09-7342_Umschlag: Final Umschlag 2005 - DVS

09-7342_Umschlag: Final Umschlag 2005 - DVS

09-7342_Umschlag: Final Umschlag 2005 - DVS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Application<br />

Highlights:<br />

Power Power Engineering Engineering and and<br />

Solid Solid Oxide Oxide Fuell Fuell Cell Cell<br />

Gas Gas Turbines Turbines<br />

Aerospace Aerospace Industry Industry<br />

Off-Shore Off-Shore<br />

Industrial Industrial Engineering<br />

Engineering<br />

Paper Paper and and Printing Printing<br />

Biomedical Biomedical Coatings Coatings<br />

Young Young Scientists<br />

Scientists<br />

Organizers:<br />

Media Sponsors:<br />

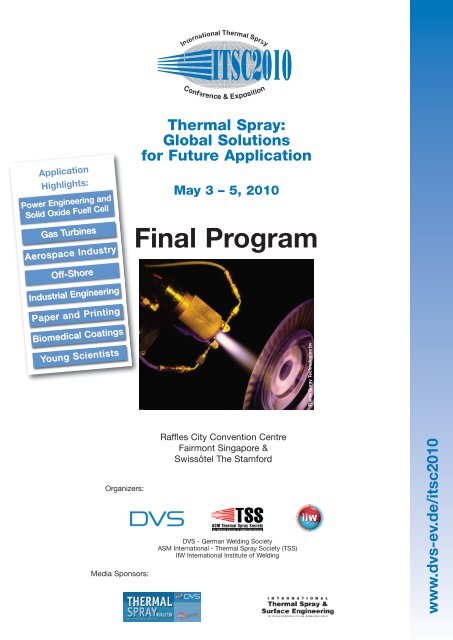

Thermal Spray:<br />

Global Solutions<br />

for Future Application<br />

May 3 – 5, 2010<br />

<strong>Final</strong> Program<br />

Raffles City Convention Centre<br />

Fairmont Singapore &<br />

Swissôtel The Stamford<br />

ASM Thermal Spray Society<br />

An Affiliate Society of ASM International<br />

<strong>DVS</strong> - German Welding Society<br />

ASM International - Thermal Spray Society (TSS)<br />

IIW International Institute of Welding<br />

Flame Spray Technologies bv<br />

www.dvs-ev.de/itsc2010

Sponsoring<br />

<strong>DVS</strong> – The German Welding Society is pleased to announce<br />

the following sponsors of ITSC 2010 conference:<br />

Sulzer Metco<br />

Are you interested? Further sponsors are welcome.<br />

Please contact: tagungen@dvs-hg.de<br />

DURUM Verschleiss-Schutz GmbH<br />

(Germany)<br />

Flame Spray Technolgies bv<br />

(The Netherlands)<br />

H.C. Starck GmbH (Germany)<br />

obz innovation gmbh (Germany)<br />

Sulzer Metco AG (Switzerland)<br />

Turbocoating S.p.A. (Italy)<br />

ARTEC S.p.A. (Italy)

Welcome to Singapore!<br />

Join us to network Thermal Spray Technology<br />

in an exciting part of Asia<br />

On behalf of the German Welding Society (<strong>DVS</strong>), the ASM<br />

Thermal Spray Society (ASM-TSS) and the International<br />

Institute of Welding (IIW), we would like to extend our<br />

warmest welcome to invite you to Singapore for ITSC –<br />

International Thermal Spray Conference & Exposition<br />

2010.<br />

Nowadays in times of a worldwide financial crisis, even if<br />

it is decreasing by now, it is a challenge but also a strong<br />

positive sign to announce a well prepared ITSC in the<br />

Asian Pacific Rim representing all of our customers´ aims<br />

and aspects.<br />

Surfacing plays an important role and is widely used in<br />

various industries. Therefore Singapore as a vital economic<br />

pillar in Asia offering impressive achievements for<br />

thermal spray applications:<br />

• Asia No. 1 aerospace maintenance, repair and<br />

overhaul hub<br />

• 20 % world market share for ship repair<br />

• Among the top 3 global centres for oil and gas<br />

equipment manufacturing and servicing<br />

• 70 % world market share in jack-up rigs<br />

• One of the top oil refining centres in the world<br />

• Among the top 10 petrochemical hubs in the world<br />

At ITSC 2010, we successfully keep on featuring the<br />

latest developments in thermal spray applications, technology<br />

and science also for the above marked markets.<br />

To strengthen the Thermal Spray Technology in its existing<br />

and future markets, ITSC 2010 broadens its useoriented<br />

“Application Highlights” for growing and upcoming<br />

applications:<br />

• Power Engineering and Solid Oxide Fuel Cell<br />

• Gas Turbines<br />

• Aerospace Industry<br />

• Off-Shore<br />

• Industrial Engineering<br />

• Paper and Printing<br />

• Biomedical Coatings<br />

With a “One Day One Market” philosophy ITSC 2010<br />

continues an application oriented information concept<br />

straight forward towards practical needs, optimising<br />

invest of time for different industries.<br />

Over 200 oral- and 70 poster presentations provide the<br />

most important source of thermal spray technical information<br />

available.<br />

Additionally, more than 30 exhibitors will provide the conference<br />

attendees with optimum information about their<br />

current and ongoing developments.<br />

Supporting emerging professionals in thermal spraying<br />

becomes a forward-looking must for ITSC! With the<br />

“Young Scientist” session ITSC 2010 offers a brilliant<br />

stage for promising young talents, both from industry<br />

and universities, sharing their work. This session is<br />

accompanied by a special poster exposition. All visitors<br />

to this session can elect their favorite contribution, and<br />

the winner will be announced during the awards banquet.<br />

With ITSC a substantial worldwide personal and technical<br />

network is created. The knowledge and experiences<br />

shared between you, the authors, instructors, students<br />

and exhibitors at this outstanding three-day-event is why<br />

thermal spray will continue to flourish in the next decades,<br />

with ever-increasing new market segments and new<br />

commercial opportunities.<br />

A very special thank you not only to the numerous<br />

authors of lectures and poster contributors, but also to<br />

the sponsors and experts who are making themselves<br />

available for the Program Committee, Session Chairmen,<br />

and the employees of all societies involved. It has been<br />

due to their work that a contribution has been made for<br />

the successful staging of the conference.<br />

We look forward to welcoming you at ITSC 2010 in<br />

Singapore in May. Come and enjoy countless fascinating<br />

experiences, and take away technical innovation but also<br />

memories that are uniquely Singapore.<br />

Klaus Middeldorf<br />

General Manager<br />

<strong>DVS</strong> - German Welding Society<br />

1

2<br />

Time Schedule<br />

Monday, May 3, 2010<br />

Time Sophia Room Olivia Room Moor Room Hullet Room<br />

<strong>09</strong>:00<br />

Opening<br />

Plenary Lecture<br />

10:10 Coffee Break<br />

10:30 Cold Spraying 1 Wear Protection 1 Plasma Spraying 1 Gas Turbines 1<br />

12:30 Opening of Exposition and Poster Session<br />

13:00 Lunch Break<br />

14:00 Cold Spraying 2<br />

HVOF 1<br />

15:20 Coffee Break<br />

Power Engineering<br />

and SOFC 1<br />

Process Diagnostics 1<br />

15:40 Quality and Qualification Paper and Printing Biomedical Coatings Off-Shore<br />

Tuesday, May 4, 2010<br />

Time Sophia Room Olivia Room Moor Room Hullet Room<br />

08:40 Nanomaterial Coatings 1 Plasma Spraying 2<br />

10:20 Coffee Break<br />

Economic and Environmental<br />

Aspects<br />

Cold Spraying 3<br />

10:40 Properties 1 Hard Chrome Replacement Industrial Engineering Wear Protection 2<br />

