surface pretreatment by phosphate conversion coatings – a review

surface pretreatment by phosphate conversion coatings – a review

surface pretreatment by phosphate conversion coatings – a review

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Surface <strong>pretreatment</strong> <strong>by</strong> <strong>phosphate</strong> <strong>conversion</strong> <strong>coatings</strong> <strong>–</strong> a <strong>review</strong><br />

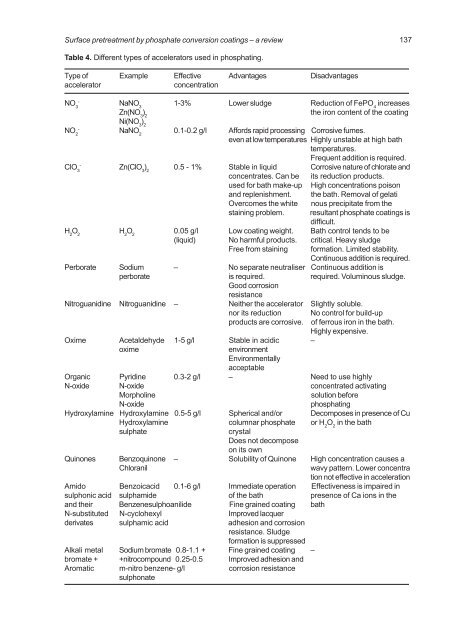

Table 4. Different types of accelerators used in phosphating.<br />

Type of Example Effective Advantages Disadvantages<br />

accelerator concentration<br />

- NO NaNO 1-3% Lower sludge Reduction of FePO increases<br />

3<br />

3 4<br />

Zn(NO ) the iron content of the coating<br />

3 2<br />

Ni(NO ) 3 2<br />

NO 2<br />

ClO 3<br />

- NaNO 2 0.1-0.2 g/l Affords rapid processing Corrosive fumes.<br />

137<br />

even at low temperatures Highly unstable at high bath<br />

temperatures.<br />

Frequent addition is required.<br />

- Zn(ClO 3 ) 2 0.5 - 1% Stable in liquid Corrosive nature of chlorate and<br />

concentrates. Can be its reduction products.<br />

used for bath make-up High concentrations poison<br />

and replenishment. the bath. Removal of gelati<br />

Overcomes the white nous precipitate from the<br />

staining problem. resultant <strong>phosphate</strong> <strong>coatings</strong> is<br />

difficult.<br />

H 2 O 2 H 2 O 2 0.05 g/l Low coating weight. Bath control tends to be<br />

(liquid) No harmful products. critical. Heavy sludge<br />

Free from staining formation. Limited stability.<br />

Continuous addition is required.<br />

Perborate Sodium <strong>–</strong> No separate neutraliser Continuous addition is<br />

perborate is required. required. Voluminous sludge.<br />

Good corrosion<br />

resistance<br />

Nitroguanidine Nitroguanidine <strong>–</strong> Neither the accelerator Slightly soluble.<br />

nor its reduction No control for build-up<br />

products are corrosive. of ferrous iron in the bath.<br />

Highly expensive.<br />

Oxime Acetaldehyde 1-5 g/l Stable in acidic <strong>–</strong><br />

oxime environment<br />

Environmentally<br />

acceptable<br />

Organic Pyridine 0.3-2 g/l <strong>–</strong> Need to use highly<br />

N-oxide N-oxide concentrated activating<br />

Morpholine solution before<br />

N-oxide phosphating<br />

Hydroxylamine Hydroxylamine 0.5-5 g/l Spherical and/or Decomposes in presence of Cu<br />

Hydroxylamine columnar <strong>phosphate</strong> or H 2 O 2 in the bath<br />

sulphate crystal<br />

Does not decompose<br />

on its own<br />

Quinones Benzoquinone <strong>–</strong> Solubility of Quinone High concentration causes a<br />

Chloranil wavy pattern. Lower concentra<br />

tion not effective in acceleration<br />

Amido Benzoicacid 0.1-6 g/l Immediate operation Effectiveness is impaired in<br />

sulphonic acid sulphamide of the bath presence of Ca ions in the<br />

and their Benzenesulphoanilide Fine grained coating bath<br />

N-substituted N-cyclohexyl Improved lacquer<br />

derivates sulphamic acid adhesion and corrosion<br />

resistance. Sludge<br />

formation is suppressed<br />

Alkali metal Sodium bromate 0.8-1.1 + Fine grained coating <strong>–</strong><br />

bromate + +nitrocompound 0.25-0.5 Improved adhesion and<br />

Aromatic m-nitro benzene- g/l corrosion resistance<br />

sulphonate