoustic<br />

Boiler Steam Leak Detection System<br />

prevents boilers ‘going down the tubes’ 20<br />

Gloves In A Bottle - Finally, an all-in-one<br />

shielding and dry skin care lotion 22<br />

thyssenkrupp celebrates its Diamond<br />

Jubilee in Africa 24<br />

Ultrasonic Sensors in Agricultural<br />

Automation 25<br />

ARCA Anti-Surge Control Valves in<br />

Operation 25<br />

Secunda Roadshow 26<br />

Sasolburg <strong>Petrochemicals</strong> IPP &<br />

Renewables Roadshow 27<br />

Gas analysis and the 4 th Industrial<br />

Revolution 28<br />

Cloud makes Unified Communications a<br />

reality for SMEs 29<br />

Stafsjö’s Double-acting pneumatic SC<br />

cylinder 30<br />

WorleyParsons completes acquisition of<br />

Jacobs ECR division 31<br />

VISIT AFRICAN PETROCHEMICALS ONLINE:<br />

www.africanpetrochemicals.co.za<br />

Visit our e-paper section to view the<br />

magazine archive:<br />

epaper.africanpetrochemicals.co.za<br />

(No Log-in details required)<br />

3

IT’S ALL SYSTEMS GO WITH<br />

SKF SYSTEM 24 LUBRICATION<br />

SOLUTION<br />

When one of SKF’s longstanding customers experienced numerous breakdowns and production losses due to<br />

lubrication issues on their cyclone extractor fans, SKF, in close collaboration with its Authorised Distributor, West<br />

Cape Bearings and Transmission (Pty) Ltd, stepped in with the perfect automatic lubricator and grease solution.<br />