12:40 Lunch Break and Poster Session<br />

13:40 Young Scientists<br />

15:20 Coffee Break<br />

15:40<br />

Gas Turbines 2<br />

Power Engineering<br />

and SOFC 2<br />

HVOF 2 Cold Spraying 4<br />

20:00 ITSC 2010 Awards Banquet, Sentosa Island, Sapphire Pavilion<br />

Wednesday, May 5, 2010<br />

Time Sophia Room Olivia Room Moor Room Hullet Room<br />

08:40<br />

Process<br />

Diagnostics 2<br />

Modeling & Simulation 1 Nanomaterial Coatings 2 Cold Spraying 5<br />

10:20 Coffee Break<br />

10:40 Aerospace Industry<br />

12:40 Lunch Break and Poster Session<br />

13:40<br />

Properties 2 Modeling and Simulation 2 Corrosion Protection<br />

Wear Protection 3 Gas Turbines 3 Properties 3<br />

Biomedical and<br />

Polymer Coatings

Sponsoring ............ Inside Front Cover<br />

Welcome to Singapore ............ 1<br />

Time Schedule ............ 2<br />

Contents ............ 3<br />

Technical Program ............ 4<br />

Poster Session ............ 24<br />

Exposition ............ 28<br />

Education Courses ............ 29<br />

General Information<br />

Registration Information ............ 34<br />

Hotel Information ............ 35<br />

Tips for Singapore ............ 35<br />

Social Event<br />

ITSC 2010 Awards Banquet ............ 35<br />

List of Presenting Authors, Poster Presenters,<br />

Session Chairmen ............ 36<br />

Conference Committees and<br />

Endorsing Sponsors ............ 47<br />

Reservation Form for Hotels ............ 48<br />

Registration Form ............ Inside Back Cover<br />

Imprint<br />

Photos by courtesy of:<br />

Flame Spray Technologies bv, The Netherlands<br />

Contents<br />

3

4<br />

Technical Program<br />

<strong>09</strong>:00<br />

10:10<br />

10:30<br />

10:50<br />

11:10<br />

11:30<br />

11:50<br />

12:10<br />

Opening<br />

Plenary Lecture:<br />

M. Oechsner<br />

Materials needs for advanced industrial gas turbines of the future<br />

Session Chairmen: M. Dorfman / P. Heinrich<br />

Cold Spraying 1<br />

Session Chairmen: P. Heinrich / C.M. Kay<br />

Cold spray technology – from academic<br />

research to the market place<br />

T. Klassen, H. Kreye*<br />

Cold spraying: exploring new materials<br />

T. Klassen*, F. Gärtner, T. Schmidt, H. Kreye<br />

New industrial applications for cold<br />

spraying<br />

S. Hartmann*<br />

Design and production of powders tailored<br />

to cold spraying<br />

A. Coleman*, K. Murray, M. Kearns<br />

Further development of process equipment<br />

for cold spraying<br />

P. Heinrich, P. Richter, T. Klassen, O. Cheng*<br />

Transmission electron microscopy of cold<br />

sprayed titanium<br />

P. King*, M. Jahedi<br />

Monday, May 3, 2010<br />

Sophia Room<br />

Coffee Break<br />

Sophia Room Olivia Room<br />

Wear Protection 1<br />

Session Chairmen: C. Moreau / R. Thorpe<br />

Microstructure and mechanical behavior of<br />

suspension plasma sprayed Al 2 O 3 and<br />

Al 2 O 3 -YSZ composite coatings<br />

G. Bertrand*<br />

Analysis of Fe-base materials and evaluation<br />

of their suitability for wear protection<br />

coatings<br />

A. Pelz*<br />

Wear behavior and performance of a cost<br />

effective iron-based, carbide reinforced, sintered<br />

coating<br />

M. Lugbauer*, E. Badisch, A. Kröll<br />

Structure and tribological characteristics of<br />

HVOF coatings sprayed from powder blends<br />

of Cr 3 C 2 -25NiCr and metallic alloys<br />

P. Vuoristo*, A. Määttä<br />

Characterization of high temperature abrasive<br />

wear of cold sprayed FeAl intermetallic<br />

compound coating<br />

C. Li*, G. Yang, H. Wang, S. Zhao, C. Bao<br />

Properties of coating by plasma spraying<br />

ultrafine Cr 3 C 2 -25%NiCr powders<br />

Z. Li*, K. Zeng, Y. Yu

Moor Room<br />

Plasma Spraying 1<br />

Session Chairmen: G. Montavon / T. Warda<br />

New conventional plasma gun with high<br />

performance: ProPlasma HP<br />

A. Allimant*, D. Billières<br />

Triplex gun platform: impacting all operational<br />

aspects of thermal spraying<br />

C. Dambra*, D. Hawley<br />

Yttria deposition by a novel plasma torch<br />

L. Pershin*, J. Mostaghimi<br />

Hybrid laser plasma coating process<br />

Y. Borisov*, I. Krivtsun, S. Vojnarovich,<br />

A. Kislitsa, E. Kuzmich-Yanchuk<br />

Investigation of atmospheric plasma<br />

sprayed tungsten carbide cobalt coatings<br />

using statistical design of experiments<br />

B. Krebs*, W. Tillmann, E. Vogli<br />

Plasma sprayed NiCr metallic coatings<br />

using Ar-shroud system<br />

M. Morks, C. Berndt*<br />

Monday, May 3, 2010<br />

Coffee Break<br />

Gas Turbines 1<br />

Technical Program<br />

Hullet Room<br />

Highlight<br />

Session Chairmen: K. Bobzin / T. Coyle<br />

Composite coatings with drag reduction<br />

and self cleaning properties<br />

V. Drescher*, J. Wilden, P. Schaaf<br />

Thermally sprayed oxidation protection coatings<br />

for ã-TiAl substrates<br />

M. Brühl, K. Bobzin, T. Schläfer*, T. Warda<br />

Erosion of ceramic abradable coatings used<br />

in gas turbines<br />

K. Laul*, R. Wellman, R. Shankar<br />

Suspension plasma spraying (SPS) as a promising<br />

process for the manufacture of thermal<br />

barrier coatings (TBCs)<br />

A. Guignard*, H. Kaßner, R. Vaßen, D. Stöver<br />

Relationships between coating microstructure<br />

and thermal conductivity in thermal<br />

barrier coatings – a modeling approach<br />

P. Nylen*, I. Tano, N. Curry, J. Wigren<br />

Oxidation behavior of MCrAlY bond coats<br />

manufactured by plasma, HVOF and cold<br />

gas dynamic spraying<br />

P. Richer*, M. Yandouzi, L. Beauvais, B. Jodoin<br />

Flame Spray Technologies bv<br />

10:10<br />

10:30<br />

10:50<br />

11:10<br />

11:30<br />

11:50<br />

12:10<br />

5

6<br />

Technical Program<br />

12:30<br />

13:00<br />

14:00<br />

14:20<br />

14:40<br />

15:00<br />

15:20<br />

Cold Spraying 2<br />

Session Chairmen: T. Klassen / J. Villafuerte<br />

Properties of titanium structures directly<br />

manufactured via cold spray<br />

S. Gulizia*, M. Jahedi, D. Fraser, C. Tang<br />

Wear behavior of titanium coatings on aluminum<br />

light alloys obtained by cold gas<br />

spraying<br />

S. Dosta*, N. Cinca, M. Barbosa, J. Guilemany<br />

Cold sprayability of pure titanium coatings<br />

W. Wong*, S. Yue, E. Irissou, J. Legoux<br />

Layer formation and impact phenomena<br />

of cold sprayed ceramic titanium dioxide<br />

particles on metal surfaces<br />

J. Kliemann*, C. Borchers, J. Stötzner,<br />

H. Gutzmann, F. Gärtner, T. Klassen<br />

Monday, May 3, 2010<br />

Sophia Room Olivia Room<br />

Opening of Exposition and Poster Session<br />

Lunch Break<br />

Coffee Break<br />

HVOF 1<br />

Session Chairmen: S. Kuroda /<br />

J. Beczkowiak<br />

Functionalization of high performance<br />

polymers by the use of a combined HVOF<br />

process for powder and wire<br />

C. Rupprecht*, B. Wielage, G. Paczkowski<br />

HVOF spraying of ultrahigh boron high carbon<br />

tool steel coating for wear resistance<br />

applications<br />

R. Balasudaram*, G. Mauer, R. Vaßen,<br />

A. Röttger, S. Weber, W. Theisen<br />

CFD modeling to assist the development of<br />

efficient thermal spray systems<br />

S. Gu*, H. Tabbara<br />

Correlation of wear resistant functions of<br />

HVOF and warm sprayed WC-Co coatings<br />

with in-flight particle characteristics<br />

K. Sato*, J. Kitamura, G. Raman, M. Watanabe,<br />

S. Kuroda, M. Komatsu

Monday, May 3, 2010<br />

Moor Room Hullet Room<br />

Opening of Exposition and Poster Session<br />

Highlight<br />

Power<br />

Engineering and SOFC 1<br />

Session Chairmen: C. Coddet / T. Lampke<br />

Dense ceramic coatings by thermal spray<br />

technology for applications in solid oxide<br />

fuel cells<br />

R. Vaßen*, M. Karger, D. Stöver, U. Maier,<br />

M. Hoffmann<br />

Plasma sprayed LSCF oxygen electrode for<br />

SOFC<br />

A. Ansar*, D. Soysal, Z. Ilhan, N. Wagner<br />

Technical challenges of suspension plasma<br />

spraying of nanopowders for SOFCs<br />

D. Soysal*, A. Ansar<br />

