Automation Technologies 4/2014

Automation Technologies 4/2014

Automation Technologies 4/2014

- TAGS

- automation

- technologies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

international<br />

ONLINE Edition<br />

4<br />

October <strong>2014</strong><br />

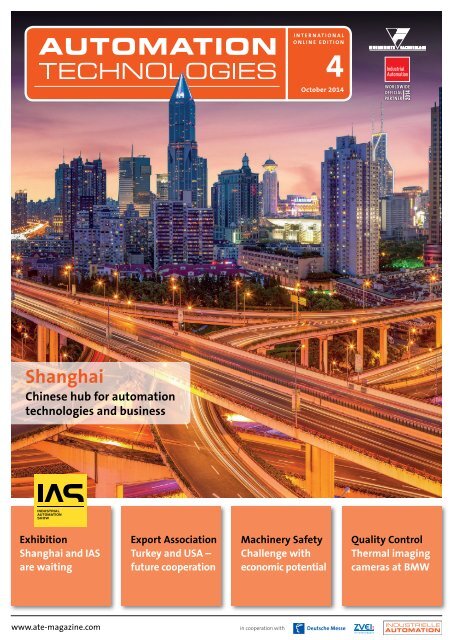

Shanghai<br />

Chinese hub for automation<br />

technologies and business<br />

Exhibition<br />

Shanghai and IAS<br />

are waiting<br />

Export Association<br />

Turkey and USA –<br />

future cooperation<br />

Machinery Safety<br />

Challenge with<br />

economic potential<br />

Quality Control<br />

Thermal imaging<br />

cameras at BMW<br />

www.ate-magazine.com<br />

in cooperation with

Editorial<br />

read editorial<br />

The future has begun<br />

Dear readers,<br />

Global competition and continuous market changes put pressure on the<br />

production industry. Costs must be reduced and profits maximised.<br />

This is also the case in China.<br />

Dirk Schaar<br />

AUTOMATION TECHNOLOGIES<br />

Andreas Wolf<br />

Hannover Fairs International<br />

AUTOMATION TECHNOLOGIES 4/<strong>2014</strong>

COLOMBIA<br />

SLOVAKIA<br />

table of content<br />

China is the place to be<br />

with its strong position in<br />

machine production<br />

Shanghai and the IAS Show<br />

<strong>2014</strong> are waiting<br />

The automation market<br />

in China from Bernstein’s<br />

perspective<br />

Turkish Machinery to expand<br />

in the US machinery market<br />

like us on facebook<br />

News and Markets<br />

The importance of<br />

photovoltaic for the<br />

agriculture in Nicaragua<br />

Connectivity at sea<br />

Humans working together<br />

with robots: safe and flexible<br />

Columns<br />

Editorial<br />

Product News / Imprint<br />

News and Markets<br />

Big picture: Balloon Fiesta at IMTS show in Chicago<br />

What do you expect from the Chinese automation market<br />

in the next years?<br />

The <strong>Automation</strong> Market in China from Bernstein’s perspective<br />

