African Petrochemicals Edition 16.3

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

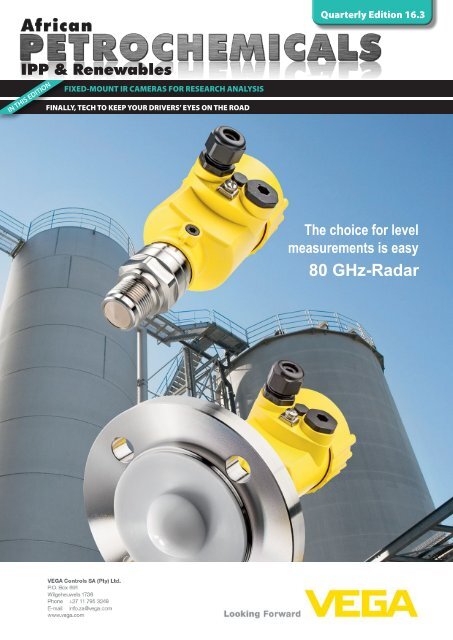

Quarterly <strong>Edition</strong> <strong>16.3</strong><br />

IPP & Renewables<br />

IN THIS EDITION<br />

FIXED-MOUNT IR CAMERAS FOR RESEARCH ANALYSIS<br />

FINALLY, TECH TO KEEP YOUR DRIVERS’ EYES ON THE ROAD<br />

The choice for level<br />

measurements is easy<br />

80 GHz-Radar

IPP & Renewables<br />

RAND-AIR’S PORTABLE<br />

LED LIGHTING UNITS:<br />

PLACING MINES IN A<br />

FAVOURABLE LIGHT<br />

With the enormous investment placed<br />

in large open-pit mines, the pressure<br />

is on these operations to produce.<br />

Inevitably, this dictates that they work<br />

around the clock. However, working<br />

at night does present some very real<br />

potential safety hazards which are not<br />

present during the hours of daylight.<br />

2<br />

This is according to Craig Swart, Fleet Manager<br />

at Rand-Air, the leading local provider of<br />

compressed air and power to the mines, as<br />

well as to many other industry sectors.<br />

“The most serious potential hazard in an<br />

open-pit mine - even during daylight hours<br />

- are the very large load-hall-dumpers,<br />

excavators and rope shovels used to excavate<br />

and transport broken ore. Apart from vehicle<br />

headlights, better all-round area lighting is an<br />

absolute necessity to ensure safe operations,”<br />

says Swart, adding that having clear, strong<br />

area lighting means that drivers of off-theroad<br />

mining equipment will be able to pick<br />

up the reflective strips on a pedestrian’s<br />

safety vest with much greater ease.<br />

Rand-Air has the solution in its portable<br />

LED lighting units.<br />

“As these units are fitted with LED bulbs,<br />

they are remarkably economical and will run<br />

for days without requiring refuelling or any<br />

other attention. In addition, modern LED<br />

bulbs last longer and fail less often than their<br />

earlier filament counterparts, and can handle<br />

harsh mining conditions without burning out<br />

prematurely,” Swart explains.<br />

As the diesel engine, generator and lighting<br />

tower are all contained on a single trailer,<br />

there are no trailing cables to either get cut,<br />

damaged or trip over. Furthermore, as they<br />

are mounted on a robust trailer, moving<br />

them to new positions as mining shifts in the<br />

pit, takes a matter of minutes.<br />

What makes Rand-Air portable lighting units<br />

an even more attractive rental proposition<br />

is that the company regularly upgrades<br />

its equipment fleet with new machines.<br />

In addition, Rand-Air lighting units are all<br />

manufactured by world leader Atlas Copco<br />

and, as such, these units deliver the most<br />

cost-effective, lowest maintenance service.<br />

Rand-Air portable lighting units are also<br />

backed up by the company’s unmatched<br />

As Rand-Air portable lighting units are fitted with LED bulbs, they are remarkably economical and will<br />

run for days without requiring refuelling or any other attention.<br />

service ethic. In the unlikely event of an<br />

issue with one of these machines, Rand-Air’s<br />

qualified technicians are on standby 24/7 to<br />

ensure that full lighting is restored without<br />

delay.<br />

Speaking to the all-important requirement<br />

for safety at all times – particularly<br />

within the mining environment - where<br />

occupational health and safety challenges<br />

are amongst the biggest causes of injuries<br />

and fatalities – Swart makes the following<br />

recommendation:<br />

“Outdated lighting units in any industry that<br />

are not operating at a satisfactory level pose<br />

a serious threat to the working environment<br />

and its people. A preventative maintenance<br />

strategy is therefore critical, to guarantee safe<br />

operation of the equipment - and is key to<br />

minimising the risk of injuries or accidents.”<br />

Rand-Air lighting units are available for<br />

short-term hire, as well as via the company’s<br />

long-term rental scheme which allows<br />

customers to take advantage of considerable<br />

cost savings.<br />

“In the past couple of years, our portable<br />

lighting units have been a boon to the<br />

surface mining industry. With proper<br />

lighting, workers can concentrate on getting<br />

the job done and being more productive,<br />

but in a well-lit and therefore far safer<br />

environment. In a nutshell – and true to our<br />

Rand-Air business ethos - we always place<br />

our customers in a ‘favourable light’, ” he<br />

concludes.<br />

About Rand-Air<br />

With several depots, branches and<br />

substantial representation across Southern<br />

Africa, Rand-Air continues to expand their<br />

footprint to service a diverse market. Since<br />

1973, Rand-Air has been driven by an<br />

ethos to exceed customer expectation and<br />

satisfaction. This is complemented by a<br />

product offering that adheres to the highest<br />

quality standards in the industry. Rand-<br />

Air’s products portfolio includes oil-free<br />

compressors, industrial air compressors,<br />

diesel compressors, electric air compressors<br />

(all screw compressors), diesel generators<br />

and lighting towers.<br />

As the market leader in portable air<br />

compressors and generator rental, Rand-<br />

Air upholds its reputation through regular<br />

training and upskilling in business related<br />

and product-specific matters.<br />

Rand-Air is part of the Atlas Copco group and<br />

is a Level 4 B-BBEE rated company.

IPP & Renewables<br />

<strong>African</strong> <strong>Petrochemicals</strong> is published quarterly by Direct Publications cc<br />

Quarterly <strong>Edition</strong> <strong>16.3</strong><br />

Direct Publications<br />

Publisher<br />

Richard Scott<br />

richard@africanpetrochemicals.co.za<br />

Accounts and Admin<br />

Ashni Padiachie<br />

accounts@africanpetrochemicals.co.za<br />

Sales<br />

Sales Team<br />

sales@africanpetrochemicals.co.za<br />

Graphic Designer<br />

Linda Graae<br />

production@africanpetrochemicals.co.za<br />

The views and opinions expressed in this<br />

magazine are those of the respective authors<br />

and do not necessarily express the views and<br />

opinions of Direct Publications cc. We do not<br />

endorse any of the products , services or<br />

expertise offered by any of our advertisers or<br />

contributors. No liability will be accepted for<br />

artwork supplied incorrectly or slight colour<br />

deviations. Editorial contributions relevant<br />

to any section of the magazine are more than<br />

welcome. Email submissions to<br />

production@africanpetrochemicals.co.za<br />

Direct Publications reserves the right to cut and<br />

alter editorials received for publication.<br />

Reproduction<br />

No part of this magazine may be reproduced<br />

without written permission from the editor or<br />

publisher.<br />

Subscription Service<br />

For address changes, subscriptions or missed<br />

issues, please call 011 083 5125 or<br />

email: accounts@africanpetrochemicals.co.za<br />

CONTENTS<br />

Rand-Air’s portable LED lighting units:<br />

placing mines in a favourable light .............. 2<br />

RTS Africa Technologies principal H2Scan<br />

opens new Environmental Conditioning<br />

Laboratory to further ‘refine’ hydrogen<br />

detection in gas process streams .................. 4<br />

The step toward a Universal Measuring<br />

Instrument ............................................................. 5<br />

In-depth material knowledge - a ‘Vital’<br />

service to the petrochemical sector ............. 6<br />

BMG’s Spanjaard lubricants, oils and<br />

greases for efficient lubrication in mining<br />

and industrial applications .............................. 8<br />

Namdock’s ‘naval offensive’ secures<br />

milestone Angolan Navy maintenance<br />

contract .................................................................. 9<br />

