You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

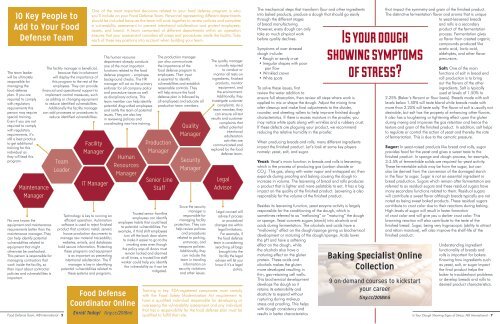

10 Key People to<br />

Add to Your Food<br />

Defense Team<br />

The team leader<br />

will be ultimately<br />

responsible for<br />

managing the<br />

food defense<br />

plan. If you are<br />

required to comply<br />

with regulatory<br />

requirements this<br />

person may require<br />

special training.<br />

Even if you are not<br />

required to comply<br />

with regulatory<br />

requirements, it’s<br />

still a best practice<br />

to get additional<br />

training for this<br />

individual as<br />

they will lead this<br />

program.<br />

Maintenance<br />

Manager<br />

No one knows the<br />

equipment and maintenance<br />

requirements better than the<br />

maintenance manager. They<br />

can help identify potential<br />

vulnerabilities related to<br />

equipment that might<br />

otherwise be overlooked.<br />

This person is responsible for<br />

managing contractors that<br />

work inside the facility, so<br />

their input about contractor<br />

policies and vulnerabilities is<br />

important.<br />

The facility manager is beneficial,<br />

because their involvement<br />

will display the importance of<br />

this program to the rest of the<br />

employees. They can provide<br />

financial and operational support to<br />

implement control measures, such<br />

as adding or changing equipment<br />

to reduce identified vulnerabilities.<br />

Additionally the facility manager<br />

can add processes or procedures to<br />

reduce identified vulnerabilities.<br />

Team<br />

Leader<br />

Food Defense Team, <strong>AIB</strong> International - 2<br />

One of the most important decisions related to your food defense program is who<br />

you’ll include on your Food Defense Team. Personnel representing different departments<br />

should be included because the team will work together to review policies and complete<br />

a vulnerability assessment to prevent intentional adulteration and protect employees,<br />

assets, and brand. A team comprised of different departments within an operation<br />

ensures that your assessment considers all areas and procedures inside the facility. Take<br />