The cyclone extractor fans are used to extract sawdust from the work<br />

areas in a wooden door and window manufacturing plant and are<br />

safety critical units as the facility cannot operate if there is excessive<br />

air contamination.<br />

In addition to a number of products supplied by SKF to the customer,<br />

including bearings, seals, and lubricators, West Cape Bearings and<br />

Transmission carried out condition monitoring which was analysed<br />

by SKF. “It was the data collected through the condition monitoring<br />

that alerted the customer to serious lubrication issues,” explains Eddie<br />

Martens, Product Manager: MaPro at SKF.<br />

The manufacturer approached the SKF Authorised Distributor, West<br />

Cape Bearings and Transmission, for assistance. After conducting a<br />

mini lubrication audit, SKF found that many of the cyclone fan units<br />

were being over greased whilst some units were not being greased<br />

at all. This inconsistent greasing was causing, on average, two<br />

catastrophic failures on the cyclone fans every month.<br />

SKF recommended a trial run on its System 24 lubricator and LGHP 2<br />

grease fitted on one cyclone fan.<br />

According to Martens, positive results were evident within the first<br />

month of testing which impressed the customer so highly that they<br />

decided to convert all of their cyclone fans to automatic System 24<br />

lubricators. Martens adds that the original test fan has now been<br />

running for over twelve months without interruption or failure.<br />

The fact that these advanced automatic System 24 lubricators require<br />

minimal maintenance means extended service intervals on the fans,<br />

maximising uptime. The elimination of manual lubrication further<br />

boosts uptime and, importantly, enhances the safety of personnel<br />

who are now freed up to perform other tasks. Cost savings due to less<br />

grease being used contribute to lowest total cost of ownership for the<br />

customer.<br />

“SKF is committed to equipping customers with knowledge and the<br />

knowledge that has been transferred to our customer’s maintenance<br />

team has both improved uptime on the units and created greater<br />

awareness of areas that need improvement,” notes Martens. This<br />

has resulted in SKF providing training courses to the maintenance<br />

teams as well as guidance on the establishment of the improved<br />

lubrication store. According to Martens, the customer is also in the<br />

process of implementing a lubrication planner to further enhance<br />

the knowledge they have received. Furthermore, they are purchasing<br />

special tools to improve maintenance.<br />

“As a global bearings and lubrication system specialist, we strive to<br />

provide customers with cutting-edge solutions that not only solve<br />

their problems but tranform the way in which they operate,” says<br />

Martens. “This project has prompted a collaborative partnership<br />

between our customer, our Authorised Distributor, West Cape<br />

Bearings and Transmission, and SKF. We are committed to providing<br />

state-of-the-art solutions to our customers so that we remain their<br />

preferred bearings and lubrication partners along their business<br />

growth journeys.”<br />

About SKF<br />

SKF’s mission is to be the undisputed leader in the bearing business.<br />

SKF offers solutions around the rotating shaft, including bearings,<br />

seals, lubrication, condition monitoring and maintenance services.<br />

SKF is represented in more than 130 countries and has around 17,000<br />

distributor locations worldwide. Annual sales in 2018 were SEK 85 713<br />

million and the number of employees was 44,428. www.skf.com<br />

4

FRONT COVER STORY<br />

SKYRIDERS ELIOS SKYEYE DRONE POWERS<br />

UP EMERGENCY TUBE-LEAK INSPECTION<br />

The project was a showcase<br />

for the rapid deployability<br />

and flexibility of the drone.<br />

When a major coal-fired power station<br />

in Limpopo experienced a tube leak in<br />

a boiler that subsequently resulted in a<br />

burst pipe, Skyriders Access Specialists<br />

(Pty) Ltd. was called upon to deploy its<br />

Elios SkyEye drone technology for an<br />

emergency inspection.<br />

This is the first time that the confined-space<br />

inspection technology has been deployed in<br />

such an application, Marketing Manger Mike<br />

Zinn reports. “The client required an urgent<br />

visual inspection, in addition to determining<br />

the possible collateral damage associated<br />

with the area.”<br />

Zinn explains that the drone was controlled<br />

just outside of the boiler itself. “We were not<br />

necessarily flying it blind due to the presence<br />

of its cameras, but it did have to cover a<br />

considerable distance.”<br />

The drone was not only able to take highdefinition<br />

photographs of the internal area<br />

of the boiler in question, but was able to<br />

pinpoint the exact location of the suspected<br />

tube leak. “We also piloted the drone around<br />

the adjacent walls and surrounding area in<br />

order to verify whether or not there were any<br />

additional issues,” Zinn explains.<br />

While the Elios SkyEye drone has been used for<br />

inspection work on two previous occasions at<br />

the same power station, this was the first time<br />

it was called upon in an emergency situation.<br />

Skyriders dispatched a two-person team that<br />

was quickly on-site, and able to get the drone<br />

into the boiler as soon as possible.<br />

The project was a showcase for the rapid<br />

deployability and flexibility of the drone.<br />

Traditionally, scaffolding or other rather<br />

time-consuming means of access would have<br />

to be first erected prior to inspections being<br />

carried out.<br />

Skyriders dispatched a two-person team that was<br />

quickly on-site, and able to get the drone into the<br />

boiler as soon as possible.<br />

The Elios SkyEye drone has dramatically<br />

improved the health and safety of on-site<br />

crews in such projects, allowing specialised<br />

teams to enter only once the situation has<br />

been thoroughly analysed and verified. If<br />

need be, rope access is then used for teams<br />

to carry out additional inspection services<br />

such as ultrasonic wall thickness testing or<br />

other non-destructive testing methods.<br />

Imported from Flyability of Switzerland, the<br />

hi-tech Elios SkyEye drone includes a full HD<br />

camera, a thermal camera, and an onboard<br />

LED lighting system with remotely-adjustable<br />

intensity. Hence an array of onboard tools is<br />

available for any lighting conditions.<br />

The drone can be brought into usually<br />

inaccessible places up to many hundred<br />

metres beyond the line of sight due to<br />

the fact that it is equipped with a wireless<br />

communications system with a live video<br />

feedback.<br />

“The main issue with this project is that it was<br />

an incredibly difficult area to access. Here<br />

the collision-tolerance feature of the drone<br />

meant it was able to access the affected area<br />

quickly and reliably. The fully-qualified and<br />

trained pilot means that the inspection work<br />

itself is carried out rapidly and professionally,<br />

producing real-time results for the client,”<br />

Zinn concludes.<br />

About Skyriders<br />

Skyriders (Pty) Ltd, established in 1998, is<br />

a leader in the South <strong>African</strong> rope access<br />

industry, providing cost- and time-saving<br />

solutions to clients in the power generation<br />

and petrochemical industries who require<br />

rope access aided inspection, NDT and<br />

maintenance work to be done in difficult to<br />

reach, high-up locations.<br />

Skyriders Contact<br />

Mike Zinn<br />

Skyriders Marketing Manager<br />

Phone: (011) 312 1418<br />

Email: mike@ropeaccess.co.za<br />

Web: www.ropeaccess.co.za<br />

5

ACHIEVING GREATER ENERGY<br />

EFFICIENCY WITH THERMAL SOLAR<br />

Our country’s climate is blessed to have some of the best<br />

sunlight in the world. With the current energy situation<br />

and the ever-increasing electricity costs, we are forced to<br />

evaluate our energy consumption and implement more<br />

efficient and cost-effective solutions.<br />

By Nicole Viljoen, project manager at Energas Technologies.<br />

6<br />

There are two common ways to collect<br />

energy from the sun. One is through a<br />

thermal solar collector, to gather the sun’s<br />

heat and the other is a photovoltaic (PV)<br />

solar system, which converts the sun’s energy<br />

into electricity. In the case of solar thermal,<br />

the conversion efficiency is much higher than<br />

PV. Another advantage is that solar thermal<br />

panels only cost a small fraction of what PV<br />

panels cost per square meter. On the other<br />

hand, PV is more expensive and less efficient<br />

but the electricity generated from PV can be<br />

used for more than just heating up water.<br />

Into detail<br />

A thermal solar system can provide<br />

approximately 60% of the energy required<br />

each year for heating domestic hot water<br />

(DHW). The key element of a thermal<br />

system is the solar thermal collector, which<br />

absorbs solar radiation from the sunlight.<br />

The purpose of the collector is to efficiently<br />

convert the sunlight into heat. The heat is<br />

transmitted to a fluid, which transports the<br />

heat to the heat exchanger via pumps with<br />

minimum heat loss. The exchanger transfers<br />

the heat into the geyser. The distance<br />

between the collector and the geyser should<br />

be as short as possible to minimise heat loss.<br />

There are two main types of solar thermal<br />

collectors available. The first, an evacuatedtube<br />

collector is made of parallel glass tubes.<br />

Each tube contains two glass tubes, between<br />

the two glass tubes there is a vacuum which<br />

allows small heat loss. The absorber is<br />

included in a tube. The second type is the flatplate<br />

collector which comprises an insulated<br />

box with a glass or plastic cover on the top<br />

and a solar absorber located at the bottom.<br />

In comparison, evacuated-tube collectors<br />

are more expensive than flat-plate collectors.<br />

However, they can achieve higher efficiencies.<br />

Achieving optimum heat yield<br />

The integration of solar thermal systems<br />

requires precisely matched individual<br />

components to achieve optimum heat yield<br />

and to keep costs under control. This must be<br />

supported by the right system engineering.<br />

Solar water heating systems almost always<br />

require a backup system for cloudy days and<br />

times of increased demand and therefore most<br />

solar water heaters require a well-insulated<br />

storage tank or DHW cylinder. Dual mode<br />

DHW cylinders work to heat the DHW with<br />

separate indirect coils that are connected<br />

directly to the solar thermal system. DHW<br />

is also heated by a boiler via an indirect coil<br />

arranged in the upper section of the cylinder.<br />

The demand for hot water varies<br />

considerably from household to household.<br />

The number of occupants has to be taken<br />

into account, as well as their bathing and<br />

showering habits.<br />

For example, if three members of a family<br />

set off for work and school at the same time,<br />

lots of hot water needs to be continuously<br />

available for the shower in a short space of<br />

time. Those who prefer a bath will also want<br />

to have enough hot water to fill the tub. The<br />

DHW cylinder should also be able to provide<br />

sufficient water if hot water is drawn from<br />

more than one outlet at the same time, in<br />

apartment blocks for example.<br />

Vitocell DHW cylinders fulfil these<br />

requirements in every respect and can also<br />

meet every aspiration where equipment<br />

levels are concerned. In all instances, the<br />

installation of a solar thermal system is<br />

recommended to save energy and heat the<br />

water without cost.<br />

Energas’ Thermal range<br />

Energas offers Viessmann’s Solar Thermal<br />

range. Installers and end-users are urged<br />

to recognise the role of hot water storage<br />

in optimising environmentally-friendly<br />

installations. Viessmann has introduced<br />

two new floor-standing Vitocell 300-V DHW<br />

cylinders, with capacities of 160 and 200<br />

litres, and are twice as energy efficient in<br />

terms of standby losses as the industry norm.<br />

Both new versions of the Vitocell 300-V<br />

replace the previous A rated models, and<br />

both are suitable for domestic installations<br />

with boiler outputs up to 80 kW. Higher<br />

DHW demands can be accommodated by<br />

combining several Vitocell 300-V cylinders<br />

into cylinder banks with common headers.<br />

The 300-V’s exceptional heat retention is<br />

made possible by using a highly-effective<br />

vacuum panel insulation as well as the very<br />

efficient Polyurethane hard foam. Heat losses<br />

are merely 0,7 kWh per 24 hours for the<br />

160-litre model and 0,75 kWh per 24 hours<br />

for the 200-litre model.<br />

The new 300-V combines unmatched energy<br />

efficiency with high performance. The indirect<br />

heating coil is larger than in most common<br />

cylinders and drawn all the way down to<br />

the cylinder floor to heat the entire water<br />

content. Heat-up time from 10 to 60 degrees<br />

is just 20 minutes for the 160-litre cylinder<br />

and 24 minutes for the 200-litre cylinder.<br />

The low pressure-drop of the heating coil,<br />

at only 15 millibars, is approximately 35%<br />

lower than a typical competitor cylinder. This<br />

negates the requirement for oversizing the<br />

circulating pump; specifying a smaller pump<br />

will save electricity. Maximum hot water<br />

flow rates are 24 and 34 litres per minute<br />

respectively.<br />

The 300-V’s insulation package can be<br />

removed for easy handling. Transportation<br />

and installation are also made easy by the<br />

300-V’s low weight and compact dimensions.<br />

Both 300-Vs are 581 mm long and 605 mm<br />

wide, with the smaller-capacity model<br />

measuring 1189 mm in height and the largercapacity<br />

model 1 409 mm.<br />

Regardless of the size of your home, how many<br />

people live there and how much hot water<br />

they use, our Vitocell range will have the right<br />

cylinder for your DHW heating system.<br />

Energas Technologies contact:<br />

Laetitia Jansen van Vuuren<br />

Tel: +27 (0)11 397 6809<br />

Email: laetitia@energas.co.za<br />

Web: www.energas.co.za<br />

https://www.viessmann-us.com/en/press/vitosol_fm.html<br />

References:<br />

https://www.viessmann.co.uk/products/domestic-hotwater-cylinders<br />

https://www.viessmann.co.uk/press/current-topics/newvitocell-300-v<br />

https://www.viessmann-us.com/en/press.html

AFROX ADVANCES CYLINDER TRACKING<br />

Leading gases supplier Afrox has completed the national roll-out of its state-of-the-art digital cylinder<br />

