May/June 2010 - Global Aquaculture Alliance

May/June 2010 - Global Aquaculture Alliance

May/June 2010 - Global Aquaculture Alliance

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>May</strong>/<strong>June</strong> <strong>2010</strong>

THAT WHICH<br />

SUSTAINS US<br />

MUST ALSO BE<br />

SUSTAINABLE.<br />

Our business is dependent on the sustainability of the oceans’ resources as the most<br />

efficient and environmentally sound way to feed a growing global population. We believe<br />

that sustainability is as much about feeding people as it is about managing the world’s<br />

natural resources. To that end, we work tirelessly with our global supply network to<br />

ensure a consistent supply of the products our customers demand, while protecting<br />

and replenishing our common resource: the ocean.<br />

NO ONE ELSE.<br />

SLADE GORTON & CO., INC • WWW.SLADEGORTON.COM<br />

BOSTON 800-225-1573 • MIDWEST 800-524-8237<br />

SOUTHEAST 877-885-5499 • WEST COAST 800-567-5002<br />

may/june <strong>2010</strong><br />

24 Biofloc Technology Expanding At White Shrimp Farms<br />

Nyan Taw, Ph.D.<br />

28 Microbial Flocs Spare Protein In White Shrimp Diets<br />

Alberto J. P. Nunes, Ph.D.; Leandro Fonseca Castro, M.S.;<br />

Hassan Sabry-Neto. M.S.<br />

31 Bioreactor Technology For Tilapia Advances<br />

In Latin America<br />

Sergio Zimmermann<br />

32 Water Temperature In <strong>Aquaculture</strong><br />

Claude E. Boyd, Ph.D.<br />

35 Smoked Fish – Old Product With New Appeal<br />

Offers Enhanced Taste, Shelf Life<br />

George J. Flick, Jr., Ph.D.<br />

38 New Zealand Addresses Social Factors<br />

In <strong>Aquaculture</strong> Development<br />

Wendy Banta<br />

40 GESIT Tilapia: Indonesia’s Genetic Supermales<br />

Ratu Siti Aliah, Komar Sumantadinata, Maskur,<br />

Sidrotun Naim<br />

42 Chile’s Salmon Industry Addresses Health Crises<br />

Adolfo Alvial<br />

45 Varied Feed Additives Improve Gut, Animal Health<br />

Pedro Encarnação<br />

48 Fish Vaccines In <strong>Aquaculture</strong> – Proactive Treatment<br />

Protects Salmon, Catfish, Other Fish<br />

Dr. Julia W. Pridgeon, Dr. Phillip H. Klesius<br />

51 Managing Tilapia Health In Complex Culture Systems<br />

Neil Wendover, B.S.<br />

54 Disease Factors For Shrimp Production In Brazil<br />

Victoria Alday-Sanz, Ph.D.; Ana C. Guerrelhas, B.S.;<br />

João L. Rocha, Ph.D.<br />

58 Fish Farming Supports Ecological Efficiency<br />

Neil Anthony Sims<br />

60 Consumer Attitudes Toward <strong>Aquaculture</strong> –<br />

Spanish Study Correlates Knowledge, Opinions<br />

José Fernandez-Polanco, Ph.D.; Ladislao Luna, Ph.D.;<br />

Ignacio Llorente<br />

62 Farmed Or Wild? Both Types Of Salmon Taste Good<br />

And Are Good For You<br />

Pamela D. Tom; Paul G. Olin, Ph.D.<br />

65 Bangladesh Seeks Export Markets For Striped Catfish<br />

Dr. Peter Edwards, Md. Sazzad Hossain<br />

69 Shrimp Problems In Indonesia? Imports From Ecuador<br />

Continue Strong As White Conversion Continues;<br />

Norwegian, U.K. Salmon Fillets Jump As Chile<br />

Recovers From Earthquake;<br />

Fresh Tilapia Fillet Prices Spike After Lent,<br />

Frozen Imports Set Monthly Record<br />

Paul Brown, Jr.; Janice Brown; Angel Rubio<br />

72 Life Cycle Assessment In <strong>Aquaculture</strong> – ‘Not A Single<br />

Event, But A Combination Of Processes’<br />

William Davies<br />

DEPARTMENTS<br />

From The President 2<br />

From The Editor 3<br />

GAA Activities 6<br />

Advocate Advertisers 92<br />

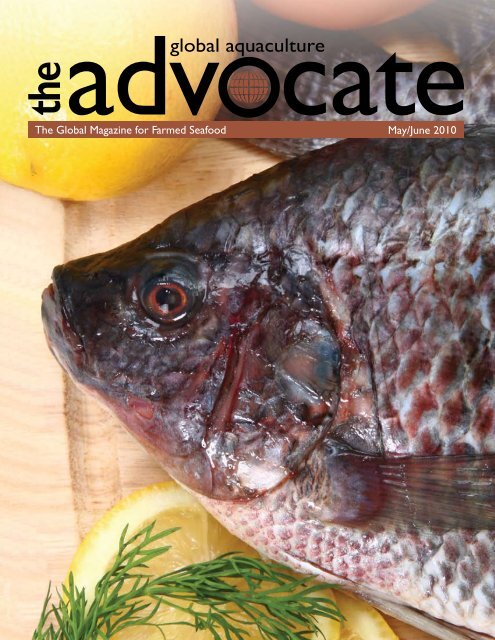

On the cover:<br />

Ongoing advances in tilapia breeding have resulted in lines of fastgrowing<br />

fish that have helped make tilapia the world’s second mostproduced<br />

