small angle X-ray scattering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Article<br />

Cite This: Chem. Mater. 2018, 30, 1127−1135<br />

pubs.acs.org/cm<br />

Tuning Precursor Reactivity toward Nanometer-Size Control in<br />

Palladium Nanoparticles Studied by in Situ Small Angle X‐<strong>ray</strong><br />

Scattering<br />

Liheng Wu, †,‡ Huada Lian, ‡ Joshua J. Willis, ‡,§ Emmett D. Goodman, ‡,§ Ian Salmon McKay, ‡ Jian Qin, ‡<br />

Christopher J. Tassone,* ,† and Matteo Cargnello* ,‡,§<br />

† Stanford Synchrotron Radiation Lightsource, SLAC National Accelerator Laboratory, Menlo Park, California 94025, United States<br />

‡ Department of Chemical Engineering, Stanford University, Stanford, California 94305, United States<br />

§ SUNCAT Center for Interface Science and Catalysis, Stanford University, Stanford, California 94305, United States<br />

*S Supporting Information<br />

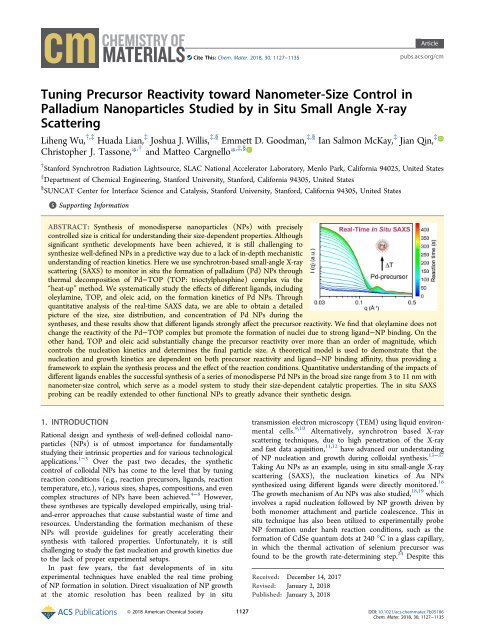

ABSTRACT: Synthesis of monodisperse nanoparticles (NPs) with precisely<br />

controlled size is critical for understanding their size-dependent properties. Although<br />

significant synthetic developments have been achieved, it is still challenging to<br />

synthesize well-defined NPs in a predictive way due to a lack of in-depth mechanistic<br />

understanding of reaction kinetics. Here we use synchrotron-based <strong>small</strong>-<strong>angle</strong> X-<strong>ray</strong><br />

<strong>scattering</strong> (SAXS) to monitor in situ the formation of palladium (Pd) NPs through<br />

thermal decomposition of Pd−TOP (TOP: trioctylphosphine) complex via the<br />

“heat-up” method. We systematically study the effects of different ligands, including<br />

oleylamine, TOP, and oleic acid, on the formation kinetics of Pd NPs. Through<br />

quantitative analysis of the real-time SAXS data, we are able to obtain a detailed<br />

picture of the size, size distribution, and concentration of Pd NPs during the<br />

syntheses, and these results show that different ligands strongly affect the precursor reactivity. We find that oleylamine does not<br />

change the reactivity of the Pd−TOP complex but promote the formation of nuclei due to strong ligand−NP binding. On the<br />

other hand, TOP and oleic acid substantially change the precursor reactivity over more than an order of magnitude, which<br />

controls the nucleation kinetics and determines the final particle size. A theoretical model is used to demonstrate that the<br />

nucleation and growth kinetics are dependent on both precursor reactivity and ligand−NP binding affinity, thus providing a<br />

framework to explain the synthesis process and the effect of the reaction conditions. Quantitative understanding of the impacts of<br />

different ligands enables the successful synthesis of a series of monodisperse Pd NPs in the broad size range from 3 to 11 nm with<br />

nanometer-size control, which serve as a model system to study their size-dependent catalytic properties. The in situ SAXS<br />

probing can be readily extended to other functional NPs to greatly advance their synthetic design.<br />

1. INTRODUCTION<br />

Rational design and synthesis of well-defined colloidal nanoparticles<br />

(NPs) is of utmost importance for fundamentally<br />

studying their intrinsic properties and for various technological<br />

applications. 1−3 Over the past two decades, the synthetic<br />

control of colloidal NPs has come to the level that by tuning<br />

reaction conditions (e.g., reaction precursors, ligands, reaction<br />

temperature, etc.), various sizes, shapes, compositions, and even<br />

complex structures of NPs have been achieved. 4−8 However,<br />

these syntheses are typically developed empirically, using trialand-error<br />

approaches that cause substantial waste of time and<br />

resources. Understanding the formation mechanism of these<br />

NPs will provide guidelines for greatly accelerating their<br />

synthesis with tailored properties. Unfortunately, it is still<br />

challenging to study the fast nucleation and growth kinetics due<br />

to the lack of proper experimental setups.<br />

In past few years, the fast developments of in situ<br />

experimental techniques have enabled the real time probing<br />

of NP formation in solution. Direct visualization of NP growth<br />

at the atomic resolution has been realized by in situ<br />

transmission electron microscopy (TEM) using liquid environmental<br />

cells. 9,10 Alternatively, synchrotron based X-<strong>ray</strong><br />

<strong>scattering</strong> techniques, due to high penetration of the X-<strong>ray</strong><br />

and fast data aquisition, 11,12 have advanced our understanding<br />

of NP nucleation and growth during colloidal synthesis. 13−37<br />

Taking Au NPs as an example, using in situ <strong>small</strong>-<strong>angle</strong> X-<strong>ray</strong><br />