tracking service. Cylinder deliveries are now being replaced with an advanced software solution to<br />

offer customers improved account management, accurate customer cylinder records, and the ability to<br />

track individual cylinder movements and recall cylinders accurately if required.<br />

“This fully integrated solution will hugely<br />

benefit customers through greater reliability<br />

and accuracy of cylinder holding details,<br />

ensuring Afrox can handle customer<br />

enquiries more effectively,” says AJ Keith,<br />

Cylinder Tracking Programme Manager at<br />

Afrox. He explains that all industrial, special<br />

and medical gas cylinders now carry a unique<br />

barcode, which is scanned during delivery<br />

and return actions using a state-of-the-art<br />

hand-held device, creating an immediate<br />

electronic record of the transaction.<br />

“The scans record on the cylinder tracking<br />

system that the individual cylinder is located<br />

at a specific customer. This system generates<br />

absolutely accurate customer cylinder<br />

records, something our customers have<br />

wanted for many years,” enthuses Keith. Every<br />

cylinder supplied by Afrox will be scanned<br />

and automatically allocated to a customer’s<br />

account, and conversely every cylinder<br />

returned to or collected by Afrox will be<br />

scanned and automatically removed from the<br />

customer’s account. A delivery advice note is<br />

created after all cylinders have been scanned,<br />

which lists the barcode numbers of all tracked<br />

gas cylinders supplied and returned.<br />

“With this system, we can now provide our<br />

customers with a record of all individually<br />

tracked cylinders supplied and returned on<br />

their rental account,” says Keith. He notes<br />

that customers should be aware that if they<br />

have swapped or inadvertently changed<br />

cylinders with another Afrox customer, any<br />

returned cylinders will be deducted from<br />

the original customer account supplied, not<br />

from the returning account. Customers are<br />

therefore advised to notify Afrox of any such<br />

“off-system” movements to enable Afrox to<br />

correct the holdings before any potentially<br />

incorrect billing occurs.<br />

Keith adds that all Afrox retail outlets,<br />

including official Afrox agents, will be scanning<br />

cylinders supplied to and returned from<br />

customers. The cylinder tracking system is<br />

fully integrated and, therefore, all transactions<br />

are updated and cylinder records adjusted<br />

automatically, irrespective of how and where<br />

the cylinder was supplied and returned. For<br />

smaller customers, Afrox cylinders can be<br />

returned to any Gas & Gear store or Afrox<br />

agent where they will be scanned and<br />

automatically removed from the account on<br />

which they were originally supplied.<br />

“From a safety and quality perspective, the<br />

new cylinder tracking system adds immense<br />

value to our customers. We now have an<br />

electronic system that ensures only those<br />

cylinders that have passed their pre-fill<br />

inspection and are within their statutory test<br />

period can be refilled,” says Keith. He explains<br />

further that any reported faulty cylinders<br />

are also blocked in the system at collection<br />

and cannot be refilled until corrective action<br />

has been taken. Furthermore, in the unlikely<br />

event that a batch of cylinders needs to be<br />

recalled, the system is able to identify the<br />

current location of each and every cylinder<br />

in that batch by barcode and location, be it<br />

internally or at a customer. This is the first<br />

time any gas company in South Africa has<br />

been able to offer a recall at this level of<br />

detail and accuracy.<br />

He emphasises that the introduction of the<br />

electronic cylinder tracking system at each<br />

customer has had minimal direct impact and<br />

there has been no significant difference in<br />

the time taken to complete deliveries.<br />

“A special mention must go to the Afrox<br />

drivers, regional transport, inventory, retail<br />

staff and their respective supervisors, as well<br />

as the IS, Commercial and Sales teams that<br />

have all contributed to the successful roll-out<br />

of one of the biggest recent changes to the<br />

way we do business,” concludes Keith.<br />

7

BOSCH REXROTH SOUTH AFRICA GROUP HOSTS CUSTOMERS AT THE REXROTH HUBB<br />

The Bosch Rexroth South Africa Group of<br />

Companies held its first customer day on<br />

24 May at the Rexroth HUBB in Kempton<br />

Park.<br />

In a celebration of the Group’s relationships<br />

it shares with its customers and business<br />

partners, customers of each of the Group<br />

companies were treated to a tour around the<br />

16 000 m2 facility, showcasing the numerous<br />

modern engineering and production facilities<br />

that have been the heart of Bosch Rexroth<br />

South Africa Group operations for the past<br />

12 months.<br />

Working demonstrations of the various<br />

technologies and systems offered by the<br />

Group, in addition to a large collection of<br />

products and components from across<br />

the 30+ international brands it represents<br />

in Africa, were on show in the companies’<br />

assembly areas.<br />

Customers had the opportunity to see many of the Group’s technologies in action and discuss their<br />

application directly with the Group’s knowledgeable staff.<br />

Facilities such as the Group’s hydraulics and<br />

pneumatics test rigs and training rooms,<br />

and solutions such as Hytec Services Africa’s<br />

containerised mobile hose workshops for<br />

mines were also open to customers.<br />

“Bosch Rexroth South Africa is an integral<br />

part of the entire Rexroth Group,” said Bosch<br />

Rexroth Group Executive President and<br />

Chief Financial Officer Dr Markus Forschner.<br />

“Our commitment to quality, innovation<br />

and customer focus is clearly demonstrated<br />

today. The building, the production<br />

environment, but most importantly everyone<br />

in this organisation, reflects our motto, We<br />

Move, You Win. We moved into the HUBB to<br />

set the highest standards in our industry, and<br />

our customers benefit from multi-technology<br />

solutions all under one roof.”<br />

Over 250 of the Group’s valued customers<br />

attended, and were joined by Regional<br />

President for Africa and Group CEO Tillmann<br />

Olsen; Dr Markus Forschner; as well as general<br />

managers and staff from across Group’s<br />

various regional operations across Africa.<br />

At each of the demonstrations, customers<br />

were able to pose and discuss their<br />

application challenges with the Group’s<br />

specialists across its hydraulics, pneumatics,<br />

assembly, linear motion and automation<br />

offerings to identify potential avenues of<br />

performance and process optimisation.<br />

Bosch Rexroth continues to invest in new<br />

locations in Africa, and is currently building<br />

up local value add activities such as the repair<br />

of pumps, motors and hydraulic cylinders in<br />

Botswana, Ghana, Kenya and Morocco. These<br />

are the latest investment made by the Group<br />

in developing its footprint in Africa, which in<br />

Hytec Services Africa’s containerised hose workshops are a complete packaged mobile solution for<br />