fish species.<br />

page 58<br />

Sustainably farmed fish<br />

may represent 60 times<br />

more efficient use of<br />

baitfish than wild fish.<br />

Farmed fish have more<br />

efficient life cycles, trophic<br />

transfer and by-catch.<br />

75 Biofloc: Novel Sustainable Ingredient For Shrimp Feed<br />

David D. Kuhn, Ph.D.; George J. Flick, Jr., Ph.D.;<br />

Gregory D. Boardman, Ph.D.; Addison L. Lawrence, Ph.D.<br />

78 Two-Stage Selection Key For Fast Shrimp<br />

Growth In Mexico<br />

Héctor Castillo-Juárez, Ph.D.; Hugo H. Montaldo, Ph.D.;<br />

Gabriel R. Campos-Montes, Ph.D.<br />

80 SPF Shrimp Breeding In Brazil – Genetic, Phenotypic<br />

Trends After Generation Of Selection<br />

João L. Rocha, Ph.D.; Ana C. Guerrelhas; Ana K. Teixeira;<br />

Flávio A. Farias; Ana P. Teixeira<br />

83 Seafood Chilling, Preservation With Ice Slurry<br />

Ming-Jian Wang, Ph.D.<br />

85 Ultrasound Helps Stage Sturgeons For Caviar Production<br />

Brian C. Donahower, Ph.D.; Steve DuMond; Leo Ray;<br />

Linda Lemmon; Gary Fornshell; Terry Patterson; Jodi Rockett;<br />

Madison S. Powell; Wendy M. Sealy<br />

87 The True Cost Of Thai Shrimp<br />

Robins McIntosh<br />

page 24<br />

Biofloc technology provides<br />

high productivity, low feedconversion<br />

ratios and a<br />

stable culture environment<br />

that delivers sustainable<br />

production at lower cost.<br />

ii <strong>May</strong>/<strong>June</strong> <strong>2010</strong> global aquaculture advocate global aquaculture advocate <strong>May</strong>/<strong>June</strong> <strong>2010</strong> 1<br />

the<br />

The <strong>Global</strong> Magazine for Farmed Seafood<br />

global aquaculture<br />

January/February 2009

GLOBAL AQUACULTURE<br />

ALLIANCE<br />

The <strong>Global</strong> <strong>Aquaculture</strong> Al li ance is an international<br />

non-profit, non-gov ernmental<br />

association whose mission is to further en viron<br />

men tally responsible aqua culture to meet<br />

world food needs. Our members are producers,<br />

pro cessors, marketers and retailers of seafood<br />

prod ucts worldwide. All aqua culturists<br />

in all sectors are welcome in the organization.<br />

OFFICERS<br />

George Chamberlain, President<br />

Bill Herzig, Vice President<br />

Ole Norgaard, Secretary<br />

Lee Bloom, Treasurer<br />

Wally Stevens, Executive Director<br />

BOARD OF DIRECTORS<br />

Bert Bachmann<br />

Lee Bloom<br />

Rittirong Boonmechote<br />

George Chamberlain<br />

Shah Faiez<br />

John Galiher<br />

Bill Herzig<br />

Ray Jones<br />

Alex Ko<br />

Jordan Mazzetta<br />

Sergio Nates<br />

Ole Norgaard<br />

John Peppel<br />

Antonio Pino<br />

John Schramm<br />

Iain Shone<br />

Wally Stevens<br />

EDITOR<br />

DARRYL JORY<br />

editorgaadvocate@aol.com<br />

PRODUCTION STAFF<br />

ASSISTANT EDITOR<br />

DAVID WOLFE<br />

davidw@gaalliance.org<br />

MARKETING/ADVERTISING<br />

SALLY KRUEGER<br />

sallyk@gaalliance.org<br />

GRAPHIC DESIGNER<br />

LORRAINE JENNEMANN<br />

lorrainej@gaalliance.org<br />

HOME OFFICE<br />

5661 Telegraph Road, Suite 3A<br />

St. Louis, Missouri 63129 USA<br />

Telephone: +1-314-293-5500<br />

FAX: +1-314-293-5525<br />

E-mail: homeoffice@gaalliance.org<br />

Website: http://www.gaalliance.org<br />

All contents copyright © <strong>2010</strong><br />

<strong>Global</strong> <strong>Aquaculture</strong> <strong>Alliance</strong>.<br />

<strong>Global</strong> <strong>Aquaculture</strong> Advocate<br />

is printed in the USA.<br />

ISSN 1540-8906<br />

from the president<br />

Past The<br />

Tipping Point<br />

Three years ago, I wrote that the <strong>Global</strong> <strong>Aquaculture</strong><br />