<strong>scattering</strong> (SAXS), the nucleation kinetics of Au NPs<br />

synthesized using different ligands were directly monitored. 16<br />

The growth mechanism of Au NPs was also studied, 18,19 which<br />

involves a rapid nucleation followed by NP growth driven by<br />

both monomer attachment and particle coalescence. This in<br />

situ technique has also been utilized to experimentally probe<br />

NP formation under harsh reaction conditions, such as the<br />

formation of CdSe quantum dots at 240 °C in a glass capillary,<br />

in which the thermal activation of selenium precursor was<br />

found to be the growth rate-determining step. 24 Despite this<br />

Received: December 14, 2017<br />

Revised: January 2, 2018<br />

Published: January 3, 2018<br />

© 2018 American Chemical Society 1127 DOI: 10.1021/acs.chemmater.7b05186<br />

Chem. Mater. 2018, 30, 1127−1135

Chemistry of Materials<br />

success, important questions still unanswered are whether the<br />

measured nucleation and growth kinetics is valid in the lab-scale<br />

batch synthesis and how the kinetics can be utilized for<br />

designing better synthetic strategies toward well-defined NPs<br />

for desired applications.<br />

Here we report the in situ SAXS probing of the synthesis of<br />

Pd NPs through thermal decomposition of Pd−TOP complex<br />

in 1-octadecene solution using a “heat-up” method. 38−40 We<br />

use a custom-made flask reactor to mimic typical laboratory<br />

reaction conditions (e.g., high temperature, inert atmosphere)<br />

for solution-phase colloidal synthesis. 41 We chose to study the<br />

synthesis of Pd NPs because of their widespread catalytic<br />

applications in many important chemical reactions, including<br />

methane combustion reaction, 42 methane steam reforming<br />

reaction, 43 and electrochemical oxidation of formic acid. 44,45<br />

Understanding the size−activity relationship is critical for<br />

designing better catalysts for those reactions. Although different<br />

synthetic approaches have allowed for the preparation of<br />

different-sized Pd NPs with narrow size distributions, 38,46−52<br />

currently, there is still no general guideline for precisely<br />

controlling their size due to the lack of insights into the<br />

formation kinetics. By systematically studying the roles of<br />

different ligands (i.e., trioctylphosphine (TOP), oleylamine,<br />

and oleic acid) via in situ SAXS, we are able to quantitatively<br />

explore the reaction kinetics. We find that the Pd−TOP<br />

precursor reactivity is strongly affected by the type and amount<br />

of ligands used, which controls the nucleation kinetics and<br />

allows for the fine control of the final particle size. Theoretical<br />

models suggest that the growth of Pd NPs is limited by surface<br />

reaction between monomers and NPs or by thermal activation<br />

of Pd-precursor depending on the precursor reactivity. The<br />

mechanistic understanding of the effects of different ligands<br />

enables the synthesis of Pd NPs in the size range of 3 to 11 nm<br />

with nanometer-size control. We believe that the in situ SAXS<br />

characterization coupled with the versatile reactor geometry<br />

described here can be extended to accelerate the synthetic<br />

developments of various functional NPs.<br />

2. EXPERIMENTAL SECTION<br />

2.1. Chemicals and Materials. Pd(acac) 2 (acac = acetylacetonate,<br />

35% Pd) was purchased from Acros Organics. Oleic acid (90%),<br />

oleylamine (70%), and 1-octadecene (90%) were purchased from<br />

Sigma-Aldrich and degassed under vacuum at 100 °C for 1 h before<br />

use. TOP (97%) was purchased from Sigma-Aldrich and used without<br />

further purification. Hexanes and isopropanol were purchased from<br />

Fisher Scientific.<br />

2.2. Syntheses of Pd NPs. The syntheses were performed in a<br />

custom-made flask reactor under inert Ar gas. Pd NPs were<br />

synthesized via thermal decomposition of Pd−TOP complex modified<br />

from previously reported procedures. 38,39 In a typical procedure, 1-<br />

octadecene (10 mL) and Pd(acac) 2 (0.25 mmol) were mixed via<br />

magnetic stirring under a gentle flow of Ar for 15 min. Then TOP was<br />

injected, immediately forming a light yellow Pd−TOP complex, 53<br />

followed by the addition of oleylamine or oleic acid depending on<br />

experimental choices (Table 1). The mixture was kept at 60 °C for 30<br />

min under the Ar flow to remove air and moisture and then heated to<br />

280 °C using a heating rate of ∼15 °C min −1 (the heating rates for all<br />

the reactions are very similar) and kept at the final temperature for up<br />

to 30 min. After the reaction, the flask was cooled down to room<br />

temperature by removing the heating tape. The obtained Pd NPs were<br />

isolated by precipitation with 20 mL of 2-propanol followed by<br />

centrifugation at 8000 rpm for 3 min. The precipitated Pd NPs were<br />

further purified by another two cycles of precipitation (5 mL of<br />

hexanes as the solvent and 20 mL of 2-propanol as the antisolvent).<br />

After purification, the Pd NPs were redispersed in 5 mL of hexanes for<br />

1128<br />

Article<br />

Table 1. Different Combinations of Ligands for the Synthesis<br />

of Pd NPs in This Work a<br />

reaction TOP oleylamine oleic acid<br />

A 1.25 mmol - -<br />

B 1.25 mmol 0.63 mmol -<br />

C 1.25 mmol 2.50 mmol -<br />

D 2.50 mmol 2.50 mmol -<br />

E 1.25 mmol - 3.75 mmol<br />

F 1.25 mmol - 9.40 mmol<br />

G 1.25 mmol - 15.60 mmol<br />

a The amount of Pd(acac) 2 used in each synthesis is 0.25 mmol.<br />

further characterizations. Different combinations of ligands were<br />

studied to systematically evaluate their effect on reaction kinetics and<br />

are summarized in Table 1. For reactions E−G, due to large volume of<br />

oleic acid used, the amount of 1-octadecene used was tuned such that<br />

the total volume of 1-octadecene and oleic acid was 10 mL to maintain<br />

similar precursor concentration for these reactions.<br />

2.3. In Situ SAXS Characterization. In Situ SAXS measurements<br />

were performed at Beamline 1-5 of Stanford Synchrotron Radiation<br />

Lightsource (SSRL) using our custom-made setup (Figure S1). 41 The<br />

X-<strong>ray</strong> path length within the reactor was 5 mm. The X-<strong>ray</strong> energy was<br />

15.5 keV, and the beam spot size was 500 μm × 500 μm. The sampleto-detector<br />

distance was calibrated to be 741.6 mm using a silver<br />

behenate standard. For each data acquisition, an exposure time of 5 s<br />

was applied. A Rayonix SX165 CCD area detector was used to collect<br />

the two-dimensional (2D) <strong>scattering</strong> patterns. The 2D SAXS patterns<br />

were reduced to 1D data, calibrated to absolute scale using a glassy<br />

carbon standard (Figure S2a), 54 and were further analyzed using the<br />

Irena package (available at usaxs.x<strong>ray</strong>.aps.anl.gov/staff/ilavsky/irena.<br />

html from the APS). 12 The size, size distribution, concentration, and<br />

volume fraction of the Pd NPs were modeled in Irena package using a<br />

spherical form factor (see details in the Supporting Information). The<br />

yield (Y) of Pd NPs was obtained based on the equation Y = ϕ/ϕ max ,<br />

where ϕ is the volume fraction of total Pd NPs at a specific reaction<br />

time and ϕ max is the maximum volume fraction of Pd NPs in the<br />

solution at 100% conversion of Pd-precursor to Pd nanoparticles.<br />

2.4. Ex Situ Characterization. The purified Pd NPs were<br />

characterized by TEM. TEM samples were prepared by drop-casting a<br />

dilute NP dispersion in hexane onto carbon-coated 300 mesh Cu grids.<br />

TEM images were collected on a FEI Tecnai transmission electron<br />

microscope operated with an accelerating voltage of 200 kV. The<br />

obtained superlattices of Pd NPs with the oleic acid ligand were<br />

imaged using a FEI Magellan 400 XHR scanning electron microscopy<br />

operating at 5 kV. Fourier transform infrared spectra of the NPs were<br />

recorded on a Nicolet iS50 spectrometer.<br />

3. RESULTS AND DISCUSSION<br />

Pd NPs were synthesized through thermal decomposition of<br />

Pd−TOP complex in 1-octadecene (see Experimental Section<br />

for details). The synthesis procedure using only TOP as<br />

surfactant (reaction A in Table 1) is taken as standard. The<br />

Pd−TOP complex solution was heated up from 60 to 280 °C<br />

and kept at 280 °C for up to 30 min. During the reaction, SAXS<br />

patterns were acquired at an exposure time of 5 s for each<br />

pattern. The obtained 2D SAXS data were integrated into 1D<br />

data, and the background signal from the reactor and solvent<br />

were subtracted. As reaction temperature increases up to 230<br />

°C, the <strong>scattering</strong> from nuclei with diameter larger than 1 nm<br />

appears. This temperature, defined as the nucleation temperature,<br />

is taken as t = 0 s. Representative background-subtracted<br />

SAXS patterns are shown in Figures 1a and S2b. As the reaction<br />

proceeds, the <strong>scattering</strong> intensity at low <strong>scattering</strong> vector q<br />