Turkish Machinery to expand in the US Machinery Market<br />

Plastics for longer life – a very special birthday tour<br />

Industrial <strong>Automation</strong> IA Beijing: Comprehensive solutions<br />

for intelligent manufacturing<br />

Global Machinery Safety: Challenge with economic potential<br />

sensors and measurement<br />

High-performance 2D laser scanner with integrated<br />

control interface<br />

Smart Wireless Technology helps improve leak detection<br />

control and drive technology<br />

The importance of photovoltaic for the agriculture in<br />

Nicaragua

www.escha.net<br />

Bright prospects for Industrial<br />

<strong>Automation</strong> North America<br />

High-performance 2D laser scanner<br />

with integrated control interface<br />

robotic<br />

Round connectors M12x1 | M8x1<br />

Drag-chain adapted<br />

10 million cycles<br />

Backgrounds and perspectives of the<br />

new USB 3.0 interface<br />

INDUSTRIAL COMMUNICATION<br />

Sercos and Rexroth help streamline servo-driven<br />

case packers<br />

Difficult conditions – Connectivity at sea<br />

Components and Software<br />

Working together with robots: safe and flexible<br />

Enclosures: more than just a housing<br />

Machine Vision<br />

Thermal imaging cameras in automotive quality<br />

control at BMW<br />

Torsion-resistant<br />

10 million cycles | 360°<br />

Weld-field immune<br />

IP67<br />

See you at Industrial <strong>Automation</strong> Show<br />

11-15 Nov. <strong>2014</strong> | Hall E3/B08<br />

ESCHA <strong>Automation</strong> Connectivity (Shanghai) Co., Ltd.<br />

2060 Duhui Road, Building F, 2nd Floor, Minhang District<br />

201108Shanghai |+862152968180| info.china@escha.net

News and Markets<br />

WIN EURASIA <strong>Automation</strong> 2015 will<br />

take place in March<br />

The 2015 WIN EURASIA <strong>Automation</strong><br />

- World of Industry, the<br />

international event for industrial<br />

technology and capital goods in<br />

Turkey, will take place from<br />

19-22 March 2015 at the Tüyap<br />

FairConvention and Congress<br />

Center in Istanbul. The event that is organized by<br />

Deutsche Messe AG in collaboration with<br />

Hannover Messe Bilesim Fuarcilik A.S. combines<br />

four trade fairs: Hydraulic & Pneumatic<br />

EURASIA, Otomasyon EURASIA, Electrotech<br />

EURASIA and Materials Handling EURASIA.<br />

Highlights will be the Industrial Activities<br />

Summit, company and product presentations,<br />

panel discussions and matchmaking program. In<br />

<strong>2014</strong>, 77,000 visitors attended the event and 1,950<br />

companies exhibited their products and services.<br />

www.win-fair.com<br />

WIN INDIA will return to New Dheli<br />

in December<br />

This year’s WIN INDIA - World of Industry, India’s<br />

international event for industrial technology and<br />

capital goods, will take place from 10-13 December<br />

<strong>2014</strong> at the Pragati Maidan exhibition centre<br />

in New Dheli. The event that is organized by<br />

Deutsche Messe AG in collaboration with<br />

Hannover Milano Fairs India combines four trade<br />

fairs: MDA INDIA, Industrial <strong>Automation</strong><br />

INDIA, Surface Technology INDIA and CeMAT<br />

INDIA. Highlights will be live demonstrations,<br />

application parks, industrial forums, the<br />

Purchase Managers’ Summit as well as an extensive<br />

networking program. In 2013, when the trade<br />

fair took place for the first time almost 11,500<br />

visitors attended the event.<br />

www.win-india.com<br />

New accreditation for CSA Group’s lab in Turkey<br />

CSA Group, a leading global organization in standards<br />

development and testing and certification<br />

services, is expanding local services with a new<br />

accreditation for its lab in Turkey. The new accreditation<br />

allows for testing of information technology<br />

equipment, uninterruptable power systems,<br />

machinery, lighting control systems, including LED<br />

modules, lighting fixtures and non-metallic materials<br />

under TS EN ISO/IEC 17025:2012. Since 2002,<br />

the lab in Izmir has been offering product safety<br />

tests and certification services for household appliances,<br />

AV equipment and electrical equipment.<br />

The lab plans to further expand its scope of services<br />

to meet growing client needs in the areas of machinery,<br />

LED Lighting, IT equipment and automotive.<br />

www.csagroup.org<br />

AUTOMATION TECHNOLOGIES 4/<strong>2014</strong>

TKD Kabel expanding international<br />

presence<br />

Ready-to-install<br />

cable carrier systems:<br />

e-chains ®<br />

For the first time, German-based cable specialist<br />

TKD Kabel will generate more than 50 % of its<br />

annual revenue in foreign markets. This achievement<br />

was made possible by the company’s<br />

expanded international presence. In the last two<br />

years alone, TKD has established three new<br />

national subsidiaries. This latest expansion began<br />

in October 2012 with the launch of TKD Italia,<br />

followed by TKD Cable Suzhou in China in the<br />

middle of last year and TKD Mexico at the end of<br />

2013. “Our three ‘youngsters’ have enjoyed strong<br />

growth from the beginning – and turned into a<br />

real fixture in their respective markets”, says<br />

Dr. Wilhelm Engst, CEO of TKD Kabel.<br />

+ chainflex ® cables<br />

= readychain ®<br />

www.tkd-kabel.de<br />

Binder opens subsidiary in<br />

Singapore<br />

Having already established subsidiaries in China,<br />

USA, France, UK, Sweden and the Netherlands<br />

“Binder Singapore” opened this month. The<br />

manufacturer of circular connectors continues<br />

with its company philosophy of strengthening<br />

the headquarters in Neckarsulm as the heart of<br />

the company and expanding its international<br />

presence. Managing shareholder Markus Binder<br />

is fully convinced of Singapore as a hub: “From<br />

there we can perfectly serve the local demands in<br />

South East Asia, India, Middle East and the Asia<br />

Pacific region with our broad portfolio.” Binder<br />

has moved into office and warehouse premises in<br />

the “Singapore German Centre”.<br />

www.binder-connector.de<br />

readychain ®<br />

is a pre-harnessed system that is<br />

ready to plug-and-play upon delivery. Available<br />

from 24 hours! ... plastics for longer life ®<br />

Request a free sample: Tel. +49 2203 9649-800<br />

readychain@igus.eu www.igus.eu/rc<br />

AUTOMATION TECHNOLOGIES 4/<strong>2014</strong><br />

Igus-englisch.indd 1 23.09.<strong>2014</strong> 15:12:23

News and Markets<br />

Deutsche Messe expands its industrial<br />

tradeshow portfolio in the U.S.<br />

Deutsche Messe AG has organized Industrial<br />

<strong>Automation</strong> North America in the U.S. since 2012<br />

and launched MDA North America in <strong>2014</strong>. The<br />

success of these two events underscores the<br />

ongoing re-industrialization trend in the U.S.,<br />

where low labor and energy costs are spurring on<br />

industrial production and filling manufacturers’<br />

order books. Following this trend, in 2016<br />

Deutsche Messe will organize three additional<br />

events – ComVac North America, Industrial<br />

Supply North America and Surface Technology<br />

North America – which cover compressed-air<br />

and vacuum technology, industrial subcontracting<br />

and surface treatment, respectively. These<br />

five trade fairs will run parallel to IMTS (International<br />

Manufacturing Technology Show) from 12<br />

to 17 September 2016 at McCormick Place in<br />

Chicago. With more than 2,000 exhibitors and<br />

110,000 trade visitors, IMTS is North America’s<br />

leading trade fair for manufacturing technology.<br />

www.ia-northamerica.com<br />

Eaton intensifies cooperation<br />

with SAE<br />

Power management company Eaton and SAE<br />

Schaltanlagenbau Erfurt GmbH (SAE) have finalised<br />

a cooperation agreement which will see<br />

them work closely together to build machine<br />

control panels for export to North America, and<br />

also for use in large scale projects. “The requests<br />

from machine builders for support in exports to<br />

the North American market have continued to<br />

increase in recent years,” reports Martin Kram,<br />

Sales Director Germany, Eaton Electrical Sector<br />

EMEA. “The requirements that have to be met in<br />

order to be allowed to supply machinery to the<br />

USA and Canada differ in their complexity considerably<br />

from the European IEC standards. The<br />

extension of our partnership with SAE now puts<br />

us in the position of being able to also offer our<br />

customers the systems as well as the specialist<br />

know-how.” Headquartered in Erfurt, Germany,<br />

SAE has over 200 employees and has specialised<br />

in the development and manufacture of switchboards<br />

for automation technology and machine<br />

building, as well as power and low-voltage power<br />

distribution systems up to 5,000 A. The company<br />

focuses on projects for export to the North<br />

American market.<br />

www.eaton.com<br />

AUTOMATION TECHNOLOGIES 4/<strong>2014</strong>

News and Markets<br />

Eplan with three new subsidiaries<br />

New Eplan subsidiaries have been founded in Japan, South Africa<br />

and Turkey. Until now, the three countries have been supported by<br />

co-operation partners. At the start of the year, Eplan Software &<br />

Services K.K. was founded with its headquarters in Tokyo. In June,<br />

the new subsidiary Eplan Software & Services (Pty) Ltd. started<br />

trading in South Africa. The office was established in Edenvale near<br />

Johannesburg. A further subsidiary was established in July in Turkey:<br />

Eplan Yazılım ve Yazılım Hizmetleri A.S. trades in Istanbul. “As a<br />

manufacturer of engineering solutions, we can market new products<br />

and our comprehensive service portfolio better and much more<br />

quickly”, explains Haluk Menderes (photo), Managing Director of<br />

Eplan Software & Service. “Our customers, who are largely active in<br />

international circles, profit from our extensive presence in the global<br />

market and a uniformly high-quality level with respect to services.”<br />

www.eplan.de<br />

EtherCAT Technology Group: 1,000 th member in Asia<br />

Two successful Ether-<br />

CAT Plug Fests , along<br />

with two Safety over<br />

EtherCAT seminars in<br />

Japan and Korea , highlight<br />

the widespread<br />

implementation of<br />

EtherCAT and support<br />

of the EtherCAT Technology<br />

Group (ETG) on<br />

the Asian continent.<br />

Almost 80 participants attended this year’s Ether-<br />

CAT Plug Fests, the developer meetings conducted<br />

by the ETG, in Japan and Korea. ETG events in<br />

Japan have seen particularly overwhelming growth,<br />

with significant increases in member attendance<br />

over the past four<br />

years. Conducted for<br />

the first time in 2010,<br />

the EtherCAT Plug<br />

Fest in Japan has reached<br />

the same attendance<br />

level as its<br />

European counterparts.<br />

Looking back at<br />

the success of the<br />

EtherCAT events in<br />

Japan and Korea , the latest milestone of the ETG is<br />

hardly surprising , given the recent welcome to the<br />

organization ’s 1,000 th member in Asia.<br />

www.ethercat.org<br />

AUTOMATION TECHNOLOGIES 4/<strong>2014</strong>

BARE IS<br />

BEAUTIFUL.<br />

BASLER’S NEW DART IS SIMPLY STUNNING IN ITS SIMPLICITY.<br />

Sometimes you don’t need lot of bells and whistles. Or a fancy<br />

wrapper. Just the basics will do. Like performance. Reliability. Flexibility.<br />

And a price that makes sense for your system. Sometimes the stripped<br />

down solution is the right solution. And now you can get it from Basler.<br />

Basler’s board level dart camera is the smallest USB3 Vision compliant<br />

camera in the world. It is available as bare board and also with S and<br />

CS-lens mounts, weighing under 15 grams at 29 mm x 29 mm. The dart<br />

consumes less power, produces less heat and fits easily into systems<br />

with limited space. And Basler’s new dart hits the mark on both<br />

performance and price, offering higher image quality than any<br />

other board level camera and starting at just €99.<br />

At Basler, we have a unique vision of value.<br />

Learn more at baslerweb.com.

news and markets<br />

big<br />

our<br />

picture<br />

Chicago<br />

AUTOMATION TECHNOLOGIES 4/<strong>2014</strong>

news and markets<br />

Balloon Fiesta at IMTS show in Chicago: If there is<br />

one thing anyone who attended IMTS remembers,<br />

it is the fantastic balloon that appeared on the front<br />

lawn of McCormick Place and the exhibition halls.<br />

Two of our editors stayed in Chicago to pursue the<br />

latest trends in the American automation sector for<br />

you. More in this issue…<br />

AUTOMATION TECHNOLOGIES 4/<strong>2014</strong>

AUTOMATION TECHNOLOGIES<br />

The place to be<br />

Gerald Scheffels<br />

China is by far the biggest market for machines<br />

– and the largest manufacturer of machines, too.<br />

This means: The Chinese industry attracts the<br />

global manufacturers of machines as well as<br />

their suppliers.<br />

hall plan

ead article<br />

AUTOMATION TECHNOLOGIES

AUTOMATION TECHNOLOGIES<br />

Shanghai and IAS are waiting<br />

Shanghai is not only the most important industrial city<br />

of China but also one of the largest cities in the world.<br />

The city is a major transport hub and an important<br />

cultural and educational center with numerous universities,<br />

colleges and research institutions. This also means that<br />

there is an important location for the automation industry.<br />

The trade fair IAS will be again the impressive proof.