Sentinel launches new 6 Channel Mobile<br />

DVR ......................................................................... 10<br />

Air Products ends 50 th Birthday year on<br />

high note .............................................................. 11<br />

Engen and Clicks partner in a winning<br />

loyalty formula .................................................. 12<br />

Incledon launches latest Tekflo Nylon<br />

Ball and Check Valves ...................................... 13<br />

Keeping up with industry changes is<br />

the only way to manage connectivity<br />

expenditure ...........................................................14<br />

Three myths of lubrication that need<br />

busting .................................................................. 16<br />

Emerson releases new magnetic slurry<br />

sensor and transmitter designed to help<br />

customers cut through the noise ............... 17<br />

T-Systems upskills high school learners<br />

and teachers through the highly successful<br />

ICT Academy Initiative .................................... 18<br />

Rockwell Automation named a leader<br />

in Gartner’s Magic Quadrant for<br />

manufacturing execution systems for<br />

second consecutive year ................................ 19<br />

Atlas Copco donates safety equipment &<br />

promotes safety consciousness at Manger<br />

Care Centre ......................................................... 20<br />

SKF turns up the heat with a portable<br />

bearing heating solution ............................... 21<br />

Compact / Remote Magnetic Inductive<br />

Flowmeter in Stainless Steel ......................... 21<br />

Finally, tech to keep your drivers’ eyes on<br />

the road ................................................................ 23<br />

BMG’s Interapp Desponia and Bianca<br />

butterfly valves .................................................. 24<br />

Fixed-Mount IR Cameras for research<br />

analysis ................................................................ 25<br />