increases quickly, indicating increased particle size. Obvious<br />

oscillation peaks appear as well, suggesting the narrowing of the<br />

DOI: 10.1021/acs.chemmater.7b05186<br />

Chem. Mater. 2018, 30, 1127−1135

Chemistry of Materials<br />

Figure 1. (a) Representative SAXS data (colored plots) and the<br />

corresponding fits (black plots) of Pd NPs at different reaction times<br />

during the synthesis using only TOP as surfactant (reaction A,<br />

Pd:TOP molar ratio = 1:5). The <strong>scattering</strong> intensities are offset for<br />

clarity. Time t = 0 s is set when nucleation starts. (b) Quantitative<br />

analysis of the concentration of Pd NPs as a function of reaction time.<br />

(c) Size (dots) and size distribution (bars) of Pd NPs as measured by<br />

in situ SAXS. (d) Reaction temperature profile during the synthesis.<br />

Article<br />

NP size distribution. To obtain more information about size,<br />

size distribution, and concentration of the Pd NPs, the SAXS<br />

data were fitted using a spherical NP model in the Irena<br />

package (see SI for details). Figure 1b−d shows the quantitative<br />

analysis of the mean diameter, polydispersity, and concentration<br />

of Pd NPs as a function of reaction time. Based on the<br />

analysis of particle concentration, burst nucleation occurs in the<br />

first 50 s, during which the NP concentration increases with a<br />

constant nucleation rate of 1.22 × 10 14 mL −1 s −1 in the case of<br />

the standard reaction A (Table 1). Meanwhile, the polydispersity<br />

of the formed nuclei dropped significantly to ∼14%. The<br />

narrow size distribution of the nuclei is critical for their further<br />

simultaneous growth into uniform NPs. During this nucleation<br />

stage ∼27% of the Pd atoms in the precursor are incorporated<br />

into Pd NPs (Figure 2c). Between 50 to 115 s, the Pd NPs<br />

continue to slowly grow in size from 2.8 to 3.7 nm. Although a<br />

<strong>small</strong> concentration of new nuclei is formed during this period,<br />

the much slower nucleation rate (2.4 × 10 13 mL −1 s −1 )<br />

guarantees that the fraction of newly formed nuclei is relatively<br />

<strong>small</strong> and the overall polydispersity was not increased but<br />

instead dropped to ∼10%. Between 115 and 160 s Pd NPs<br />

slowly grow to 3.9 nm at nearly constant particle concentration<br />

due to much decreased monomer concentration. After 160 s,<br />

there is a slight decrease in particle concentration (Figure 1b),<br />

suggesting the existence of NP−NP coalescence or Ostwald<br />

ripening, which is common in the colloidal synthesis of<br />

NPs. 18,24,55,56 After 5 min, Pd NPs with the final size of 4.0 ±<br />

0.4 nm are obtained, and their size and concentration do not<br />

change during further aging process. The final Pd NPs were<br />

also characterized by TEM, as shown in Figure 2d. The size<br />

based on TEM characterization was measured to be 3.7 ± 0.3<br />

nm, which is in good agreement with the SAXS measurement<br />

(Figure 2e,f and Table 2).<br />

To study the effect of different ligands on the synthesis of Pd<br />

NPs, we started by comparing the standard reaction condition<br />

(reaction A) with those where oleylamine, a widely used<br />

stabilizing ligand for metallic NPs, 57 is present. Real-time SAXS<br />

patterns using different amounts of oleylamine are shown in<br />

Figure 3. We observed a similar nucleation temperature at<br />

Figure 2. (a−c). Quantitative analysis of (a) size, (b) concentration, and (c) yield of Pd NPs with different amounts of oleylamine as measured via in<br />

situ SAXS. (d) TEM images of the final Pd NPs synthesized with different ligands. (e) SAXS patterns (colored plots) and the corresponding fits<br />

(black plots) of the as-synthesized Pd NPs. (f) Size and size distribution measured from TEM (histogram) and SAXS (dotted plots, normalized to<br />

the maximum of the histogram). Results from reactions A, B, and C are shown in red, blue, and purple, respectively.<br />

1129<br />

DOI: 10.1021/acs.chemmater.7b05186<br />

Chem. Mater. 2018, 30, 1127−1135

Chemistry of Materials<br />

Article<br />

Table 2. Average Pd NP Sizes Measured from TEM and SAXS<br />

reaction A B C D E F G<br />

SAXS (nm) 4.0 ± 0.4 3.8 ± 0.4 3.4 ± 0.4 5.5 ± 0.6 7.5 ± 0.5 9.2 ± 0.6 11.0 ± 0.9<br />

TEM (nm) 3.7 ± 0.3 3.5 ± 0.3 3.3 ± 0.3 5.2 ± 0.7 7.3 ± 0.3 8.7 ± 0.6 10.5 ± 0.9<br />

Figure 3. Representative SAXS patterns (colored plots) and the<br />

corresponding fits (black plots) of Pd NPs at different reaction times<br />

in the presence of (a) TOP 1.25 mmol + oleylamine 0.65 mmol<br />

(reaction B); (b) TOP 1.25 mmol + oleylamine 2.50 mmol (reaction<br />

C). The <strong>scattering</strong> intensities are offset for clarity. Time t = 0 s is set<br />

when nucleation starts and the nucleation temperature is at ∼230 °C<br />

for both reactions.<br />

Although oleylamine changes the nucleation rate, the change is<br />

<strong>small</strong> which leads to limited tunability of final particle size. We<br />

also tested the effect of final reaction temperature on the<br />

formation of Pd NPs and found that it has minimal or no effect<br />

on particle size and size distribution, as long as it is above the<br />

critical nucleation temperature that enables burst nucleation.<br />

For example, there is no obvious difference in the final size of<br />

Pd NPs ex situ synthesized using the same ligand mixture from<br />

reaction C but at different final reaction temperatures of 240<br />

and 290 °C (Figure S4).<br />

In contrast to oleylamine, TOP substantially changes the<br />

reactivity of Pd precursor. It has been demonstrated that Pd(II)<br />

forms a stable Pd II −(TOP) 4 complex and a large excess of TOP<br />

retards the thermal decomposition of the Pd−TOP complex. 53<br />

Taking advantage of the in situ SAXS, we quantitatively studied<br />

the effect of TOP by doubling its amount (molar ratio of<br />

Pd:TOP increases from 1:5 to 1:10, reaction D). We observed<br />

the formation of Pd NPs at 255 °C rather than 230 °C due to<br />

the shift in the reaction equilibrium of the decomposition of<br />

Pd−TOP complex into Pd NPs, which requires higher energy<br />

to activate it. Quantitative analysis of the SAXS data (Figure<br />

S5) shows that the formation rate of Pd NPs is reduced by a<br />

factor of 5 (Figure 4c). Due to a depressed precursor reactivity<br />

in the presence of large excess of TOP which cannot support a<br />

∼230 °C, indicating that oleylamine does not affect the<br />

formation of monomer species or the chemistry of the Pd−<br />

TOP complex. The Pd NP size and concentration are derived<br />

from the fits of the SAXS results, and their quantitative<br />

comparisons are shown in Figure 2a−c. Similar to the case<br />

without oleylamine, a rapid nucleation occurred in the first ∼50<br />

s, followed by a slow growth of NP from ∼2.8 nm in size. The<br />

similar yield of Pd NPs over reaction times suggests that<br />

oleylamine does not affect precursor reactivity (Figure 2c).<br />

However, slightly higher nucleation rate (1.37 × 10 14 mL −1 s −1 )<br />

was observed when 0.63 mmol of oleylamine was used<br />

(reaction B), generating more nuclei. Since the precursor<br />

amount is constant, the more nuclei formed, the <strong>small</strong>er the<br />

final Pd NPs, as confirmed by the <strong>small</strong>er size measured from<br />