Plasma spraying of lanthanum silicate electrolytes<br />

for intermediate temperature solid<br />

oxide fuel cells<br />

S. Dru*, K. Wittmann-Tenèze, E. Meillot,<br />

M. Saboungi, R. Benoit<br />

Lunch Break<br />

Coffee Break<br />

Technical Program<br />

Process Diagnostics 1<br />

Session Chairmen: A. Bachmann / J. Schein<br />

NIR (Near-Infra-Red) sensor – an alternative<br />

diagnostic tool for the online process control<br />

of thermal spray processes<br />

A. Schwenk*, S. Marke, T. Wallendorf<br />

The next step in intelligent gun technology:<br />

EvoLink for plasma spraying<br />

A. Kilchenmann, M. Koller*, H. Hoehle<br />

Measurement of particle parameters at detonation<br />

spraying<br />

I. Smurov*, D. Pervushin, V. Ulianitsky, S. Zlobin,<br />

B. Laget<br />

Shadow imaging of liquid precursors under<br />

plasma spraying conditions<br />

A. Vardelle*, M. Vardelle, S. Goutier,<br />

C. Chazelas<br />

12:30<br />

13:00<br />

14:00<br />

14:20<br />

15:40<br />

15:00<br />

15:20<br />

7

8<br />

Technical Program<br />

15:40<br />

16:00<br />

16:20<br />

16:40<br />

17:00<br />

Quality and Qualification<br />

Session Chairmen: W. Herlaar / T. Kraak<br />

Education, training and certification in thermal<br />

spraying<br />

R. Huber*, A. Ohliger-Volmer, F. Zech<br />

GTS – the guarantor of quality in thermal<br />

spraying<br />

P. Heinrich*<br />

The shear test for thermally sprayed coatings<br />

in quality management<br />

S. Hartmann, F. Deuerler, R. Winkler*<br />

Development and use of e-learning system<br />

of thermal spraying for promoting and educating<br />

engineer<br />

S. Hirose*, A. Ohmori, K. Mori<br />

Qualifying of new spray powders for the use<br />

with cold spraying<br />

E. Baehr*, H. Hoell, P. Richter<br />

Monday, May 3, 2010<br />

Sophia Room Olivia Room<br />

Paper and Printing<br />

Session Chairmen: V. Guipont / S. Oki<br />

Highlight<br />

On-site thermal spraying in paper machines<br />

H. Jungklaus*, A. Etschmaier<br />

ColferoloyTM – an iron-based alternative for<br />

wear resistance applications<br />

G. Stratford, P. Allnatt, H. Burkard*<br />

Thermally sprayed fine Fe-based materials<br />

for wear protection applications in the printing<br />

industry<br />

T. Warda*, K. Bobzin, T. Schläfer<br />

Cold spraying of Zn and Zn-alloy coatings<br />

for print applications<br />

K. Onizawa*, J. Jansen, M. Schulze, F. Gärtner,<br />

T. Klassen<br />

An alternative to chromium oxide: reduced<br />

exposition to hexavalent Cr with RUBY powder<br />

A. Allimant*, D. Billières, H. Wallar

Moor Room Hullet Room<br />

Biomedical Coatings<br />

Session Chairmen: P. Hanneforth /<br />

C. Wasserman<br />

Monday, May 3, 2010<br />

Highlight<br />

Evaluation of the photocatalytic activity of<br />

TiO 2 -coatings prepared by different thermal<br />

spray techniques<br />

H. Gutzmann*, F. Toma, J. Kliemann,<br />

J. Stötzner, L. Berger, B. Leupolt, F. Gärtner,<br />

T. Klassen<br />

High velocity suspension flame spraying<br />

(HVSFS) deposition of bioactive glass coatings<br />

on Ti substrates with and without TiO 2<br />

bond coating<br />

V. Cannillo*, G. Bolelli, R. Gadow, A. Killinger,<br />

L. Lusvarghi, A. Sola, N. Stiegler<br />

A morphological study of hydroxyapatite<br />

splats flame sprayed onto commercially<br />

pure titanium<br />

S. Saber-Samandari*, C. Berndt, K. Gross,<br />

J. Wang<br />

Cold spray copper antimicrobial coatings<br />

V. Champagne, M. Trexler*, D. Helfritch<br />

Deposition of TiO 2 ceramic particles on cold<br />

spray process<br />

M. Yamada*, H. Isago, K. Shima, H. Nakano,<br />

M. Fukumoto<br />

Off-Shore<br />

Technical Program<br />

Highlight<br />

Session Chairmen: C. Rupprecht / J. Ryan<br />

Thermal spraying of zinc and zinc-aluminum<br />

alloys for corrosion protection<br />

F. Prenger*, J. Spriestersbach<br />

The performance of different WC-based<br />

cermet coatings in oil and gas applications<br />

– a comparison<br />

H. Meng*, X. Hu, P. Gourdji, A. Neville<br />

Cavitation erosion characteristics and fracture<br />

morphology of thermal spray coating<br />

A. Kanno*, T. Takabatake, Y. Nanba, K. Tani,<br />

S. Uematsu, S. Sugasawa, M. Yoshioka,<br />

Y. Ishihara<br />

The advancement and positioning of laser<br />

cladding in the surface engineering industry<br />

T. Marchione*, A. Choong, D. Dezert<br />

Study of corrosion behavior of Al and Al-Zn<br />

wire arc sprayed mild steel in offshore<br />

applications<br />

H. Salimijazi*, E. Abedi, M. Golozar,<br />

J. Mostaghimi, L. Pershin<br />

15:40<br />

16:00<br />

16:20<br />

16:40<br />

17:00<br />

9

Technical Program<br />

10<br />

08:40<br />

<strong>09</strong>:00<br />

<strong>09</strong>:20<br />

<strong>09</strong>:40<br />

10:00<br />

10:20<br />

Tuesday, May 4, 2010<br />

Sophia Room Olivia Room<br />

Nanomaterial Coatings 1<br />

Session Chairmen: P. Fauchais / L. Berger<br />

Composition of alumina titania coatings<br />

manufactured by suspension plasma<br />

spraying<br />

G. Montavon*, G. Darut, E. Klyatskina,<br />

S. Valette, A. Denoirjean, H. Ageorges,<br />

P. Fauchais, F. Segovia, M. Salvador<br />

Duration and reliability of axial plasma<br />

spraying slurry process<br />

Z. Tang*, P. Hartell, G. Masindo, I. Yaroslavski,<br />

D. Ellsworth, A. Burgess<br />

Crystal and micro structures of plasma<br />

sprayed yttrium oxide coatings by axial<br />

injection of fine powder slurries<br />

J. Kitamura*, H. Mizuno, K. Sato, Z. Tang,<br />

A. Burgess<br />

Integrated property evaluation of kinetic and<br />

thermal sprayed multi-walled carbon nanotube<br />

reinforced copper composite coatings<br />

K. Kang*, J. Kim, G. Bae, C. Lee<br />

Tribological behavior of carbon nanotube<br />

reinforced plasma sprayed aluminum oxide<br />

coating at elevated temperature<br />

A. Keshri*, A. Agarwal<br />

Coffee Break<br />

Plasma Spraying 2<br />

Session Chairmen: H. Jungklaus / Y. Borisov<br />

High temperature behavior of CoNiCrAlY<br />

coatings made by laser cladding<br />

L. Lusvarghi, C. Giolli*, K. Partes, A. Fossati,<br />

M. Di Ferdinando, G. Bolelli, A. Lavacchi,<br />

F. Vollertsen, A. Scrivani<br />

Effect of powder size distribution on the<br />

reproducibility of plasma spray process: a<br />

case study of plasma sprayed YSZ coatings<br />

G. Dwivedi*, J. Colmenares, T. Nakamura,<br />

S. Sampath<br />

Influence of feedstock powder for fabrication<br />

of aluminum nitride in reactive atmospheric<br />

plasma spray process<br />

M. Shahien*, M. Yamada, T. Yasui,<br />

M. Fukumoto<br />

The effect of plasma gas on structure of<br />

plasma sprayed forsterite<br />

T. Coyle*, H. Samadi, L. Pershin<br />

Plasma spray physical vapor deposition<br />

(PS-PVD); Vapor phase deposition using<br />

a plasma spray process<br />

K. von Niessen*, R. Schmid, A. Zaugg,<br />

M. Gindrat<br />

Flame Spray Technologies bv

Moor Room Hullet Room<br />

Economic and<br />

Environmental Aspects<br />

Session Chairmen: G. Bertrand / J. Stricker<br />

Advanced spray gun technologies for<br />

industrial markets<br />

J. Girgulis*, C. Dambra, A. Barth, D. Hawley<br />

Selective impact of industrial gases on the<br />

thermal spray process<br />

W. Krömmer*, P. Heinrich<br />

The use of national and EC public funds for<br />

financing R&D activities: the case of a thermal<br />

spray shop<br />

C. Giolli, S. Meneghetti*, A. Scrivani,<br />

A. Giorgetti<br />

Life cycle assessment of using powder and<br />

liquid precursors in plasma spraying: the<br />

case of yttria-stabilized zirconia<br />

A. Vardelle*, A. Moign, C. Chazelas, J. Legoux,<br />

N. Themelis<br />

Measurement of particle emissions generated<br />

by arc spray and flame spray processes<br />

D. Billiers*, D. Bemer, I. Subra, M. Lecler,<br />

R. Regnier, Y. Morelle<br />

Tuesday, May 4, 2010<br />

Coffee Break<br />

Cold Spraying 3<br />

Technical Program<br />

Session Chairmen: S. Hartmann / C. Li<br />

Portable high pressure cold spray process:<br />