Rope-access service from Skyriders keeps<br />

lights on at major warehouse ...................... 26<br />

Top three reasons for businesses to be<br />

PCI DSS compliant ........................................... 28<br />

Infobip enables WhatsApp Business API<br />

for ChatFin – simplifies SA vehicle license<br />

renewals over WhatsApp ............................... 30<br />

A smooth ride in rough conditions with<br />

SKF’s new fork seal ........................................... 31<br />

Total South Africa Celebrates its<br />

Commitment to Transformation ................. 31<br />

VISIT AFRICAN PETROCHEMICALS ONLINE:<br />

www.africanpetrochemicals.co.za<br />

Visit our e-paper section to view the<br />

magazine archive:<br />

epaper.africanpetrochemicals.co.za<br />

(No Log-in details required)<br />

3

IPP & Renewables<br />

RTS AFRICA TECHNOLOGIES PRINCIPAL H2SCAN OPENS NEW<br />

ENVIRONMENTAL CONDITIONING LABORATORY TO FURTHER<br />

‘REFINE’ HYDROGEN DETECTION IN GAS PROCESS STREAMS<br />

4<br />

Hydrocarbon fuels are essential for our<br />

daily existence. However, extracting<br />

usable fuels from crude oil is a complex<br />

process in which hydrogen plays a cardinal<br />

role, as the correct levels of hydrogen in a<br />

refinery process stream largely determine<br />

the quality of the final product.<br />

“At RTS Africa Technologies, we have been<br />

distributing H2Scan hydrogen detection<br />

and analysis products for the past decade.<br />

In particular, H2Scan’s Hy-Optima range<br />

of products have numerous applications<br />

in South Africa’s oil refineries,” says Ian<br />

Fraser, MD of RTS Africa Group, a Tshwanebased<br />

company specialising in innovative<br />

technologies which provide solutions<br />

to industrial challenges. Among other<br />

things, the company has been involved in<br />

supplying hydrogen production and analysis<br />

equipment for many years.<br />

To ensure correct and accurate functioning,<br />

the sensors in the Hy-Optima instruments<br />

need to be conditioned. Until now, H2Scan<br />

has been using the services of a remote<br />

laboratory which could only condition<br />

H2Scan’s standardised products. Now,<br />

H2Scan has opened a new expanded<br />

Environmental Conditioning Laboratory for<br />

its Hy-Optima hydrogen analyser products.<br />

“This gives H2Scan the capability to expand<br />

its production and deliver customised<br />

products to refineries and petrochemical<br />

facilities,” continues Fraser. “In an oil refinery,<br />

they are as many as 23 points where<br />

the level of hydrogen needs to be very<br />

accurately monitored and where H2Scan new<br />

conditioned instruments can play a key role.”<br />

Hy-Optima products are used in process<br />

applications to ensure production<br />

optimisation of oil and petrochemical<br />

products. Each Hy-Optima sensor is rated for<br />

background monitoring of hydrogen in the<br />

presence of gases such as hydrogen sulphide<br />

and carbon monoxide at predetermined<br />

concentrations with no interference with the<br />

H2 reading. “The laboratory will be used to<br />

ensure that the sensors are conditioned to<br />

provide accurate hydrogen indication in the<br />

presence, or absence, of these gases,” he adds.<br />

“This laboratory gives us the flexibility to<br />

develop products that are unmatched in the<br />

industry currently,” he continues. “The ability<br />

to certify hydrogen sensing in the presence<br />

of 50% carbon monoxide and 5% hydrogen<br />

sulphide is unheard of in the industry and<br />

this offers new alternatives to our refinery<br />

and petrochemical customers,” Fraser asserts.<br />

The new laboratory now conditions Hy-<br />

Optima products which have been marketed<br />

for more than 10 years and can currently<br />

measure hydrogen concentrations from 0.5%<br />

to 100%, in the presence of carbon dioxide<br />

of up to 20% concentration and in the<br />

presence of hydrogen sulphide at up to 3%<br />

concentration.<br />

The Hy-Optima 2700, for example, is fitted<br />

with a solid-state, non-consumable sensor<br />

that is configured to operate in process gas<br />

streams. The Hy-Optima 2700’s thin film<br />

technology ensures that instrument is not in<br />

any way affected, or cross-sensitive, to other<br />

gases in the process stream. The 2700 has<br />

been designed to continuously measure only<br />

hydrogen - which it does with great accuracy<br />

and reliability,” Fraser continues. In addition,<br />

the Hy-Optima 2700 is rated explosion-proof<br />

and conforms to the requirements for Class<br />

I, Division 1 or 2 locations. Should hydrogen<br />

get into the instrument and ignite, the 2700’s<br />

robust, cast-iron casing will safely contain<br />

the event. With Hy-Optima 2700, the need<br />

for calibration is greatly reduced. “In most<br />

cases, an annual calibration using standard<br />

calibration gases is all that is needed,” he<br />

explains.<br />

H2Scan was founded in 2002 and has its<br />

headquarters in Valencia, California. The<br />

company provides the most accurate,<br />

tolerant and affordable hydrogen leak<br />

detection and process gas monitoring<br />

solutions for industrial markets. The<br />

company’s customer base includes some<br />

of the largest manufacturing enterprises in<br />

the world including General Electric, DOD,<br />

ABB, Siemens, ExxonMobil, Shell, Chevron,<br />

NASA, Procter & Gamble and more. H2Scan<br />

designed and built its new laboratory to<br />

its own specifications in a secured facility<br />

adjacent to its corporate offices.<br />

An H2Scan spokesman explains that the<br />

expanded laboratory has already paid<br />

dividends in increasing production and<br />

streamlining the company’s product delivery<br />

process. “This has allowed us to cut our<br />

backlog and shorten delivery times,” says<br />

Mike Nofal, H2Scan Vice President of Sales<br />

and Business Development. “With this<br />

resource, H2Scan becomes one of the most<br />

agile players in this market and we have the<br />

room to expand as the economy grows,”<br />

Nofal adds.<br />

“From an RTS Africa Technologies’<br />

perspective, thanks to the establishment of<br />

the new laboratory, we are pleased to be<br />

able to offer H2Scan’s enhanced range of<br />

instruments which will have the potential<br />

to improve the output of Africa’s many oil<br />

refineries,” concludes Fraser.<br />

About RTS Africa<br />

RTS Africa Group is a specialised, Tshwanebased<br />

company offering innovative<br />

technologies for - and solutions to - industrial<br />

challenges.<br />

Led by Managing Director Ian Fraser since its<br />

inception in the early 1990’s, the company<br />

offers globally-sourced, quality products<br />

via two operational divisions, namely RTS<br />

Africa Engineering (supplying inertial spin<br />

filters and hydrogen technology solutions);<br />

and RTS Africa Technologies (supplying all<br />

instrumentation-related solutions such as<br />

boiler tube leak detection, laser-based gas<br />

detection devices for hot or corrosive areas).<br />

Product delivery and technical consultation<br />

by highly trained staff is offered throughout<br />

Southern Africa to a range of clients in industry<br />

sectors such as mining, power generation,<br />

petrochemicals, glass, steel and energy.<br />

www.rtsafrica.co.za

FRONT COVER STORY<br />

THE STEP TOWARD A UNIVERSAL MEASURING INSTRUMENT<br />

Simple measurement of liquid levels: 80-GHz radar sensors VEGAPULS 64<br />

In 2016, VEGA introduced the VEGAPULS<br />

64, the first radar level sensor for<br />

liquids on the market that measures at a<br />

frequency of 80 GHz. This feature allows<br />

considerably better focusing of the radar<br />

beam. With VEGAPULS 64, measuring<br />

is much easier and more reliable, even<br />

under difficult conditions, such as tanks<br />

fitted with heating coils, baffles, or<br />

agitators.<br />

Until then, a radar sensor with a transmission<br />

frequency of 26 GHz and an 80 mm-diameter<br />

antenna had a beam angle of approximately<br />

10°. With the same size of antenna, the<br />

VEGAPULS 64 has a beam angle of only 3°.<br />

This allows the sensor to be used in vessels<br />

with internal installations or heavy build up<br />

on the walls, because the focused microwave<br />

beam simply avoids these obstacles.<br />

Radar sensors with a larger dynamic range<br />

have a higher measurement certainty, and<br />

these sensors can be used for a wider range<br />

of applications. With VEGAPULS 64, media<br />

with very poor reflective properties – a low<br />

dielectric constant – can be measured with<br />

more certainty than with previous radar<br />

sensors. Foam, turbulent product surfaces,<br />

condensation, or build up on the antenna are<br />

no problem. The radar level sensor measures<br />

more reliably due to its greater measurement<br />

certainty. It has an accuracy of +/-2 mm and a<br />

measuring range of up to 30 m.<br />

The device is ideal for wide use across<br />

industries ranging from demanding<br />

applications in the chemical industry to<br />

hygienic applications in the pharmaceutical<br />

and food industries. The relevant approvals<br />

for this sector, such as 3A and EHEDG, are<br />

available. The 80-GHz radar sensor can be<br />

used universally for the majority of industrial<br />

level applications. And since the sensor can<br />

also be equipped with the smallest antenna<br />

of its kind, there’s hardly a mounting location<br />

where it won’t fit.<br />

Your benefits with VEGAPULS 64 at a<br />

glance:<br />

• Ideal for use in vessels with small process<br />

connections, such as those used in<br />

the pharmaceutical, biotech, and food<br />

industries.<br />

• Media can be measured with much higher<br />

accuracy than ever before – right up to<br />

the process fitting and down to the very<br />

bottom of the container.<br />

With VEGAPULS 64, there is hardly a mounting<br />

location where it wouldn’t fit.<br />

• The new sensor can be easily installed<br />

using existing process connections,<br />

eliminating the need for costly equipment<br />

modifications.<br />

• Since radar signals pass right through<br />

viewing windows and glass containers,<br />

the sensor can also be mounted outside<br />

containers.<br />

The article’s author, Juergen Skowaisa. He is<br />

Product Manager, Radar at VEGA’s headquarters<br />

in Schiltach, Germany.<br />

• The larger dynamic range provides a higher<br />

measurement certainty, especially when<br />

there is buildup, condensate, foam, or a<br />

turbulent liquid surface in the vessel.<br />

• Radar technology is immune to process<br />

conditions like changing temperature,<br />

pressure, and density. With VEGAPULS 64,<br />

levels can be measured in applications<br />

where the process and/or structural<br />

conditions were previously not suitable for<br />

radar.<br />

Radar level sensor VEGAPULS 64 for liquids is available in three antenna versions: With plastic horn<br />

antenna of PP, thread with integrated horn antenna, or flange with encapsulated antenna system.<br />