SAXS (3.8 ± 0.4 nm) and TEM (3.5 ± 0.3 nm) (Figure 2d−f<br />

and Table 2). The difference in the nucleation rate in the<br />

presence of oleylamine is likely due to stronger binding<br />

between oleylamine and the Pd 0 nuclei, which facilitates the<br />

formation of nuclei by stabilizing them with reduced nuclei−<br />

solvent interfacial tension. This observation is also supported<br />

by the fact that the TOP ligand on the Pd surface can be easily<br />

exchanged with oleylamine (Figure S3) and further corroborated<br />

by previous studies involving NMR. 53 Further increasing<br />

the amount of oleylamine from 0.63 to 2.50 mmol<br />

correspondingly increases the nucleation rate to 1.86 × 10 14<br />

mL −1 s −1 (Figure 2), leading to even <strong>small</strong>er Pd NPs with an<br />

average diameter of 3.4 ± 0.4 nm from SAXS (Figure 2d−f).<br />

Figure 4. Quantitative analysis of (a) size, (b) concentration, and (c)<br />

yield of Pd NPs as measured via in situ SAXS during the syntheses<br />

with different amounts of TOP. (d) Representative TEM image of the<br />

final Pd NPs. (e) SAXS pattern (colored plot) and the corresponding<br />

fit (black plot) of the as-synthesized Pd NPs. (f) Size and size<br />

distribution measured from TEM (histogram) and SAXS (dotted<br />

plots, normalized to the maximum of the histogram).<br />

1130<br />

DOI: 10.1021/acs.chemmater.7b05186<br />

Chem. Mater. 2018, 30, 1127−1135

Chemistry of Materials<br />

Article<br />

Figure 5. (a, b) Quantitative analysis of (a) size and (b) yield of Pd NPs measured via in situ SAXS at varying molar ratios of oleic acid:TOP<br />

(reactions E−G). (c) Represenative TEM images of the dispersed Pd NPs synthesized from reaction E (upper), reaction F (middle), and reaction G<br />

(lower). Scale bars are 20 nm. (d) SAXS patterns (colored plots) and corresponding fits (black line) of the as-synthesized Pd NPs. (e) Size and size<br />

distribution measured from TEM (histogram) and SAXS (dotted plots, normalized to the maximum of the histogram). Results from reactions E, F,<br />

and G are shown in red, blue, and purple, respectively.<br />

Figure 6. Classical modeling of the formation kinetics of Pd NPs using different ligands. (a) Only TOP (reaction A). (b) A mixture of TOP and<br />

oleylamine (reaction C). (c) A large excess of TOP (reaction D). (d) A mixture of oleic acid and TOP (reaction F). The red lines are from the<br />

classical model, and the size and size distribution are experimental results from SAXS.<br />

large amount of monomer, the nucleation rate (1.01 × 10 13<br />

mL −1 s −1 ) is more than an order of magnitude <strong>small</strong>er<br />

compared to that for reaction C (1.86 × 10 14 mL −1 s −1 ), and<br />

the nucleation process lasts much longer (∼290 s) compared to<br />

the rapid nucleation (∼50 s) for reaction C (Figure 4a,b). As a<br />

result, fewer nuclei are formed (1.9 × 10 15 mL −1 vs 8.5 × 10 15<br />

mL −1 ) and the final Pd NPs are larger in diameter (5.5 ± 0.6<br />

nm for reaction D vs 3.4 ± 0.4 nm for reaction C) from SAXS,<br />

Figure 4e,f), which are also confirmed by ex situ TEM (Figure<br />

4d). It is worth mentioning that, due to much longer nucleation<br />

process in reaction D, the particle size distribution is wider<br />

(Figure 4d), thus highlighting the importance of controlling<br />

precursor reactivity for burst nucleation in order to obtain<br />

narrow size distribution.<br />

Recently we reported that, in stark contrast to conventional<br />

colloidal synthesis, the Pd NPs rapidly crystallize into threedimensional<br />

superlattices in the presence of oleic acid rather<br />

than dispersed NPs, and weak binding between oleic acid and<br />

Pd NPs plays a critical role in the crystallization. 41 We found<br />

that, in the presence of oleic acid (1:1 molar ratio of oleic<br />

1131<br />

DOI: 10.1021/acs.chemmater.7b05186<br />

Chem. Mater. 2018, 30, 1127−1135

Chemistry of Materials<br />

Article<br />

Table 3. Fitting Parameters Used for Modelling the Nucleation and Growth Kinetics<br />