<strong>Alliance</strong> seemed to be approaching a tipping point.<br />

A tipping point is the threshold before which<br />

small changes have little or no effect, but after which<br />

further small changes “tip” the system, resulting in a<br />

large effect. The term originated in the field of epidemiology,<br />

where it is used to describe the point at<br />

which an infectious disease reaches the outbreak<br />

stage. It has also been used to describe the point at<br />

which global warming stops ocean currents, leading<br />

to major climatic change. Some have even used it to<br />

describe the phenomena by which products or individuals rise from anonymity to popular<br />

demand or celebrity status.<br />

GAA’s tipping point involves Best <strong>Aquaculture</strong> Practices (BAP) certification. For nearly<br />

a decade, we steadily pursued BAP’s principles, which resulted in incremental advances in<br />

the program’s circle of supporters and overall reach. Three years ago BAP certification, then<br />

based only on shrimp, was adopted by Wal-Mart and Darden Restaurants, and progress<br />

began accelerating. A critical mass of support developed through unexpected new linkages<br />

and synergies. Soon, the tipping point threshold was reached – and surpassed.<br />

Now, the BAP certification program has been adopted by most major retailers in the<br />

United States and is gaining traction in the United Kingdom and elsewhere. Over<br />

500,000 mt of seafood from BAP-certified facilities enter the global market annually,<br />

and GAA has become the world’s leading<br />

aquaculture standard-setting organization.<br />

Many exciting developments are under<br />

way. The BAP standards have broadened to<br />

include channel catfish and tilapia. New<br />

standards for feed mills, Pangasius farms and<br />

salmon farms are expected soon, and a technical<br />

committee for mussel farm standards is<br />

forming. The United States Food and Drug<br />

Administration pilot study on food safety<br />

verification has been completed, and the <strong>Global</strong> Food Safety Initiative is expected to<br />

benchmark the BAP processing plant standards in a few weeks.<br />

To help the BAP program meet the challenges of mainstream certification, GAA is<br />

reorganizing its structure to integrate functions, expand outreach and improve efficiency.<br />

It has formed a charitable organization called the Responsible <strong>Aquaculture</strong><br />

Foundation (RAF), which will house the BAP Standards Oversight Committee, technical<br />

committees and training, research and development functions. One of the first<br />

international missions of the newly formed RAF will be a cooperative program with<br />

Malaysia’s Department of Fisheries and Ministry of Health to help train aquaculture<br />

producers in environmental, social and food safety excellence.<br />

We are especially pleased with the strong response from sister aquaculture associations<br />

around the world to our reciprocal membership program. This will help improve<br />

communication and coordination at many levels.<br />

Thank you for throwing your weight behind the BAP effort to tip the scales toward<br />

a brighter and more sustainable future for aquaculture. It is thrilling to see the ongoing<br />

progress being achieved at so many levels. This could not have been realized without<br />

your dedicated support.<br />

Sincerely,<br />

George W. Chamberlain<br />

George W.<br />

Chamberlain, Ph.D.<br />

President<br />

<strong>Global</strong> <strong>Aquaculture</strong> <strong>Alliance</strong><br />

georgec@gaalliance.org<br />

Thank you for throwing<br />

your weight behind the<br />

BAP effort to tip the scales<br />

toward a brighter<br />

and more sustainable<br />

future for aquaculture.<br />

from the editor<br />

Readers Respond<br />

To Digital Advocate<br />

Feedback received by me and other members<br />

of the <strong>Global</strong> <strong>Aquaculture</strong> <strong>Alliance</strong> staff has indicated<br />

that the exciting change we introduced to<br />

the <strong>Global</strong> <strong>Aquaculture</strong> Advocate magazine in its last<br />

issue – a digital edition – has been well received.<br />

This is very encouraging to us.<br />

Like its print-based Advocate “sister,” the new<br />

digital Advocate continues to include the up-todate,<br />

factual industry information that is our<br />

trademark, but makes it available online in forms<br />

that are easily downloaded and stored electronically. This content will remain permanently<br />

available on our website or in your electronic storage.<br />

Our goal in distributing the Advocate electronically is to further GAA’s mission<br />

of “feeding the world through responsible<br />

aquaculture” by focusing attention on the<br />

Best <strong>Aquaculture</strong> Practices program and<br />

certified facilities around the world, on<br />

sustainability developments in the marketplace<br />

and on new technologies that<br />

improve production efficiency and sustainability.<br />

The digital Advocate is available free<br />

at www.gaalliance.org.<br />

Going forward, we will continue our<br />

coverage of the entire seafood production<br />

value chain, keeping an eye on the rapid<br />

expansion of the aquaculture industry<br />

driven by increasing global seafood<br />

demand. Through this coverage, we will pay particular attention to potential<br />

impacts, life cycle assessments and long-term sustainability issues.<br />

Another change we are introducing with this issue is our further effort to<br />

become more environmentally responsible. This magazine is printed on paper stock<br />

with at least 10% post-consumer recycled content. In addition, the masthead<br />

includes the logo of the Sustainable Forestry Initiative certification system for<br />

responsible forestry practices.<br />

The Sustainable Forestry Initiative (SFI) standard addresses issues like worker<br />

health and safety, civil rights, anti-discrimination and fair wages. The SFI mark is a<br />

sign that wood and paper products are bought from a responsible source, backed by<br />

a rigorous, third-party certification audit.<br />

As always, we encourage your suggestions for current topics you would like us to<br />

cover, as well as your contributions of short articles that are aligned with our mission<br />

to support responsible aquaculture. Please contact me at your convenience for<br />

details about our article submission guidelines.<br />

Through the years, your critical comments have significantly improved our magazine,<br />

and I urge you to continue sending us your comments on how we can best<br />

represent and serve our industry.<br />

Thank you for your continuing support.<br />

2 <strong>May</strong>/<strong>June</strong> <strong>2010</strong> global aquaculture advocate global aquaculture advocate <strong>May</strong>/<strong>June</strong> <strong>2010</strong> 3<br />