hydraulic equipment spares and components for mining machinery.<br />

addition to South Africa, includes Namibia,<br />

Zambia and Mozambique.<br />

The Group’s Customer Day was followed the<br />

day after by a Family Day, where the families<br />

of the company’s staff were invited and<br />

shown around the numerous facilities of the<br />

Rexroth HUBB.<br />

About Bosch Rexroth South Africa Group<br />

of Companies<br />

The Bosch Rexroth South Africa Group of<br />

Companies (previously the Hytec Group) is<br />

Africa’s largest fluid power and automation<br />

company. It comprises eight specialist<br />

companies: Bosch Rexroth South Africa<br />

(previously Hytec Holdings), Hytec South<br />

Africa, Tectra Automation, Hytec Fluid<br />

Technology, Hydraulic and Automation<br />

Warehouse, Hytec Engineering, Hytec<br />

Services Africa and HYSA, which collectively<br />

source, market and distribute over 30<br />

international hydraulic, pneumatic and<br />

automation brands. The Group employs<br />

approximately 850 people through a network<br />

of 40 sales and service branches across sub-<br />

Saharan Africa.<br />

Contact:<br />

Willem Gijzelaar, Group Marketing Manager<br />

Bosch Rexroth South Africa<br />

Tel: +27 (0) 11 979 4630<br />

Email: info@hytec.co.za<br />

Website: www.hytecgroup.co.za<br />

8

NEW SENSORS AND LANGUAGES FOR VENTIS PRO SERIES<br />

GAS MONITORS<br />

Updates to the Ventis Pro Series make it accessible<br />

for a broader range of users and applications.<br />

COMTEST - local representative of Industrial Scientific, global leader in gas detection - has announced<br />

that firmware version 2.1 for Ventis Pro Series Multi-Gas Monitors is now available and offers support<br />

for additional sensor and language options. Ventis Pro Series monitors are<br />

small, highly configurable instruments offering LENS Wireless and the<br />

industry’s only Guaranteed for Life warranty.<br />

New sensors for the Ventis Pro Series include a dual-range methane IR<br />

sensor, a phosphine sensor, and a long-life oxygen sensor. The dual-range<br />

methane IR sensor is ideal for use in inert atmospheres and for seal checks,<br />

leak detection, and when high concentrations of gas would otherwise<br />

damage a catalytic bead LEL sensor. The sensor range is 0-100% volume<br />

methane with 0.01% resolution from 0-5% volume and 0.1% resolution<br />

from 5-100% volume. The phosphine sensor is commonly required for<br />

agricultural and food & beverage industry applications. The long-life<br />

oxygen sensor is suitable for most industries and is designed to perform in<br />

the field for three to five years.<br />

With firmware version 2.1, Ventis Pro Series instruments are now accessible<br />

for more global users with the addition of Italian, Dutch, Portuguese,<br />

and Polish documentation and instrument interfaces. The Ventis Pro also<br />

supports English, French, Spanish, and German. Contact COMTEST on<br />

010 595 1821 or sales@comtest.co.za for more information on Industrial<br />

Scientific’s Ventis Pro Series Gas Monitors<br />

9

thyssenkrupp COMBINES STANDARD ENGINEERING WITH SOFTWARE DEVELOPMENT<br />

TO OFFER A HOLISTIC LIQUID FUEL STORAGE SOLUTION<br />

Stepping into the Engineering 4.0 space, Process Industries, a<br />

business line within thyssenkrupp Industrials, delivers turnkey<br />

project solutions, from pre-feasibility studies through to full<br />

operation, for Africa’s Liquid Fuel Storage sector.<br />

“Having looked closely at this market, we have identified good<br />

growth potential not only in South Africa but also in countries with<br />

rapidly growing populations like Ethiopia, Ghana, Kenya, Nigeria, and<br />

Tanzania,” says Process Industries Business Product Developer and<br />

Futurist Louis W. Coetzee. “Rising populations drive up the demand for<br />

water, energy, infrastructure, agriculture, etc. which require vehicles,<br />

machines and equipment. This, in turn, prompts the development of<br />

tank farms to store the fuel.”<br />

Coetzee points out that, opportunities aside, Liquid Fuel Storage<br />

is a highly competitive industry with costs such as accumulative<br />

transportation tariffs along each leg of the supply chain, from<br />

terminals to storage depots to fuel stations. Recognising that the<br />

sector needs and is ready for a cost effective, efficient tank farm<br />

solution, thyssenkrupp looked outside the box and shifted its overall<br />

project capability focus to be able to deliver a holistic offering. “Not<br />

only are we revisiting our standard engineering expertise to be able<br />

to develop new products for customers but we have also adjusted<br />

our horisontal approach to a vertical one to add holistic Front End<br />

Loading (FEL) to our traditional EPC (Engineering, Procurement and<br />

Construction) portfolio.”<br />

In the pre-feasibility phase (FEL 1) and feasibility phase (FEL 2) Process<br />

Industries delivers a tariff target based solution to ensure client<br />

competitivesness. Future plans are to automate the basic engineering<br />

phase (FEL 3) as well.<br />

What the future will hold for Engineering 4.0 is difficult to foresee but<br />

we have done our foresight development and are working towards it.<br />

This was a relatively simple evolution given the fact that thyssenkrupp<br />

has earned a reputation for innovative product development, cuttingedge<br />

technology and specialist engineering. This proactive move will<br />

enable us to create products that customers need even before they<br />

realise that they need them.”<br />

Coetzee emphasises that for any company to remain competitive and<br />

Industry 4.0 relevant, basic engineering can no longer be the prime<br />

focus; it must be the means to an end i.e. the final product that is<br />

produced through basic engineering. “We are focussed on reducing<br />

the engineering time and effort required to develop a product so that<br />

we can get it deployed as quickly as possible. A perfect analogy here<br />

is the progression from finding directions using a map book, to using<br />

a satellite navigation device and now to using a cell phone. With each<br />

development, the amount of effort required by the driver to look for<br />

a road is lessened. The advent of autonomous vehicles will eventually<br />

diminish this effort altogether, creating a completely different<br />

business model.”<br />

A Typical Diesel Fuel Storage Arrangement<br />

In the EPC phase, thyssenkrupp provides services such as<br />

instrumentation and control, structural and civils through third part<br />

collaboration. “We are fastidious in selecting reputable partners who<br />

are aligned with our world-class standards,” says Coetzee. He further<br />

elaborates that for this holistic solution, instead of taking risks on<br />

behalf of third party contractors at a cost to customers, thyssenkrupp<br />

has adopted a horizontal consortia approach where the risk<br />

responsibilities now lie with the particular executing contractor. “This<br />

enables us to reduce costs for our customers.”<br />

In order to ensure that customers receive the best possible solution,<br />

thyssenkrupp has the ability to source detail engineering required in<br />

the EPC stage from its centre of excellence in India. “Our ability to tap<br />

into thyssenkrupp’s global knowledge pool also gives us an added<br />

competitive edge in the market.”<br />

Process Industries has considerable experience in the petrochemical<br />

industry but the business line’s in-depth expertise in the field of liquid<br />

fuel storage motivated the decision to develop a cost effective holistic<br />

solution for this sector. “A key value add for us is that we are able to<br />

implement this new-knowledge age strategy across any industry,<br />

the only proviso being that it must lend itself to standardisation,”<br />

highlights Coetzee.<br />

Coetzee predicts a future that will see the rise of project engineering<br />

where Process Industries will, together with the customer, design<br />

a complete plant using VR (Virtual Reality). “There can be no doubt<br />

that we are on the cusp of an exciting Engineering 4.0 future that is<br />

poised for the taking, giving us the ability to automate the boring and<br />

engineer the awesome!”<br />

10<br />

Online<br />

epaper.africanpetrochemicals.co.za<br />

VIEW THE BACK EDITIONS ONLINE<br />

(No opt in or log in details required)