AUTOMATION TECHNOLOGIES<br />

IAS hall plan<br />

read article

news and markets<br />

“What do you expect from the<br />

Chinese automation market in<br />

the next years?”<br />

China remains one of the world’s fastest growing economies and<br />

the fastest growing market for manufacturing. China has also<br />

experienced double-digit growth in many segments of automation.<br />

The Data from National Bureau of Statistics showed: the main<br />

business revenue of enterprises in industrial automatic control<br />

system equipment manufacturing industry was CNY 0.1997 billion<br />

in 2011, CNY 0.2450 billion in 2012, and up to CNY 0.2686 billion by<br />

the end of November 2013, which exceeded the total of 2012.<br />

Industrial automation industry has become one of the driving<br />

forces to promote rapid growth of economy in China.<br />

With the industrial transformation of China, more and more largescale<br />

equipment require a control system with higher precision,<br />

which means there will be more high-end products in the market in<br />

future. For the purpose of precision, labor cost control and real-time<br />

on site operation, there will be more robotic applications. The<br />

Chinese government keeps supporting high-tech industries and<br />

cultivating new economic growth area, the technology of domestic<br />

brands has been substantially increased and local suppliers are<br />

confident to compete with foreign technologies in some automation<br />

segments now. The R&D and production target are highly<br />

based on customer needs, which could lead to polarization of<br />

automation products: one side are highly precise or customized<br />

control systems, the other side are standardized products for<br />

low-end users. Market for mid-end products is shrinking and<br />

system integration is playing a more important role.<br />

John Jiang, Managing Director, Lapp Kabel Shanghai Co. Ltd.

news and markets<br />

For Harting, the Chinese automation market will represent one of the major growth<br />

markets also in the future. At the same time, we can see that the market is in a<br />

transition phase. If, in the past, it was characterised by a rather conservative<br />

approach in terms of connectivity, which became visible in the high demand for<br />

classic board-to-board connectivity, today it features not only innovative backplane<br />

solutions but also mezzanine connectors.<br />

Also in China, decentralisation further asserts itself through ethernet<br />

communication. To this purpose, automation profiles are used. Interestingly<br />

enough, a large number of profiles is required - not just regional<br />

ones - in addition to CC-Link, also Ethernet IP, Profinet or EtherCAT.<br />

Among market players, it is the globally established automation<br />

manufacturers who make decisions regarding connectivity also at a local level, as<br />

well as an increasing number of Chinese manufacturers. For us, a very special<br />

highlight is represented by the fact that we have fitted with har-flex the internal<br />

connection between two PCBs in the HMI of a renowned Chinese manufacturer. Thus<br />

we will be continuing our growth path in China.<br />

Andreas Huhmann, Strategy Consultant Connectivity & Networks at the Harting Technology Group<br />