equipment, coatings and applications<br />

J. Karthikeyan*, C. Kay, H. Hoell<br />

Potential of cold gas spraying in power<br />

electronic applications<br />

K. Donner*, F. Gärtner, T. Klassen<br />

Defined metallization of thin ceramic substrates<br />

via cold spray process<br />

C. Rupprecht*, B. Wielage, T. Grund,<br />

S. Kümmel, J. Wilde, E. Rastjagajev<br />

Study of the influence of the substrate temperature<br />

on Al coatings deposited by cold<br />

spray<br />

S. Rech*, S. Vezzù, A. Trentin, E. Irissou,<br />

J. Legoux, M. Guagliano<br />

Residual stresses in cold sprayed coatings<br />

F. Gärtner*, H. Assadi, T. Schmidt, K. Binder,<br />

T. Klassen<br />

Flame Spray Technologies bv<br />

08:40<br />

<strong>09</strong>:00<br />

<strong>09</strong>:20<br />

<strong>09</strong>:40<br />

10:00<br />

10:20<br />

11

Technical Program<br />

12<br />

10:40<br />

11:00<br />

11:20<br />

11:40<br />

12:00<br />

12:20<br />

Properties 1<br />

Tuesday, May 4, 2010<br />

Sophia Room Olivia Room<br />

Session Chairmen: B. Wielage / E. Irissou<br />

Influence of substrate temperature on the<br />

microstructures and properties of APS<br />

Al 2 O 3 coatings<br />

C. Li*, S. Hao, G. Yang<br />

Thermophysical studies on thermally<br />

sprayed tungsten carbide-cobalt coatings<br />

S. Thiele*, L. Berger, J. Spatzier,<br />

K. Jaenicke-Roessler, K. Sempf<br />

Properties of thick Cr 2 O 3 and Cr 2 O 3 -5SiO 2 -<br />

3TiO 2 coatings deposited by water stabilized<br />

plasma spray process<br />

P. Vuoristo*<br />

Effect of blasting angle and blasting time on<br />

the amount of residual grit blasted on steel<br />

substrate and adhesive property of sprayed<br />

coating<br />

T. Maruyama*, T. Miyazaki, T. Kishita,<br />

T. Kobayashi<br />

Thermal shakedown of thermal spray coatings<br />

A. Valarezo*, M. Bejarano, D. Welch,<br />

S. Sampath<br />

Comparative study of the electrical properties<br />

and microstructures of the spinel and<br />

alumina coatings<br />

F. Toma*, L. Berger, S. Scheitz, V. Sauchuk,<br />

M. Kusnezoff<br />

Hard Chrome<br />

Replacement<br />

12:40 Lunch Break and Poster Session<br />

Session Chairmen: W. Tillmann / B. Marple<br />

APS-Al 2 O 3 coatings versus arc sprayed and<br />

plasma anodized Al layers<br />

T. Grund, T. Lampke*, D. Meyer,<br />

H. Pokhmurska, B. Wielage<br />

HVOF chrome replacement coating – effect<br />

of process conditions<br />

S. Dixit*, M. Chin, R. Dixit<br />

Microstructures of metallic NiCrBSi coatings<br />

manufactured via hybrid plasma spray<br />

process<br />

N. Serres*, F. Hlawka, S. Costil, C. Langlade,<br />

F. Machi<br />

Deposition of WC-base coating for wear and<br />

high impact resistance application<br />

B. Prawara*, E. Riyanto, B. Priyono<br />

The interaction of process and particle size<br />

in HVOF spraying of WC-CoCr sub-micron<br />

carbide powders<br />

T. Varis*, T. Suhonen, A. Ghabchi, U. Kanerva,<br />

X. Liu, J. Oksanen, O. Söderberg, S. Hannula<br />

Microstructure and enhanced mechanical<br />

properties of WC-Co coatings obtained by<br />

warm spraying<br />

S. Kuroda*, G. Sundra Raman, M. Watanabe,<br />

M. Komatsu, K. Kitamura, J. Kitamura

Moor Room Hullet Room<br />

Industrial Engineering<br />

Tuesday, May 4, 2010<br />

Highlight<br />

Session Chairmen: T. Schläfer / M. Khor<br />

Wire arc sprayed iron-based anti corrosion<br />

coatings for waste incineration plants<br />

V. Drescher, J. Wilden*, R. Durham, M. Schütze<br />

Effect of MCrAlY coating for corrosion resistance<br />

in specific high temperature atmosphere<br />

A. Niwa*, K. Hamashima<br />

Assessment of HVOF sprayed coatings for<br />

wear and corrosion protection in the steel<br />

industry<br />

C. Lima*, F. Camargo<br />

Functional wear resistant tool surfaces for<br />

novel friction spinning forming process to<br />

manufacture parts with graded thermo<br />

mechanical properties<br />

I. Baumann*, W. Tillmann, E. Vogli,<br />

F. Hoffmann, W. Homberg, C. Beerwald,<br />

D. Hornjak<br />

Microstructure and NO 2 sensing<br />

performance of APS ZnO coatings<br />

C. Zhang*, M. Debliquy, H. Liao, C. Coddet<br />

Tungsten-based coatings to increase the<br />

lifetime of permanent-mold casting molds<br />

V. Drescher*, J. Wilden<br />

Wear Protection 2<br />

Lunch Break and Poster Session<br />

Technical Program<br />

Session Chairmen: X. Huang / T. Grund<br />

Improved hardfacing for drill bits and drilling<br />

tools<br />

A. Sue*, H. Sreshta<br />

Carbon-based films on HVOF sprayed WC-<br />

Co-Cr coatings for the protection of aluminum<br />

alloys<br />

L. Lusvarghi*, G. Bolelli, B. Bonferroni,<br />

F. Pitacco, G. Coletta<br />

The influence of particle temperature, particle<br />

velocity and coating surface temperature<br />

on the sliding wear performance HVOF<br />

sprayed TiO 2 -Cr 2 O 3 coatings<br />

L. Berger*, R. Trache, S. Saaro, R. Lima,<br />

B. Marple<br />

Extension of erosion life of turbine housing<br />

by HVOF thermal spraying<br />

K. Sonoya*, M. Nakamura, K. Ishida<br />

Wear properties of Ni-based composite coatings<br />

sprayed by HVAF<br />

C. Wu*, K. Zhou, C. Deng, C. Deng<br />

Development and characterization of amorphous<br />

steel base cermets<br />

M. Parco*, I. Fagoaga, G. Barykin<br />

10:40<br />

11:00<br />

11:20<br />

11:40<br />

12:00<br />

12:20<br />

12:40<br />

13

Technical Program<br />

14<br />

13:40<br />

13:45<br />

13:50<br />

13:55<br />

14:00<br />

14:05<br />

14:10<br />

14:15<br />

14:20<br />

Young Scientists<br />

Tuesday, May 4, 2010<br />

Sophia Room<br />

Session Chairmen: C. Berndt / K. Nassenstein<br />

A particle image velocimetry method for low illumination conditions based on continuous<br />

particle image velocimetry<br />

L. Rockstroh*, M. Wroblewski, J. Hillebrand, A. Balevic, M. Shaikh, S. Simon, R. Gadow<br />

Bioactive coatings applied by cold spray coating technology for biomedical implants<br />

S. Ang*, J. Cizek, C. Berndt, P. Cheang, M. Khor<br />

Mathematical modeling and simulation of a kerosene driven HVOF process<br />

M. Schäfer*, K. Bobzin, D. Bagcivan, D. Parkot<br />

Cold spraying for titanium dioxide coatings with high photo catalytic activity<br />

J. Kliemann*, J. Stötzner, H. Gutzmann, D. Bahnemann, F. Gärtner, T. Klassen<br />

Flattening and cooling of millimetre and micrometre sized alumina drops<br />

S. Goutier*, M. Vardelle, J. Labbe, P. Fauchais<br />

Highlight<br />

Effect of annealing on microstructure of cold sprayed cBNp/NiCrAl composite coating<br />

C. Li, X. Luo*, G. Yang<br />

Coating of aluminum components with iron-based nanocrystalline solidifying materials to<br />

improve wear resistance<br />

O. Lehmann*, J. Wilden, V. Drescher<br />

PIV measurements of metallic powders produced by liquid metal atomization using laval nozzle<br />

O. Khatim*, M. Planche, Y. Bailly, F. Guermeur, L. Dembinski, L. Gerardot, C. Coddet<br />

Columnar structured thermal barrier coatings by thin film low pressure plasma spraying<br />

(LPPS-TF)<br />

A. Hospach*, R. Vaßen, D. Stöver

Tuesday, May 4, 2010<br />

Sophia Room<br />

Technical Program<br />

Velocity diagnostics for gas velocity distributions in cold gas and plasma spraying using<br />

non-resonant laser scattering<br />

S. Lange*, M. Sieber, J. Marques, G. Forster, J. Schein<br />

Effect of heat treatment on porosity and corrosion performance of cold sprayed titanium<br />

coatings<br />

T. Hussain*, D. McCartney, P. Shipway, T. Marrocco<br />

Relations between in flight particle characteristics and coating properties by HVOF spraying<br />

B. Hussong*, W. Tillmann, E. Vogli<br />

Process map for plasma sprayed carbon nanotube reinforced aluminum oxide nanocomposite<br />

coatings<br />

A. Keshri*, R. Patel, A. Agarwal<br />

Consolidation of Al 2 O 3 /Al nanocomposite powder by cold spray<br />

D. Poirier*, J. Legoux, R. Drew, R. Gauvin<br />

Changes observed in anelastic behavior of plasma sprayed YSZ coatings by modifying the<br />