11

12<br />

CREATING A FORCE<br />

FOR THE FUTURE<br />

OF RESOURCES<br />

AND ENERGY<br />

Following the announcement<br />

in October 2018 of<br />

WorleyParsons’ binding offer<br />

for Jacobs’ Energy, Chemicals<br />

and Resources (ECR) line of<br />

business, the combined new<br />

entity has come together<br />

under a new brand – Worley –<br />

as of 29 April <strong>2019</strong>.<br />

Denver Dreyer.<br />

Robert Hull.<br />

Ed Hanbidge.<br />

While financially an acquisition, operationally<br />

the transaction is a combination of two<br />

highly complementary organisations that<br />

creates a pre-eminent global provider of<br />

professional project and asset services in<br />

energy, chemicals and resources, offering<br />

global sector leadership across hydrocarbons,<br />

chemicals, and minerals and metals.<br />

As one of the world’s largest project delivery<br />

organisations, Worley has been a leading<br />

global provider of professional services to the<br />

resources and energy sectors, and the complex<br />

process industries, covering the full project<br />

lifecycle in the hydrocarbons, power, minerals<br />

and metals, chemicals, and infrastructure<br />

sectors. This now includes key strengths<br />

from the heritage Jacobs ECR business of<br />

complex petrochemical and chemical projects,<br />

maintenance, modifications and operations<br />

(MMO) for hydrocarbons projects, including<br />

onshore and offshore production facilities and<br />

integrated project delivery, construction and<br />

technical services.<br />

Andrew Wood says, “This merger is about<br />

more than capacity and capability. It’s about<br />

opportunity. The opportunity to become<br />

the partner of choice for our customers,<br />

the employer of choice for our people,<br />

and to deliver enhanced returns for our<br />

shareholders.”<br />

Wood adds that the integration of the two<br />

organisations will create a global company<br />

of nearly 60 000 people across 50+ countries,<br />

fully committed to helping customers meet<br />

the world’s changing energy, chemicals and<br />

resources needs. The combined force will<br />

offer full life cycle services for customers<br />

across hydrocarbons, chemicals, and minerals<br />

and metals, with extended global delivery<br />

centre capabilities, supported by world-class<br />

people and systems.<br />

Outgoing CEO of WorleyParsons RSA<br />

Denver Dreyer, who effective immediately<br />

is taking up the role of Senior Vice President<br />

Mining, Minerals & Metals (MM&M) for<br />

Europe, Middle East and Africa for Worley,<br />

comments that the merger will increase<br />

the organisation’s global footprint in the<br />

minerals, metals and mining sector. South<br />

Africa will continue to be a Global Centre<br />

of Excellence in mining and minerals<br />

processing, providing solutions for each<br />

step of the mining value chain. The Worley<br />

MM&M division for Africa will be headed up<br />

by Robert Hull, who had been responsible<br />

for the management of all projects delivered<br />

locally and globally from WorleyParsons RSA.<br />

Hull’s counterpart, Ed Hanbidge, will head<br />

up the E&C Services (Energy & Chemicals<br />

Services) division for southern and eastern<br />

Africa. Hanbidge was previously MD of Jacobs<br />

Matasis, the South <strong>African</strong> arm of Jacobs ECR.<br />

In South Africa since 2010, Jacobs Matasis has<br />

been a significant contributor of expertise<br />

to the region and a major service provider<br />

of engineering, technical, professional and<br />

construction services to the refining, oil and<br />

gas, and chemicals industries. The company<br />

is known for its long-standing customer<br />

relationships, as well as project portfolio and<br />

alliance experience.<br />

“The presence of these two complementary<br />

divisions in South Africa – one focusing<br />

on minerals and mining, the other one on<br />

energy, oil and gas – will create a stronger,<br />

united entity in many respects, through<br />

combined services, delivery programmes,<br />

resources and expertise,” says Hanbidge. “As<br />

a unified, integrated organisation, we will<br />

be able to serve our clients better, not just<br />

in one particular area, but in a number of<br />

areas. Our synergies of executing work will<br />

be stronger. Our clients won’t have to deal<br />

with multiple companies, but rather with one<br />

company that can now provide much more<br />

in terms of service, which in turn will also<br />

deliver cost benefits to our customers.<br />

Hull concurs. “As one of the biggest onestop-shops<br />

in Africa for professional services<br />

in energy, chemicals and resources, our<br />

customers can expect greater efficiencies,<br />

more services, and a greater diversity of<br />

skills.” He assures that customers will be<br />

working with the same people under an<br />

integrated, unified banner.<br />

“We won’t be changing our DNA of working<br />

– our relationship-based way of working<br />

will continue,” affirms Hanbidge. “Business<br />

will continue as usual, but services will be<br />

delivered in a more cost-effective way, while<br />

bringing our customers the best of both<br />

worlds.”<br />

Dreyer further comments that while this is a<br />

global merger, locally the new entity will be<br />

focusing on issues that are relevant to South<br />

Africa.<br />

“This is a merger of two equals in terms<br />

of capabilities and competencies, strong<br />

track records of delivering projects, and<br />

ethical codes of conducts. As a combined<br />

organisation of substantial size and expertise,<br />

we are strongly positioned to help our<br />

customers in South Africa navigate some of<br />

the complex local challenges such as the new<br />

mining requirements, gas programme, power<br />

programme, and the demand for clean fuels.<br />

“Together, the new entity – Worley – is even<br />

more equipped to solving our customers’<br />

energy, chemical and resources needs,”<br />

concludes Dreyer.<br />

Worley Contact:<br />

Denver Dreyer<br />

Senior Vice President MM&M EMEA<br />

E-mail: Denver.dreyer@worley.com

13

VERT ENERGY’S LEROY-SOMER LSK DIRECT CURRENT<br />

(DC) MOTORS PROVIDE COST-EFFECTIVE SOLUTIONS<br />

FOR VARIABLE SPEED APPLICATIONS.<br />

“Leroy-Somer has a depth of experience with AC and DC variable speed drive<br />

systems and designs its standard motors to withstand the new demands<br />

being imposed by frequency converters and variable speed operation,” says<br />

Grant Robertson, managing director of Vert Energy, exclusive distributors<br />

for Leroy-Somer in Southern Africa. “Motors are thus able to withstand<br />

frequent speed or torque changes and reversals, running at overspeed<br />

(up to 6 000 rpm for the standard four pole machine) and at lower speeds<br />

with full torque, without drawbacks like overheating, loosening of stator<br />

windings and damage to rotors or bearings.<br />

Vert Energy’s Leroy-Somer LSK direct current<br />

(DC) motors provide cost-effective solutions<br />

for variable speed applications.<br />

14<br />

“The major advantage of direct current<br />

motors is the ease of effecting accurate<br />

speed control and LSK’s advanced<br />

technology enables motors to respond to<br />

electronic controllers which place great<br />

demands on the performance of DC motors.<br />

Smooth running has been achieved by the<br />

introduction of an advanced frame design,<br />

incorporating the largest dimensioned shaft.”<br />