each of these key positions into account when building your team.<br />

Facility<br />

Manager<br />

IT Manager<br />

Technology is key to running an<br />

efficient operation. Automation<br />

software is used to reject finished<br />

product that contains metal; servers<br />

house production documents to<br />

manage raw material traceability;<br />

websites, emails, and databases<br />

hold secure information. Protecting<br />

these programs and equipment<br />

is as important as preventing<br />

intentional adulteration. The IT<br />

manager is key in identifying<br />

potential vulnerabilities related to<br />

these systems and programs.<br />

The human resource<br />

department already conducts<br />

one of the most important<br />

functions related to the food<br />

defense program – employee<br />

background checks. The HR<br />

manager will act as the primary<br />

enforcer for all company policy<br />

and procedure issues as well<br />

as disciplinary actions. This<br />

team member can help identify<br />

potential disgruntled employees<br />

and notify the team of potential<br />

issues. They are also key<br />

in reviewing policies and<br />

coordinating new hire training.<br />

Human<br />

Resources<br />

Manager<br />

Food Defense<br />

Coordinator Online<br />

Enroll Today! tiny.cc/<strong>2018</strong>m1<br />

Trusted senior frontline<br />

employees can identify<br />

employee habits that could lead<br />

to potential vulnerabilities. For<br />

example, if third shift employees<br />

turn off the back door alarm<br />

to make it easier to go to the<br />

smoking area even though<br />

the policy says all doors must<br />

remain locked and alarmed<br />

at all times, a trusted line staff<br />

worker could help you identify<br />

the vulnerability so it can be<br />

mitigated.<br />

The production manager<br />

can also communicate<br />

the importance of the<br />

food defense program to<br />

employees. Their input<br />

is essential to identify<br />

vulnerabilities and establish<br />

reasonable controls. They<br />

will help ensure the food<br />

defense plan is followed by<br />

all employees and educate all<br />

production team members.<br />

Production<br />

Manager<br />

Senior Line<br />

Staff<br />

Quality<br />

Manager<br />

Security<br />

Manager<br />

Since the security<br />

manager is<br />

responsible for<br />

managing facility<br />

protection. They can<br />

help review policies<br />

and procedures<br />

related to parking,<br />

entrances, and<br />

weapons policies.<br />

Additionally, they<br />

can include the<br />

team in trending<br />

information on<br />

security violations<br />

and other issues.<br />

The quality manager<br />

is usually required<br />

to conduct or<br />

monitor all tests on<br />

ingredients, finished<br />

products, monitor<br />

equipment, and<br />

the environment.<br />

Additionally, they<br />

investigate customer<br />

complaints. As a<br />

team member, they<br />

can ensure all test<br />

results and customer<br />

complaints that<br />

reflect potential<br />

intentional<br />

adulteration<br />

activities are<br />

communicated and<br />

explored by the food<br />

defense team.<br />

Legal<br />

Advisor<br />

Legal counsel will<br />

advise if process<br />

or procedural<br />

changes are within<br />

legal limitations.<br />

For example, if<br />

the food defense<br />

team is considering<br />

searching all bags<br />

brought into the<br />

facility the legal<br />

adviser will let you<br />

know if it’s a legal<br />

policy.<br />

Training is key. FDA-registered companies must comply<br />

with the Food Safety Modernization Act requirement to<br />

have a qualified individual responsible for developing or<br />

overseeing the vulnerability assessment and any individual<br />

that has a responsibility for the food defense plan must be<br />

qualified to fulfill that role.<br />

The mechanical steps that transform flour and other ingredients<br />

into baked products, produce a dough that should go easily<br />

through the different stages<br />

of bread manufacturing.<br />

However, every dough can only<br />

take so much physical work<br />

before quality declines.<br />

Symptoms of over stressed<br />

dough include:<br />

• Rough or sandy crust<br />

• Irregular shapes with poor<br />

pan flow<br />

• Wrinkled crown<br />

• White spots<br />

To solve these issues, first<br />

review the water addition to<br />

ensure full absorption, then review all steps where work is<br />

applied to mix or shape the dough. Adjust the mixing time<br />

after cleanup and make final adjustments to the divider,<br />

rounder, and sheeting rollers to help improve finished dough<br />

characteristics. If there is excess moisture in the proofer, you<br />

may notice white spots along with wrinkles and a rubbery crust.<br />

If these defects are plaguing your product, we recommend<br />

reducing the relative humidity in the proofer.<br />

When producing breads and rolls, many different ingredients<br />

impact the finished product. Let’s look at some key players<br />

namely: yeast, salt, and sugar.<br />

Yeast: Yeast’s main function in breads and rolls is leavening,<br />

which is the process of producing gas (carbon dioxide or<br />

CO 2<br />

). This gas, along with water vapor and entrapped air, then<br />

expands during proofing and baking causing the dough to<br />

increase in volume. The leavening of bread and rolls produces<br />

a product that is lighter and more palatable to eat. It has a big<br />

impact on the quality of the finished product. Leavening is also<br />

responsible for the volume of the finished product.<br />

Besides its leavening function, yeast enzyme activity is largely<br />

responsible for the conditioning of the dough, which is<br />

sometimes referred to as “mellowing” or “maturing” the dough<br />

or sponge. Yeast converts sugars (starch) into alcohols and<br />

acids during fermentation. The alcohols and acids have a<br />

“mellowing” effect on the dough/sponge giving us biochemical<br />

development or maturing of the dough/sponge. Acids lower<br />

the pH and have a softening<br />

effect on the dough, while<br />

the alcohols also have a<br />

maturing effect on the gluten<br />

protein. These acids and<br />

alcohols makes the gluten<br />

more developed resulting in<br />

thin, gas-retaining cell walls.<br />

This biochemical development<br />

develops the dough so it<br />

retains its extensibility and<br />

elasticity to expand without<br />

rupturing during makeup<br />

stress and proofing. This helps<br />

with dough consistency and<br />

results in better characteristics<br />

Is your dough<br />

showing symptoms<br />

of stress?<br />

Baking Specialist Online<br />

Collection<br />

9 on-demand courses to kickstart<br />

your career<br />

tiny.cc/<strong>2018</strong>m5<br />

that impact the symmetry and grain of the finished product.<br />

The distinctive fermentation flavor and aroma that is unique<br />

to yeast-leavened breads<br />

and rolls is a secondary<br />

product of the fermentation<br />

process. Fermentation gives<br />

us flavor from created organic<br />

compounds produced like<br />

acetic acid, lactic acid,<br />

aldehydes, and other flavor<br />

precursors.<br />

Salt: One of the main<br />

functions of salt in bread and<br />

roll production is to bring<br />

out the flavors of the other<br />

ingredients. Salt is typically<br />

used at levels of 1.50% to<br />

2.25% (Baker’s Percent or flour basis). Breads made with salt<br />

levels below 1.50% will taste bland while breads made with<br />

more than 2.25% will taste salty. The flavor of salt is usually not<br />

desirable, but salt has the property of enhancing other flavors.<br />

It also has a toughening or tightening effect upon the gluten<br />

during mixing and improves the gas retention and hence the<br />

texture and grain of the finished product. In addition, salt helps<br />

to regulate or control the action of yeast and thereby the rate<br />

of fermentation. This is due to the osmotic pressure.<br />

Sugar: In yeast-raised products like bread and rolls, sugar<br />

provides food for the yeast and gives a sweet taste to the<br />

finished product. In sponge and dough process, for example,<br />

3-3.5% of fermentable solids are required for yeast activity.<br />

These fermentable solids may be from the sugar, but can<br />

also be derived from the conversion of the damaged starch<br />

in the flour to sugar. Sugar is not an essential ingredient in<br />

bread production. Sugars which remain after fermentation are<br />

referred to as residual sugars and these residual sugars have<br />

many secondary functions related to them. Residual sugars<br />

will contribute a sweet flavor although breads typically are not<br />

noted as being sweet baked products. These residual sugars<br />

contribute to crust color due to their reactions during baking.<br />

High levels of sugar will result in faster formation<br />

of crust color and will give you a darker crust color. This<br />

browning reaction will also contribute to the taste of the<br />

finished bread. Sugar, being very hygroscopic (ability to attract<br />

and retain moisture), will also improve the shelf-life of the<br />

finished product.<br />

Understanding ingredient<br />

functionality of breads and<br />

rolls is important for bakers.<br />

Knowing how ingredients such<br />

as yeast, salt, or sugar impact<br />

the final product helps the<br />

baker to troubleshoot problems<br />

or develop breads and rolls to<br />

desired product characteristics.<br />

Is Your Dough Showing Signs of Stress, <strong>AIB</strong> International - 7