Visit us!<br />

➔ Nov. 04.–08. <strong>2014</strong> · Shanghai<br />

Hall W2 · Booth B112<br />

Get connected<br />

with innovative cables and systems for<br />

industrial applications<br />

The FieldLink product range offers:<br />

Fieldbus cables for factory automation<br />

Cables and cable systems for drive technology<br />

The Quality Connection<br />

Business Unit Industrial Solutions · www.leoni-industrial-solutions.com

news and markets<br />

The <strong>Automation</strong> Market in China<br />

from Bernstein’s perspective<br />

Uwe Birnbaum, Nicole Steinicke<br />

International safety is becoming more and<br />

more important for the Chinese market.<br />

Bernstein AG ranks among the world’s leading<br />

providers of industrial safety technology<br />

and has a Chinese subsidiary located in<br />

Taicang. With its comprehensive range of<br />

switches, sensors, enclosures, suspension<br />

systems and other components for industrial<br />

applications, Bernstein offers effective and<br />

versatile solutions that address a range of<br />

issues.<br />

Bernstein products are designed to perfectly integrate<br />

in individual system solutions, conforming<br />

to rigorous international safety guidelines. In addition<br />

to classic plant and machine construction,<br />

Bernstein also works with customers in a range of<br />

industries including lift construction, automotive,<br />

agriculture, conveyor construction, automation<br />

engineering, wood-working, renewable energy,<br />

medical technology industries, AS-Interface and AT-<br />

EX. In 2005 Bernstein established a branch and set<br />

up a manufacturing plant in Taicang, situated 50 km<br />

north from the business metropolis of Shanghai. The<br />

expansion of the Chinese market offers significant<br />

opportunities for industrial safety engineering.<br />

Market development in general<br />

Since early 2000, before the economic crisis in<br />

2007/2008, the worldwide automation market developed<br />

rapidly at an average annual growth rate of<br />

8-9 %. China enjoyed annual average growth of up to<br />

20 % at that time. Bernstein ’s Chinese subsidiary was<br />

established just two years before the outbreak of the<br />

global economic crash which seriously hit the whole<br />

industry. While the world market took several years<br />

to recover, the Chinese market recovered faster than<br />

expected with growth in China remaining stable at<br />

7-8 %. Export trade, an important part of the wellknown<br />

Chinese success story of the last two decades,<br />

continued to play a vital role in the country’s growth<br />

whilst a new focus on the domestic market began to<br />

gain increasing momentum.<br />

Huge investment was made in the field of automation<br />

for the automotive industry and machine building<br />

for improvement of the production standards.<br />

This was triggered by the market development in<br />

general and also expressed in China’s 12th Five-Year<br />

Development Plan of high-end equipment manufacturing<br />

industry.<br />

The plan pointed out the importance of upgrading<br />

manufacturing, but also improving the production<br />

efficiency, technical level and product quality. A<br />

transition from “Made in China” to “Designed in<br />

China” became the focus.<br />

The aim is that China’s machinery products shall<br />

be considered as an “intelligent generation” by 2030.<br />

It is also forecasted that Power Generation in China<br />

will double by adding 1,500 gigawatts of capacity in<br />

the same period of time. Actually, this is not a new<br />

industrial revolution, but rather an evolution already<br />

started several years ago.<br />

Impact of the daily business<br />

Let us first consider product and production<br />

related requirements: customers need better monitoring<br />

and control capabilities than ever before<br />

and the needs of respective product categories are<br />

getting more complex. Large volumes of data<br />

needs to be measured, transported via a bus system<br />

and processed, resulting in more complex<br />

products. The needs of machine builders are no<br />

longer the same; they are interested in more customized<br />

solutions rather than standard products

news and markets<br />

and want to obtain an end-to-end solution from<br />

the supplier.<br />

High quality level and machine safety<br />

In view of the rapid evolution of technology, Bernstein<br />

has observed that safety aspects are getting<br />

more and more important in China. On the one hand<br />

this concerns the safety of humans, and on the other<br />

hand the process safety management concerning<br />

minimizing stand-still times of machines. Stable production<br />

processes must be ensured. This goes along<br />

with a growing demand on energy efficiency solutions<br />

due to tremendous increases in energy costs.<br />

Awareness of the importance of safety started with<br />

CCC certification in 2002. Another important milestone<br />

was China’s GB 22530-2008 safety standard for<br />

rubber and plastic injection molding machines. 50<br />

basic standards and regulations for safety related<br />

applications have since been published in China.<br />

The National Machinery Safety Standardization<br />

Technical Committee, which was founded in 1994, is<br />

responsible for ensuring these regulations and standards<br />

are controlled and adhered to. However, the<br />

National Standardization Management Committee<br />

and the State Administration of Work Safety are also<br />

organisations to be mentioned here.<br />

View of automation technology<br />

The high specifications demanded by the quality<br />

guidelines and machine safety standards no longer<br />

only concern products manufactured for export, but<br />

also for domestic and industrial customers. This<br />

change in quality awareness has resulted in a new<br />

way of thinking in China – products at favorable prices<br />

are no longer the main focus and it is now understood<br />

that modern, high-quality products and services lead<br />

to satisfied customers. Foreign brands were trendsetting<br />

in the past. Today it’s just a question of time<br />

that more and more domestic companies are raising<br />

their standards of processes and products as well.<br />

Of the 740 Chinese companies engaged in the<br />

automation industry, about 50 % are located in<br />

About<br />

Company name: Bernstein Safe Solutions Co., Ltd<br />

Headquarters: BERNSTEIN AG, Porta Westfalica, Germany<br />

Employees: appr. 540<br />

Products: Switches, sensors, enclosures, suspension<br />

systems and other components for industrial applications<br />

the area of Shanghai, Jiangsu and Zhejiang – already<br />

catching up with international companies. The<br />

competition for foreign companies is getting more<br />

serious. Even so, China is still the most important<br />

region of growth for international companies.<br />

New evolutions and conclusion<br />

The awareness of safety (human and machine)<br />

aspects and the automation level is growing. Due to<br />

the increasing complexity, the industrial market<br />

requests more and more total solution providers and<br />

system integrators. Component suppliers are<br />

becoming less important. To be successful in the<br />

future, it is compulsory to offer to customers high<br />

quality products with absolutely competitive prices<br />

and a service perfectly in keeping with the customer’s<br />

requirements. Focusing on specific regional<br />

needs is vital in order for companies to be able to<br />

react quickly and remain flexible.<br />

The whole world “goes smart”. So does the Chinese<br />

<strong>Automation</strong> Industry. Sensors, switches, actuators<br />

will be “intelligent” and can be connected to a bus<br />

system. By using AS- Interface, Bernstein products<br />

can be connected via a gateway to e.g. Profibus,<br />

Ethernet, controlLogix, CANopen, CC-Link and other<br />

bus and control systems. Bernstein is ideally prepared<br />

to meet the future demands of the Chinese<br />

market of controlling and monitoring applications in<br />

different industries such as Automotive, Agriculture,<br />

Transportation, Material Handling and <strong>Automation</strong><br />

Engineering industries, as well as Medical Technology.<br />

www.bernstein.eu/en<br />

Author: Uwe Birnbaum, Managing Director<br />

of Bernstein Safe Solutions Co., Ltd., Taicang,<br />

China;<br />

Nicole Steinicke, editor, <strong>Automation</strong><br />

<strong>Technologies</strong>, Mainz, Germany

AUTOMATION TECHNOLOGIES<br />

Bright prospects for Industrial<br />

<strong>Automation</strong> North America<br />

Peter Becker<br />

Robotics and mobile solutions. Only two of the growing<br />

trends in automation that have been key topics at this<br />

year’s Industrial <strong>Automation</strong> North America in Chicago.<br />

But there was even more to discover as our editorial<br />

team saw for themselves at the fairground.

AUTOMATION TECHNOLOGIES<br />

video<br />

Video review of the fair<br />

video<br />

Interview with Larry Turner<br />

read article

AUTOMATION TECHNOLOGIES<br />

Turkish Machinery to expand i<br />

in the US Machinery Market<br />

The Industrial <strong>Automation</strong> North America fair in Chicago<br />

marks a renewed interest in Turkish Machinery given their<br />

recent expansion and market growth in Europe.<br />

Since Turkish Machinery is on its way to strengthening its<br />

position in the manufacturing industry in Europe, as well<br />

as in many developing countries, it now plans to foster a<br />

greater partnership with the US machinery and machine<br />

tool industry.

AUTOMATION TECHNOLOGIES<br />

read article<br />

video<br />

the turkish export association

News and markets<br />

A very special<br />

birthday tour<br />

Iglidur on tour in Chicago<br />

Plastics for longer life – that is the slogan of<br />

Igus. To prove their point, the iglidur car<br />

travelled around the world and inspired<br />

engineers on<br />

almost all<br />

continents. Watch<br />

our video of the<br />

car in Chicago<br />

Video<br />

Peter Becker<br />

If you read our magazine thoroughly, you<br />

will already know: German polymer specialist<br />

igus sent a Smart car around the world<br />

– equipped with 56 of the manufacturer’s<br />

bearings to prove their capabilities in every<br />

possible climate and environment. Our<br />

editorial team finally met the car and its<br />

drivers at Industrial <strong>Automation</strong> North<br />

America in Chicago.<br />

Author: Peter Becker, editor,<br />

AUTOMATION TECHNOLOGIES<br />

About<br />

Company name: igus<br />

Established: 1964<br />

Headquarters: Cologne, Germany<br />

Turnover: € 427 million<br />

Employees: 2,400 worldwide<br />

Products: motion plastics, plastic components for moving<br />

applications: energy chain systems, cables, polymer bearings,<br />

linear bearings, low-cost automation<br />

On October 18, Igus turned 50. We wish the specialist<br />

for cables, energy chains, connectors and<br />

bearings: Happy birthday! To celebrate this special<br />

day and to promote their idea of motion plastics, they<br />

had an unusual idea: the company equipped an orange<br />

Smart car with 56 of its bearings made of plastics<br />

and sent it on a trip around the world. The tour started<br />

in India in January – followed by stops in China, Japan,<br />

Brazil, Canada and the US, among others, and will<br />

continue across Europe in the upcoming months.<br />

With this ambitious effort, the company wants to<br />

prove the resilience and durability of their bearings in<br />

automotive and moving applications. And according<br />

to Stefan Kombüchen, head of marketing and corporate<br />

communications at Igus, to whom we spoke at<br />

Industrial <strong>Automation</strong> North America in Chicago, the<br />

results were impressive: “The car has driven 54,500 km<br />

until our stop in Chicago and, so far, we hadn’t had<br />

any problems at all despite the harsh climate conditions<br />

in the deserts of India or the cold of Alaska.”<br />

After its stop in Chicago, the orange car travelled to<br />

Detroit and New York, before it returned to Germany;<br />

to celebrate igus’ 50 th anniversary in Cologne.<br />

We had the opportunity to take a look at the car for<br />

ourselves in Chicago. Watch our video including<br />

footage of the car in Chicago and a video interview<br />

with Stefan Kombüchen.<br />

www.igus.com

AUTOMATION TECHNOLOGIES<br />

IA Beijing: Comprehensive<br />

solutions for intelligent<br />

manufacturing

AUTOMATION TECHNOLOGIES<br />

Industrial <strong>Automation</strong> Beijing <strong>2014</strong> is one of the<br />

most significant shows in China’s northern area.<br />

More than 200 leading automation enterprises<br />

displayed high-grade products and solutions of<br />

industrial automation. Read more about<br />

the importance of this exhibition and<br />

what are the demands of Chinese<br />

customers? Watch our video<br />

statements and find out.<br />

read article

AUTOMATION TECHNOLOGIES<br />

Global Machinery Safety:<br />

Challenge with economic potential<br />

John McAuliffe<br />

In a globalized economy, international companies are looking for ways to<br />

standardize their production processes and associated machinery and plants.<br />

A special challenge is the machinery safety, because depending on the<br />

country, the requirements and provisions differ significantly. With its<br />

International Service Group Pilz has adjusted to this challenge.

ead article<br />

AUTOMATION TECHNOLOGIES

AUTOMATION TECHNOLOGIES<br />

High-performance 2D laser<br />

scanner with integrated<br />

control interface<br />

Arno Hagemann<br />

The 2D laser scanners in the R2000<br />

family of Pepperl+Fuchs are noted for<br />

their exceptional detection performance<br />

in distance measurement technology.<br />

The latest device variant now makes it<br />

particularly easy for users to benefit<br />

from the system‘s facilities.

The Germany-China Business Association.<br />

Exchange expertise.<br />

Extend your network.<br />

Since 1987, the German-Chinese Business Association (DCW) has made it its mission to work for<br />

better economic relations between China and Germany. Our non-profit association has become a<br />

valuable platform for members and partners to initiate and deepen long-term partnerships. DCW<br />

members are united in a common goal: Create the right conditions for sustainable growth in trade<br />

and investment between Germany and China.<br />

As a member, you will join over 380 companies, organizations and private individuals in working towards<br />

these goals. Members enjoy a range of privileges that include the following:<br />

• Talk to us about your business plans in China<br />

• Find new business partners on the online platform www.DeZhong.de<br />

• Participate in our regional seminars to exchange experiences and gain new expertise<br />

• Join business delegations to China, connect to member companies of European partner organisations<br />

• Gain online access to our member-only information archive<br />

• Benefit from discounts at professional conferences, trade fairs and other events<br />

• State your views on fair investment and trade relations and help us draft our next position paper<br />

• Present your company as a contributor for better economic relations between China, Europe, and<br />

Germany<br />

The advantages of a membership are available to both private individuals and businesses. They will be<br />

granted to all employees of your institution or company.<br />

We are excited about welcoming you to our network. If you have any question, please do not hesitate to<br />

talk to us.<br />

www.dcw-ev.de<br />

German-Chinese Business Assiciation<br />

Unter Sachsenhausen 10–26 · 50667 Cologne, Germany<br />

Phone: +49 221 120370 · Fax: +49 221 120417 · E-mail: info@dcw-ev.de

AUTOMATION TECHNOLOGIES<br />

Smart Wireless Technology<br />

helps improve leak detection<br />

New regulations often demand changes in industrial<br />

production sites. To meet the newly established<br />

requirements by the government, BP had to ensure<br />

continuous leak detection at its plant in Geel,<br />

Belgium. A wireless transmitter network by Emerson<br />

Process Management in combination with hydrocarbon<br />

sensors was installed to enable continuous<br />

monitoring of tanks, valves and pipelines.

