African Petrochemicals- 16.1 2019

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ZWICK FOR MOLTEN SULPHUR OR SULPHUR TAIL GAS<br />

If you work with Molten Sulphur or Sulphur Tail gas, please take time to read more.<br />

Design engineers at Zwick in Germany have looked at solving on-going problems being<br />

experienced with valves on sulphur units.<br />

Typical valve problems on large bore line sizes range from seizing of the packing to severe<br />

seat damage when valve need to be operated after long periods of time of inactivity.<br />

Valves should be specified as steam jacketed valves as this is a standard mandatory type of<br />

valve requirement.<br />

Generally a standard valve may be suitable in an ideal line were<br />

there are never any shutdowns or upset conditions as once the<br />

valves body temperature has reached that of the hot sulphur or<br />

tail gas passing through it will not allow for any solidification,<br />

however in an upset condition were the valve body cools down<br />

with sulphur cooling also, then this will solidify in the bearing /<br />

shaft areas which will consequently generate a seizure of these<br />

elements.<br />

Based on international experience, Zwick engineers recommend the use<br />

of steam jacketed valves as these would maintain the critical areas under a<br />

constant temperature, thus eliminating any potential seizure.<br />

Zwick are capable of supplying valves in both wafer and double flanged style<br />

with steam jackets, and we can also apply a steam traced trim (stem and disc).<br />

Zwick Tri-Con series valves come with bearing protectors, which<br />

reduce the ingress of the medium into the critical areas, which<br />

coupled with the bearing flush purge ports constitute a true<br />

cleansing and protection of these critical areas.<br />

The following explanation highlights the technical differences<br />

between the Zwick Tri-Con valve and other manufacturers of valves ranging<br />

from double eccentric to unjacketed valves which will fail in this type of application.<br />

2<br />

The Zwick Tri-Con series valve is a specially designed process isolation, on/off and control<br />

valve, which has a wide range of application uses limited only by that of the actual<br />

materials used, in fact Zwick manufacture valves for applications which range from -196ºC<br />

up to +815ºC. Valves can be manufactured in any machinable form of alloy available on<br />

the market for specific client requirements.<br />

The Zwick Tri-Con series valve is a triple offset valve with true cone in cone design which<br />

totally eliminates any rubbing of the seats, hence eliminates any wear and tear which<br />

would generate leakages across the seat, this is technically not possible for other typical<br />

high performance valves, which means it is limited to a double eccentric design, rubbing<br />

sealing in the last 15-18º which will generate leakage as the time goes by.<br />

The other standard double eccentric are not designed for these severe applications<br />

therefore any attempt to use it for particular process applications may result in a<br />

problematic outcome.<br />

Self Centering disc<br />

With it’s unique self centering temperature compensating disc, the Tri-Con series<br />

construction guarantees the optimal position of the laminated seal against the seat.<br />

Jamming due to thermal expansion is therefore eliminated.<br />

The torque transmission with keys<br />

The disc is keyed to the shaft and not pinned, providing equal torque transmission and<br />

eliminating the danger of pins sheering off.<br />

Ideal lamination and disc design<br />

The strong disc with it’s elliptical supporting surface offers the best fixing of the<br />

lamination. The zero leakage is achieved by the special machining of thre lamination.<br />

Supporting bearing bushing<br />

The optimal position of the bearing reduces the bending of the shaft. This guarantees<br />

bi-directional tightness under maximum pressure.<br />

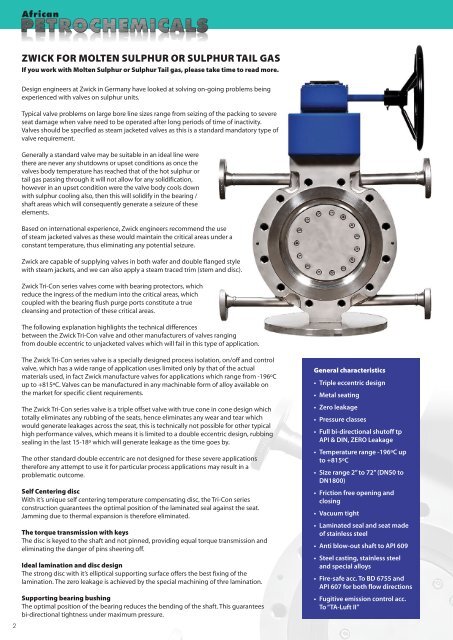

General characteristics<br />

• Triple eccentric design<br />

• Metal seating<br />

• Zero leakage<br />

• Pressure classes<br />

• Full bi-directional shutoff tp<br />

API & DIN, ZERO Leakage<br />

• Temperature range -196ºC up<br />

to +815ºC<br />

• Size range 2” to 72” (DN50 to<br />

DN1800)<br />

• Friction free opening and<br />

closing<br />

• Vacuum tight<br />

• Laminated seal and seat made<br />

of stainless steel<br />

• Anti blow-out shaft to API 609<br />

• Steel casting, stainless steel<br />

and special alloys<br />

• Fire-safe acc. To BD 6755 and<br />

API 607 for both flow directions<br />

• Fugitive emission control acc.<br />

To “TA-Luft II”