LSK square laminated frame DC motors,<br />

which have been designed by Leroy-<br />

Somer to the latest European standards for<br />

industrial requirements, have ratings from 2<br />

to 750 kW. Leroy-Somer also produces nonstandard<br />

motors, providing a range of power<br />

from 0,06 kW to 18,5 kW.<br />

Vert Energy’s LSK DC range includes enclosed<br />

permanent magnet motors, enclosed wound<br />

motors, drip-proof wound motors and dripproof,<br />

force-cooled wound motors.<br />

These motors can be foot, flange or foot and<br />

flange mounted. Flanges are incorporated<br />

into the steel stator castings, giving a robust<br />

construction that eliminates vibrations.<br />

Four removable plates allow direct access<br />

to brushes for easy replacement, thus<br />

simplifying maintenance.<br />

Leroy Somer’s advanced design of the DC<br />

motor incorporates cooling and ventilation<br />

systems that reduce wear and tear on the<br />

brush gear, by the elimination of dirty<br />

particles.<br />

These motors, with a Class H insulation<br />

system, can operate at ambient temperatures<br />

of between +5°C and +40°C and are<br />

protected with a range of surface treatments<br />

that withstand harsh environments.<br />

The quality of the winding, insulation<br />

and impregnation guarantees optimum<br />

performance, even in arduous conditions.<br />

Optional features include flange adapters<br />

which enable the easy modification of<br />

motors to all types of situations, without<br />

the need for costly and time-consuming<br />

adjustments. Pressure switches monitor air<br />

flow to detect if the ventilation motor has<br />

stopped working. Where there is little vertical<br />

space for installing a motor, a connection kit<br />

can be used to mount the standard forced<br />

cooling unit in an axial position. Transparent<br />

doors can be fitted to facilitate maintenance<br />

procedures like brush inspection, without<br />

having to remove inspection doors.<br />

Leroy-Somer has developed an online<br />

configurator to assist in the selection of<br />

motors, brake motors or geared motors,<br />

combined with variable speed drives. The link<br />

to the energy savings website is http://acim.<br />

nidec.com/motors/leroy-somer/services/<br />

calculate-your-energy-savings<br />

The modular concept of this range enables<br />

a continuous production line for the entire<br />

LS product range, thus reducing delivery<br />

times. Lead times for adapted motors are also<br />

significantly shortened.<br />

Vert Energy offers a maintenance programme<br />

which ensures optimum performance of DC<br />

motors and significantly extends service life.<br />

This range includes enclosed permanent<br />

magnet motors, enclosed wound motors,<br />

drip-proof wound motors and drip-proof,<br />

force-cooled wound motors<br />

For further information:<br />

Mr Ryan Robertson, Sales and Marketing<br />

Director, Vert Energy<br />

Tel: 086 111 VERT (8378)<br />

Email: ryan.robertson@vertgroup.co.za<br />

Website: www.vertgroup.co.za

BMG FLUID TECHNOLOGY- INDUSTRIAL SLURRY VALVES FOR<br />

HARSH CONDITIONS<br />

BMG’s extensive range of industrial slurry valves, which has been designed to cope efficiently in harsh<br />

conditions, includes robust butterfly and knife gate valves, as well as diaphragm and pinch valves.<br />

“These industrial slurry valves – which meet<br />

stringent quality and safety specifications<br />

– are highly efficient for the control and<br />

isolation of abrasive slurries in many<br />

industries, including power generation,<br />

chemical and petrochemical, cement<br />

handling, water treatment and pulp and<br />

paper,” says Willie Lamprecht, national<br />

product manager, Valves, BMG. “Failure of<br />

a valve and subsequent leaking of corrosive<br />

media can have devastating effects on the safety<br />

of personnel and equipment, leading to premature<br />

system failure and costly downtime. It is critical that the correct valve is<br />

selected for every application, for maximum safety, ongoing operation<br />

of the plant and minimum unscheduled maintenance.<br />

“BMG’s highly-skilled team has a thorough understanding of<br />

the processes where valves are installed and supports every<br />

component with a dependable solutions service, to ensure<br />

optimum safety, efficiency and the extended service life of each<br />

system. The selection of the correct industrial slurry valve is based<br />

on factors that include the size and shape of particles, pressure,<br />

temperatures and chemical content.”<br />

Polyurethane-lined knife gate valves are available from BMG in<br />

standard sizes between DN 50 and DN 600, with manual, pneumatic<br />

and electric actuation. These knife gate valves have a wafer pattern<br />

and are manufactured from cast and ductile iron, with Stainless Steel<br />

discs. They can withstand operating temperatures of between – 20˚C<br />

and +80 ˚C as standard, with higher temperatures on request.<br />

Polyurethane liner abrasion-resistant butterfly valves – in a wafer<br />

pattern or with a lugged design – are used for on-off and control<br />

of abrasive slurries. Butterfly valves are available from BMG in<br />

standard sizes between DN 50 and DN 400.<br />

Locally-manufactured KLEP BMG diaphragm valves – between DN<br />

50 and DN 350, with manual or pneumatic actuation – are designed<br />

for abrasive slurry applications. These flanged diaphragm valves<br />

have a body pressure of PN 10 and can withstand temperatures<br />

between -10°C and +80°C.<br />

Long-lasting rubber and jumbo rubber linings are suited for fullbore<br />

diaphragm valves with a high flow capacity and an efficient<br />

sealing capability, which shuts off any flow and prevents leakage.<br />

Full bore diaphragm valves also have a low pressure drop because<br />

there is almost nothing obstructing the flow of the fluid when the<br />

valve is fully opened. This creates little resistance to flow, which<br />

makes these valves suitable for fluids with abrasive particles.<br />

Also in the range, are unlined diaphragm valves, which are suitable<br />

for water treatment and general industrial applications.<br />

FPV pinch valves – featuring a design where the sleeve is pinched<br />

to close mechanically or automatically by means of hand-wheel or<br />

actuator – are ideal for the control and isolation of abrasive slurries.<br />

Open frame pinch valves are available from BMG with a short and<br />

long frame design, in sizes between DN 50 and DN 600.<br />

The body is made from mild steel, but Stainless Steel is also<br />

available for specific applications. These valves, with soft rubber<br />

sleeves, have manual, hydraulic and pneumatic actuation and can<br />

withstand temperatures between -20°C and +80°C.<br />

BMG’s extensive range of components for fluid technology systems<br />

and general industrial applications encompasses valves, hydraulic<br />

hoses and fittings, accumulators, cylinders, heat exchangers,<br />

pneumatics, hydraulic motors and hydraulic plumbing, as well as<br />

pumps and reservoir accessories.<br />

The company also offers a total process and lubrication<br />

management solution, to meet exact market requirements.<br />

For further information:<br />

Willie Lamprecht, National Product Manager, BMG<br />

Mobile: +27 72 326 4832 Tel: +27 11 620 1581<br />

Fax: +27 86 639 5680<br />

Email: williaml@bmgworld.net Website: www.bmgworld.net<br />

15

SOMETIMES THE CHOICE<br />

IS DIFFICULT …

… THE CHOICE FOR LEVEL<br />

80 GHZ RADAR!<br />

One radar sensor<br />

for liquids.