defect surfaces<br />

G. Dwivedi*, A. Valarezo, S. Sampath, T. Nakamura<br />

Adhesion of nanostructured YSZ plasma sprayed coating on thin substrates<br />

R. Vert*, E. Meillot, A. Vardelle, G. Mariaux, C. Dublanche-Tixier<br />

Thermal spray forming of high efficiency, metal foam heat exchangers tubes<br />

N. Tsolas, S. Chandra*, H. Salimi-Jazi, L. Pershin, J. Mostaghimi<br />

Coffee Break<br />

14:25<br />

14:30<br />

14:35<br />

14:40<br />

14:45<br />

14:50<br />

14:55<br />

15:00<br />

15:20<br />

15

Technical Program<br />

16<br />

15:40<br />

16:00<br />

16:20<br />

16:40<br />

17:00<br />

20:00<br />

Gas Turbines 2<br />

Tuesday, May 4, 2010<br />

Sophia Room Olivia Room<br />

Highlight<br />

Session Chairmen: B. Jodoin / W. Krömmer<br />

On the oxidation behavior of a thermal barrier<br />

coating with cold gas dynamic spray<br />

CoNiCrAlY bond coat<br />

E. Irissou*, W. Chen, J. Legoux, X. Wu,<br />

B. Marple<br />

Characterization of elastic plastic properties<br />

of thermal sprayed NiCoCrAlY coatings<br />

P. Nylen, A. Fasth*, R. Musalek, N. Markocsan<br />

Effect of Ca addition in CoNiCrAlY powder<br />

for high temperature oxidation resistance<br />

HVOF coatings<br />

L. Lusvarghi, C. Giolli, A. Scrivani*, G. Rizzi,<br />

G. Bolelli, U. Bardi, A. Fossati, A. Lavacchi,<br />

M. Di Ferdinando<br />

Design of a thick thermal barrier coating to<br />

minimize in-service stresses<br />

T. Coyle*, H. Samadi<br />

Challenges for plasma spray deposition of<br />

decomposition prone perovskite coatings<br />

M. Jarligo*, G. Mauer, D. Mack, R. Vaßen,<br />

D. Stöver<br />

ITSC 2010 Awards Banquet<br />

Sentosa Island, Sapphire Pavilion<br />

Highlight<br />

Power<br />

Engineering and SOFC 2<br />

Session Chairmen: R. Vaßen / K. Middeldorf<br />

Microstructure of thermal sprayed silicon<br />

coatings using various particle sizes and<br />

spray conditions<br />

D. Jackson*, M. Sereda, R. Nafzinger,<br />

R. Gansert<br />

Deposition of NiO and YSZ composite<br />

anode and YSZ electrolyte by suspension<br />

plasma spray<br />

Y. Wang*, J. Legoux, R. Neagu, R. Hui,<br />

B. Marple<br />

Low pressure plasma sprayed zirconium<br />

metal diffusion barrier coatings<br />

K. Hollis*<br />

Study on microstructure and electrochemical<br />

performance of Ni/YSZ anode deposited<br />

by APS<br />

C. Li, C. Li*, R. Li, G. Yang<br />

The structure and properties of plasma<br />

sprayed Fe-doped manganese cobalt oxide<br />

spinel coatings for SOFC metallic interconnectors<br />

J. Puranen*, L. Hyvärinen, P. Vuoristo,<br />

J. Lagerbom, M. Kylmälahti

HVOF 2<br />

Moor Room Hullet Room<br />

Session Chairmen: S. Chandra / F. Schreiber<br />

Expansion of the applicable range of HVOF<br />

process conditions<br />

A. Wank*, A. Schwenk, M. Liu, K. Zhou,<br />

C. Deng, C. Deng<br />

Thermal spray processing of metal based<br />

coatings with the oxy fuel ionisation process<br />

M. Parco*, I. Fagoaga, G. Barykin<br />

Relationships between process parameters,<br />

residual stresses and adhesion in HVOF<br />

sprayed IN718 coatings<br />

P. Nylen, C. Lyphout*, L. Östergren<br />

Development of a low temperature, air fuel<br />

(LTAF) thermal spray gun<br />

R. Dhiman*, F. Farhadi, L. Pershin, S. Chandra,<br />

J. Mostaghimi<br />

Evaluation of boron carbide based thermal<br />

sprayed coatings for tribological applications<br />

C. Lima*, F. Camargo<br />

Tuesday, May 4, 2010<br />

Cold Spraying 4<br />

Technical Program<br />

Session Chairmen: M. Fukomoto / P. Richter<br />

Effects of nanosize particles on the intermetallic<br />

compound formations of cold sprayed<br />

coatings<br />

H. Lee*, J. Choi, K. Ko<br />

Characterization of corrosion resistant<br />

deposits by cold gas dynamic spray<br />

T. Marrocco*, D. Harvey, T. Hussain<br />

ITSC 2010 Awards Banquet<br />

Sentosa Island, Sapphire Pavilion<br />

Comparison of cold spray and detonation<br />

spraying coating properties<br />

I. Smurov*, V. Ulianitsky, S. Zlobin, A. Sova<br />

Characterization of the shockwave induced<br />

spraying process (SISP)<br />

E. Irissou*, J. Legoux, C. Moreau, J. Villafuerte<br />

Effects of surface morphology of MCrAlY<br />

bond coat on the isothermal oxidation and<br />

thermal fatigue behavior of thermal barrier<br />

coatings<br />

C. Li, Y. Li*, L. Xing, G. Yang<br />

15:40<br />

16:00<br />

16:20<br />

16:40<br />

17:00<br />

20:00<br />

17

18<br />

Technical Program<br />

08:40<br />

<strong>09</strong>:00<br />

<strong>09</strong>:20<br />

<strong>09</strong>:40<br />

10:00<br />

10:20<br />

Wednesday, May 5, 2010<br />

Sophia Room Olivia Room<br />

Process Diagnostics 2<br />

Session Chairmen: A. Vardelle / J. Heberlein<br />

Correlations between the oscillation modes<br />

of arc voltage and pressure in cathode cavity<br />

of dc plasma torches<br />

V. Rat*, J. Coudert<br />

Loading effect in plasma spraying: from inflight<br />

particle state distributions to diagnostic<br />

reliability<br />

K. Shinoda*, Y. Tan, S. Sampath<br />

Error analysis of image-based measurement<br />

methods in thermal spraying processes:<br />

a simulation driven approach<br />

L. Rockstroh*, M. Wroblewski, J. Hillebrand,<br />

A. Balevic, M. Shaikh, S. Simon, R. Gadow<br />

Improving powder injection in plasma<br />

spraying by optical diagnostics of the plasma<br />

and particle characterization<br />

G. Mauer*, R. Vaßen, D. Stöver, S. Kirner,<br />

J. Marqués-López, S. Zimmermann, G. Forster,<br />

J. Schein<br />

Influence of the vortex component on jet<br />

characteristics and particle velocity when<br />

operating a multi-cathode triplex pro plasma<br />

torch<br />

J. Marques, S. Kirner, S. Zimmermann,<br />

G. Forster, J. Schein*<br />

Coffee Break<br />

Modeling and Simulation 1<br />

Session Chairmen: J. Jerzembeck / R. Bolot<br />

Microstructural modeling and performance<br />

simulation of engineered bio composites<br />

S. Ang, U. Tietz*, C. Berndt, K. Schmitz<br />

Variable density volume-of-fluid model for<br />

particle impact in thermal spray process<br />

B. Samareh Abolhassani*, J. Mostaghimi,<br />

C. Moreau<br />

Effect of ambient pressure on dynamic wetting/heat<br />

transfer at interface between molten<br />

droplet and substrate surface<br />

M. Fukumoto*, K. Tanaka, K. Yang, T. Usami,<br />

M. Yamada, T. Yasui<br />

Homogenization of coating properties in<br />

atmospheric plasma spraying – current<br />

results of a DFG- (German Research<br />

Foundation) Funded Research Group<br />

J. Prehm*, F. Bach, K. Möhwald, K. Bobzin,<br />

N. Bagcivan, I. Petkoviæ, J. Schein,<br />

J. Marqués, S. Zimmermann, G. Forster,<br />

S, Kirner, K. Hartz-Behrend, D. Parkot<br />

Development of a high velocity wire arc<br />

spraying system by means of numerical<br />

calculations<br />

C. Rupprecht, B. Wielage, G. Paczkowski*

Moor Room Hullet Room<br />

Nanomaterial Coatings 2<br />

Session Chairmen: J. Wilden / G. Bolelli<br />

Suspension plasma spraying of oxide ceramic<br />

with twin cathode type plasma spray<br />

gun<br />

M. Suzuki*, Y. Tsutai<br />

Wednesday, May 5, 2010<br />

Improved mechanical properties of coatings<br />

and bulk components as a function of grain<br />

size<br />

R. Gansert*, C. Melnyk, S. Schroeder, D. Grant,<br />

M. Watson<br />

Fabrication and characterization of Al 2 O 3 -<br />

SiC-nano-composite powders and HVOF<br />

sprayed coatings<br />

T. Suhonen*, T. Varis, U. Kanerva, J. Lagerbom,<br />

O. Söderberg, Y. Ge, X. Liu, S. Hannula<br />

Novel in situ transformable coating for elevated<br />

temperature applications<br />

D. Branagan*, J. Zhou, J. Walleser,<br />

B. Meacham, B. Merkle<br />

Mullite suspension plasma spraying: effect<br />

of particles size distribution on coating<br />

structure<br />

G. Montavon*, A. Arcondeguy, A. Denoirjean,<br />

P. Fauchais<br />

Coffee Break<br />

Cold Spraying 5<br />

Technical Program<br />

Session Chairmen: W. Krömmer / F. Gärtner<br />

Shockwave induced spraying: a new solid<br />

state spraying process<br />

J. Villafuerte*<br />

Effect of the ceramic component on cold<br />

sprayed metal ceramic coatings<br />

I. Smurov*, A. Sova, V. Kosarev, A. Papyrin<br />

Investigation of impact behavior of cold<br />

sprayed large annealed copper particles<br />

and characterizations of coatings<br />

W. Li*, X. Guo, H. Liao, C. Coddet<br />

Characterization and performance evaluation<br />

of a helium recovery system designed<br />

for cold spraying<br />

E. Irissou, J. Legoux*, B. Harvey, E. Gagnon,<br />

S. Desaulniers, J. Bobyn, S. Yue<br />

Study on adhesion strength of cold sprayed<br />

aluminum deposit<br />

Y. Ichikawa*, K. Ogawa, I. Nonaka<br />

08:40<br />

<strong>09</strong>:00<br />

<strong>09</strong>:20<br />

<strong>09</strong>:40<br />

10:00<br />

10:20<br />

19

Technical Program<br />

20<br />

10:40<br />

11:00<br />

11:20<br />

11:40<br />

12:00<br />

12:20<br />

12:40<br />

Wednesday, May 5, 2010<br />

Sophia Room Olivia Room<br />

Aerospace Industry<br />

Highlight<br />