AUTOMATION TECHNOLOGIES<br />

read article<br />

Providing unmatched precision.<br />

Delivering Providing 360° unmatched performance.<br />

precision.<br />

Advancing Delivering intuitive 360° performance.<br />

control.<br />

Advancing intuitive control.<br />

R2000 Detection<br />

2DR2000 Laser Detection Scanner<br />

2D 2D 2DLaser Scanner<br />

R2000 Detection – Object detection as easy it can be<br />

R2000 Detection – – Object – detection as easy easy easy it can it can it be can be be<br />

Stable, wobble-free scanning axis for precise field monitoring<br />

Stable, wobble-free scanning axis axis axis for for for precise field field field monitoring<br />

Highest angular resolution on the market allows detection of extremely small objects<br />

Highest angular resolution on on the on the the market allows detection of of of extremely small small small objects<br />

User-defined detection fields make configuration simple, intuitive, and user friendly<br />

User-defined detection fields fields fields make make make configuration simple, intuitive, and and user and user user friendly<br />

www.pepperl-fuchs.com/A-distance-ahead<br />

www.pepperl-fuchs.com/A-distance-ahead

AUTOMATION TECHNOLOGIES<br />

The importance of<br />

photovoltaic for the<br />

agriculture in Nicaragua<br />

Klaas Eßmüller, Dennis Kortstock<br />

A school project in Hamburg is looking at the specific application<br />

of photovoltaics in agriculture. The main focus is on the<br />

development and sizing of solar-powered groundwater<br />

irrigation systems. This is a learning process in<br />

which control equipment and the Siemens<br />

expertise also play a role.

ead article<br />

AUTOMATION TECHNOLOGIES

AUTOMATION TECHNOLOGIES<br />

Sercos and Rexroth help streamline<br />

servo-driven case packers<br />

Brenton Engineering designed a new line of side-loading<br />

case packers to exceed current “green manufacturing”<br />

end user trends, featuring servo control to increase speed<br />

and reduce energy costs within a compact footprint.

AUTOMATION TECHNOLOGIES<br />

read article<br />

video<br />

Peter Lutz about the future of Sercos

AUTOMATION TECHNOLOGIES<br />

Connectivity at sea<br />

Valentin Scheltow<br />

The demands placed on products in the maritime markets<br />

vary depending on the location, and are often extremely<br />

high. The crucial environmental factors in this sector are<br />

vibration, salt water mist and magnetic compatibility<br />

with compasses. Connectors and Ethernet Switches by<br />

Harting perform well even under these difficult conditions.

ead article<br />

AUTOMATION TECHNOLOGIES

AUTOMATION TECHNOLOGIES<br />

Humans working together<br />

with robots: safe and flexible<br />

Peter Becker<br />

According to Larry Turner, CEO Hannover Fairs USA,<br />

robotics is one of the growing branches in automation.<br />

Robot specialists Universal Robots presented the third<br />

generation of its products, UR5 and UR10, at Industrial<br />

<strong>Automation</strong> North America featuring advanced safety<br />

functions and true absolute encoders.

ead article

AUTOMATION TECHNOLOGIES<br />

Enclosures:<br />

more than just a housing<br />

Michael Schell, Christan Moritz<br />

Enclosure housings protect the electrical equipment housed inside them,<br />

as well as the people who operate a switchgear or controlgear systems.<br />

Protection requirements and safety procedures are defined by various<br />

guidelines depending on the operating site, sector or application.<br />

In order to comply with these guidelines, various tests are required.

ead article<br />

AUTOMATION TECHNOLOGIES

AUTOMATION TECHNOLOGIES<br />

Camera change with potential:<br />

USB 3.0 instead of FireWire<br />

René von Fintel<br />

How long will I be able to maintain my<br />

FireWire camera system? When should<br />

I switch, and which interface should I<br />

pick? Users of FireWire cameras around<br />

the world are wondering these things<br />

at the moment. The new USB 3.0 interface<br />

and its standard USB3 Vision are<br />

an attractive successor due to the<br />

technical proximity to FireWire. Basler,<br />

a globally active developer of industrial<br />

cameras, explains the backgrounds<br />

and perspectives.

AUTOMATION TECHNOLOGIES<br />

read article<br />

video<br />

USB 3.0

AUTOMATION TECHNOLOGIES<br />

Thermal imaging cameras in<br />

automotive quality control<br />

Chris Brown, Frank Liebelt<br />

The BMW 5-Series, 6-Serie, 7-Series and 3-Series Gran Turismo are<br />

produced in the Dingolfing plant in Lower Bavaria. Around 18,500<br />

people work at the site. Basic functions from signal horn to enginespecific<br />

performance are thoroughly tested. Thermographic<br />

cameras are ideally suited for this type of quality control and<br />

ensure the proper functioning of automobile production.

ead article<br />

AUTOMATION TECHNOLOGIES

imprint<br />

Editor-in-chief:<br />

Dirk Schaar; Email: d.schaar@vfmz.de<br />

Editorial board:<br />

Peter Becker; Email: p.becker@vfmz.de<br />

Nicole Steinicke; Email: n.steinicke@vfmz.de<br />

Small and fast – temperature<br />

transmitter with IO-Link<br />

Assistant editor:<br />

Svenja Stenner<br />

Design/Layout:<br />

Sonja Schirmer, Doris Buchenau, Anette Fröder,<br />

Conny Grothe, Melanie Lerch, Mario Wüst<br />

E-Paper Designer:<br />

Katja Rüdell, Mathias Göbel<br />

Managing editor:<br />

Winfried Bauer<br />

Publisher:<br />

Vereinigte Fachverlage GmbH<br />

Lise-Meitner-Str. 2<br />

55129 Mainz, Germany<br />

Managing director:<br />

Dr. Olaf Theisen<br />

Publishing director:<br />

Dr. Michael Werner; Email: m.werner@vfmz.de<br />

Advertising sales director:<br />

Beatrice Thomas-Meyer<br />

Advertising sales manager:<br />

Oliver Jennen; Email: o.jennen@vfmz.de<br />

Sales representatives<br />

Austria<br />

Heinz-Joachim Greiner<br />

Email: verlagsbuero-greiner@vfmz.de<br />

Brazil<br />

Carlos Frederico Graf Schaffgotsch<br />

Email: datadress@vfmz.de<br />

China<br />

Oliver Jennen<br />

Email: o.jennen@vfmz.de<br />

France<br />

Marc Jouanny<br />

Email: marc-jouanny@wanadoo.fr<br />

Great Britain<br />

Rob Brewer<br />

Email: rob.brewer1@btinternet.com<br />

India<br />

Oliver Jennen<br />

Email: o.jennen@vfmz.de<br />

Italy, Switzerland<br />

Hermann Jordi<br />

Email: info@jordipublipress.de<br />

Poland<br />

Dr. Miroslaw Bugajski<br />

Email: premiummedia.mb@gmail.com<br />

Russia, Ukraine, Kazakhstan<br />

Natalia Hretschkova<br />

Email: nhrethkova@ivdk.ru<br />

Sweden, Finland, Norway<br />

Malte Mezger<br />

Email: verlagsbuero-mezger@vfmz.de<br />

USA, Canada<br />

Aryan Zandieh<br />

Email: aryan@hfusa.com<br />

Advertising disposition:<br />

Helge Rohmund; Email: h.rohmund@vfmz.de<br />

In cooperation with:<br />

Hannover Fairs International GmbH<br />

Messegelände, 30521 Hannover, Germany<br />

Modular designed controls:<br />

no cables, no batteries<br />

Powerful ace USB 3.0 Cameras<br />

with 2 and 4 MP CMOSIS Sensors<br />

Monitoring energy consumption<br />

with CC-Link IE<br />

EKS Engel presents Industrial<br />

Ethernet switch with Profinet<br />

conformance class B<br />

Additional Partner:<br />

ZVEI - Zentralverband Elektrotechnik- und<br />

Elektronikindustrie e. V.<br />

Moskauer Deutsche Zeitung<br />

Internet:<br />

www.ate-magazine.com<br />

Second year (<strong>2014</strong>)