MEASUREMENT IS EASY:<br />

One sensor for bulk solids.<br />

Sounds simple, is simple!

RADAR LEVEL MEASUREMENT<br />

WITH 80 GHZ<br />

Industrial processes are becoming increasingly customized<br />

and complex. Now it’s even easier to select the right level<br />

transmitter for your needs. For a reliable non-contact level<br />

measurement solution, just choose VEGAPULS 64 for<br />

liquids or VEGAPULS 69 for bulk solids.<br />

DYNAMIC RANGE 120 dB<br />

Poorly refl ecting media? Dust,<br />

condensation, or buildup? Radars with<br />

best-in-class dynamic range deliver<br />

constant visibility of your process levels.<br />

PROCESS FITTINGS FROM ¾"<br />

With small connections and a compact<br />

design, VEGAPULS 64 is the perfect fi t<br />

in the smallest liquid containers.<br />

FOCUSING 3°<br />

No interfering signals from internal<br />

installations. A radar beam angle from<br />

3° for liquids and 4° for bulk solids.<br />

ACCURACY +/-1 mm<br />

Every drop counts with VEGAPULS 64.<br />

It really scores points for accuracy,<br />

especially with high value liquids.<br />

ADJUSTMENT<br />

80 GHz radar sensors can be adjusted wirelessly with<br />

a smartphone or tablet. Did you know? All VEGA level<br />

sensors since 2002 can also get Bluetooth. Just click-in<br />

a new PLICSCOM display and adjustment module and<br />

it’s done!<br />

More information: www.vega.com/radar<br />

Phone +27 11 795 3249 | E-mail info.za@vega.com

SKYRIDERS CONSULTS ON FALL-PROTECTION<br />

PLAN FOR PLATINUM-SMELTER PROJECT<br />

Skyriders Access Specialists<br />

(Pty) Ltd. was recently<br />

called upon to carry out<br />

consultancy work at a<br />

major project at a platinum<br />

smelter. According to<br />

South Africa’s construction<br />

regulations, any workplace<br />

involving a risk of a fall<br />

must have a verified fallprotection<br />

plan drafted<br />

by a competent person<br />

accredited by the Institute<br />

for Work at Height (IWH).<br />

Skyriders often carries out<br />

such consultancy work as a valueadded<br />

service for its clients.<br />

16<br />

This plan encompasses the entire site, the<br />

scope of work, and the different personnel<br />

involved during that work, Skyriders<br />

Marketing Manager Mike Zinn explains. The<br />

client had a number of contractors on-site<br />

for this particular project, and hence the<br />

planning had to take work-at-height into<br />

consideration.<br />

“The main contractor wanted to verify<br />

that the fall-protection plan in place was<br />

sufficiently comprehensive, and complied<br />

with all of the necessary health and safety<br />

standards and regulations pertaining to<br />

work-at-height in particular,” Zinn highlights.<br />

Skyriders dispatched its own highlyexperienced<br />

Safety Manager to site, who<br />

spent a day ascertaining the scope of the<br />

project and the client’s specific requirements.<br />

For example, general fall-arrest principles<br />

require workers to wear a safety harness for<br />

any work-at-height.<br />

The fall-protection plan encompasses<br />

appointment letters for all contractors onsite,<br />

a detailed risk assessment of the scope<br />

of work, and a full record of any training<br />

conducted and competencies verified. For<br />

example, a worker cannot carry out any<br />

work-at-height if they have not undertaken a<br />

certified fall-arrest course.<br />

In addition, medical certificates have to<br />

be secured for all workers involved in any<br />

work-at-height. This requirement is especially<br />

stringent with mining operations, due to<br />

the arduous operating environments and<br />

the attendant hazards and risks. Also, all<br />

equipment to be deployed on-site has to<br />

be deemed as being fit-for-purpose, as well<br />

as having been properly stored, tested, and<br />

inspected.<br />

“We also examine the access techniques<br />

that are to be used, such as rope access,<br />

scaffolding, man boxes, cherry pickers, or<br />

cranes. Lastly, a rescue plan needs to be<br />

outlined that includes an evacuation plan<br />

and appropriate rescue techniques,” Zinn<br />

elaborates.<br />

Skyriders often carries out such consultancy<br />

work as a value-added service for its<br />

clients. Due to the rope-access specialist’s<br />

experience and skills in this area, it is able to<br />

sign off on fall-protection plans, for example,<br />

which means that the client has peace of<br />

mind that any risk in this regard has been<br />

ameliorated.<br />

About Skyriders<br />

Skyriders (Pty) Ltd, established in 1998, is<br />

a leader in the South <strong>African</strong> rope access<br />

industry, providing cost- and time-saving<br />

solutions to clients in the power generation<br />

and petrochemical industries who require<br />

rope access aided inspection, NDT and<br />

maintenance work to be done in difficult to<br />

reach, high-up locations.<br />

Skyriders Contact<br />

Mike Zinn<br />

Skyriders Marketing Manager<br />

Phone: (011) 312 1418<br />

Email: mike@ropeaccess.co.za<br />

Web: www.ropeaccess.co.za<br />

Fall-arrest principles<br />

require workers<br />

to wear a safety<br />

harness for any<br />

work-at-height.