Sincerely,<br />

Darryl E. Jory<br />

Darryl E. Jory, Ph.D.<br />

Editor<br />

<strong>Global</strong> <strong>Aquaculture</strong> Advocate<br />

editorgaadvocate@aol.com<br />

FOUNDING MEMBERS<br />

Agribrands International Inc.<br />

Agromarina de Panama, S.A.<br />

Alicorp S.A. – Nicovita<br />

Aqualma – Unima Group<br />

Aquatec/Camanor<br />

Asociación Nacional de Acuicultores de Colombia<br />

Asociación Nacional de Acuicultores de Honduras<br />

Associação Brasileira de Criadores de Camarão<br />

Bangladesh Chapter – <strong>Global</strong> <strong>Aquaculture</strong> <strong>Alliance</strong><br />

Belize <strong>Aquaculture</strong>, Ltd.<br />

Bluecadia <strong>Aquaculture</strong> Group, LLC<br />

Bluepoints Co., Inc.<br />

Cámara Nacional de Acuacultura<br />

Camaronera de Cocle, S.A.<br />

Cargill Animal Nutrition<br />

Continental Grain Co.<br />

C.P. <strong>Aquaculture</strong> Business Group<br />

Darden Restaurants<br />

Deli Group, Ecuador<br />

Deli Group, Honduras<br />

Diamante del Mar S.A.<br />

Eastern Fish Co.<br />

El Rosario, S.A.<br />

Empacadora Nacional, C.A.<br />

Empress International, Ltd.<br />

Expack Seafood, Inc.<br />

Expalsa – Exportadora de Almientos S.A.<br />

FCE Agricultural Research<br />

and Management, Inc.<br />

Fishery Products International<br />

India Chapter – <strong>Global</strong> <strong>Aquaculture</strong> <strong>Alliance</strong><br />

Indian Ocean <strong>Aquaculture</strong> Group<br />

INVE <strong>Aquaculture</strong>, N.V.<br />

King & Prince Seafood Corp.<br />

Long John Silver’s, Inc.<br />

Lu-Mar Lobster & Shrimp Co.<br />

Lyons Seafoods Ltd.<br />

Maritech S.A. de C.V.<br />

Meridian Aquatic Technology Systems, LLC<br />

Monsanto<br />

Morrison International, S.A.<br />

National Food Institute<br />

National Prawn Co.<br />

Ocean Garden Products, Inc.<br />

Overseas Seafood Operations, SAM<br />

Preferred Freezer Services<br />

Productora Semillal, S.A.<br />

Promarisco, S.A.<br />

Red Chamber Co.<br />

Rich-SeaPak Corp.<br />

Sahlman Seafoods of Nicaragua, S.A.<br />

Sanders Brine Shrimp Co., L.C.<br />

Sea Farms Group<br />

Seprofin Mexico<br />

Shrimp News International<br />

Sociedad Nacional de Galapagos<br />

Standard Seafood de Venezuela C.A.<br />

Super Shrimp Group<br />

Tampa Maid Foods, Inc.<br />

U.S. Foodservice<br />

Zeigler Brothers, Inc.

JOIN THE wORLD’S LEADING<br />

AQUACULTURE ORGANIzATION<br />

<strong>Aquaculture</strong> is the future of the world’s seafood supply.<br />

Be part of it by joining the <strong>Global</strong> <strong>Aquaculture</strong> <strong>Alliance</strong>,<br />

the leading standards-setting organization for farmed<br />

seafood.<br />

Access science-based information on efficient aquaculture<br />

management. Connect with other responsible<br />

companies and reach your social responsibility goals.<br />

global aquaculture<br />

Improve sales by adopting GAA’s Best <strong>Aquaculture</strong><br />

Practices certification for aquaculture facilities.<br />

Annual dues start at U.S. $150 and include a subscription<br />

to the <strong>Global</strong> <strong>Aquaculture</strong> Advocate magazine,<br />

GAA e-newsletters, event discounts and other benefits.<br />

Visit www.gaalliance.org or contact the GAA office<br />

for details.<br />

<strong>Global</strong> <strong>Aquaculture</strong> <strong>Alliance</strong><br />

Feeding the World Through Responsible <strong>Aquaculture</strong><br />

St. Louis, Missouri, USA – www.gaalliance.org – +1-314-293-5500<br />

®<br />

Breaded Mussels • Mussel Meat • Mussels in the Shell • Gourmet Salmon Portions • Langostino Lobster Tails<br />