2. rubrizierungsebene I 1. rubrizierungsebene<br />

China<br />

November 4-8, <strong>2014</strong><br />

Shanghai New International Expo Centre (SNIEC), Shanghai<br />

Discover International Industrial Intelligence &<br />

<strong>Automation</strong> at<br />

INDUSTRIAL AUTOMATION SHOW<br />

Your Exchange Platform for Innovation, Components and Applications<br />

■ The Industrial <strong>Automation</strong> Show is China’s biggest industry<br />

networking hub. It offers the following advantages:<br />

▪ Ideal framework for successfully gaining new customers<br />

▪ Enhanced opportunity to transact direct business deals,<br />

since the 70,000 trade visitors at the show come armed<br />

with concrete investment plans<br />

▪ All the leading manufacturers appear as exhibitors here<br />

▪ Presents an overview of all the latest innovations<br />

▪ Affords you an opportunity to measure yourself against<br />

the competition<br />

■ Thanks to the official government support and corresponding<br />

media attention, exhibiting companies benefit<br />

from enhanced brand recognition, and their solutions are<br />

presented to a large audience.<br />

■ Government support of the event promotes direct contact<br />

with decision-makers from government and interest groups<br />

who hold the key to investments. This affords you a comprehensive<br />

overview of planned investment projects and can<br />

help significantly accelerate the decision-making process.<br />

Mr. Michael Peng, Marketing Manager of Beckhoff <strong>Automation</strong> (Shanghai) Co., Ltd.<br />

“Beckhoff participates at IAS since 2005. We consider it as the best automation show in China,<br />

widely viewed as a barometer of Chinese industrial development. We are satisfied with everything at IAS 2013, the topic,<br />

the visitors’ number, the delegations and other supporting service, everything is amazing! We really appreciate that HMFS<br />

provides such a platform for us to show our products. Best wish to IAS.“<br />

www.hannovermesse.de/worldwide

1. Rubrizierungsebene I 2. rubrizierungsebene<br />

Reach international markets.<br />

New business is<br />

just one click away.<br />

52 Industrielle <strong>Automation</strong> online 4/2013<br />

www.fh-intralogistics.com<br />

www.mda-technologies.com<br />

www.ate-magazine.com

Editorial<br />

The future has begun<br />

Dear readers,<br />

Global competition and continuous market changes put pressure on the<br />

production industry. Costs must be reduced and profits maximised.<br />

This is also the case in China. Increasing acquisition and production<br />

costs drive up demand for flexible and energy-efficient production with<br />

modern automation systems. Innovations play a decisive role in the<br />

land of superlatives, especially where the use of IT and software, or<br />

production and industrial, facilities that are completely linked to each<br />

other in a network is concerned.<br />

These are the subjects on which everything is centred when the gates of<br />

the open Industrial <strong>Automation</strong> Show IAS <strong>2014</strong> in Shanghai. In combination<br />

with two other events, this one has in the meantime become one<br />

of the leading trade fairs for tool machines and metal processing,<br />

production, processing and Industrial Building <strong>Automation</strong>, as well as<br />

conventional and renewable energies in Eastern China. If you visit IAS<br />

in early November, you will see that the subjects of Industry 4.0 or<br />

Smart-<strong>Automation</strong> are increasingly gaining in importance. The first<br />