For more information:<br />

www.vega.com/radar.<br />

5

IPP & Renewables<br />

IN-DEPTH MATERIAL KNOWLEDGE - A ‘VITAL’<br />

SERVICE TO THE PETROCHEMICAL SECTOR<br />

The South <strong>African</strong> petrochemical industry plays a<br />

significant role in the local economic growth so desperately<br />

required in South Africa currently. The sector is under<br />

pressure from many reasons including the trend towards<br />

the reduction of operational carbon footprint, there is also<br />

a proliferation of new technological developments.<br />

6<br />

These represent new and dynamic<br />

opportunities for the industry to exploit, if it<br />

can evolve apace with industry developments.<br />

This is an exciting and concerning time<br />

according to Glen Pringle, Director of Vital<br />

Engineering.<br />

“Looking at this exciting industry further<br />

afield, there is a myriad of positive<br />

developments throughout the rest of Africa,”<br />

Pringle observes.<br />

“Increased oil and gas exploration, potential<br />

new refineries and extensions to existing<br />

refineries are planned along the East and<br />

West <strong>African</strong> coasts. This is a clear indication<br />

that the greater petrochemical sector is<br />

definitely not stagnant,” he adds.<br />

Having been a key supplier of a wide<br />

range of products including gratings, stair<br />

treads, pressed pattern floors and safety<br />

handrails to the petrochemical, mining<br />

and other industries for the past 80 years,<br />

Vital Engineering is very well acquainted<br />

with the needs of the industry - and with<br />

developments in materials technology. This<br />

has placed the company in the privileged<br />

position of being able to continually meet<br />

the needs of their petrochemical clients<br />

by adapting and expanding their product<br />

ranges in line with international industry<br />

requirements and trends.<br />

“We are pleased to have a secure base of<br />

repeat business within the petrochemical<br />

sector - and a growing base of referred clients<br />

– Vital Engineering enjoys a reputation for<br />

supplying uncompromising quality products<br />

which are reliably produced on-time, onspecification<br />

and within budget,” he says.<br />

The petrochemical industry furthermore<br />

has very specific requirements of the<br />

construction materials used, depending on<br />

the particular context or application.<br />

Vital’s glass-fibre reinforced resin (GRP) or<br />

aluminium gratings are suitable for nonspark<br />

environments” Pringle points out.<br />

Petrochemical plants also produce certain<br />

products that could be either mechanically or<br />

chemically aggressive and corrosive, acidic or<br />

alkaline in nature - representing yet another<br />

set of limitations and specific requirements<br />

regarding the construction materials of choice.<br />

“As we thoroughly understand the properties<br />

of our products, which are influenced by<br />

factors such as manufacturing method,<br />

structural configuration and chemical<br />

additives, we can lend valuable support to<br />

our clients, so that the correct products are<br />

specified, leading to enhanced plant lifetime<br />

and performance - and, most importantly,<br />

reduced safety risks,” he adds.<br />

Vital Engineering’s products which are<br />

particularly popular in the petrochemical<br />

industry typically include its mini-mesh<br />

or solid top GRP products, aluminium or<br />

stainless-steel patterned plate products, and<br />

expanded metal products for applications<br />

such as safety guards, lock-out areas, and<br />

secure areas on petrochemical plants.<br />

“Our clients value the fact that our entire<br />

range of products - which includes mild<br />

steel, GRP, aluminium, ferritic and non-ferritic<br />

stainless steel - is manufactured according to<br />

the most stringent international standards,<br />

including ISO 9000 /15. Meaning they can<br />

rely on Vital Engineering to supply them with<br />

an exceptional quality product,” he continues.<br />

It is therefore no wonder that a growing<br />

number of clients have been specifying Vital<br />

Engineering’s product ranges in their designs.<br />

“Vital Engineering are extremely proud<br />

to be the supplier of choice to these<br />

consulting engineers and clients, and we<br />

truly go the extra mile to keep it that way.<br />

Vital engineering offer our clients many<br />

configurations with tailored products to<br />

meet their specific industry requirements as<br />

far as possible.<br />

We also do our best to provide them with<br />

valuable guidance and advice based on our<br />

deep-seated manufacturing knowledge<br />

of each product, and its suitability and<br />

application. We therefore invite clients<br />

to include us at the initial project design<br />

stage. Sometimes new product variations<br />

or material additives may have become<br />

available, which could make their design<br />

more optimal,” he remarks.<br />

“Our success is dependent upon that of<br />

our clients, and we are determined to<br />

continue providing this ‘vital’ service to the<br />

petrochemical sector,” concludes Pringle.<br />

About Vital Engineering<br />

Since 1939 Angus McLeod and Vital<br />

Engineering have established a reputation<br />

for quality and service in the manufacture<br />

of all types of gratings, stair treads, pressed<br />

floors and safety handrails. Its brand names<br />

of Vitagrid® and Maclock® have become<br />

synonymous with versatility, quality and<br />

service.<br />

The Group offers a wealth of product<br />

expertise and has been involved in the<br />

supply to power plants, petrochemical<br />

plants, materials handling projects, mining,<br />

process plants, food, beverage as well<br />

as most facets of the civil and structural<br />

engineering industries, both domestically<br />

and internationally.<br />

A variety of products and materials for<br />

numerous applications are readily available,<br />

when either costs or corrosion are factors.<br />

The range includes bitumen dipped,<br />

galvanised (610g/m2) and mild steel. Other<br />

grades of materials such as SS304, SS316,<br />

structural grade aluminium and 3CR12 can<br />

also be manufactured.

PROTECTING THE LIVES OF YOUR<br />

GREATEST ASSET: YOUR TEAM.<br />

Protect personnel working within the blast zones of your facility with MineARC's<br />

comprehensively engineered ChemSAFE Blast Resistant Building range.<br />

Integrating blast, toxic gas, and optional fire protection with advanced monitoring<br />

and alert systems, the ChemSAFE BRB maximizes the safety of your personnel<br />

while providing a multi-purpose structure for everyday use.<br />

TOXIC GAS<br />

PROTECTION<br />

UP TO 10 PSI 200MS<br />

BLAST RATING<br />

ZERO AIR<br />

CHANGES PER<br />

HOUR<br />

INTEGRATED LIFE<br />

SUPPORT<br />

REMOTE<br />

MONITORING &<br />

DIAGNOSTICS<br />

For more information go to<br />

MINEARC.COM<br />

7

IPP & Renewables<br />

BMG’S SPANJAARD LUBRICANTS, OILS AND GREASES FOR EFFICIENT<br />

LUBRICATION IN MINING AND INDUSTRIAL APPLICATIONS<br />

BMG’s Spanjaard lubricants, oils and greases have been developed with the latest formulations and<br />

technologies, to meet the demands of all sectors, including mining, automotive, marine, general industry<br />