reaction A B C D E F G<br />

γ (J m −2 ) 1.155 1.150 1.142 1.245 1.160 1.175 1.192<br />

ξ 100000 115000 135000 80000 56700 50000 40000<br />

k r /T (nm s −1 K −1 ) 0.407 0.355 0.305 0.566 0.714 0.799 0.985<br />

acid:TOP), Pd NPs start to form at 200 °C, which is ∼30 °C<br />

lower than the standard reaction A with only TOP. Oleic acid<br />

acts like a “catalyst” for the thermal decomposition of the Pd−<br />

TOP complex, which is probably due to either the active<br />

involvement of oleic acid in the thermal decomposition of Pd−<br />

TOP complex or the formation of a Pd(oleate) x (TOP) y<br />

complex that decomposes at lower temperatures compared to<br />

pure Pd−TOP complex. 58−60 The reduced reaction temperature<br />

resulted in a <strong>small</strong>er nucleation rate, and consequently,<br />

larger particles of 6.8 ± 0.4 nm, which is ∼2.8 nm larger than<br />

the Pd NPs synthesized without oleic acid (reaction A). 41 By<br />

increasing the amount of oleic acid, we observed similar in situ<br />

assembly of Pd NPs into face-centered cubic superlattices,<br />

followed by postgrowth of Pd NPs inside the superlattices as<br />

described before 41 (Figure S6−S9). The mean diameter and<br />

the yield of Pd NPs as a function of reaction time derived from<br />

SAXS are shown in Figure 5a,b. Interestingly, increasing the<br />

molar ratio of oleic acid:TOP results in even larger Pd NPs<br />

with narrow size distributions. Pd NPs of 7.5 ± 0.5 nm, 9.2 ±<br />

0.6 nm, and 11.0 ± 0.9 nm average diameters from SAXS were<br />

synthesized using 3:1, 7.5:1, and 12.5:1 molar ratios of oleic<br />

acid:TOP, respectively (Figure 5c−e). We ascribe the large<br />

tunability of size to different nucleation rates caused by<br />

different binding affinity of oleic acid/TOP on Pd NPs.<br />

To gain more insights on the formation of Pd NPs with<br />

different ligands, we modeled the nucleation and growth<br />

kinetics using classical models 61 in which three steps are<br />

involved: (i) decomposition of Pd precursor into monomers;<br />

(ii) reaction of monomers to form nuclei; and (iii) growth of<br />

nuclei with addition of monomers (see details in SI). Fitting the<br />

experimental results to these models provides useful insights on<br />

the nucleation kinetics and the growth-limiting mechanism of<br />

Pd NPs in the presence of different ligands. The nucleation rate<br />

is dependent on the degree of supersaturation, reaction<br />

temperature, and interfacial tension between NP and the<br />

solvent. The growth rate can be expressed by the equation<br />

⎡ 2γV<br />

⎤<br />

DV C ⎣S<br />

− exp<br />

r<br />

(<br />

m<br />

d<br />

m 0<br />

rRT ) ⎦<br />

=<br />

, where D is the diffusion coefficient of<br />

dt<br />

r+<br />

D/<br />

kr<br />

Pd monomers, V m is the molar volume of Pd NPs, C 0 is<br />

monomer solubility, S is the dimensionless parameter<br />

describing the supersaturation of Pd monomer in the solution,<br />

r is the radius of Pd NPs, γ is interfacial tension between Pd NP<br />

and the solvent, k r is the surface reaction rate of the<br />

incorporation of monomers into the NPs, R is gas constant<br />

(8.314 J K −1 mol −1 ), and T is the reaction temperature. 62−64<br />

This equation is converted into dimensionless form<br />

* *<br />

dr S−<br />

exp(1 / r )<br />

=<br />

dτ<br />

*<br />

r + ξ<br />

with three dimensionless parameters: the<br />

*<br />

RT<br />

reduced radius r = γ<br />

r, the reduced kinetic length<br />

2 V m<br />

D<br />

RT<br />

RT<br />

( )<br />

ξ = , and the reduced time τ = ( kr<br />

2γVm<br />

γ<br />

VC ) Dt<br />

2 V m 0 .By<br />

m<br />

adjusting the parameters, we obtained a good fit to<br />

experimental results in both nucleation and growth regimes<br />

of reaction A with γ = 1.155 J m −2 , k r /T = 4.07 × 10 −1 nm s −1<br />

K −1 , and ξ = 1.0 × 10 5 (Figure 6a). The large ξ ≫ 1 indicates<br />

2<br />

that k r·r ≪ D, suggesting that the growth of Pd NPs is limited<br />

by surface reaction between monomers and Pd NPs rather than<br />

by diffusion of monomers to the particle surface. 62 As discussed<br />

before, oleylamine does not change the Pd−TOP precursor<br />

reactivity, and thus good fits of the growth kinetics were<br />

obtained showing similar nucleation and growth mode (Figures<br />

6b and S10 and Table 3). The slight decrease of the γ value in<br />

the presence of oleylamine is in line with our hypothesis that<br />

stronger binding ligand covers NPs more densely reducing the<br />

NP−solvent interfacial tension. However, in the presence of<br />

large excess of TOP, a classical growth kinetic model does not<br />

provide a good fit to the experimental results due to substantial<br />

decrease of precursor reactivity (Figure 6c), suggesting that the<br />

particle growth is limited neither by the monomer diffusion nor<br />

by surface reaction but instead by the thermal activation of Pd<br />

precursor, which is confirmed by our experimental observations.<br />

In the case with oleic acid, the classical model fits well<br />

with the experimental results (Figures 6d and S10), suggesting<br />

the same surface-reaction limited growth mechanism. The<br />

larger γ value in the case of oleic acid suggests less dense ligand<br />

coverage of Pd NPs, which was confirmed by weaker binding<br />

between oleic acid and Pd NPs compared to oleylamine or<br />

TOP. 41 The same trend of larger γ with oleic acid compared to<br />

oleylamine was also observed in the Au NPs. 16,64 We should<br />

emphasize that increased value of γ with oleic acid affects the<br />

nucleation and growth kinetics much more considerably, thus<br />

offering wider tunability of the particle size. These results<br />

together with the quantitative results from in situ SAXS<br />

highlight the importance of tailoring the precursor reactivity<br />

and ligand−NP binding affinity to rationally tune the final NP<br />

size. 65,66<br />

4. CONCLUSIONS<br />

Using in situ synchrotron-based SAXS, we have systematically<br />

studied the effect of different ligands (i.e., oleylamine, TOP,<br />

and oleic acid) on the synthesis of Pd NPs. Through<br />

quantitative analysis we have shown that nucleation kinetics<br />

is strongly dependent on the Pd−TOP precursor reactivity and<br />

ligand−NP binding affinity, which determines the final particle<br />

size and quality. Due to the formation of thermally stable Pd−<br />

TOP complex, an excess amount of TOP significantly retards<br />

the precursor decomposition and slows down the nucleation<br />

rate by more than an order of magnitude, and larger and more<br />

polydisperse NPs are synthesized. Oleylamine does not affect<br />

the reactivity of Pd−TOP precursor but slightly facilitates the<br />

formation of nuclei due to stronger binding between oleylamine<br />

and Pd NPs, leading to <strong>small</strong>er NPs in the presence of<br />

oleylamine. In contrast, oleic acid strongly influences the<br />

reactivity of the Pd−TOP complex and the nucleation kinetics,<br />

and larger Pd NPs are synthesized in the presence of more oleic<br />

acid. The quantitative understanding of the nucleation kinetics<br />

with different ligands studied by in situ SAXS enables the<br />

synthesis of a library of monodisperse Pd NPs (polydispersity <<br />

10%) with a wide size range from 3 to 11 nm. These welldefined<br />

Pd NPs serve as a model system for studying their sizedependent<br />

catalysis for methane combustion reaction which is<br />

1132<br />

DOI: 10.1021/acs.chemmater.7b05186<br />

Chem. Mater. 2018, 30, 1127−1135

Chemistry of Materials<br />

Article<br />

presented in a separate publication. 67 The in situ SAXS<br />

measurement coupled with the versatile flask reactor can be<br />

readily extended to a broad variety of functional NPs to<br />

accelerate their synthetic developments for both fundamental<br />

research<br />

■<br />

and technological applications.<br />

ASSOCIATED CONTENT<br />

*S Supporting Information<br />

The Supporting Information is available free of charge on the<br />

ACS Publications website at DOI: 10.1021/acs.chemmater.7b05186.<br />

Details on the SAXS data analysis, kinetic models on the<br />

formation of nanoparticles, and additional supplementary<br />

Figures S1−S10 (PDF)<br />

■ AUTHOR INFORMATION<br />

Corresponding Authors<br />

*(C.J.T.) E-mail: tassone@slac.stanford.edu.<br />

*(M.C.) E-mail: mcargnello@stanford.edu.<br />

ORCID<br />

Jian Qin: 0000-0001-6271-068X<br />

Matteo Cargnello: 0000-0002-7344-9031<br />

Notes<br />

The authors declare no competing financial interest.<br />

■ ACKNOWLEDGMENTS<br />

This work was supported by the U.S. Department of Energy<br />

(DOE), Laboratory Directed Research and Development<br />

program, at SLAC National Accelerator Laboratory under<br />

Contract No. DE-AC02-76SF00515. In situ SAXS experiments<br />

were performed at the Beamline 1-5 at the Stanford<br />

Synchrotron Radiation Lightsource (SSRL) of SLAC, and use<br />

of the SSRL is supported by the DOE Office of Science, Office<br />

of Basic Energy Sciences, under Contract No. DE-AC02-<br />

76SF00515. J.J.W. acknowledges support from the U.S.<br />

Department of Energy, Office of Sciences, Office of Basic<br />

Energy Sciences, to the SUNCAT Center for Interface Science<br />

and Catalysis. M.C. acknowledges support from the School of<br />

Engineering at Stanford University and from a Terman Faculty<br />

Fellowship. J.Q. acknowledges support from the 3M Non-<br />

Tenured Faculty Award and the Hellman Scholar Award.<br />

E.D.G. acknowledges support from the National Science<br />

Foundation Graduate Research Fellowship under Grant<br />

DGE-1656518. I.S.M. was supported by the Department of<br />

Defense through the National Defense Science & Engineering<br />

Graduate Fellowship Program and by the Fannie and John<br />

Hertz Foundation through a Hertz Foundation Fellowship.<br />

L.W. and C.J.T. thank T.J. Dunn from SSRL for his assistance<br />

during the experiments. The electron microscopy characterization<br />

was performed at the Stanford Nano Shared Facilities<br />

(SNSF) at Stanford University.<br />

■ REFERENCES<br />

(1) Wu, L.; Mendoza-Garcia, A.; Li, Q.; Sun, S. Organic Phase<br />

Syntheses of Magnetic Nanoparticles and Their Applications. Chem.<br />

Rev. 2016, 116, 10473−10512.<br />

(2) Talapin, D. V.; Lee, J.-S.; Kovalenko, M. V.; Shevchenko, E. V.<br />

Prospects of Colloidal Nanocrystals for Electronic and Optoelectronic<br />

Applications. Chem. Rev. 2010, 110, 389−458.<br />

(3) Boles, M. A.; Ling, D.; Hyeon, T.; Talapin, D. V. The Surface<br />

Science of Nanocrystals. Nat. Mater. 2016, 15, 141−153.<br />

1133<br />

(4) Park, J.; Lee, E.; Hwang, N. M.; Kang, M. S.; Kim, S. C.; Hwang,<br />

Y.; Park, J. G.; Noh, H. J.; Kim, J. Y.; Park, J. H.; Hyeon, T. Onenanometer-scale<br />