products are already subject to field tests or even in actual use. The<br />

future of the smart factory has begun.<br />

Many corresponding subjects or those that are a basic prerequisite for<br />

the pioneering technologies can also be found in the current issue of<br />

AUTOMATION TECHNOLOGIES – from sensor to control technology to<br />

industrial image processing: learn more about the potential of USB 3.0<br />

instead of FireWire when using cameras, how the future cooperation of<br />

man and robot can become safer and more flexible, how plug connectors<br />

and Ethernet switches can be perfectly adjusted to rough environments,<br />

and why machine safety poses a challenge with great economic<br />

potential. Additionally, we have many new technologies<br />

and products from the world of industrial<br />

automation at hand.<br />

Enjoy your read!<br />

Dirk Schaar<br />

AUTOMATION TECHNOLOGIES<br />

Andreas Wolf<br />

Hannover Fairs International<br />

AUTOMATION TECHNOLOGIES 4/<strong>2014</strong>

News and Markets<br />

The place to be<br />

Gerald Scheffels<br />

China is by far the biggest market for machines<br />

– and the largest manufacturer of<br />

machines, too. This means: The Chinese<br />

industry attracts the global manufacturers<br />

of machines as well as their suppliers.<br />

two – have become the Asian “workbench” not only<br />

for domestic manufacturers but also for many foreign<br />

suppliers of, say, hydraulic systems, pneumatic components,<br />

sealings, bearings and transmissions.<br />

Though there will be growth rates in the future,<br />

there are clouds on the horizon in form of increasing<br />

cost pressure, mainly – but not only – for the manufacturers<br />

of consumer goods.<br />

There is no doubt: For the manufacturers of<br />

hydraulic and pneumatic components, power<br />

transmissions and automation technology like control<br />

systems and robotics, China is the place to be –<br />

the eastern regions of China, to be precise, because it<br />

is here where many large and smaller manufacturers<br />

of machines are located.<br />

Impressive increase of the economy<br />

The rise of China within the last ten years is embarassing<br />

indeed, especially in the field of industry<br />

and machinery. In the range of the top machine facturers,<br />

China has achieved the number one position<br />

with a production value of € 678 billion (2012). In<br />

2008, it was just € 271 billion – an impressive increase<br />

over just five years.<br />

The number two, the USA, produced less than a half<br />

with € 330 billion. Japan follows on position three,<br />

while Germany is the world´s fourth largest machine<br />

manufacturer with a volume of € 248 billion. In the<br />

competition of machine exporting countries, China<br />

has acquired the third position after Germany and<br />

the USA.<br />

Strong position in machine production<br />

The strong position in machine production attracts,<br />

of course, the world-wide suppliers of drive and control<br />

and automation components. This is why fairs<br />

like the Industrial <strong>Automation</strong> Show (IAS) Shanghai<br />

are an important platform for building new business.<br />

The eastern provinces and global cities of China –<br />

including Shanghai and Guangdong, to name just<br />

Best-in-class or “good enough”?<br />

For the (domestic and foreign) machine producers,<br />

these news bear a positive aspect. When cost issues<br />

are concerned and wages are rising, industrial<br />

automation seems to be the right answer, and this is<br />

exactly what happens in the industrialized areas of<br />

China. So there are good opportunities for the worldwide<br />

automation industry and its suppliers.<br />

Chinese and foreign manufacturers are competing<br />

fiercely here, and both have learned from experience.<br />

The Chinese companies have constantly raised the<br />

quality, performance and productivity of their equipment,<br />

whereas the European manufacturers have<br />

realized that instead of best-in-class components and<br />

systems, “good enough”-equipment often is the better<br />

choice in many applications. With this strategy, they are<br />

very successful: China has become the most important<br />

market for German machine manufacturers.<br />

Chinese machines with European<br />

components<br />

In tIn the course of the approximation of quality and<br />

performance standards, many Chinese machine<br />

manufacturers use components like motors, drives<br />

and control systems hydraulic or pneumatic systems<br />

from global leaders like Bosch Rexroth, Eaton,<br />

Siemens, B&R, Beckhoff, Rockwell and Weidmüller.<br />

Others have acquired European systems suppliers<br />

like Linde Hydraulics and Fluitronics. And, of course,<br />

the Global players are well established in China. Just<br />

one example: Festo, a German-based specialist for<br />

pneumatics and automation, has 42 locations in<br />

China and employs more than 1800 people.<br />

AUTOMATION TECHNOLOGIES 4/<strong>2014</strong>

News and Markets<br />

What will the next five-year-program<br />

bring?<br />

Specialists of investment good industry all over the<br />

world are keen to know what the next five-yearprogram<br />

will contain and in which way it will affect<br />

the Chinese industry both as the most important<br />

manufacturer of and the biggest market for machines.<br />

It is expected that the plan, which will be valid from<br />

2016 to 2020, is aiming at a yearly growth rate of 7 %,<br />

putting a stress on sustainable industries and<br />

avoiding an “overheating” of sectors like the building<br />

trade. Furthermore, it is probable that the liberalization<br />

of regulations will be continued. With the “China<br />

(Shanghai) Pilot Free Trade Zone”, the economic<br />

administration has already a kind of “prototype” for<br />

its upcoming reform projects.<br />

Good reasons for optimism<br />

Even if the yearly growth rates of the Chinese economy<br />

will calm down a bit, there is no need for pessimism,<br />

as far as the automation industry and, all in<br />

all, the investment goods industry and their suppliers<br />

are concerned. Seen from now, there will still be<br />

significant growth, starting from a very high level.<br />

Today, China is by far the biggest market for automation<br />

technology including robotics. And as the<br />

wages and the standard of living are rising, the need<br />

for a higher degree of automation will continue. This,<br />

in fact, makes the Industrial <strong>Automation</strong> Show (IAS)<br />

Shanghai a place to be visited.<br />

www.industrial-automation-show.com/EN<br />

Author: Gerald Scheffels, specialized<br />

journalist, Wuppertal, Germany

News and markets<br />

Shanghai and IAS are waiting<br />

Shanghai is not only the most important<br />

industrial city of China but also one of the<br />

largest cities in the world. The city is a<br />

major transport hub and an important<br />

cultural and educational center with<br />

numerous universities, colleges and<br />

research institutions. This also means that<br />

there is an important location for the automation<br />

industry. The trade fair IAS will be<br />

again the impressive proof.<br />

“Global competition and constant market changes<br />

put nonstop pressure on the manufacturing industry<br />

to cut costs and maximize profits. This is also true in<br />

China, where increasing labor and production costs<br />

are driving demand for modern, energy-efficient<br />

manufacturing and automation systems”, says<br />

Dr. Andreas Gruchow, Member of the Managing<br />

Board, Deutsche Messe AG and organizer of the<br />

exhibition. And he continues: “Accordingly, innovation<br />

plays a crucial role in these industry sectors,<br />

particularly when it comes to using IT and software<br />

to build manufacturing plants and industrial facilities<br />

that are completely networked and self-operating<br />

– what we in Germany call Industry 4.0. “<br />

And this is what the visitor will see, when coming to<br />

the Industrial <strong>Automation</strong> Show <strong>2014</strong> (IAS) in Shanghai.<br />

Organized by Deutsche Messe AG and Hannover<br />

Milano Fairs Shanghai Ltd, the Metalworking and<br />

CNC Machine Tool Show <strong>2014</strong> (MWCS), Industrial<br />

<strong>Automation</strong> Show <strong>2014</strong> (IAS) and Energy Show <strong>2014</strong><br />

(ES), three themed shows under China International<br />

Industry Fair (CIIF) will open the doors from 4 to<br />

8 November <strong>2014</strong>. “Metalworking and CNC Machine<br />

Tool Show, Industrial <strong>Automation</strong> Show and Energy<br />

Show are eastern China’s leading trade fairs for<br />

machine tools and metalworking, production,

News and markets<br />

process and industrial building automation, and<br />

conventional and renewable energies, respectively.<br />

At this year’s events you will see that Industry 4.0 is<br />

taking hold, and products and services are now being<br />

developed with the smart factory of the future in<br />

mind”, explains Dr. Gruchow.<br />

This year, the 5-day exhibition will continue its<br />

expansion with more exhibitors, debuts and innovative<br />

services, receiving again more than 110,000 visitors<br />

and buyers. In 2013, IAS gathered 503 top-level<br />

enterprises to compete in the display area of<br />

35,000 m 2 . ABB, Siemens and Schneider Electric,<br />

three big global industry players attended. For the<br />

current event big companies such as Beckhoff,<br />

Pepperl+Fuchs, Rittal, Turck, Schmersal, B&R, Lapp,<br />

Euchner, Kübler, Wago, ifm elctronic and Pilz are<br />

expected.<br />

“These three fairs are important to China’s industrial<br />

marketplace because they provide an annual<br />

showcase for the latest technologies and trends. We<br />

organize these fairs according to the interests of visitors,<br />

emphasizing the topics that are most important<br />

in the key areas of precision manufacturing, industrial<br />

automation, and energy conversion, distribution,<br />

transmission, and storage, to create a platform where<br />

companies can quickly find the products and<br />

services they need to remain competitive”, says<br />

Dr. Gruchow.<br />

The three halls (W1-W3) are divided into specialized<br />

display areas to demonstrate latest products<br />

and technology in integrated solution, transducers,<br />

embedded system, sensors, connectors, servo<br />

motors, electric system, etc.<br />

What‘s more? Lots of conferences, meetings and<br />

lectures round off the event. Functional Safety and<br />

Energy Efficiency Conference will take place for the<br />

second time in the Chinese market, inviting professionals<br />

from end users, exhibitors, government<br />

agencies and academic institutions to present their<br />

technology, service and energy saving solutions. And<br />

again: In the German Pavilion, visitors will find a<br />

large spectrum of high-tech products „Made in<br />

Germany“. 30 exhibitors are waiting for dialogue and<br />

exchange of experiences.<br />

“China remains a booming market, and our fairs<br />

provide access to it. I wish everyone much success<br />

on the show floor”, Dr. Gruchow concludes.<br />

Voices from exhibitiors and vistors<br />

“We participate at IAS since 2005. We consider<br />

it the best automation show in China, widely<br />

viewed as a barometer of Chinese industrial<br />

development. We are satisfied with<br />

everything at the last show, the topic, the<br />

visitor numbers, the delegations and other<br />

supporting service, everything is amazing!”<br />

Beckhoff China<br />

“Compared with IAS 2012, both quality and<br />

quantity of visitors during IAS 2013 have been<br />

improved significantly. During the show, we<br />

met some of our potential customers, and we<br />

achieved pretty good results. Besides, the<br />

organizer of the show, HMFS, has strong<br />

ability to coordinate and execute, which<br />

helped us a lot in booth constructing and<br />

moving-out.”<br />

Weidmüller Interface (Shanghai) Co., Ltd.<br />

“IAS 2013 attracted a great number of<br />

manufacturing enterprises to show their<br />

products and brands from several different<br />

angles, especially those European companies.<br />

During the show, we managed to know more<br />

advanced facilities and learn the development<br />

trends of automation industry. We would not<br />

hesitate to visit IAS <strong>2014</strong>, and we expect more<br />

foreign exhibitors next year.”<br />

Hitachi Elevator (Shanghai) Co.,Ltd.<br />

www.industrial-automation-show.com<br />

AUTOMATION TECHNOLOGIES 4/<strong>2014</strong>

News and market<br />

Bright prospects for<br />

Industrial <strong>Automation</strong><br />

North America<br />

Peter Becker<br />

Robotics and mobile solutions. Only two of<br />

the growing trends in automation that<br />

have been key topics at this year’s Industrial<br />

<strong>Automation</strong> North America in Chicago. But<br />

there was even more to discover as our<br />

editorial team saw for themselves at the<br />

fairground.<br />

The weather was great when our editors arrived at<br />

O’Hare airport in Chicago. But there were not<br />

only bright prospects regarding the weather. The<br />

forecast for the second Industrial <strong>Automation</strong> North<br />

America at McCormick Place was good, too. Industrial<br />

<strong>Automation</strong> North America <strong>2014</strong> and the inaugural<br />