and consumer applications.<br />

“Included in this range are mining lubricants<br />

and allied chemicals, that offer solutions for<br />

the most difficult lubrication problems,” says<br />

Marc Gravett, BMG’s Business Unit Manager,<br />

Seals and Gaskets division. “Spanjaard<br />

lubricants and allied chemical products have<br />

been formulated to improve performance<br />

of equipment and machinery; to minimise<br />

operating costs and reduce maintenance<br />

requirements in heavy-duty applications.<br />

“Lubrication-related failures in machinery are<br />

generally preventable and can be avoided<br />

with the application of the correct lubricant.<br />

A general multipurpose grease is adequate<br />

in many applications, but more arduous<br />

operating conditions demand the selection<br />

of the correct lubricant and lubrication<br />

system. BMG takes cognisance of factors such<br />

as speed of relative movement, ambient and<br />

operating temperatures, loading, vibration<br />

and the environmental operating conditions.<br />

“The effects of friction and the resulting wear<br />

of moving components are significantly<br />

reduced by effective lubrication. The purpose<br />

of any lubricant - which may take the form of<br />

an oil, a grease or a solid - is to separate the<br />

mating surfaces and thereby reduce friction<br />

and wear. For this reason, lubrication is<br />

considered to be one of the most important<br />

aspects of most industrial equipment and<br />

machinery maintenance programmes Not<br />

only do lubricants, oils and greases extend<br />

the service life of machinery and equipment,<br />

but they also play an important role in<br />

enhancing performance of components, like<br />

bearings and industrial chain.”<br />

BMG’s range of Spanjaard industrial<br />

products includes anti-seize compounds<br />

and penetrants, assembly and disassembly<br />

products, chain lubricants, transmission<br />

oils, cleaners and degreasers, electrical<br />

maintenance products, plastic moulding and<br />

cutting compounds, as well as engineering<br />

and fabrication materials. Also available are<br />

a number of Spanjaard greasing solutions,<br />

including open gear lubricants and wire rope<br />

dressings; bearing and synthetic bearing<br />

greases, as well as other general grease<br />

products.<br />

Spanjaard EP2 multipurpose grease is an<br />

all-purpose, lithium-based grease, which is<br />

fortified with rust and oxidation inhibitors<br />

and is suitable for lubrication of plain, needle,<br />

ball and roller bearings in mining equipment.<br />

Spanjaard 1345 wire rope dressing<br />

penetrates deep into the core of the rope<br />

for continued lubrication of the wire strands<br />

and protection against fretting. This dressing<br />

contains solid lubricants and anti-corrosion<br />

additives, to resist displacement by high-load<br />

pressures and water.<br />

Also in BMG’s Spanjaard range is an electric<br />

motor cleaner, which is a high flash-point<br />

safety solvent, specially developed for<br />

removing deposits on electric motor<br />

windings. This cleaner dissolves oil and<br />

grease and removes dust and grime from<br />

electrical and mechanical components and<br />

quickly evaporates, to minimise downtime.<br />

Spanjaard chain oil 718 is a medium viscosity<br />

chain lubricant, which is used on heavy plate<br />

conveyors and is also effective on creasing<br />

and cutting machines. This chain oil is based<br />

on a highly refined mineral oil and contains<br />

MoS2 that acts as an anti-wear agent<br />

and extreme pressure additive, providing<br />

lubrication when the chain is subjected to<br />

shock loads.<br />

The range also includes chain and linkage<br />

spray that contains low-friction, soluble<br />

molybdenum in a special lubricating base<br />

that penetrates like oil deep into linkages<br />

and lubricates like grease. This water-resistant<br />

spray is suitable for standard and “O” ring<br />

type chains, linkages and cables. 360° valve<br />

technology allows spraying at all angles,<br />

including upside down. This non-staining<br />

spray resists fling-off and remains adhered to<br />

surfaces in inaccessible places to give longlasting<br />

protection in demanding conditions.<br />

For further information<br />

Marc Gravett, Business Unit Manager,<br />

Seals and Gaskets division, BMG<br />

Tel: +27 (0) 11 620 1575<br />

Email: marcg@bmgworld.net<br />

Website: www.bmgworld.net<br />

BMG’s extensive range of sealing products<br />

encompasses Spanjaard lubricants, oils and greases,<br />

which are suitable for industrial, automotive,<br />

marine, mining and consumer applications.<br />

8

Namdock’s three floating dry docks will<br />

provide an ideal and efficient location for<br />

the repair of Angolan Navy vessels.<br />

NAMDOCK’S ‘NAVAL<br />

OFFENSIVE’ SECURES MILESTONE<br />

ANGOLAN NAVY MAINTENANCE CONTRACT<br />

In September 2019, in a milestone agreement, Namdock<br />

concluded a contract to maintain and repair the vessels of the<br />

Marinha de Guerra Angolana (MGA), the Angolan Navy.<br />

According to Namdock’s Commercial and Operations Manager, Willie<br />

Esterhuyse, although the contract has been concluded, the exact date<br />

when the vessels will be arriving in Walvis Bay has not been finalised,<br />

it is anticipated that this will be early in 2020.<br />

In terms of this agreement, Namdock will take two Angolan Navy<br />

vessels into its dry docks initially. However, there is a possible<br />

extension to this contract into 2020 to service the Navy’s other vessels<br />

as well as supplying related services and training.<br />

The Angolan Navy was founded in 1976 by the country’s first<br />

president Antonio Agostinho Neto. According to wiki.org, the Navy<br />

consists of some 40 vessels including fast missile craft, fast torpedo<br />

craft, coastal patrol boats and minesweepers. The Angolan news<br />

agency Angop reports that efforts are underway to enhance the<br />

effectiveness of the Angolan force. Emphasising the importance of<br />

the Angolan Navy, the chief of the General Staff of the Angolan Armed<br />

Forces has alluded to international terrorism which he says: ‘poses a<br />

serious threat to the Gulf of Guinea’ and neighbouring countries such<br />

as Angola.<br />

The conclusion of this contract required extensive negotiations which<br />

were started in 2017. Representatives of the MGA visited Walvis Bay<br />

to inspect Namdock’s facilities, while the Namibian company also<br />

dispatched technicians to Luanda to inspect the naval vessels.<br />

Although the Angolan Navy is 42 years old, it is reported that<br />

maintenance and repairs have been carried out internally. “We are<br />

pleased to welcome this new customer to our shipyard which is<br />

arguably the most sophisticated and efficient on the West Coast of<br />

Africa,” continues Esterhuyse. In the recent past, Namdock’s has been<br />

fostering this cooperation with Angola and has carried out projects<br />

such as the repair of the Angolan Ministry of Fisheries (Pescangola)<br />

floating dry dock.<br />

He comments that the maintenance and repair of naval vessels does<br />

not require any skills that Namdock does not have. “We are used to<br />

working on naval vessels as we have been maintaining those of the<br />

Namibian Navy since our company’s inception in 2006,” he says.<br />

The first two vessels will be sailed from Angola and will undergo a<br />

turnkey maintenance operation at Walvis Bay, where all services such<br />

as dry docking, sandblasting, coating, mechanical, metalwork, valves,<br />

piping, engine work, electronics are fully available. As these vessels<br />

play a key part in the defence of Angola, Namdock will be bringing all<br />

its experience and expertise to bear to effect a rapid turnaround.<br />

“This contract is further testimony to the successful collaboration that<br />

we have had with other Angolan Ministries and clearly demonstrates<br />

the shipyard’s capacity and outstanding, effective and efficient<br />

performance to date.”<br />

The award of this contract follows an eventful year for Namdock<br />

marked by the steady increase in yard activity and significant growth<br />

in enquiries that have translated into confirmed yard bookings.<br />

“This has progressively allowed us to overcome the depressed<br />

economic cycle that has constrained our industry since 2016,” explains<br />

Namdock’s Acting CEO Heritha Nankole Muyoba.<br />

“As industry leaders, our core values of trust, excellence and integrity<br />

have assisted us in gaining recognition as the preferred ship repair<br />

partner along the West Coast of Africa,” she continues.<br />

“This Angolan contract is a proud milestone for us in the development<br />

of our company and our continuing ability to make a meaningful<br />

contribution to our Namibian economy,” Nankole Muyoba concludes.<br />

9

IPP & Renewables<br />

SENTINEL LAUNCHES NEW 6 CHANNEL MOBILE DVR<br />

Sentinel Systems has introduced a brand new state-of-the-art 6 channel mobile DVR system, a compact recording<br />

unit for vans and commercial vehicles as part of the company’s range of intelligent surveillance systems.<br />