GOVERNING MEMBERS<br />

AIS Aqua Foods, Inc.<br />

Al Fulk National Co., Ltd.<br />

Alicorp S.A. – Nicovita<br />

Alfesca<br />

American Seafoods Group<br />

Aqua Bounty Technologies<br />

Aquamarina de la Costa, C.A.<br />

Blue Archipelago<br />

Camanor Produtos Marinhos, Ltda.<br />

Capitol Risk Concepts, Ltd.<br />

Cargill<br />

Chang International, Inc.<br />

Darden Restaurants<br />

Delta Blue <strong>Aquaculture</strong>, LLC<br />

Eastern Fish Co.<br />

Empress International, Ltd.<br />

Fishery Products International, Inc.<br />

<strong>Global</strong> Food Technologies<br />

Grobest USA Inc.<br />

Harbor Seafood<br />

Imaex Seafoods<br />

Inspectorate America Corp.<br />

International Associates Corp.<br />

King & Prince Seafood Corp.<br />

Lyons Seafoods Ltd.<br />

Maloney Seafood Corp.<br />

Mazzetta Co., LLC<br />

Morey’s Seafood International<br />

National Fish and Seafood, Inc.<br />

National Prawn Co.<br />

Preferred Freezer Services<br />

Promarisco, S.A.<br />

P.T. Central Proteinaprima, TBK<br />

QVD<br />

Red Chamber Co.<br />

Rich Product Corp.<br />

Sahlman Seafoods of Nicaragua, S.A.<br />

Sea Port Products Corp.<br />

Seafood Exchange of Florida<br />

Seajoy<br />

Suram Trading Co.<br />

Thai Union Group<br />

Trace Register<br />

Tropical <strong>Aquaculture</strong> Products, Inc.<br />

Urner Barry Publications, Inc.<br />

Zeigler Brothers, Inc.<br />

SUSTAINING MEMBERS<br />

Akin Gump Strauss Hauer & Feld LLP<br />

Alltech<br />

Amanda Foods<br />

Ammon International Inc.<br />

Anova Food, Inc.<br />

Aqua Star<br />

Australis <strong>Aquaculture</strong><br />

Beaver Street Fisheries, Inc.<br />

Binh An Seafood Joint Stock Co.<br />

Black Tiger <strong>Aquaculture</strong> Sdn. Bhd.<br />

Blue Ridge <strong>Aquaculture</strong><br />

Camanchaca<br />

C.P. Products<br />

Contessa Food Products, Inc.<br />

Cooke <strong>Aquaculture</strong> Inc.<br />

Cumbrian Seafoods Ltd.<br />

Devcorp International<br />

Diamond V Mills<br />

DSM<br />

Findus Group<br />

Fortune Fish Co.<br />

Genomar A.S.<br />

Gradient <strong>Aquaculture</strong><br />

Hanwa American Corp.<br />

Harvest Select Catfish<br />

H & N Foods International, Inc.<br />

H.Q. Sustainable Maritime Industries Inc.<br />

Inland Seafood<br />

International Marketing Specialists<br />

Intervet/Schering-Plough Animal Health<br />

Ipswich Shellfish Co.<br />

Maritime Products International<br />

Mida Trade Ventures International, Inc.<br />

Mirasco, Inc.<br />

North Coast Seafoods<br />

Novozymes<br />

Novus International<br />

Orca Bay Seafoods<br />

Orion Seafood International<br />

Pacific Aqua Farms, Inc.<br />

Pacific Asset Funding<br />

Pacific Seafood Group<br />

Pacific Supreme Co.<br />

ProFish Americas<br />

P.T. Fega Marikultura<br />

Seattle Fish Co.<br />

Seattle Fish Co. of N.M.<br />

Slade Gorton & Co., Inc.<br />

Solae, LLC<br />

Starfish Foods, Inc.<br />

Stavis Seafoods, Inc.<br />

Sysco of Detroit<br />

The Fishin’ Company<br />

The Plitt Co.<br />

Trans-Pac Foods, Ltd.<br />

Trident Seafoods, Inc.<br />

TÜV SÜD PSB Corp. Pte. Ltd.<br />

ASSOCIATION MEMBERS<br />

All China Federation of Industry<br />

and Commerce Aquatic Production<br />

Chamber of Commerce<br />

American Feed Industry Association<br />

Associação Brasileira de Criadoresde Camarão<br />

Bangladesh Shrimp and Fish Foundation<br />

Cámara Nacional de Acuacultura<br />

Fats and Proteins Research Foundation, Inc.<br />

International Fishmeal and<br />

Fish Oil Organisation<br />

National Fisheries Institute<br />

National Renderers Association<br />

Oceanic Institute<br />

Prince Edward Island Seafood<br />

Processors Association<br />

Salmon of the Americas<br />

Seafood Importers and Processors <strong>Alliance</strong><br />

U.S. Soybean Export Council<br />

World <strong>Aquaculture</strong> Society<br />

Mussel Meat in Butter Garlic Sauce<br />

Serving Suggestion<br />

Camanchaca Inc. • 7200 N.W. 19th Street • Suite 410 • Miami, FL USA 33126<br />

Call 800.335.7553 • www.camanchacainc.com<br />

Pesquera Camanchaca S.A. • El Golf 99-Piso 11 • Las Condes, Santiago, Chile • www.camanchaca.cl<br />

4 <strong>May</strong>/<strong>June</strong> <strong>2010</strong> global aquaculture advocate global aquaculture advocate <strong>May</strong>/<strong>June</strong> <strong>2010</strong> 5<br />