A trusted<br />

operations,<br />

maintenance<br />

and asset<br />

integrity leader.<br />

At SNC-Lavalin, we are world renowned for our ability to<br />

design, construct, commission, maintain and enhance our<br />

clients’ assets in the most challenging environments.<br />

Our end to end engineering, maintenance, operations and<br />

asset integrity management services are delivered to energy<br />

and resources sectors across sub-Saharan Africa.<br />

We’re using technology for predictive maintenance and digital<br />

asset management to extend plant life and improve reliability.<br />

17

NATREF FUELS<br />

DOCUMENT MANAGEMENT<br />

IMPROVEMENTS WITH<br />

DATACENTRIX<br />

National Petroleum<br />

Refiners of South Africa<br />

(NATREF) has upgraded its<br />

document management environment,<br />

allowing for faster access to the critical<br />

documentation native to production<br />

and processing businesses. The<br />

ongoing project is being rolled out<br />

with the assistance of high performing<br />

and secure ICT solutions provider,<br />

Datacentrix, a long-term<br />

NATREF partner.<br />

18<br />

NATREF, South Africa’s only inland crude oil<br />

refinery, is a joint venture between Sasol and<br />

Total South Africa. The organisation produces<br />

fuel, including petrol, diesel, jet fuel, bitumen<br />

and tar, which it supplies to the inland region<br />

of South Africa.<br />

According to Andries Visagie, operational<br />

and governance manager at NATREF’s<br />

Information Management Division, the<br />

project came about when the organisation<br />

realised the time had come for it to set up<br />

its own Enterprise Information Management<br />

(EIM) system (this had previously been<br />

shared with Sasol). “We were happy with<br />

the solution being used, but found that,<br />

over time, there was a need for additional<br />

support. It made sense for us to put a team<br />

in place, not only to bolster support of the<br />

environment, but also to upgrade it for<br />

greater efficiencies.”<br />

Having partnered with Datacentrix before,<br />

the natural next step was for NATREF to<br />

engage the solution provider to complete a<br />

technical audit on the existing system, and<br />

the information contained therein, to gauge<br />

the current status, assess risks within the<br />

environment, and use this input for decision<br />

making.<br />

“The outcomes of the assessment, which<br />

encompassed a full strategy and roadmap,<br />

provided clear recommendations to NATREF’s<br />

IM team, included details such as the type of<br />

infrastructure needed, sizing, and estimated<br />

timing for data migration,” explains Visagie.<br />

When it came to the implementation, NATREF’s<br />

production environment encompassed critical<br />

information within the existing system, so a<br />

‘rip-and-replace’ approach was not possible.<br />

With this in mind, and to minimise business<br />

interruption, Datacentrix replicated the old<br />

environment and used it as a platform for<br />

testing. From a business continuity point of<br />

view, the decision was then taken to do the<br />

cut over after NATREF’s financial half-year<br />

concluded in November.<br />

“Overall there was an excellent joint effort<br />

between Datacentrix and NATREF to make<br />

this as painless as possible. At this point,<br />

we’re happy to report that the system is<br />

stable, and running across all disciplines<br />

within the business, with a total of 600<br />

permanent users.”<br />

Visagie clarifies that the EIM environment<br />

is critical across all areas of NATREF. “For<br />

instance, when it comes to production, the<br />

system holds important information on<br />

standard operational procedures that need<br />

to be accessed and adhered to at any point<br />

in time, from start-ups to shut-downs. Within<br />

the HR environment, it is used to store the<br />

relevant policies and procedures. The finance<br />

department needs access to financial records,<br />

audit documentation, and so on.<br />

“Essential within a processing and production<br />

environment, our safety team has timely<br />

access to supporting documentation such<br />

as work and task overseeing instructions.<br />

An example of this is when it comes to<br />

specialised welding, in that the welder would<br />

need access to task observations before<br />

any physical welding can take place. All of<br />

this documentation is quickly and easily<br />

accessible using the new EIM solution.”<br />

Visagie says that NATREF users are embracing<br />

the new functionalities on offer within<br />

document and content management. “Easeof-use,<br />

system speed and convenience have<br />

improved immensely for our users. We’ve also<br />

managed to completely automate workflow<br />

around the critical inspections conducted<br />

on NATREF’s production equipment, which<br />

are legally required and include mechanical<br />

integrity checks such as x-rays and infrared<br />

analyses.<br />

“The new EIM system is also now fully<br />

integrated with the other tools used<br />

by NATREF, making for a seamless user<br />

experience,” he adds.<br />

“NATREF’s partnership with Datacentrix<br />

has been extremely positive overall. Our<br />

requirement for open and transparent<br />

communications has certainly been met, and<br />

we’ve found that the team of Datacentrix<br />

experts working with us have all the skills –<br />

from document management, infrastructure<br />

and around the product itself – needed to<br />

easily manage any unexpected challenges.<br />

“For NATREF, this project was an excellent<br />

stepping stone in improving its document<br />

management environment, and we will<br />

be looking at upgrading our document<br />

archiving process next,” states Visagie.<br />

Additional future plans at NATREF include<br />

integration of the organisation’s enterprise<br />

software with the EIM solution, a real area<br />

of strength for Datacentrix, according to<br />

Tony Daubern, EIM project manager at<br />

the company. “Datacentrix has a wealth of<br />

experience in the integration of EIM and<br />

enterprise software, receiving industry<br />

recognition for exactly this in the form of<br />

several awards over the past few years.<br />

“We look forward to deepening our<br />

partnership with NATREF, and taking its EIM<br />

setup to new heights, with a view to also<br />

tackling its records management in time.”<br />

About Datacentrix:<br />

Datacentrix provides leading ICT integration<br />

services and solutions to South <strong>African</strong><br />

organisations, ensuring their success and<br />

sustainability into the digital age. The<br />

company’s approach is to partner with its<br />

customers, equipping them with valuable<br />

insight and helping to align their ICT<br />

undertakings with their business strategy.<br />

Datacentrix offers a deeply specialised skills<br />

component and is endorsed by the world’s<br />

foremost technology partners. The company<br />

is recognised for its agility, in-depth industry<br />

knowledge, proven capability and strong<br />

overall performance.<br />

Datacentrix is a Level One (AAA) B-BBEE<br />

Contributor, with 135 percent procurement<br />

recognition. For more information, please<br />

visit www.datacentrix.co.za.<br />

Contact:<br />

Nicola Read, icomm<br />

Email: datacentrix@pr.co.za<br />

Website: www.icomm-pr.co.za

®<br />

SPEEDY, RELIABLE MA LOOP<br />

VALVE TESTING<br />

The new handheld control valve tester<br />

simplifies testing with dedicated tests that<br />

perform a quick health check to provide<br />

users with good/marginal/bad results.<br />

FLUKE 710 mA<br />

Loop Valve Tester.<br />

Control valve testing has meant using complicated<br />

testers that require extensive training, the removal<br />

of the valve, and often one-to-two hours of test time<br />

on the bench. COMTEST is pleased to announce<br />

the arrival of Fluke’s new 710 mA Loop Valve Tester.<br />

The device allows technicians to source the 4-20<br />

mA signal while it interrogates HART data to collect<br />

critical information about the valve’s position and<br />

status, providing quick checks of control valves while<br />

they are in place. With built-in test procedures and an<br />

intuitive interface, the Fluke 710 allows technicians<br />

to quickly and easily perform valve tests, while the<br />

valve test quick-check results provide at-a-glance<br />

diagnostics to make faster maintenance decisions.<br />

With the tester’s built in HART<br />

communication function,<br />

technicians can source a 4-20<br />

mA signal to cause the smart<br />

control valve to move, while<br />

simultaneously interpreting<br />

the valve’s HART feedback<br />

signal to determine whether<br />

the valve is moving to the<br />

expected position. In addition<br />

to positional information, the<br />

measured pressure delivered<br />

from the valve’s internal I/P<br />

(which moves the valve)<br />

can be seen with the HART<br />

communication protocol.<br />

The 710 features preconfigured<br />

valve tests for<br />

reliable and repeatable testing.<br />

The built-in routines include:<br />

• Manually changing the mA signal and viewing the<br />

HART position and pressure variable information.<br />

• Full range ramping of the mA signal from 4 to 20 to<br />

4 mA while recording the 0-100-0 percent position,<br />

or the pressures applied that move the valve from<br />

0-100-0 percent.<br />

• Stepping the mA signal on the input to the valve in<br />

steps and evaluating the valves response to the mA<br />

input changes.<br />

• Speed tests to determine how fast the valve can<br />

open or close.<br />

• Bump and partial stroke tests that help test valves<br />

over a portion of their range so they can be tested<br />

in a live process.<br />