The new Sentry S60 series AHD DVR is a sleek and robust design<br />

allowing for easy installation and access when required. It has GPS<br />

and G-shock recording as standard, bespoke alarm inputs and remote<br />

monitoring/ download making this a comprehensive package for any<br />

vehicle whether an owner driver or large fleet.<br />

This cost-effective system has up to 2TB hard disk storage space<br />

and can be connected to up to six of Sentinel’s cameras, including<br />

reversing, side and forward facing cameras for an all-round view of<br />

the vehicle. There are an additional two channels also available to use<br />

if required at a later date. The hard disk memory can be accessed by<br />

hard wire, Wi-Fi and 3G/4G download, meaning that Live View can be<br />

seen remotely by logging in via the internet to the Sentinel hosted<br />

latest Microsoft Azure server.<br />

Allan Robertson, Director at Sentinel Systems commented, “This is<br />

an incredibly versatile mobile DVR system with a lot of advanced<br />

features. The new technology is ideal for installation in<br />

large and small vans and commercial vehicles<br />

at an extremely affordable price. We<br />

believe that it is important to provide<br />

an affordable fully featured high quality<br />

surveillance system for all road users to<br />

promote overall enhanced safety on our<br />

roads.”<br />

Designed to provide the ultimate protection for cyclists, pedestrians<br />

and other vulnerable road users, Sentinel’s systems assist in safer<br />

operations for commercial vehicles and provide drivers and operators<br />

with the confidence that they are not a threat to the public. Sentinel’s<br />

camera systems, in particular, provide an enhanced view of the<br />

vehicle’s surroundings which can allow drivers to safely manoeuvre in<br />

tight or congested areas.<br />

When combined with Sentinel’s Sentry S60 Series AHD DVR, the<br />

camera systems provide the ultimate protection for road users as they<br />

capture crucial video evidence of accidents, theft or fraudulent claims.<br />

The recorded footage may be extracted to provide evidence for court<br />

hearings and can save companies or drivers a significant amount of<br />

money in insurance claims whilst protecting themselves from fines<br />

and prosecution.<br />

Sentinel Systems has introduced a brand new<br />

state-of-the-art 6 channel mobile DVR system, a<br />

compact recording unit for vans and commercial<br />

vehicles as part of the company’s range of<br />

intelligent surveillance systems. The new Sentry<br />

S60 series AHD DVR is a sleek and robust design<br />

allowing for easy installation and access when<br />

required. It has GPS and G-shock recording<br />

as standard, bespoke alarm inputs and remote<br />

monitoring/ download making this a comprehensive package for any<br />

vehicle whether an owner driver or large fleet.<br />

10<br />

The new AHD mobile DVR system boasts six channels of superior AHD<br />

quality and an additional two channels in IP high definition, and is<br />

specially designed for intelligent application as part of vehicle safety<br />

and surveillance systems.<br />

With the increasing number of false claims and crash-for-cash<br />

incidents, recording footage from vehicle-mounted cameras using a<br />

Sentinel MDVR gives irrefutable evidence in the event of an incident<br />

so saving money, protecting drivers and providing peace of mind.<br />

Despite being small and discreet Sentinel’s camera systems are visible<br />

across the vehicle which may act as a warning to potential burglars.<br />

When they notice the cameras they are fully aware that they are<br />

captured on video which may encourage them to destroy all evidence<br />

should they know where to find it. Sentinel Systems has designed the<br />

Sentry S60 Series AHD DVR with lockable hard drive and back up SD<br />

card to prevent this from happening and to preserve all evidence that<br />

drivers and operators will need to prosecute.<br />

The new Sentry S60 Series AHD DVR unit is cleverly designed with<br />

anti-vibration technology to allow the system to be mounted<br />

anywhere within the vehicle and still operate efficiently. This<br />

technology protects the hard disk drive and recorded images even<br />

when operated in the most arduous terrain and environments.<br />

Like Sentinel’s other DVR devices, the Sentry S60 Series AHD DVR<br />

recorder houses an internal GPS system for location tracking as well<br />

as a built in inertia sensor and LED indicators to ensure the driver that<br />

the system is working at a glance. The system can provide up to 30<br />

days of recording at an effective lower cost than other comparable<br />

systems on the market.<br />

Should any of Sentinel’s systems require installing or servicing,<br />

the company’s team of engineers based throughout the UK are<br />

available 24/7 for customer support and maintenance to keep vehicle<br />

downtime to a minimum. This also ensures that vehicles and drivers<br />

are not unprotected whilst on the road.<br />

Further information:<br />

Tel: 012 85 7 71333<br />

Email: sales@sentinelsystems.co.uk<br />

Website: www.sentinelsystems.co.uk

AIR PRODUCTS ENDS 50 TH BIRTHDAY<br />

YEAR ON HIGH NOTE<br />

Air Products celebrated its 50 th birthday this year and ended<br />

it on a high note by receiving two awards at the Chemical &<br />

Allied Industries’ Association (CAIA) Responsible Care Awards<br />

Ceremony which was held in Johannesburg recently. One of<br />

the awards was focused on safety and the other was a great<br />

achievement for the company, as it is the first industry award<br />

received for their #WitnessHappiness project.<br />

The annual prestigious CAIA Responsible Care Awards is a highlight<br />

on the industry calendar and an opportunity for members to<br />

showcase their projects, initiatives and successes.<br />

Despite fierce competition the safety award, the 2019 Responsible<br />

Care Sustained High Performance Award, was awarded to the<br />

Pinetown Facility in Category A. Air Products’ General Manager -<br />

Technical, Maropeng Bahula, commented on the award: “We are<br />

extremely honoured to receive this award as safety is a crucial element<br />

in processes throughout our entire organization. It is good to see that<br />

our efforts to make safety a way of life for employees are noticed and<br />

embraced by all. At Air Products we embrace the ethos that “nothing is<br />

more important than safety”.<br />

The second award was the 2019 Responsible Care Initiative of the<br />

Year Award Winner for Corporate Social Responsibility Projects in<br />

Category B. According to Arthi Govender, Market Research and<br />

Strategy Manager at Air Products who conceptualised the project,<br />

the award coincided with the end of the of the first three year cycle<br />

of the #WitnessHappiness project. Govender explains that the project<br />

started three years ago and the employees at each of the facilities<br />

nationally had to select an early childhood development (ECD) centre<br />

in their community to support for a period of three years.<br />

Air Products’ proud recipients of the CAIA Awards.<br />

L – R: Arthi Govender, Sue Nicholls and Maropeng Bahula.<br />

She further explains: “Our Corporate Social Responsibility (CSR)<br />

Committee agreed to the project approximately three years ago and we<br />

committed to different centres nationally. During this three-year cycle,<br />

employees could visit the centres and spend time with the children on<br />

specific days. The children also received gifts and other learning aides,<br />

and infrastructure improvements were done at a number of them to<br />

ensure a safe and hygienic environment for the children.<br />

Govender further mentions that this is the first award received for the<br />

#WitnessHappiness project. The second three-year cycle has already<br />

started. “I cannot wait to see what joy, happiness and positive change<br />

the next three year cycle will make at the newly selected centres.<br />

For more information on Air Products:<br />

Website: www.airproducts.co.za<br />

Book your advert and<br />

editorial space for<br />

IPP & Renewables<br />

2020<br />

editions<br />

011 083 5125<br />

accounts@africanpetrochemicals.co.za<br />

www.africanpetrochemicals.co.za<br />

11

IPP & Renewables<br />

ENGEN AND CLICKS PARTNER IN A WINNING LOYALTY FORMULA<br />

Engen and Clicks have announced<br />

an exciting new partnership which<br />

rewards motorists every time they fill<br />

up and swipe their Clicks ClubCard at<br />

participating Engen service stations<br />

nationwide.<br />

This partnership brings Engen, South Africa’s favourite petrol station<br />

brand*, and Clicks ClubCard, the country’s leading retail loyalty<br />

programme** together in a boon for motorists.<br />

“This winning formula will now provide all Clicks ClubCard `customers<br />

with a truly convenient loyalty engagement and easier cashback earn,<br />

one we are extremely excited and proud to be a part of,” says Seelan<br />

Naidoo, Engen General Manager: Retail.<br />

Engen operates over 1 000 service stations across South Africa, far<br />

exceeding its nearest competitor.<br />

Adds Naidoo: “As Engen continues to have South Africa’s largest<br />

service station footprint, it makes sense for us to partner with<br />

Clicks ClubCard, which is South Africa’s number one retail loyalty<br />

programme.”<br />

To sweeten the deal, for the first two months of the partnership -<br />

during December 2019 and January 2020 - Clicks ClubCard members<br />

can earn double points every day when they fill up with Engen Primax<br />

Unleaded or Engen Dynamic Diesel 50ppm at participating Engen<br />

service stations.<br />

“It’s simple: the more litres of fuel you buy, the more points you earn,<br />

the greater your cashback,” says Naidoo.<br />

Exactly what you get:<br />

• 1 litre = 1 point. For every litre of Engen Primax Unleaded or<br />

Engen Dynamic Diesel 50ppm you buy at participating Engen<br />

service stations nationwide, you earn one ClubCard point.<br />

• Double points every day from 1 December 2019 to 31 January<br />

2020 (1 litre = 2 points).<br />

• Cashback is loaded six times a year and can be redeemed<br />

Online at www.clicks.co.za and at all Clicks, Claire’s and Body<br />

Shop stores nationwide.<br />

• To join ClubCard, and for a list of participating Engen service<br />

stations, download the Clicks App via Google Play or on the<br />

Apple iStore or visit https://clicks.co.za/clubcardpartnerspage<br />

Top Brands, where it has been voted South Africa’s favourite “Petrol<br />

Station” every year from 2011 to 2019 and the Sunday Times<br />

Generation Next, where the youth have voted Engen the country’s<br />

“Coolest Petroleum Brand” for 10 consecutive years (2010-2019). These<br />

accolades are further endorsed with Engen being recognised as the<br />

fastest growing brand in the country***.<br />

“Engen is eager to welcome all Clicks ClubCard members to our<br />

forecourts and looks forward to making you Number One,” says Naidoo.<br />

For further details please contact:<br />

Gavin Smith, Engen’s External Communications Manager<br />

Tel: 021 403 4312<br />

Email: gavin.smith@engenoil.com<br />

Chief Commercial Officer at Clicks, Rachel Wrigglesworth says the<br />

company has heeded customer’s requests and is pleased to offer<br />

them even more convenience.<br />

“With Engen having the largest network in the country, it is now even<br />

easier to visit, fill up and earn cashback on your Clicks ClubCard,” says<br />

Wrigglesworth.<br />

Engen’s enduring brand promise ‘With us you are Number One’ is<br />

about always going the extra mile and delighting customers. Naidoo<br />

assures that this is the focus of every decision and action of Engen.<br />

12<br />

“This partnership with Clicks ClubCard further strengthens our winning<br />

recipe by adding to our already exclusive premier relationships with<br />

FNB eBucks and Edgars Thank U. Once again, we are making our<br />

customers our Number One priority by offering them the benefits from<br />

three of the top six loyalty programmes in South Africa,” he adds.<br />

This spirit of constant innovation has catapulted Engen to the<br />

forefront of the South <strong>African</strong> motorists’ imagination, explaining<br />

the company’s enduring success in surveys like the Sunday Times<br />

*As voted in the Sunday Times Top Brands for nine consecutive years from 2011 to 2019.<br />

** Clicks Clubcard scored top spot as the Best Retail Loyalty Programme in the 2019 Truth<br />

Loyalty Awards<br />

*** As recognised by Brand Finance in partnership with Brand South Africa(Brand Finance<br />

South Africa 50 2019 report)