Memorable Meals<br />

Made in Minutes

Although Bowen had many business interests, his “crowning achievement” in aquaculture<br />

was Belize <strong>Aquaculture</strong> Ltd.<br />

Sir Barry Bowen: The Belizean<br />

Who Changed Shrimp Farming<br />

Robins McIntosh<br />

Senior Vice President<br />

Charoen Pokphand Foods Public Co.<br />

C.P. Tower 27 Floor<br />

313 Silom Road, Bangrak<br />

Bangkok, 10500, Thailand<br />

robmc101@yahoo.com<br />

Not everyone has an opportunity to work<br />

with a legend. As a past employee of Sir<br />

Barry Bowen, I did.<br />

On February 26, my old employer<br />

and still friend Sir Barry Bowen died in a<br />

plane he was piloting. Upon receiving<br />

this news in Bangkok, my mind raced as<br />

to what this man had meant to me personally<br />

and then to what he had meant to<br />

Belize and to the world community of<br />

shrimp farmers.<br />

Barry had so many times in the past<br />

picked me up from the shrimp farm in his<br />

modified Cessna 208 to take me to<br />

Ambergris Caye for a weekend. A weekend<br />

where he would discuss his dreams<br />

and, more importantly, how to make those<br />

dreams reality.<br />

Barry Bowen had been flying planes<br />

like most of us drive a car for 43 years.<br />

He made that flight daily to his home in<br />

Ambergris Caye. He was meticulous<br />

about the plane’s maintenance, and every<br />

time I entered the cockpit with him, he<br />

would spend time going over his check<br />

list before takeoff. He would arrive home<br />

in the late afternoon, but always before<br />

sunset. Barry was a risk taker, but he was<br />

careful and always meticulous in everything<br />

he did.<br />

Belize First<br />

Generally when one writes about<br />

Barry Bowen, you begin by describing<br />

him as one of the wealthiest individuals<br />

in Belize – and that he was. But that simple<br />

description does not give this man his<br />

true merit.<br />

He was first a Belizean, a man who<br />

lived for his beloved Belize. He was a very<br />

proud seventh-generation Belizean, and<br />

always let me know that any investing he<br />

did would always be in Belize.<br />

Barry did not believe in paper assets.<br />

He invested in hard assets, projects that<br />

would be good for the Belizean economy.<br />

And as he told me more than once: “I am<br />

not a passive investor. I take an active<br />

part in any investment I make.”<br />

That is the Barry Bowen I remember<br />

– the man who was ankle deep in a<br />

muddy sump installing a seawater pump.<br />

A man stooped over the hood of a truck<br />

as the final layout of ponds was decided.<br />

A man in the farm warehouse taking<br />

apart a paddlewheel aerator so he could<br />

Barry Bowen was knighted<br />

by Queen Elizabeth<br />

in 2008 for his many<br />

contributions to Belize.<br />

find ways to improve the gearing mechanism.<br />

From Beer To Belize<br />

<strong>Aquaculture</strong><br />

In the beginning, I must admit I was a<br />

bit mystified by Barry, a dreamer and<br />

visionary of the first order. Barry did<br />

dream, but it was a calculated dreaming he<br />

knew how to make a reality.<br />

There was never a better person at<br />

putting together a project from scratch<br />

than Barry Bowen, especially projects<br />

that others said just could not be done.<br />

He enjoyed sitting me down and telling<br />

me the story of Belikin Beer, for example.<br />

After obtaining an engineering degree<br />

from Cornell University, Barry returned<br />

to Belize to work with his father in the<br />

family-owned Coca-Cola bottling business.<br />

For a dreamer and young man with<br />

entrepreneurship in his veins, this would<br />

not last long. He dreamed of a beer brewery<br />

in Belize.<br />

He asked his father to invest but was<br />

quickly told, “Barry, Belize does not have<br />

the population to support a brewery.” So<br />

Barry took his life savings, a couple of<br />

thousand dollars, to Miami and looked<br />

up a retired German brewmaster living<br />

there. Could the man develop a business<br />

plan for a brewery in Belize?<br />

Belize <strong>Aquaculture</strong> was a pioneer in the use of pond liners and regular aeration. The<br />

shrimp farm’s sloped embankments were covered with fabric mesh sprigged with grass<br />