Session Chairmen: M. Trexler / D. Puerta<br />

Mechanical properties and behavior of<br />

BSAS/mullite-based environmental barrier<br />

coatings exposed to high temperature in<br />

water vapor environment<br />

C. Cojocaru*, C. Moreau, R. Lima<br />

Ti-parts for aviation industry produced by<br />

cold spraying<br />

K. Binder*, F. Gärtner, T. Klassen<br />

Effect of substrate temperature on bonding<br />

features and coating properties of cold<br />

sprayed Ti6Al4V alloy<br />

A. Rezaeian*, E. Irissou, J. Legoux, S. Yue<br />

High temperature mechanical behavior of<br />

UHTC coatings for thermal protection of<br />

re-entry vehicles<br />

M. Tului, G. Pulci*, J. Tirillò, F. Marra,<br />

S. Lionetti, T. Valente<br />

Near-net-shape HVOF coating and finishing<br />

techniques for highly stressed components<br />

in aircraft industry<br />

D. Ackermann*, G. Matthaeus, J. Henry<br />

Influence of the surface state on the<br />

adherence of the coating: case of an<br />

alumina coating plasma sprayed on SIC<br />

composites<br />

S. Costil*, S. Lukat, C. Verdy, C. Coddet<br />

Properties 2<br />

Lunch Break and Poster Session<br />

Session Chairmen: R. Eijckenboom / B. Krebs<br />

Arc spraying of WC-FeCrSiC cored wires<br />

part 1: bending, compression and tension<br />

behavior<br />

J. Nebel*, E. Vogli, W. Tillmann<br />

Characterization of mechanical properties<br />

of titanium cold spray coatings<br />

D. Goldbaum*, R. Chromik, J. Ajaja,<br />

A. Rezaeian, W. Wong, S. Yue, E. Irissou,<br />

J. Legoux<br />

Testing the reliability of thermal spray coatings<br />

with micro-nanoindentation: methodology,<br />

scope of analysis and case studies<br />

K. Gross*<br />

Comparative study of splat morphology<br />

and the splat-substrate interactions for<br />

NiCr sprayed on to stainless steel by both<br />

plasma and HVOF spraying<br />

S. Brossard*, P. Munroe<br />

Observation of microstructures in thermal<br />

sprayed coatings and single deposited<br />

splats using ion beam milling<br />

K. Kim, M. Watanabe, S. Kuroda*, N. Kawano<br />

Graded twin wire arc sprayed coatings<br />

M. Abdulgader*, W. Tillmann, E. Vogli

Moor Room Hullet Room<br />

Modeling and Simulation 2<br />

Session Chairmen: M. Schäfer / A. Schwenk<br />

Effects of fluid/solid couplings on the plasma<br />

flow inside a direct current plasma gun<br />

R. Bolot*, A. Allimant, D. Billières, C. Coddet<br />

Effect of using liquid feedstock in a high<br />

pressure cold spray nozzle<br />

A. Dolatabadi*, E. Farvardin, O. Stier,<br />

V. Luethen<br />

Metastable austenite type core wire for arc<br />

spraying – modeling of heat transfer in end<br />

face and coating structure analysis<br />

Y. Korobov*, M. Filippov, A. Belozertsev,<br />

S. Neveszin, V. Shymiakov<br />

Wednesday, May 5, 2010<br />

Predicting the thermal conductivity of<br />

AlSi/polyester abradable coatings: effects of<br />

the numerical method<br />

R. Bolot*, J. Seichepine, J. Qiao, C. Coddet<br />

In situ observation of impact phenomena of<br />

zirconia molten drops in millimeter scale via<br />

aerodynamic levitator<br />

K. Shinoda*, K. Nagashio, H. Murakami,<br />

S. Kuroda, K. Kuribayashi<br />

Investigation of in-flight particle states in<br />

plasma spraying of LSM solution precursor<br />

Y. Shan*, Y. Wang, T. Coyle<br />

Corrosion Protection<br />

Lunch Break and Poster Session<br />

Technical Program<br />

Session Chairmen: V. Drescher / E. Vogli<br />

Thermally sprayed oxide ceramic coatings<br />

for demanding wear and corrosion applications<br />

K. Niemi*, J. Laurila, P. Vuoristo, J. Knuuttila,<br />

F. Toma, L. Berger<br />

Assessment of flame sprayed glaze layers<br />

as diffusion barriers on refractory materials<br />

O. Preziosa*, A. Denoirjean, P. Denoirjean,<br />

G. Montavon, T. Chartier, C. Barthélemy,<br />

V. Laurent, D. Lombard<br />

Phase composition and microstructural<br />

responses of crystalline mullite/YSZ coating<br />

under water vapor environments<br />

E. Garcia*, J. Mesquita-Guimaraes, P. Miranzo,<br />

M. Osendi, C. Cojocaru, Y. Wang, C. Moreau,<br />

R. Lima<br />

Corrosion of titanium coating prepared by<br />

modified HVOF process<br />

C. Deng, C. Deng*, M. Liu, A. Wank<br />

Corrosion behavior of NiCrBSi alloy coatings<br />

manufactured via in situ plasma spray<br />

laser remelting process<br />

N. Serres*, F. Hlawka, S. Costil, C. Langlade,<br />

F. Machi<br />

Cyclic oxidation behavior of HVOF sprayed<br />

Ni-20Cr coating on ASTM-SA213-T 22 boiler<br />

steel at 900°C<br />

G. Kaushal*, H. Saheet, S. Prakash<br />

10:40<br />

11:00<br />

11:20<br />

11:40<br />

12:00<br />

12:20<br />

12:40<br />

21

Technical Program<br />

22<br />

13:40<br />

14:00<br />

14:20<br />

14:40<br />

15:00<br />

Wednesday, May 5, 2010<br />

Sophia Room Olivia Room<br />

Wear Protection 3<br />

Session Chairmen: P. Vuoristo / M. Jeandin<br />

Comparison of two structure scales of plasma<br />

sprayed alumina/titania coatings on the<br />

mechanical and tribological properties<br />

V. Fabio, H. Ageorges*, W. Xin, F. Vargas,<br />

P. Fauchais, M. López<br />

Tribological analysis of WC cermet coatings<br />

with friction test under tensile stress condition<br />

F. Itoigawa, K. Nomakuchi*, K. Sato,<br />

J. Kitamura<br />

Preparation and characterization of plasma<br />

sprayed NiAl-hBN composite coating<br />

L. Du*, W. Zhang, W. Liu, J. Zhang<br />

Experimental investigation of fretting wear<br />

on nitrided and thermal spray coated Ti-6-4<br />

parts for liftfan applications<br />

P. Patil*, F. Sadeghi, S. Dixit, R. Dixit, M. Chin<br />

Corrosion behavior of AZ31 magnesium<br />

alloy coated with zinc-nickel by low pressure<br />

cold spray<br />

J. Villafuerte*, R. Maev, J. Phelan,<br />

D. Dzhurinskiy, E. Maeva, V. Leshchynsky<br />

Gas Turbines 3<br />

Session Chairmen: K. Ogawa / S. Siegmann<br />

Ice dry stripping of TBC systems<br />

C. Giolli*, A. Scrivani, B. Allegrini, G. Rizzi,<br />

A. Giorgetti, L. Engl, T. Duda<br />

A durable low K APS TBC<br />

L. Liu*, P. Howard<br />

Highlight<br />

Thermal cycle resistance of oxidation resistant<br />

metallic coatings<br />

S. Takahashi*, M. Hatano, Y. Kojima, Y. Harada,<br />

A. Kawasaki, F. Ono<br />

Next generation thermal barrier coatings for<br />

the gas turbine industry<br />

N. Curry*, N. Markocsan, X. Li, A. Tricoire,<br />

M. Dorfman<br />

A study on thermal cycle life and electrochemical<br />

impedance response of plasma<br />

sprayed functionally graded thermal barrier<br />

coatings<br />

S. Gosipathala*, V. Raya<br />

Flame Spray Technologies bv

Properties 3<br />

Wednesday, May 5, 2010<br />

Moor Room Hullet Room<br />

Session Chairmen: D. Branagan / L. Lusvarghi<br />

Influence of residual stresses on cracking<br />

behavior of composite WC-17Co coating in<br />

scratch test<br />

A. Ghabchi*, K. Holmberg, A. Valarezo,<br />

E. Turunen, S. Sampath<br />

On the use of nanoindentation and surface<br />

scratch testing for HVOF and APS coatings<br />

B. Bonferroni*, J. Nohava, G. Bolelli,<br />

L. Lusvarghi<br />

Microstructures of cold sprayed coatings<br />

investigated by X-ray microtomography<br />

V. Guipont*, G. Rolland, M. Jeandin, D. Jeulin,<br />

C. Peyrega, W. Ludwig<br />

Characterization of cohesion of selected<br />

HVOF coatings by scratch testing on cross<br />

section<br />

J. Nohava*, S. Houdkova, R. Enzl<br />

Influence of pores and cracks morphology<br />

on mechanical behavior of thermally<br />

sprayed ceramics<br />

R. Musalek*, J. Matejicek, V. Pejchal, E. Mari,<br />

A. Valarezo, S. Sampath<br />

Biomedical and<br />

Polymer Coatings<br />

Session Chairmen: R. Gadow / X. Liu<br />

Technical Program<br />

Highlight<br />

Kinetic metallization of polymeric materials<br />

R. Tapphorn, J. Henness, H. Gabel*<br />

Feasibility of polycarbonate coating by cold<br />

spray process<br />

D. Seo*, N. Mahiou, K. Ogawa, T. Shoji, K. Ito<br />

3-D visualizaton of the splat substrate interface<br />

for PEEK particles sprayed onto aluminum<br />

P. Munroe*, J. Wu<br />

Microstructures and adhesive bonding<br />

strength analysis of plasma sprayed silica<br />

modified hydroxyapatite coatings on<br />

Ti-6Al-4V substrates<br />

J. Xu*, M. Khor, J. Cizek<br />

Design of experiment analysis of the Sulzer<br />

Metco DJ high velocity oxy fuel coating of<br />

hydroxyapatite for orthopaedic applications<br />

J. Stokes*, S. Hasan<br />

Flame Spray Technologies bv<br />

13:40<br />

14:00<br />

14:20<br />

14:40<br />

15:00<br />

23

24<br />

Poster Session<br />

Poster Session<br />

During the conference a Poster Session will be held in the Collyer/Padang Foyer of the Raffles City Convention<br />

Centre. The poster presenters will be available for discussion scheduled as follows:<br />

Monday, May 3, 2010, 12:30 – 13:30<br />

Tuesday, May 4, 2010, 12:40 – 13:40<br />

Wednesday, May 5, 2010, 12:40 – 13:40<br />

In addition further contacts with the authors can be arranged.<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