Size-controlled Synthesis of Monodisperse Magnetic<br />

Iron Oxide Nanoparticles. Angew. Chem., Int. Ed. 2005, 44, 2872−<br />

2877.<br />

(5) Wang, C.; Daimon, H.; Onodera, T.; Koda, T.; Sun, S. H. A<br />

General Approach to the Size- and Shape-controlled Synthesis of<br />

Platinum Nanoparticles and Their Catalytic Reduction of Oxygen.<br />

Angew. Chem., Int. Ed. 2008, 47, 3588−3591.<br />

(6) Wang, C.; Hou, Y. L.; Kim, J. M.; Sun, S. H. A General Strategy<br />

for Synthesizing FePt Nanowires and Nanorods. Angew. Chem., Int. Ed.<br />

2007, 46, 6333−6335.<br />

(7) Yan, Y.; Du, J. S.; Gilroy, K. D.; Yang, D.; Xia, Y.; Zhang, H.<br />

Intermetallic Nanocrystals: Syntheses and Catalytic Applications. Adv.<br />

Mater. 2017, 29, 1605997.<br />

(8) De Trizio, L.; Manna, L. Forging Colloidal Nanostructures via<br />

Cation Exchange Reactions. Chem. Rev. 2016, 116, 10852−10887.<br />

(9) Liao, H. G.; Cui, L. K.; Whitelam, S.; Zheng, H. M. Real-Time<br />

Imaging of Pt 3 Fe Nanorod Growth in Solution. Science 2012, 336,<br />

1011−1014.<br />

(10) Yuk, J. M.; Park, J.; Ercius, P.; Kim, K.; Hellebusch, D. J.;<br />

Crommie, M. F.; Lee, J. Y.; Zettl, A.; Alivisatos, A. P. High-Resolution<br />

EM of Colloidal Nanocrystal Growth Using Graphene Liquid Cells.<br />

Science 2012, 336, 61−64.<br />

(11) Pauw, B. R. Everything SAXS: Small-<strong>angle</strong> Scattering Pattern<br />

Collection and Correction. J. Phys.: Condens. Matter 2013, 25, 383201.<br />

(12) Ilavsky, J.; Jemian, P. R. Irena: Tool Suite for Modeling and<br />

Analysis of Small-<strong>angle</strong> Scattering. J. Appl. Crystallogr. 2009, 42, 347−<br />

353.<br />

(13) Sun, Y.; Ren, Y. In Situ Synchrotron X-Ray Techniques for Real-<br />

Time Probing of Colloidal Nanoparticle Synthesis. Part. Part. Syst.<br />

Char. 2013, 30, 399−419.<br />

(14) Ingham, B. X-<strong>ray</strong> Scattering Characterisation of Nanoparticles.<br />

Crystallogr. Rev. 2015, 21, 229−303.<br />

(15) Li, T.; Senesi, A. J.; Lee, B. Small Angle X-<strong>ray</strong> Scattering for<br />

Nanoparticle Research. Chem. Rev. 2016, 116, 11128−11180.<br />

(16) Abecassis, B.; Testard, F.; Spalla, O.; Barboux, P. Probing in Situ<br />

the Nucleation and Growth of Gold Nanoparticles by Small-<strong>angle</strong> X-<br />

<strong>ray</strong> Scattering. Nano Lett. 2007, 7, 1723−1727.<br />

(17) Henkel, A.; Schubert, O.; Plech, A.; Sonnichsen, C. Growth<br />

Kinetic of a Rod-Shaped Metal Nanocrystal. J. Phys. Chem. C 2009,<br />

113, 10390−10394.<br />

(18) Polte, J.; Ahner, T. T.; Delissen, F.; Sokolov, S.; Emmerling, F.;<br />

Thunemann, A. F.; Kraehnert, R. Mechanism of Gold Nanoparticle<br />

Formation in the Classical Citrate Synthesis Method Derived from<br />

Coupled in Situ XANES and SAXS Evaluation. J. Am. Chem. Soc. 2010,<br />

132, 1296−1301.<br />

(19) Polte, J.; Erler, R.; Thunemann, A. F.; Sokolov, S.; Ahner, T. T.;<br />

Rademann, K.; Emmerling, F.; Kraehnert, R. Nucleation and Growth<br />

of Gold Nanoparticles Studied via in situ Small Angle X-<strong>ray</strong> Scattering<br />

at Millisecond Time Resolution. ACS Nano 2010, 4, 1076−1082.<br />

(20) Takesue, M.; Tomura, T.; Yamada, M.; Hata, K.; Kuwamoto, S.;<br />

Yonezawa, T. Size of Elementary Clusters and Process Period in Silver<br />

Nanoparticle Formation. J. Am. Chem. Soc. 2011, 133, 14164−14167.<br />

(21) Koerner, H.; MacCuspie, R. I.; Park, K.; Vaia, R. A. In Situ UV/<br />

Vis, SAXS, and TEM Study of Single-Phase Gold Nanoparticle<br />

Growth. Chem. Mater. 2012, 24, 981−995.<br />

(22) Peng, S.; Okasinski, J. S.; Almer, J. D.; Ren, Y.; Wang, L.; Yang,<br />

W.; Sun, Y. Real-Time Probing of the Synthesis of Colloidal Silver<br />

Nanocubes with Time-Resolved High-Energy Synchrotron X-<strong>ray</strong><br />

Diffraction. J. Phys. Chem. C 2012, 116, 11842−11847.<br />

(23) St. John, S.; Hu, N. P.; Schaefer, D. W.; Angelopoulos, A. P.<br />

Time-Resolved, in Situ, Small- and Wide-Angle X-<strong>ray</strong> Scattering To<br />

Monitor Pt Nanoparticle Structure Evolution Stabilized by Adsorbed<br />

SnCl 3 − Ligands During Synthesis. J. Phys. Chem. C 2013, 117, 7924−<br />

7933.<br />

(24) Abecassis, B.; Bouet, C.; Garnero, C.; Constantin, D.; Lequeux,<br />

N.; Ithurria, S.; Dubertret, B.; Pauw, B. R.; Pontoni, D. Real-Time in<br />

DOI: 10.1021/acs.chemmater.7b05186<br />

Chem. Mater. 2018, 30, 1127−1135

Chemistry of Materials<br />

Situ Probing of High-Temperature Quantum Dots Solution Synthesis.<br />

Nano Lett. 2015, 15, 2620−2626.<br />

(25) Liu, Q.; Gao, M. R.; Liu, Y.; Okasinski, J. S.; Ren, Y.; Sun, Y.<br />

Quantifying the Nucleation and Growth Kinetics of Microwave<br />

Nanochemistry Enabled by in Situ High-Energy X-<strong>ray</strong> Scattering. Nano<br />