Motion, Drive & <strong>Automation</strong> (MDA) North<br />

America <strong>2014</strong> trade shows and conferences were<br />

co-located with IMTS – The International Manufacturing<br />

Technology Show – providing the events with<br />

a well-known and established partner in North<br />

America.<br />

This co-location was one of the reasons for the fair’s<br />

success. But for the organizers, there were even more<br />

reasons to be happy as Larry Turner, CEO Hannover<br />

Fairs USA, points out: “We doubled our size from<br />

2012 and sold out the show six months before the<br />

event.” Industrial <strong>Automation</strong> North America and<br />

Motion, Drive & <strong>Automation</strong> North America together<br />

attracted 194 exhibiting companies from 14 countries,<br />

covering more than 50,000 ft² of exhibition<br />

space in the East Building of McCormick Place.<br />

Together with the IMTS, the show attracted more<br />

than 114,000 total registrants.<br />

Author: Peter Becker, editor,<br />

AUTOMATION TECHNOLOGIES<br />

AUTOMATION TECHNOLOGIES 4/<strong>2014</strong>

News and market<br />

Up-to-date and international<br />

Addressing many of the current challenges of the<br />

fourth industrial revolution, or Industry 4.0, Industrial<br />

<strong>Automation</strong> North America <strong>2014</strong> focused on a<br />

variety of core topics, such as flexible manufacturing,<br />

network security, technology integration,<br />

worker productivity, as well as data collection and<br />

analysis. The show’s roster of global exhibitors<br />

expressed excitement about the growth of the <strong>2014</strong><br />

event since its founding in 2012 and acknowledged<br />

that attending the show is a critical component of<br />

their North American brand extension and end-user<br />

marketing programs.<br />

National pavilions from Germany, Taiwan and Italy<br />

added to the internationality of the event. And the<br />

organizers are expecting this trend to grow even<br />

further. Turner paints a picture of the future of the<br />

fair: “In 2016, we already got delegations coming in<br />

from the Netherlands and South Korea. We see it<br />

even expanding from an international standpoint.”<br />

Exhibitor highlights<br />

Among the exhibitors at Industrial <strong>Automation</strong><br />

North America were some of the leading companies<br />

in their respective branches such as Beckhoff <strong>Automation</strong>,<br />

Molex, Rockwell <strong>Automation</strong> or Weidmüller.<br />

Beckhoff incorporated Google Glass in a demonstration<br />

of a wearable Human Machine Interface (HMI)<br />

Video review of the fair<br />

Our editorial team captured the fair for you.<br />

Watch our video impressions from<br />

McCormick Place, Chicago.<br />

Video<br />

Interview with Larry Turner,<br />

CEO Hannover Fairs USA<br />

We had the<br />

opportunity<br />

to interview the<br />

CEO of Hannover<br />

Fairs USA at the fair<br />

in Chicago. Watch<br />

the full interview<br />

regarding the<br />

future of the event,<br />

trends in the North<br />

American market and the cooperation<br />

with Hannover Fairs in Germany here.<br />

for operation and monitoring. Its smart technology<br />

solutions represent the fusion of the Internet and<br />

automation technologies within the framework of<br />

advanced manufacturing. Molex presented “quick<br />

disconnect” connectors that enable the replacement<br />

of motors in production lines, eliminating costly<br />

downtime in the production process. Weidmüller<br />

launched its “u-remote” distributed I/O platform<br />

with IP 20, ensuring faster installation and setup and<br />

improving machine performance and productivity.<br />

Patty Roberts, Rockwell <strong>Automation</strong> Marketing<br />

Manager, summarizes: “Industrial <strong>Automation</strong><br />

North America is the meeting place for advanced<br />

manufacturing innovations, strategic partnerships<br />

and product collaborations. The show gave us the<br />

ability to expand our presence in discreet manufacturing<br />

and to secure new business leads.”<br />

A look into the future<br />

The CEO of Hannover Fairs USA was pleased with the<br />

event as well – and the organizers have big plans for<br />

2016: “Overall, attendees were very satisfied with the<br />

show and plan on returning in 2016. To that end, we<br />

expect to double our space in the East Building at<br />

IMTS 2016 and look forward to introducing additional<br />

product and service categories.” The next<br />

Industrial <strong>Automation</strong> North America and Motion,<br />

Drive & <strong>Automation</strong> North America events will be<br />

held from September 12-17, 2016.<br />

www.ia-northamerica.com<br />

Video<br />

AUTOMATION TECHNOLOGIES 4/<strong>2014</strong>

Turkish Machinery to expand<br />

in the US Machinery Market<br />

The Industrial <strong>Automation</strong> North America<br />

fair in Chicago marks a renewed interest<br />

in Turkish Machinery given their recent<br />

expansion and market growth in Europe.<br />

Since Turkish Machinery is on its way to<br />

strengthening its position in the manufacturing<br />

industry in Europe, as well as in<br />

many developing countries, it now plans to<br />

foster a greater partnership with the US<br />

machinery and machine tool industry.<br />

Adnan Dalgakıran, President of the Board at<br />

Turkish Machinery said “with rapid development,<br />

Turkish Machinery sector is increasing its<br />

export share in the Turkish economy and exports.<br />

Turkey’s machinery exports, which were USD 3.0 billion<br />

in 2003, have reached USD 14 billion in 2013.<br />

The ratio of exports to imports in the machinery sector<br />

has gone up from 29 to 45 % in the last 10 years.”<br />

According to Dalgakıran, “Turkey currently exports<br />

into more than 200 countries and is already expanding<br />

into Latin America. Significant cooperation opportunities<br />

exist for both the US and Turkey at this<br />

time.” By participating in this international trade<br />

event as well as targeted advertising, “Turkish<br />

Machinery aims to expand awareness about the<br />

AUTOMATION TECHNOLOGIES 4/<strong>2014</strong>

News and Markets<br />

Joint partnership: The board members of Turkish<br />

machinery Sevda Kayhan Yılmaz (left) and Ferdi Murat<br />

Gül (right) with the editor of automation technologies<br />

Nicole Steinicke<br />

quality as well as the recent technological developments<br />

in their machinery sector and the benefits of a<br />

strategic joint US – Turkey partnership.” The Turkish<br />

machinery industry is growing exponentially due<br />

much in part to a very strong partnership already<br />

existing with Germany and the Netherlands.<br />

Dalgakıran, ‘‘Given the success in the German market<br />

and the knowledge gained from this relationship,<br />

Turkey is now poised to enter the US market and<br />

ready to build an equally profitable partnership.’’ Given<br />

their rapid growth, enormous potential now exists<br />

for the US market in terms of shared technology and<br />

joint projects in research and development, increased<br />

marketing opportunities, brand purchases, as well as<br />

shared technical training and expertise. Dalgakiran<br />

went on further to state that, “with an improved<br />

mutual understanding and awareness, economic and<br />

commercial opportunities abound for both countries.<br />

International manufacturing standards<br />

Turkey is a rapidly growing market and has shown<br />

consistent stable growth in the manufacturing and<br />

machinery sector. Its proximity to developing countries<br />

also makes it highly attractive to the US since its<br />

strategic location allows for strong economic and<br />

trade relations with many countries. It has a young,<br />

dynamic, creative and affordable highly skilled workforce<br />

and a strong infrastructure with increasing<br />

tools for government sponsored financial support. It<br />

has shown rapid adaptation to international manufacturing<br />

standards and has the highest quality of<br />

machinery equipment. It has a strong domestic<br />

supply of raw materials.<br />

Foreign trade and exports are on the rise<br />

Turkish foreign trade is equally on the rise. Exports,<br />

which were 47billion USD in 2003, rose to 152 billion<br />

USD in 2013. The Machinery and accessories industry<br />

accounts for most of this growth, having almost<br />

doubled its production in this sector in the past ten<br />

years. Turkey is the sixth largest manufacturer of<br />

machinery in Europe and is preferred by leading<br />

countries throughout the world.<br />

Turkish machinery exports comprise an average<br />

annual growth of 20 %, while imports have shown an<br />

average annual growth of 15 % in the last decade.<br />

Due in part to their strategic partnership, Germany<br />

and the Netherlands account for the largest shares of<br />

this expansive growth. US currently has a 4.8 % share<br />

in Turkish machinery exports and imports roughly<br />

4 %. With the American manufacturing industry once<br />

again on the rise, there are many opportunities surfacing<br />

for a joint partnership and joint growth at this<br />

time.<br />

Turkish export association for machines<br />

and accessories<br />

The export association for machines and accessories<br />

(MAIB) represents the machine exporters of Turkey.<br />

The association took up its work in 2002 and coordinates<br />

all activities that promote export of the industrial<br />

area. It has more than 8,000 member companies.<br />

The promotion group machinery (MTG) founded by<br />

the association in 2007 has the objective of making the<br />

Turkish engineering industry more widely known in<br />

and outside the country. For this purpose, it participates<br />

in international trade fairs, organizes delegation<br />

travels and promotional campaigns.)<br />