to control erosion.<br />

The brewmaster repeated Barry’s<br />

father’s advice, but Barry insisted that<br />

even though Belize had a small population<br />

and one with the lowest beer consumption<br />

in Central America, he could<br />

make it work. He also told the brewmaster<br />

he would give him his savings to help.<br />

And so Barry Bowen got a business plan<br />

for developing a brewery in Belize.<br />

Then he figured he needed to learn<br />

the business, and so off for the summer<br />

went Barry to see a family friend who<br />

owned Cerveceria Hondurena in Honduras.<br />

He left for Honduras and volunteered<br />

his work in the brewery to learn<br />

more about beer.<br />

After a couple of months, Barry scheduled<br />

an appointment with the owner and<br />

asked him if he would like to invest in a<br />

brewery in Belize. As Barry would tell it,<br />

the owner just about laughed him out of<br />

the office. “I bet you don’t even have a<br />

business plan,” the owner said. Barry<br />

smiled and presented him with his business<br />

plan. A bit shocked, the owner told<br />

Barry to come back in a week after he<br />

studied the document.<br />

Upon his return, the owner told<br />

Barry, “I will financially back your plan,<br />

provided you promise that you will personally<br />

work in this brewery business for<br />

five years.” And with that, Barry Bowen<br />

had found a backer and the technical support<br />

for his first brewery.<br />

It is said that Barry personally helped<br />

lay the bricks for the foundation of the<br />

Belikin Brewery, and as Barry was all too<br />

proud to tell, “I turned a profit in my second<br />

year, two years ahead of the plan.” In<br />

not too long a period, Belize went from<br />

last place in Central American beer consumption<br />

to first place. And, of course,<br />

that was not the end of the story.<br />

With profits from the brewery, Barry<br />

bought out his father’s shares in the<br />

Coca-Cola bottling company, establishing<br />

the cash flow that would fund his<br />

future dreams. These included buying<br />

Belize Estates, a company that held title<br />

to over 400,000 ha of land or 20% of<br />

Belize; the world-class jungle ecotourism<br />

resort Chan Chich Resort on his Gallon<br />

Jug Estate Lands; a livestock farm that<br />

produced hybrid cattle with the best-tasting,<br />

most tender beef in all of Central<br />

America; a 1,200-ha organic coffee plantation;<br />

the private Island Academy school<br />

on Ambergris Caye; and what I consider<br />

his crowning achievement, Belize <strong>Aquaculture</strong><br />

Ltd. (BAL).<br />

Barry Bowen thought shrimp aquaculture<br />

was good for Belize. He worried<br />

about the citrus and banana industries<br />

remaining competitive as the world<br />

moved to a global economy. Shrimp, on<br />

the other hand, was a high-value commodity<br />

that Belize could cultivate competitively.<br />

He envisioned being close to the<br />

North American markets, providing<br />

shrimp that were grown in “environmentally<br />

friendly systems.” His greatest dream<br />

was the delivery of newly harvested<br />

shrimp by air directly from the farm to<br />

Bowen’s Belize farm consistently produced<br />

greater volumes of larger shrimp than were typical<br />

of the time.<br />

the major markets of the United States.<br />

Breaking Rules<br />

I first met Barry Bowen through Russ<br />

Allen. I was not sold on working in<br />

Belize. Before I went to meet Barry, an<br />

owner of a major farm in Ecuador had<br />

advised: “Don’t do it. Shrimp cannot be<br />

cultured profitably in Belize. There are<br />

no wild brooders or postlarvae there.”<br />

With that in the back of my mind, I sat<br />

down to talk with Barry Bowen, and we<br />

had the conversation he loves to tell and<br />

retell. This is my version of the story.<br />

It was <strong>May</strong> 1996, and we were on a<br />

porch outside his home on Ambergris<br />

Caye, drinking, of course, Belikin Beer.<br />

He told me he had studied the shrimp<br />

business and was about to invest in it<br />

back in 1992, when disease hit farms in<br />

Central America. He decided there was<br />

too much risk in the way shrimp were<br />

being cultivated in large ponds using lots<br />

of water exchange and wild shrimp. So he<br />

studied some more.<br />

After a visit to the Waddell Center in<br />

South Carolina, USA, Barry decided that<br />

the future was in smaller ponds using little<br />

if any water exchange, closed systems<br />

that would not pollute the waters outside<br />

the farm and using domesticated shrimp<br />

lines that were known to be free of any<br />

diseases. Then he told me the goal of his<br />

farm would be 11 mt/ha/crop with three<br />

crops yearly.<br />

I am sure I looked pretty stunned,<br />

having come from Guatemala, where the<br />

best I had ever accomplished was 7.7 mt/<br />

ha in a couple of ponds. But in the end, I<br />

was on board, and we were going to give<br />

it the best try that technology would<br />

allow – even if it meant breaking all the<br />

rules of shrimp culture that were accepted<br />

in 1996.<br />

Barry made it clear he would invest<br />

U.S. $10 million without losing any<br />

6 <strong>May</strong>/<strong>June</strong> <strong>2010</strong> global aquaculture advocate global aquaculture advocate <strong>May</strong>/<strong>June</strong> <strong>2010</strong> 7