Tekflo Nylon Ball Valves are<br />

ideal for arduous applications<br />

INCLEDON LAUNCHES<br />

LATEST TEKFLO NYLON<br />

BALL AND CHECK VALVES<br />

Nylon ball and check valves designed and<br />

developed for irrigation and agricultural<br />

applications have been introduced by<br />

Incledon, a leading provider of quality<br />

fluid conveyance products and solutions.<br />

Featuring a nylon body with a steel ball and<br />

stem, Tekflo nylon ball valves are particularly<br />

suited for such arduous applications in<br />

that they are resistant to hydrocarbons and<br />

various harsh chemicals. The valves have a<br />

nominal pressure of 1.6 MPa, with a working<br />

temperature of –20°C to 120°C, and are<br />

available in sizes from 15 mm to 50 mm.<br />

Additional features include a low thermal<br />

conductivity, a higher corrosion resistance<br />

than traditional metal, a light weight for easy<br />

installation, high resistance to freezing and<br />

high temperatures, a high UV resistance, a<br />

low material cost compared to brass, and a<br />

BSP thread.<br />

With similar features and applications, Tekflo<br />

nylon check valves boast a nylon body, a<br />

polycarbonate disc, a SS304 spring, a BSP<br />

thread, and a working temperature range<br />

of –20°C to 120°C. Suitable for use where<br />

water is a medium, the valves are designed to<br />

handle a nominal pressure of 1.6 MPa.<br />

Incledon distributes products utilised in the<br />

conveyance of water, gases and liquids. It has<br />

the largest and widest consolidated quality<br />

product offering in order to service the diverse<br />

industries it operates in and is well-positioned<br />

to take advantage of the government’s<br />

infrastructure development programmes.<br />

Today Incledon has branches in every major<br />

South <strong>African</strong> city, with a formidable national<br />

footprint, including Bloemfontein, Upington,<br />

Cape Town, Durban, East London, George,<br />

Johannesburg, Mbombela, Polokwane, Port<br />

Elizabeth, Secunda and Rustenburg in order<br />

to ensure that customer service remains the<br />

top priority.<br />

About Incledon<br />

Incledon stocks over 15 000 preferred<br />

products and provides a wide range of<br />

approved and highly recognised brands<br />

of pipes, fittings, valves, flanges, rigid pipe<br />

working tools & threading machines, HDPE,<br />

compression fittings, pumps, electro-fusion<br />

fittings, windmills, sprinkler systems, water<br />

meters, residential, commercial & golf<br />

irrigation systems, plumbing products and<br />

related products used in the engineering,<br />

mining, municipal, civil, plumbing merchant<br />

and irrigation markets. All product and<br />

company information available at www.<br />

incledon.co.za.<br />

Incledon Contact<br />

Charmaine Munian, Marketing Manager<br />

Tel: (011) 323 0800<br />

Email: charmaine.munian@incledon.co.za<br />

Web: www.incledon.co.za<br />

360° Integrated<br />

Customer Application<br />

Solutions<br />

It’s all in the outcome<br />

Afrox’s 360° Integrated Customer Application Solutions<br />

and Safety Solutions Programmes for the energy,<br />

transport, mining and fabrication industries offer<br />

customers innovative solutions that increase productivity,<br />

lower production costs, and improve quality. From<br />

identifying customers’ gas and welding challenges to<br />

developing a complete solution in partnership with the<br />

customer, Afrox’s 360° Integrated Customer Application<br />

Solutions maximise value at the lowest possible cost in a<br />

highly safe environment..<br />

Africa’s leading gases and welding solutions partner<br />

Customer Service Centre: 0860 020202 Shop online: www.afroxshop.co.za www.afrox.co.za<br />

IntSolutions 190x130.indd 1 2018/11/13 15:45<br />

13

IPP & Renewables<br />

KEEPING UP WITH INDUSTRY CHANGES IS THE ONLY WAY TO MANAGE<br />

CONNECTIVITY EXPENDITURE<br />

By Vishal Barapatre, Chief Technology Officer at In2IT Technologies<br />

The connectivity space has changed<br />

drastically in the last decade mainly due<br />

to the decreasing cost of connectivity<br />

year on year. While the cost of bandwidth<br />

continues to come down, the stability<br />

and security of connectivity available<br />

to businesses have increased. Thanks to<br />

changes in technology from Leased Lines,<br />

Multiprotocol Label Switching (MPLS)<br />

and Internet through to SD-WAN and<br />

dedicated connectivity with broadband,<br />

and now the evolution from 4G to 5G<br />

- businesses no longer have to choose<br />

between speed and capacity when it<br />

comes to commercial connectivity. Soon<br />

5G will be the new enterprise standard,<br />

making it essential to pay attention to<br />

this evolution and invest in connectivity<br />

that is modern, relevant and capable, or<br />

risk being left behind as other businesses<br />

power on ahead, fuelled by connectivity<br />

that matches their digital ambitions.<br />

14<br />

The new speed of business<br />

As more businesses take to the cloud and<br />

explore the opportunities in the Internet<br />

of Things services and technologies,<br />

there is a growing pressure to provide the<br />

connectivity that can handle such varied,<br />

intensive demands. One of the key trends<br />

influencing the speed at which we can do<br />

business is the move to the cloud. To get<br />

there, organisations require robust, secure<br />

connectivity in order to take advantage of<br />

modern cloud architecture that requires<br />

enhanced integration between apps in order<br />

to execute their functions.<br />

Another factor reinforcing the need for<br />

better connectivity a rapidly growing mobile<br />

workforce - according to Strategy Analytics’<br />

‘Global Mobile Workforce Forecast Update<br />

2017-2023’, the world’s mobile workforce will<br />

swell to 1.88 billion people and account for<br />

43.3% of the workforce total in 2023. In order<br />

to accommodate this shifting workforce<br />

dynamics, enterprises will need to establish<br />

secure, stable connectivity in order to evolve<br />

their technology consumption to become<br />

more open and agile.<br />

Investing in connectivity wisely<br />

While there are many connectivity options<br />

that businesses can invest in today, cost<br />

still remains a major concern for most,<br />

especially during an economic slump.<br />

However, given that business today is near<br />

impossible without Internet connectivity,<br />

it’s important to bear in mind that it’s not<br />

a luxury, it’s an absolute necessity. For<br />

example, we have seen organisations move<br />

from MPLS to Internet-based connectivity,<br />

effectively cutting costs by as much as 50%.<br />

Furthermore, businesses now have greater<br />

choice, and for global companies, it’s now<br />

possible for each branch location to choose<br />

a provider that offers the best services at<br />

an affordable price and delivers on their<br />

promises.<br />

It’s a digital evolution not a revolution<br />

For employees that do their best work<br />

outside of the office, 4G and 5G now offer<br />

the best flexibility and choice for businesses,<br />

especially smaller organisations, as there<br />

is the added benefit of choosing when<br />

to use the service, effectively providing<br />

connectivity on-demand. SD-WAN still has<br />

an important role to play in reducing costs,<br />

improving security, enhancing agility and<br />

help build a platform for future technology<br />

innovation, because it is still one of the most<br />

effective ways to connect business network<br />

endpoints, like branch offices and data<br />

centres, creating adaptive networks to suit<br />

specific organisational needs while lowering<br />

operational costs, gradually shifting IT models<br />

toward consuming architecture, applications<br />

and business functionality as a service.<br />

The cost of ensuring sustainability and<br />

relevance<br />

While the biggest cost associated with<br />

connectivity today is the recurring annual<br />

cost of bandwidth along with operational<br />

spend, both expenditures are critical<br />

to secure sustainability and relevance.<br />

Ultimately, the best financial outcome is<br />

only possible when companies do their due<br />

diligence and plan ahead when investing in<br />

connectivity. Additionally, organisations need<br />

to remember that speed of the connectivity<br />

alone is insufficient for sustainability, and<br />

thus they should place just as much emphasis<br />

on security measures that will both protect<br />

and enable every connection that the<br />

business requires.<br />

Contacts<br />

Vishal Barapatre<br />

In2IT Technologies<br />

Tel: 011 054 6900<br />

Email: vishal@in2ittech.com

Pumps • Valves • Systems<br />

RPH process pump – robust, reliable, efficient and<br />

now to API 610 11 th edition<br />

The RPH process pump for the chemical and petrochemical industries is a horizontal,<br />

radially split volute casing pump designed for flow rates of up to 4800 cubic metres per hour<br />

and pressures of up to 110 bar. It meets all requirements of API 610,11th edition and<br />