Lett. 2016, 16, 715−20.<br />

(26) Karim, A. M.; Al Hasan, N.; Ivanov, S.; Siefert, S.; Kelly, R. T.;<br />

Hallfors, N. G.; Benavidez, A.; Kovarik, L.; Jenkins, A.; Winans, R. E.;<br />

Datye, A. K. Synthesis of 1 nm Pd Nanoparticles in a Microfluidic<br />

Reactor: Insights from in Situ X-<strong>ray</strong> Absorption Fine Structure<br />

Spectroscopy and Small-Angle X-<strong>ray</strong> Scattering. J. Phys. Chem. C 2015,<br />

119, 13257−13267.<br />

(27) van der Stam, W.; Rabouw, F. T.; Geuchies, J. J.; Berends, A. C.;<br />

Hinterding, S. O. M.; Geitenbeek, R. G.; van der Lit, J.; Prevost, S.;<br />

Petukhov, A. V.; de Mello Donega, C. D. In Situ Probing of Stack-<br />

Templated Growth of Ultrathin Cu 2‐x S Nanosheets. Chem. Mater.<br />

2016, 28, 6381−6389.<br />

(28) Mozaffari, S.; Li, W.; Thompson, C.; Ivanov, S.; Seifert, S.; Lee,<br />

B.; Kovarik, L.; Karim, A. M. Colloidal Nnanoparticle Size Control:<br />

Experimental and Kinetic Modeling Investigation of the Ligand-Metal<br />

Binding Role in Controlling the Nucleation and Growth Kinetics.<br />

Nanoscale 2017, 9, 13772−13785.<br />

(29) Cheong, S.; Watt, J.; Ingham, B.; Toney, M. F.; Tilley, R. D. In<br />

Situ and ex Situ Studies of Platinum Nanocrystals: Growth and<br />

Evolution in Solution. J. Am. Chem. Soc. 2009, 131, 14590−14595.<br />

(30) Cormary, B.; Li, T.; Liakakos, N.; Peres, L.; Fazzini, P. F.; Blon,<br />

T.; Respaud, M.; Kropf, A. J.; Chaudret, B.; Miller, J. T.; Mader, E. A.;<br />

Soulantica, K. Concerted Growth and Ordering of Cobalt Nanorod<br />

Ar<strong>ray</strong>s as Revealed by Tandem in Situ SAXS-XAS Studies. J. Am. Chem.<br />

Soc. 2016, 138, 8422−8431.<br />

(31) Lassenberger, A.; Grunewald, T. A.; van Oostrum, P. D. J.;<br />

Rennhofer, H.; Amenitsch, H.; Zirbs, R.; Lichtenegger, H. C.;<br />

Reimhult, E. Monodisperse Iron Oxide Nanoparticles by Thermal<br />

Decomposition: Elucidating Particle Formation by Second-Resolved in<br />

Situ Small-Angle X-<strong>ray</strong> Scattering. Chem. Mater. 2017, 29, 4511−4522.<br />

(32) Ortiz, N.; Hammons, J. A.; Cheong, S.; Skrabalak, S. E.<br />

Monitoring Ligand-Mediated Growth and Aggregation of Metal<br />

Nanoparticles and Nanodendrites by in Situ Synchrotron Scattering<br />

Techniques. ChemNanoMat 2015, 1, 109−114.<br />

(33) Sakamoto, N.; Harada, M.; Hashimoto, T. In situ and Timeresolved<br />

SAXS Studies of Pd Nanoparticle Formation in a Template of<br />

Block Copolymer Microdomain Structures. Macromolecules 2006, 39,<br />

1116−1124.<br />

(34) Harada, M.; Tamura, N.; Takenaka, M. Nucleation and Growth<br />

of Metal Nanoparticles during Photoreduction Using In Situ Time-<br />

Resolved SAXS Analysis. J. Phys. Chem. C 2011, 115, 14081−14092.<br />

(35) Manocchi, A. K.; Seifert, S.; Lee, B.; Yi, H. In Situ Small-Angle<br />

X-<strong>ray</strong> Scattering Analysis of Palladium Nanoparticle Growth on<br />

Tobacco Mosaic Virus Nanotemplates. Langmuir 2011, 27, 7052−<br />

7058.<br />

(36) Wang, J. A.; Winans, R. E.; Anderson, S. L.; Seifert, S.; Lee, B.;<br />

Chupas, P. J.; Ren, Y.; Lee, S.; Liu, Y. Z. In Situ Small-Angle X-<strong>ray</strong><br />

Scattering from Pd Nanoparticles Formed by Thermal Decomposition<br />

of Organo-Pd Catalyst Precursors Dissolved in Hydrocarbons. J. Phys.<br />

Chem. C 2013, 117, 22627−22635.<br />

(37) Sun, Y.; Zuo, X.; Sankarana<strong>ray</strong>anan, S.; Peng, S.; Na<strong>ray</strong>anan, B.;<br />

Kamath, G. Quantitative 3D Evolution of Colloidal Nanoparticle<br />

Oxidation in Solution. Science 2017, 356, 303−307.<br />

(38) Kim, S. W.; Park, J.; Jang, Y.; Chung, Y.; Hwang, S.; Hyeon, T.;<br />

Kim, Y. W. Synthesis of Monodisperse Palladium Nanoparticles. Nano<br />

Lett. 2003, 3, 1289−1291.<br />

(39) Cargnello, M.; Doan-Nguyen, V. V. T.; Gordon, T. R.; Diaz, R.<br />

E.; Stach, E. A.; Gorte, R. J.; Fornasiero, P.; Mur<strong>ray</strong>, C. B. Control of<br />

Metal Nanocrystal Size Reveals Metal-Support Interface Role for Ceria<br />

Catalysts. Science 2013, 341, 771−773.<br />

(40) van Embden, J.; Chesman, A. S. R.; Jasieniak, J. J. The Heat-Up<br />

Synthesis of Colloidal Nanocrystals. Chem. Mater. 2015, 27, 2246−<br />

2285.<br />

1134<br />

Article<br />

(41) Wu, L.; Willis, J. J.; McKay, I. S.; Diroll, B. T.; Qin, J.; Cargnello,<br />