Aerospace Industry<br />

Mechanical behavior of air plasma<br />

sprayed functionally graded YSZ-mullite<br />

environmental barrier coatings: a study<br />

via instrumented indentation<br />

C. Cojocaru*, Y. Wang, C. Moreau, R. Lima,<br />

J. Mesquita-Guimarães, E. Garcia,<br />

P. Miranzo, M. Osendi<br />

Kinetic metallization - dimensional restoration<br />

of Mg and Al alloy components<br />

R. Tapphorn*, H. Gabel, J. Henness<br />

Kinetic metallization of interior diameter<br />

(ID) bores<br />

J. Henness*, R. Tapphorn, H. Gabel<br />

Characterization of NiAl bond coat with<br />

ZrC additions prepared by cold spraying<br />

of ball milled Ni-Al alloy powders<br />

C. Li*, R. Xie, D. Li, G. Yang, H. Cui<br />

Research of plasma spraying process of<br />

nanostructured zirconia thermal barrier<br />

coating<br />

H. Sun*, C. Wang, X. Liu, Z. Qu, J. Bi<br />

Case Studies<br />

Atomization gas and air cap type effect<br />

on arc sprayed coating properties<br />

E. Altuncu*, F. Üstel, A. Türk<br />

Corrosion and Wear<br />

Protection<br />

Effect of temperature on the wear<br />

characteristic of cast iron<br />

S. Shaha*, M. Haque<br />

8.<br />

9.<br />

10.<br />

11.<br />

12.<br />

13.<br />

14.<br />

Assessment of flame sprayed glaze layers<br />

as diffusion barriers on refractory<br />

materials<br />

G. Montavon*, O. Preziosa, A. Denoirjean,<br />

P. Denoirjean, T. Chartier, C. Barthélemy,<br />

V. Laurant, D. Lombard<br />

Microstructure and electrochemical behavior<br />

of Fe-based amorphous metallic coatings<br />

fabricated by atmospheric plasma<br />

spraying<br />

Z. Zhou*, L. Wang, F. Wang, Y. Liu, D. He<br />

Analysis of different Fe-base materials<br />

and evaluation of their suitability for wear<br />

protection coatings<br />

A. Pelz*<br />

Comparative analysis of anti-cavitation<br />

and abrasion resistance properties of two<br />

different detonation coatings<br />

K. Huang*, S. Wu, J. Fang, Z. Liu, L. Ye,<br />

Y. Shi, S. Yin<br />

Corrosion behavior of thermally sprayed<br />

high entropy stainless steel coatings<br />

before and after heat treatments<br />

A. Lekatou*, D. Zois, M. Vardavoulias,<br />

T. Vaimakis<br />

Corrosion resistance of HVOF micro- and<br />

nanocermet coatings on AL 7075<br />

A. Lekatou*, D. Sioulas, D. Grimanelis,<br />

A. Karantzalis<br />

Degradation mechanisms of thermally<br />

sprayed coatings in chloride containing<br />

electrolytes<br />

J. Laurila*, K. Niemi, P. Vuoristo

15.<br />

16.<br />

17.<br />

18.<br />

19.<br />

20.<br />

21.<br />

22.<br />

23.<br />

24.<br />

25.<br />

Experimental investigation of fretting<br />

wear on nitrided and thermal spray<br />

coated Ti-6-4 parts for liftfan applications<br />

P. Patil*, F. Sadeghi, S. Dixit, R. Dixit,<br />

M. Chin<br />

Corrosion properties of conventional and<br />

nanostructured HVOF sprayed titania<br />

coatings<br />

S. Forghani*, M. Jameelah Ghazali<br />

HVOF, Cold and Kinetic<br />

Spraying<br />

Effects of WC particle size on deposition<br />

of cold spray WC-Co coatings<br />

S. Ang*, J. Wang, C. Berndt, P. Cheang<br />

A multipurpose surface protection system<br />

I. Gorlach*<br />

Modeling of particle consolidation by cold<br />

spray<br />

J. Kocimski*, R. Maev, A. Ambroziak,<br />

V. Leshchynsky<br />

Influence of helium and nitrogen gases on<br />

the properties of cold gas dynamic<br />

sprayed pure titanium coatings<br />

W. Wong*, S. Yue, E. Irissou, J. Legoux<br />

Effect of powder pre-heating temperature<br />

on the properties of Cu based amorphous<br />

coating layer by cold spray deposition<br />

K. Lee*, J. Cho, D. Park, J. Lee<br />

Diagnostics and coating formation in low<br />

pressure cold spray process<br />

H. Koivuluoto*, S. Tolvanen, P. Sirkka,<br />

P. Harkko, T. Alahautala, J. Larjo, P. Vuoristo<br />

Kinetic metallization systems and<br />

equipment<br />

J. Henness*, H. Gabel, R. Tapphorn<br />

Characteristic features of different crystalline<br />

metals in kinetic spray deposition<br />

G. Bae*, K. Kang, H. Na, C. Lee<br />

Location of the powder injection point as<br />

an independent parameter for controlling<br />

particle velocity and temperature in cold<br />

spray<br />

I. Smurov*, A. Sova, S. Klinkov, V. Kosarev<br />

26.<br />

27.<br />

28.<br />

29.<br />

30.<br />

31.<br />

Poster Session<br />

Structure and properties of Ni-Cr coatings<br />

deposited by HVOF<br />

T. Coyle*, J. Saaedi, H. Arabi, S. Mirdamadi<br />

Industrial Engineering<br />

Comparison of atmospheric plasma<br />

sprayed electrolyte layers for IT-SOFCs<br />

using different feedstock<br />

W. Gao*, H. Liao, F. Lapostolle, C. Coddet<br />

Performance of thermal sprayed coatings<br />

used in internal valvules in oil industry<br />

L. Gil*, S. Liscano, M. Staia, M. Rocco,<br />

A. Fragiel<br />

Medical Technologies<br />

Characterization of biocompatible<br />

HA/TiO 2 coatings obtained by thermal<br />

spray<br />

S. Dosta*, F. Javier, I. Canno, A. Ferrer,<br />

J. Guilemany<br />

Modeling and Simulation<br />

Computer aided cooling curve used to<br />

predict the solidification behavior of cast<br />

iron<br />

S. Shaha*, M. Haque<br />

The improvements of thermal spray toolkit,<br />

an extended software for robotic<br />

off-line programing<br />

D. Fang*, S. Deng, H. Liao, C. Coddet<br />

Flame Spray Technologies bv<br />

25

26<br />

Poster Session<br />

32.<br />

33.<br />

34.<br />

35.<br />

36.<br />

37.<br />

38.<br />

39.<br />

40.<br />

Nanomaterial Coatings<br />

and Solution Precursors<br />

Wear resistence of chromium carbide<br />

CNTs nanocomposites coatings<br />

M. Rodriguez*, L. Gil<br />

The effect of volume ratio of nano<br />

alumina fillers and polymers on the<br />

properties of alumina polycer composites<br />

W. Xie*, J. Wang, K. Alamara, C. Berndt<br />

Plasma and Laser<br />

Spraying<br />

Characteristics of Cu film-like deposited<br />

by using VLPPS<br />

N. Zhang*, M. Planche, F. Sun, L. Zhu,<br />

C. Verdy, H. Liao, C. Coddet<br />

Roles of Si, B and C in suppressing<br />

oxidation of iron during atmospheric<br />

plasma spray<br />

Z. Zeng*, J. Kawakita, S. Kuroda<br />

The bond mechanism of WC-12Co<br />

coatings prepared by supersonic plasma<br />

spraying<br />

H. Yang*, S. Pan<br />

Effect of the nitrogen flow on the microstructure<br />

and transformation rate of TiN<br />

coatings in reactive plasma spraying<br />

H. Yang*, H. Chen<br />

Microstructural characterization of<br />

plasma sprayed Fe 3 Al/TiC composite<br />

coatings<br />

C. Li*, L. Tian, C. Li, X. Wang, B. Song<br />

Enhanced deposition characteristics of<br />

bronze/diamond composite coating via<br />

innovative hybrid spraying<br />

H. Na*, G. Bae, J. Kim, H. Kim, C. Lee<br />

Power Engineering<br />

The role of parameters on the hardness of<br />

HVOF sprayed bond coats in thermal<br />

barrier coatings<br />

M. Minisker*, T. Bengi, E. Ciftyurek, O. Keles,<br />

I. Taptik<br />

41.<br />

42.<br />

43.<br />

44.<br />

45.<br />

46.<br />

47.<br />

Effect of directional re-solidification on<br />

thermal plasma spray silicon depositions<br />

D. Jackson*, R. Patterson, M. Suda,<br />

M. Sereda, R. Gansert<br />

Pre- and Post-Treatment<br />

The protal® process applied on cold<br />

spraying to improve interface adherence<br />

and coating cohesion – case of titanium<br />

and nickel based alloys<br />

S. Costil*, C. Moreau, E. Irissou, J. Legoux,<br />

V. Guipont, M. Jeandin, C. Coddet<br />

Surface pre-treatment including laser<br />

texturing for thermal spraying<br />

S. Costil*, A. Lamraoui, C. Langlade,<br />

C. Coddet<br />

Process Diagnostics,<br />

Sensors and Controls<br />

Studying of the relationship between<br />

robot kinematics and the coating quality<br />

D. Fang*, S. Deng, H. Liao, C. Coddet<br />

Influence of improved plasma gun on the<br />

particle in-flight properties of temperature<br />

and velocity<br />

H. Yang*, G. Li, L. Wang<br />

Effects of radial liquid injection on<br />

atmospheric plasma characteristics<br />

D. Soysal*, A. Ansar, T. Kavka, J. Arnold<br />

The oxy fuel ionization (OFI) process:<br />

experimental process analysis<br />

M. Parco*, G. Barykin, I. Fagoaga,<br />

G. Mariaux, S. Goutier, M. Vardelle<br />

Flame Spray Technologies bv

48.<br />

49.<br />

50.<br />

51.<br />

52.<br />

53.<br />

54.<br />

55.<br />

56.<br />

Properties,<br />

Characterization and<br />

Testing<br />

Comparison of structure and wear<br />

properties of babbit layers which are<br />

produced by arc spraying and pouring<br />

Y. Korobov*, B. Potechin, L. Gogolev,<br />

V. Ilushin, M. Deviatiarov<br />

Characterization of some electric arc<br />

sprayed cored wire and nano cored wire<br />

cermet coatings<br />

S. Wirojanupatump*, S. Jiansirisomboon,<br />

M. Tuiprae<br />

Arc spraying of WC-FeCrSiC cored wires<br />

part 2: E-module measurement and<br />

simulation<br />

J. Nebel*, B. Svensen, B. Klusemann,<br />

E. Vogli, W. Tillmann<br />

Effect of powder compressive strength<br />

on deposition characteristics in cold<br />

spraying<br />

T. Sonoda*, T. Saito, T. Kuwashima,<br />

M. Nakamura<br />

Comparison of hBN addition NiAl coatings<br />

deposited using APS and HVOF thermal<br />

spraying<br />

W. Hsiao*, C. Su, W. Liao, M. Leu<br />

Preparation process and property<br />

research of Fe-Cr-Al intermatellic compound<br />

coating<br />

C. Wang*, H. Sun, X. Liu, Z. Qu, J. Bi<br />

Characterization of shrouded plasma<br />

sprayed Cu-based BMG coating against<br />

atmospheric plasma sprayed coating<br />

J. Kim*, S. Yoon, K. Kang, S. Kumar, H. Na,<br />

