MEM47

Marine Engineers Messenger, Volume 3, Issue 47

Marine Engineers Messenger, Volume 3, Issue 47

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

POWER<br />

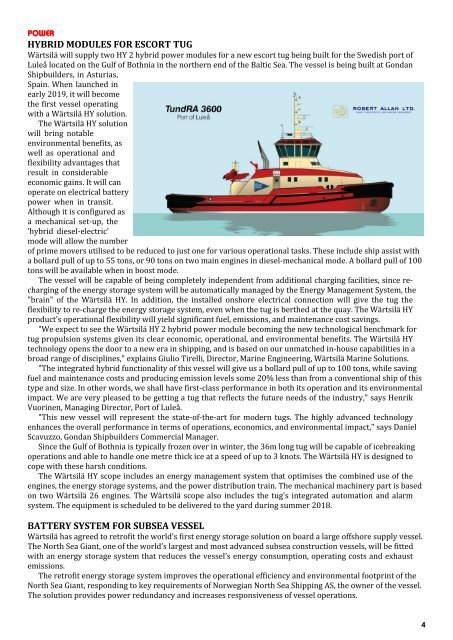

HYBRID MODULES FOR ESCORT TUG<br />

Wärtsilä will supply two HY 2 hybrid power modules for a new escort tug being built for the Swedish port of<br />

Luleå located on the Gulf of Bothnia in the northern end of the Baltic Sea. The vessel is being built at Gondan<br />

Shipbuilders, in Asturias,<br />

Spain. When launched in<br />

early 2019, it will become<br />

the first vessel operating<br />

with a Wärtsilä HY solution.<br />

The Wärtsilä HY solution<br />

will bring notable<br />

environmental benefits, as<br />

well as operational and<br />

flexibility advantages that<br />

result in considerable<br />

economic gains. It will can<br />

operate on electrical battery<br />

power when in transit.<br />

Although it is configured as<br />

a mechanical set-up, the<br />

'hybrid diesel-electric'<br />

mode will allow the number<br />

of prime movers utilised to be reduced to just one for various operational tasks. These include ship assist with<br />

a bollard pull of up to 55 tons, or 90 tons on two main engines in diesel-mechanical mode. A bollard pull of 100<br />

tons will be available when in boost mode.<br />

The vessel will be capable of being completely independent from additional charging facilities, since recharging<br />

of the energy storage system will be automatically managed by the Energy Management System, the<br />

"brain" of the Wärtsilä HY. In addition, the installed onshore electrical connection will give the tug the<br />

flexibility to re-charge the energy storage system, even when the tug is berthed at the quay. The Wärtsilä HY<br />

product's operational flexibility will yield significant fuel, emissions, and maintenance cost savings.<br />

"We expect to see the Wärtsilä HY 2 hybrid power module becoming the new technological benchmark for<br />

tug propulsion systems given its clear economic, operational, and environmental benefits. The Wärtsilä HY<br />

technology opens the door to a new era in shipping, and is based on our unmatched in-house capabilities in a<br />

broad range of disciplines," explains Giulio Tirelli, Director, Marine Engineering, Wärtsilä Marine Solutions.<br />

"The integrated hybrid functionality of this vessel will give us a bollard pull of up to 100 tons, while saving<br />

fuel and maintenance costs and producing emission levels some 20% less than from a conventional ship of this<br />

type and size. In other words, we shall have first-class performance in both its operation and its environmental<br />

impact. We are very pleased to be getting a tug that reflects the future needs of the industry," says Henrik<br />

Vuorinen, Managing Director, Port of Luleå.<br />

"This new vessel will represent the state-of-the-art for modern tugs. The highly advanced technology<br />

enhances the overall performance in terms of operations, economics, and environmental impact," says Daniel<br />

Scavuzzo, Gondan Shipbuilders Commercial Manager.<br />

Since the Gulf of Bothnia is typically frozen over in winter, the 36m long tug will be capable of icebreaking<br />

operations and able to handle one metre thick ice at a speed of up to 3 knots. The Wärtsilä HY is designed to<br />

cope with these harsh conditions.<br />

The Wärtsilä HY scope includes an energy management system that optimises the combined use of the<br />

engines, the energy storage systems, and the power distribution train. The mechanical machinery part is based<br />

on two Wärtsilä 26 engines. The Wärtsilä scope also includes the tug's integrated automation and alarm<br />

system. The equipment is scheduled to be delivered to the yard during summer 2018.<br />

BATTERY SYSTEM FOR SUBSEA VESSEL<br />

Wärtsilä has agreed to retrofit the world’s first energy storage solution on board a large offshore supply vessel.<br />

The North Sea Giant, one of the world’s largest and most advanced subsea construction vessels, will be fitted<br />

with an energy storage system that reduces the vessel’s energy consumption, operating costs and exhaust<br />

emissions.<br />

The retrofit energy storage system improves the operational efficiency and environmental footprint of the<br />

North Sea Giant, responding to key requirements of Norwegian North Sea Shipping AS, the owner of the vessel.<br />

The solution provides power redundancy and increases responsiveness of vessel operations.<br />

4