M.; Tassone, C. J. High-Temperature Crystallization of Nanocrystals<br />

into Three-Dimensional Superlattices. Nature 2017, 548, 197−201.<br />

(42) Cargnello, M.; Jaen, J. J. D.; Garrido, J. C. H.; Bakhmutsky, K.;<br />

Montini, T.; Gamez, J. J. C.; Gorte, R. J.; Fornasiero, P. Exceptional<br />

Activity for Methane Combustion over Modular Pd@CeO 2 Subunits<br />

on Functionalized Al 2 O 3 . Science 2012, 337, 713−717.<br />

(43) Cargnello, M.; Wieder, N. L.; Montini, T.; Gorte, R. J.;<br />

Fornasiero, P. Synthesis of Dispersible Pd@CeO 2 Core-Shell<br />

Nanostructures by Self-Assembly. J. Am. Chem. Soc. 2010, 132,<br />

1402−1409.<br />

(44) Jin, T.; Guo, S. J.; Zuo, J. L.; Sun, S. H. Synthesis and Assembly<br />

of Pd Nanoparticles on Graphene for Enhanced Electrooxidation of<br />

Formic Acid. Nanoscale 2013, 5, 160−163.<br />

(45) Xi, Z.; Erdosy, D. P.; Mendoza-Garcia, A.; Duchesne, P. N.; Li, J.<br />

R.; Muzzio, M.; Li, Q.; Zhang, P.; Sun, S. H. Pd Nanoparticles<br />

Coupled to WO 2.72 Nanorods for Enhanced Electrochemical<br />

Oxidation of Formic Acid. Nano Lett. 2017, 17, 2727−2731.<br />

(46) Liu, Q. S.; Bauer, J. C.; Schaak, R. E.; Lunsford, J. H. Supported<br />

Palladium Nanoparticles: An Efficient Catalyst for the Direct<br />

Formation of H 2 O 2 from H 2 and O 2 . Angew. Chem., Int. Ed. 2008,<br />

47, 6221−6224.<br />

(47) Niu, Z. Q.; Peng, Q.; Gong, M.; Rong, H. P.; Li, Y. D.<br />

Oleylamine-Mediated Shape Evolution of Palladium Nanocrystals.<br />

Angew. Chem., Int. Ed. 2011, 50, 6315−6319.<br />

(48) Man, R. W. Y.; Brown, A. R. C.; Wolf, M. O. Mechanism of<br />

Formation of Palladium Nanoparticles: Lewis Base Assisted, Low-<br />

Temperature Preparation of Monodisperse Nanoparticles. Angew.<br />

Chem., Int. Ed. 2012, 51, 11350−11353.<br />

(49) Lv, T.; Wang, Y.; Choi, S. I.; Chi, M. F.; Tao, J.; Pan, L. K.;<br />

Huang, C. Z.; Zhu, Y. M.; Xia, Y. N. Controlled Synthesis of<br />

Nanosized Palladium Icosahedra and Their Catalytic Activity towards<br />

Formic-Acid Oxidation. ChemSusChem 2013, 6, 1923−1930.<br />

(50) Mazumder, V.; Sun, S. H. Oleylamine-Mediated Synthesis of Pd<br />

Nanoparticles for Catalytic Formic Acid Oxidation. J. Am. Chem. Soc.<br />

2009, 131, 4588−4589.<br />

(51) Liu, Y.; Wang, C.; Wei, Y. J.; Zhu, L. Y.; Li, D. G.; Jiang, J. S.;<br />

Markovic, N. M.; Stamenkovic, V. R.; Sun, S. H. Surfactant-Induced<br />

Postsynthetic Modulation of Pd Nanoparticle Crystallinity. Nano Lett.<br />

2011, 11, 1614−1617.<br />

(52) Ortiz, N.; Skrabalak, S. E. Manipulating Local Ligand<br />

Environments for the Controlled Nucleation of Metal Nanoparticles<br />

and their Assembly into Nanodendrites. Angew. Chem., Int. Ed. 2012,<br />

51, 11757−11761.<br />

(53) Cargnello, M.; Doan-Nguyen, V. V. T.; Mur<strong>ray</strong>, C. B.<br />

Engineering Uniform Nanocrystals: Mechanism of Formation and<br />

Self-assembly into Bimetallic Nanocrystal Superlattices. AIChE J. 2016,<br />

62, 392−398.<br />

(54) Zhang, F.; Ilavsky, J.; Long, G. G.; Quintana, J. P. G.; Allen, A.<br />

J.; Jemian, P. R. Glassy Carbon as an Absolute Intensity Calibration<br />

Standard for Small-Angle Scattering. Metall. Mater. Trans. A 2010, 41,<br />

1151−1158.<br />

(55) Zheng, H. M.; Smith, R. K.; Jun, Y. W.; Kisielowski, C.;<br />

Dahmen, U.; Alivisatos, A. P. Observation of Single Colloidal Platinum<br />

Nanocrystal Growth Trajectories. Science 2009, 324, 1309−1312.<br />

(56) Wang, F. D.; Richards, V. N.; Shields, S. P.; Buhro, W. E.<br />

Kinetics and Mechanisms of Aggregative Nanocrystal Growth. Chem.<br />

Mater. 2014, 26, 5−21.<br />

(57) Mourdikoudis, S.; Liz-Marzan, L. M. Oleylamine in Nanoparticle<br />

Synthesis. Chem. Mater. 2013, 25, 1465−1476.<br />

(58) Gallagher, P. K.; Gross, M. E. The Thermal-Decomposition of<br />

Palladium Acetate. J. Therm. Anal. 1986, 31, 1231−1241.<br />

(59) Amatore, C.; Jutand, A.; M'barki, M. A. Evidence of the<br />

Formation of Zerovalent Palladium from Pd(OAc) 2 and Triphenylphosphine.<br />

Organometallics 1992, 11, 3009−3013.<br />

(60) Stephenson, Ta; Morehouse, Sm; Powell, A. R.; Heffer, J. P.;<br />

Wilkinson, G. Carboxylates of Palladium Platinum and Rhodium and<br />

Their Adducts. J. Chem. Soc. 1965, 0, 3632−3640.<br />

DOI: 10.1021/acs.chemmater.7b05186<br />

Chem. Mater. 2018, 30, 1127−1135

Chemistry of Materials<br />

Article<br />

(61) Lamer, V. K.; Dinegar, R. H. Theory, Production and<br />

Mechanism of Formation of Monodispersed Hydrosols. J. Am.<br />

Chem. Soc. 1950, 72, 4847−4854.<br />

(62) Talapin, D. V.; Rogach, A. L.; Haase, M.; Weller, H. Evolution<br />

of an Ensemble of Nanoparticles in a Colloidal Solution: Theoretical<br />

Study. J. Phys. Chem. B 2001, 105, 12278−12285.<br />

(63) van Embden, J.; Sader, J. E.; Davidson, M.; Mulvaney, P.<br />

Evolution of Colloidal Nanocrystals: Theory and Modeling of their<br />

Nucleation and Growth. J. Phys. Chem. C 2009, 113, 16342−16355.<br />

(64) Chen, X. L.; Schroder, J.; Hauschild, S.; Rosenfeldt, S.; Dulle,<br />

M.; Forster, S. Simultaneous SAXS/WAXS/UV-Vis Study of the<br />

Nucleation and Growth of Nanoparticles: A Test of Classical<br />

Nucleation Theory. Langmuir 2015, 31, 11678−11691.<br />

(65) Hendricks, M. P.; Campos, M. P.; Cleveland, G. T.; Jen-La<br />

Plante, I.; Owen, J. S. A Tunable Library of Substituted Thiourea<br />

Precursors to Metal Sulfide Nanocrystals. Science 2015, 348, 1226−<br />

1230.<br />

(66) Yin, X.; Shi, M.; Wu, J.; Pan, Y. T.; G<strong>ray</strong>, D. L.; Bertke, J. A.;<br />

Yang, H. Quantitative Analysis of Different Formation Modes of<br />

Platinum Nanocrystals Controlled by Ligand Chemistry. Nano Lett.<br />

2017, 17, 6146−6150.<br />

(67) Willis, J. J.; Gallo, A.; Sokaras, D.; Aljama, H.; Nowak, S. H.;<br />

Goodman, E. D.; Wu, L. H.; Tassone, C. J.; Jaramillo, T. F.; Abild-<br />

Pedersen, F.; Cargnello, M. Systematic Structure Property Relationship<br />

Studies in Palladium Catalyzed Methane Complete Combustion.<br />

ACS Catal. 2017, 7, 7810−7821.<br />

1135<br />

DOI: 10.1021/acs.chemmater.7b05186<br />

Chem. Mater. 2018, 30, 1127−1135