C. Lee<br />

Microwave joining of copper and its<br />

characterization<br />

S. Sri*, A. Kumar Sharma, P. Kumar<br />

Development and characterization of<br />

microwave cladding of tungsten carbide<br />

rich powder on SS316 steel<br />

D. Gupta*, A. Kumar Sharma<br />

57.<br />

58.<br />

59.<br />

60.<br />

61.<br />

62.<br />

63.<br />

64.<br />

65.<br />

Poster Session<br />

Effect of mullite on thermal shock<br />

behavior of yitria stabilized zirconia (YSZ)<br />

coatings<br />

E. Altuncu*, A. Türk, F. Üstel<br />

Solid Oxide Fuel Cell<br />

Post-treatment of plasma sprayed<br />

zirconia based electrolytes<br />

C. Christenn*, A. Ansar<br />

Plasma sprayed electrolyte of magnesium<br />

doped lanthanum silicate with apatite<br />

type structure<br />

F. Sun*, H. Liao, N. Zhang, C. Coddet<br />

Preparation of nanocomposite GDC/LSCF<br />

cathode material for IT-SOFC by RF<br />

induction plasma spraying<br />

Y. Shen*, F. Gitzhofer, V. Almeida<br />

Functionally graded anodes with<br />

nanostructure for intermediate<br />

temperature SOFCs<br />

L. Jia*, F. Gitzhofer<br />

Preparation of Sm0.5Sr0.5CoO 3 of fine<br />

structure by solution precursor plasma<br />

spraying for SOFC cathode<br />

C. Li*, X. Wang, L. Tian, B. Song, G. Yang<br />

Thermal Spray and other<br />

Surface Engineering<br />

Technologies<br />

Effect of carbide type on the properties of<br />

low vacuum plasma sprayed W-based<br />

composite coating layer<br />

K. Lee*, J. Ahn, Y. Jin<br />

Examination on surface properties of<br />

modified AiSi5140 steel by pulse plasma<br />

technique<br />

A. Ayday*, M. Durman, S. Kurnaz<br />

Influence of thermal residual strains on<br />

bonding strength and fracture of plasma<br />

sprayed Ni/LDC anode coating on Ni<br />

substrate<br />

Y. Yang*, C. Hwang, C. Tsai<br />

27

28<br />

Exposition<br />

Concurrent with the conference, the ITSC 2010<br />

exposition, organized by ASM International, will<br />

be held in the Padang and Collyer Rooms of the<br />

Raffles City Convention Centre.<br />

Exhibitor List (November, 20<strong>09</strong>)<br />

Exposition hours are from:<br />

Monday, May 3, 2010 12:30-17:30<br />

Tuesday, May 4, 2010 08:00-17:00<br />

Wednesday, May 5, 2010 08:00-14:00<br />

Company Booth no.<br />

Beijing Advanced Materials Co. Ltd., P.R. China 21<br />

CGT Cold Gas Technology GmbH, Germany 79<br />

DeWal Industries, Inc., United States of America 17<br />

Diamant Coating Systems, United States of America 81<br />

DURUM Verschleiss-Schutz GmbH, Germany 68<br />

ECKA Granules, United States of America 18<br />

Flame Spray Technologies bv, The Netherlands / H.C. Starck, SEA 38<br />

Green Belting Industries Ltd., United States of America 29<br />

Grillo-Werke AG, Germany 8<br />

GTV IMPEX GmbH, Germany 65<br />

HAI Advanced Material Specialists, Inc., United States of America 44<br />

HÖGANÄS AB, Sweden 16<br />

Inovati, United States of America 20<br />

Metallizing Equipment Co. Ltd., India 26<br />

MilliDyne OY, Finland 4<br />

Northwest Mettech Corporation, Canada 56<br />

Oseir Ltd., Finland 3<br />

Polymet Corporation, United States of America 5<br />

Praxair Surface Technologies, United States of America 1<br />

Progressive Technologies, Inc., United States of America 12<br />

Saint-Gobain, United States of America 48<br />

Sulzer Metco AG, Switzerland 32<br />

Technogenia / Wilhelm SEA 71<br />

Tecnar Automation LTEE, Canada 72<br />

THERMICO GMBH & CO. KG, Germany 56<br />

UniqueCoat Technologies, United States of America 19

April 30 – May 2, 2010, 8:00 – 17:00<br />

Location: Fairmont Singapore, Room Clark<br />

Instructor:<br />

Christopher C. Berndt, PhD, FASM, HoF<br />

Professor, Swinburne University of<br />

Technology<br />

Melbourne, Australia<br />

Course Overview:<br />

Thermal spray technology and coatings solve critical problems<br />

in demanding environments. They provide “solutions”<br />

to problems involving repair, wear, high temperature<br />

and aqueous corrosion, and thermal protection. Thermal<br />

spray can also be used to manufacture net-shapes,<br />

advanced sensors and materials for the biomedical and<br />

energy/environmental sectors. These and other emerging<br />

applications take advantage of the rapid and cost-effective<br />

capabilities of thermal spray technology in the OEM and<br />

repair industries. Thermal spray processes - twin wire-arc,<br />

combustion, high velocity oxy-fuel (HVOF), cold spray and<br />

plasma spray, and associated technologies, can deposit<br />

virtually any material as a surface coating onto a wide<br />

range of other materials. Coating reliability and effectiveness<br />

requires that these overlay coatings be selected,<br />

engineered and applied correctly. This course (i) provides<br />

a thorough grounding and understanding of thermal spray<br />

processes, (ii) presents the complex scientific concepts in<br />

terms of simple physical models, and (iii) integrates this<br />

knowledge to practical applications and accepted thermal<br />

spray practices. NO mathematics is used to explain the<br />

processes or materials/mechanical engineering.<br />

Participants are encouraged to contact the instructor<br />

prior to the course so that any particular application or<br />

problem can be discussed as a case history. Each registrant<br />

receives the Handbook of Thermal Spray<br />

Technology and a comprehension set of notes that include<br />

the presentation slides.<br />

Learning Objectives:<br />

Upon completion of this course, participants will:<br />

Determine the historical basis for thermal spray technology<br />

and have detailed knowledge regarding the<br />

development of equipment and materials as related to<br />

present-day technology<br />

Recognize the terminology, principles and underlying<br />

theory of thermal spray technology<br />

Explain how feedstocks are designed and manufactured<br />

and how to select them for different spray processes<br />

Identify applicable testing methods and currently<br />

accepted industrial practices used for quality control of<br />

coatings<br />

Thermal Spray Technology<br />

Education Courses<br />

Who Should Enroll:<br />

Technologists<br />

Engineers<br />

Technicians<br />

Technical marketing personnel<br />

Graduate students and other professionals entering<br />

the thermal spray field or who wish to update their<br />

knowledge<br />

Course Outline:<br />

1. Surface Science<br />

2. Equipment & Theory<br />

3. Processing & Design<br />

4. Materials<br />

5. Applications<br />

6. Testing & Characterization<br />

About the Instructor:<br />

Chris Berndt earned his Ph.D. from Monash University,<br />

Melbourne in the area of "The Adhesion of Flame and<br />

Plasma Sprayed Coatings.” See < http://www.swinburne.edu.au/feis/iris/staff/cberndt.html<br />

> He took on several<br />

post-doc fellowships in the U.S. before returning to<br />

Monash, where he rose to the rank of Senior Lecturer in<br />

Materials Engineering before joining the faculty at Stony<br />

Brook University, where he was appointed Associate<br />

Dean for Undergraduate Studies in 2001. He is also qualified<br />

as an ABET visitor for materials and engineering<br />

science programs. Berndt remains an Adjunct Professor<br />

at Stony Brook.<br />

In <strong>2005</strong>, Berndt returned to Australia as the founding<br />

Professor of Surface and Interface Engineering at James<br />

Cook University, Queensland. He moved to Swinburne<br />

University of Technology, Melbourne in 2008 as the founding<br />

Professor of Surface Science and Interface<br />

Engineering. He also serves as Director of the Industrial<br />

Research Institute Swinburne (aka ‘IRIS’). Berndt has<br />

served as President of the ASM Thermal Spray Society<br />

and as an ASM Trustee, and he was inducted into the<br />

Thermal Spray Hall of Fame in 2007. He has more than<br />

350 publications in the field of materials science and<br />

engineering, and has served as editor for 10 conference<br />

proceedings on thermal spray.<br />

Registration Fees: Before After<br />

April 15, 2010 April 15, 2010<br />

Member Fee: 995 US Dollars 1.055 US Dollars<br />

(TSS/<strong>DVS</strong>/IIW)<br />

ASM Member Fee: 1.055 US Dollars 1.105 US Dollars<br />

Non-Member Fee: 1.195 US Dollars 1.245 US Dollars<br />

Student Fee: 295 US Dollars 345 US Dollars<br />

To register for the courses or for any questions,<br />

please contact ASM Member Service Center at<br />

memberservicecenter@asminternational.org<br />

(Product Code: 253081410)<br />

29

30<br />

Education Courses<br />

May 1 – 2, 2010, 08:00 – 18:30<br />

Location: Fairmont Singapore, Room Ord<br />

Instructors:<br />

Dr. Maher Boulos, TS-HoF<br />

Professor, University of Sherbrooke<br />

Sherbrooke, Canada<br />

Dr. Pierre Fauchais, FASM, TS-HoF<br />

Professor, University of Limoges<br />

Limoges, France<br />

Dr. Joachim Heberlein, FASM, TS-HoF<br />

Professor, University of Minnesota<br />

Minneapolis, United States of America<br />

Understanding and Improving<br />

your Thermal Spray Processes<br />

Course Overview:<br />

Thermal spray coatings are receiving increased attention<br />

as solutions to corrosion, wear and materials compatibility<br />

problems. Thermal spray processes using electric<br />

arcs, combustion and plasma spray can apply almost<br />

any material to the surface of another. These coatings<br />

must be correctly engineered and applied to operate as<br />

an overlay surface. Education is vital to understanding<br />

coating systems and improving thermal spray coating<br />