ISO 13709 (heavy duty).<br />

Benefits of the RPH Process pump:<br />

• Low maintenance costs<br />

• Low operating costs<br />

• Long service life of mechanical seal and bearings<br />

• High flexibility<br />

• Reliable and robust<br />

• Economical<br />

KSB Pumps and Valves (Pty) Ltd<br />

www.ksb.com/ksb-za<br />

15

IPP & Renewables<br />

THREE MYTHS OF LUBRICATION THAT NEED BUSTING<br />

As specialists in lubrication reliability<br />

solutions, the team at Lubrication<br />

Engineers (LE) South Africa frequently<br />

comes up against myths relating to<br />

lubricants. “People believe things<br />

or are taught things about oils and<br />

greases that are not necessarily<br />

true, and by implementing this bad<br />

advice or outdated practices, they<br />

risk compromising their equipment,”<br />

says Callum Ford, National Marketing<br />

Manager at LE South Africa. “We try<br />

to educate the market about best<br />

practice to help raise the bar and fight<br />

misinformation.”<br />

These are the three most common myths the<br />

company comes up against:<br />

16<br />

1. The colour of a lubricant affects its<br />

efficacy<br />

“We often have people phoning us up and<br />

saying things like, ‘I want the red lubricant<br />

because it’s the best.’ In truth, the colour of a<br />

lubricant is normally something that is added<br />

as a marketing tactic or to differentiate it<br />

from other products – it has no bearing<br />

on the effectiveness of the lubricant itself,”<br />

says Ford. “The most important aspect of<br />

lubrication choice is selecting a product that<br />

is best suited for your particular application.”<br />

Ford explains that LE South Africa uses colour<br />

in its products to differentiate between<br />

product types. Edible lubricants are white;<br />

lithium-based lubricants are yellow; opengear<br />

lubricants are purple and lubricants for<br />

cars and trucks (especially oils) are red. Some<br />

companies, on the other hand, will colour<br />

lubricants to match their brand colours.<br />

2. Grease it until it leaks<br />

Ford says that this line of thinking holds that<br />

greasing machinery with more lubricant<br />

means you will have to re-apply the product<br />

less often. However, overlubricating can<br />

create problems instead of resolving them.<br />

“Overgreasing equipment will mean the<br />

lubricant begins to work against itself,<br />

causing internal friction,” he explains. “This<br />

can lead to temperatures rising in the<br />

machine, seals collapsing, and even eventual<br />

equipment failure. For optimal performance,<br />

you need the right lubricant applied at the<br />

right frequency and in the right dosage.<br />

This is why lubrication schedules are<br />

important, and why many companies are<br />

moving to single-point lubrication systems,<br />

which automatically dispense lubrication<br />

into machinery in optimal quantities at set<br />

intervals.”<br />

3. A grease is a grease<br />

Not all greases are created equal. Some are<br />

the consistency of honey; others of peanut<br />

butter; still others of toffee. Naturally, these<br />

greases will behave differently.<br />

“When it comes to grease viscosity, there’s<br />

a scale created by the National Grease<br />

Lubricating Institute (NLGI) ranging from<br />

000 to 6, representing very low to very high<br />

viscosity greases,” says Ford. “Equipment<br />

manufacturers will specify the NLGI grade<br />

required on the equipment. If it specifies<br />

NLGI 002 and you’re using NLGI 3, you’re<br />

going to run into problems, because the<br />

grease penetration is different.”<br />

Furthermore, even greases with the same<br />

NLGI rating will behave differently depending<br />

on the base and additives with which they<br />

are made. “For example, I use a test machine<br />

we call a ‘rat trap’ to show clients how two<br />

lubricants with the same NLGI grade react<br />

to the same force or pressure over time.<br />

The one lubricant disperses from the joint<br />

where it’s been applied much quicker than<br />

the other, loses its tackiness and heats up far<br />

more quickly. This is why we take the time<br />

to understand what the specific lubrication<br />

application is, and what a customer needs<br />

before we recommend a product. Each of<br />

our unique, proprietary additives has been<br />

designed to yield specific benefits.”<br />

About Lubrication Engineers<br />

Lubrication Engineers (LE) South Africa<br />

represents the LE brand in South Africa,<br />

Botswana, Namibia, Mozambique, Zimbabwe<br />

and Zambia. LE hold the rights to Southern<br />

Africa on the LE brand, recognised<br />

internationally as a specialist in lubrication.<br />

Through LE Incorporated, they are a member<br />

of a worldwide network of companies<br />

spanning Europe, South America, Asia and<br />

Africa, while LE Incorporated operates in the<br />

USA and covers North America including<br />

Canada, Mexico and the USA.<br />

LE provides high performance, heavy-duty,<br />

quality lubricants for virtually every industry<br />

and application, as well as expert technical<br />

back-up and support.<br />

For more information:<br />

www.lubricationengineers.co.za<br />

Contact:<br />

Callum Ford<br />

National Marketing Manager, LE<br />

Tel: 011 464 1735<br />

Email: callum@lubricationengineers.co.za

EMERSON RELEASES NEW MAGNETIC SLURRY SENSOR AND TRANSMITTER<br />

DESIGNED TO HELP CUSTOMERS CUT THROUGH THE NOISE<br />

Flow measurement solution helps improve product quality, reduce<br />

raw material cost and minimise waste and re-work.<br />

Emerson’s new slurry magnetic<br />

flow meter designed for high<br />

noise slurry applications.<br />

Emerson’s Rosemount MS Slurry Sensor<br />

with the Rosemount 8782 Slurry Transmitter<br />

is a slurry magnetic flow meter specifically<br />

designed for high noise and slurry<br />

applications for use in the oil and gas, mining,<br />

and pulp and paper industries. Featuring<br />

robust coils and advanced signal processing,<br />

a responsive yet stable flow signal is possible<br />

even in high noise applications. With over<br />

25 years of experience delivering products<br />

for these challenging applications, the new<br />

Slurry Magnetic Flow Meter helps improve<br />

product quality, reduce raw material cost, and<br />

minimise waste and re-work.<br />

The Slurry Magnetic Flow Meter, or Slurry<br />

Mag, provides a flow measurement solution<br />

for customers with fluids that contain large<br />

solids, mining ore, pulp or sand, or that<br />

experience high process noise or signal<br />

instability. Featuring the latest advanced<br />

signal processing that is the first to adapt to<br />

changing process conditions in real time, the<br />

Slurry Mag eliminates noise from the flow<br />

signal without using excessive damping,<br />

giving operators confidence in their<br />

measurement calculations.<br />

Accurate measurement of process flow<br />

rates is essential to running a plant or mill<br />

efficiently - that is why the Slurry Magnetic<br />

Flow Meter uses advanced signal processing<br />

with real-time diagnostics to deliver flow<br />

measurement confidence and the ability to<br />

automatically control the loop.<br />

The Slurry Mag Meter includes more<br />

standard diagnostics such as the grounding<br />

and wiring fault detection that helps ensure<br />

the meter is installed correctly the first time.<br />

Optional advanced process diagnostics help<br />

provide insight into performance through<br />

a high process noise detection diagnostic<br />

as well as enable proactive maintenance<br />

in applications where coating may be a<br />

concern, such as in pulp digester applications<br />

where pitch from the wood fibres may result<br />

in coating of the meter.<br />

Finally, the 8782 contains Emerson’s<br />

patented Smart Meter Verification<br />

capabilities providing a simplified means<br />

of troubleshooting or verifying the meter,<br />

taking a process that used to take hours and<br />

simplifying it down to minutes. While the<br />

8782 transmitter is designed to work with the<br />

MS sensor, it is also compatible with existing<br />

8707 installations making the performance,<br />

signal processing and advanced diagnostic<br />

capabilities available to anyone who is<br />

already using Emerson’s solutions for these<br />

challenging applications.<br />

“Through the utilisation of advanced<br />

features, the Rosemount Slurry Magnetic<br />

Flow Meter can help our customers better<br />

achieve their operational goals,” said Laura<br />

Chemler, product manager with Emerson’s<br />

Automation Solutions business. “The<br />

advanced signal processing is able to adapt<br />

to changing flow rates without getting<br />

bogged down by traditional damping<br />

practices, providing more accurate flow<br />

rate feedback when it’s needed most which<br />

in turn helps to ensure an efficient overall<br />

process that minimises waste and optimizes<br />

utilization of precious resources.”<br />

To learn more, please visit:<br />

www.Emerson.com/RosemountSlurryMagnetic<br />

About Emerson<br />

Emerson (NYSE: EMR), headquartered<br />

in St. Louis, Missouri (USA), is a global<br />

technology and engineering company<br />

providing innovative solutions for customers<br />

in industrial, commercial, and residential<br />

markets. Our Emerson Automation Solutions<br />

business helps process, hybrid, and discrete<br />

manufacturers maximize production, protect<br />

personnel and the environment while<br />

optimizing their energy and operating costs.<br />

Our Emerson Commercial and Residential<br />

Solutions business helps ensure human<br />

comfort and health, protect food quality<br />

and safety, advance energy efficiency, and<br />

create sustainable infrastructure. For more<br />

information visit: Emerson.com/MEA<br />

Additional resources:<br />

• Join the Emerson Exchange 365<br />

Community<br />

• Connect with Emerson’s Automation<br />

Solutions business via Twitter Facebook<br />

LinkedIn YouTube<br />

Further information:<br />

Devesh Roopnarain, Area Director<br />

Southern Africa, Emerson Automation<br />

Solutions.<br />

Email: Devesh.Roopnarain@Emerson.com<br />

17

IPP & Renewables<br />