sleep, understanding it was risk money<br />

doing a project that was somewhat<br />

untested. It would be research and development.<br />

He loved the term “R & D.” But<br />

the way Barry thought, to do a project in<br />

typical shrimp farm fashion would have<br />

no long-term future.<br />

Industry Status: 1996<br />

Shrimp farming in Central America<br />

during 1996 was dominated by large 10-<br />

to 20-ha ponds stocked at 10-30/m 2 densities<br />

and producing 2,000-3,000 mt/ha.<br />

All stocking was done with postlarvae<br />

derived directly from the wild or from wild<br />

broodstock.<br />

Taura syndrome was having a major<br />

impact on shrimp survivorship, and if<br />

that was not a serious-enough problem,<br />

postlarvae just did not grow into large<br />

shrimp. A harvest at 15-g size would<br />

have been considered large due to what at<br />

the time was known as dry season slow<br />

growth syndrome.<br />

Pond management centered on managing<br />

phytoplankton populations that<br />

would periodically crash if water exchange<br />

rates were not great enough. The more<br />

water you flowed, the higher your pond<br />

yields. Ponds were therefore always sited<br />

at low elevations so that high-volume,<br />

low-head pumps could be used.<br />

During most harvests, crabs, fish and<br />

wild shrimp would also come out with<br />

the cultured shrimp. Postlarvae were<br />

judged by price. Guatemala had superior<br />

seed because the cost was less than U.S.<br />

$1 per thousand. Only wild seed was<br />

acceptable, because seed from a domesticated<br />

source would be so weak they<br />

would die in a pond.<br />

Shrimp genetics were unheard of, and<br />

no one ever talked about pedigree or<br />

source of broodstock. Every white shrimp<br />

was equivalent to every other white<br />

shrimp. Bacterial ecology was never<br />

talked about, and the only bacteria were<br />

the pathogenic variety.<br />

Pond bottom preparation, however,<br />

was a major topic of discussion. You had<br />

to dry, till and lime the bottoms between<br />

crops. This limited most farms to no<br />

more than two cycles per year.<br />

BAL Contributions<br />

Against this background, consider the<br />

contributions that Barry Bowen made to<br />

shrimp farming through his vision and<br />

development of Belize <strong>Aquaculture</strong> Ltd.:<br />

• A farm designed to produce 11 mt/<br />

ha. In fact, his first harvest on February<br />

3, 1998, yielded 14 mt/ha<br />

with a survivorship of 92%. On that<br />

night, Barry had a smile of great<br />

satisfaction.<br />

I remember Barry took some of those<br />

first shrimp back to his farm house and<br />

Dixie, his wife, cooked them up for an<br />

after-harvest celebration. The shrimp,<br />

grown in pure seawater and on plastic<br />

with no water exchange, were so very<br />

tasty.<br />

The first harvest was not a fluke. For<br />

the next three years, the farm averaged<br />

over 15.2 mt/ha with shrimp sizes as<br />

large as 24 g. No dry season syndrome on<br />

the BAL farm.<br />

• A farm constructed on land with an<br />

elevation greater than 12 m because<br />

he was a firm believer in being<br />

above the hurricane zone. Because<br />

of this head requirement, ponds<br />

were built to operate on little water<br />

exchange. In fact, the phrase “zero<br />

Belize <strong>Aquaculture</strong> distributed feed by mechanical blower. Heavy foam on the surface<br />

of the pond indicates incomplete transition to a bacterially dominated pond community.<br />

water exchange” was coined to<br />

describe pond management there.<br />

There were no high-volume, low-head<br />

pumps at BAL. And the term “biofloc”<br />

came from the bacterial communities that<br />

developed in zero-water-exchange ponds.<br />

There were brown flocs, black flocs and<br />

green flocs.<br />

• A farm that would practice “green”<br />

aquaculture. Since the farm was in<br />

an environmentally sensitive area,<br />

Barry insisted on settling and treatment<br />

ponds to receive harvest<br />

drainage water. This water then<br />

could be recycled at a lower cost in<br />

pumping and reduced the chance of<br />

pumping in an infection.<br />

• A farm that was built for biosecure<br />

management. Before any other<br />

shrimp farm owner I knew in the<br />

Americas even knew the word or<br />

concept, Barry had ideas on biosecurity.<br />

He knew disease could literally<br />

kill his project.<br />

A sign stating “Biosecurity Zone” was<br />

on prominent display at the farm entrance.<br />

Visitors were discouraged, not because of<br />

keeping secrets, but for fear of bringing in<br />

disease. No one was ever allowed to bring a<br />

“foreign” shrimp or crab onto the farm site.<br />

A major feature of biosecurity is the<br />

ability to screen carriers and competitors<br />

out of the water before it enters ponds.<br />

Barry designed a filter system that<br />

allowed us to completely filter all pond<br />

water down to 200 µ – unheard of at the<br />

time. But harvests at BAL were always<br />

clean, with never a fish, crab or wild<br />

shrimp.<br />

• A farm based on the use of specific<br />

pathogen-free (SPF) domesticated<br />

shrimp. Barry was not the first<br />

farmer in the Americas to use<br />

Hawaiian SPF shrimp, but he was<br />

the first to use SPF shrimp after the<br />

initial failed introduction to Ecuador<br />

and, more importantly, the first<br />

to show the importance of SPF<br />

shrimp in large-scale commercial<br />

farming outside the boundaries of<br />

the United States. The success that<br />

BAL demonstrated with SPF<br />

shrimp provided the base for SPF<br />

acceptance in other locations<br />

throughout the world.<br />

• A farm that used high-density polyethylene<br />

(HDPE) liners. BAL was<br />

one of the first farms to demonstrate<br />

the merits of lining ponds<br />

with HDPE plastic. A few ponds<br />

had been lined previously, but no<br />

farm had actually understood or<br />

demonstrated the benefits of lining.<br />

Barry Bowen was a proud Belizean who actively participated in his “hard asset”<br />

investments.<br />

BAL clearly showed that HDPE<br />

allowed quick pond turnaround times,<br />

increasing the number of harvest cycles<br />

per year. HDPE also protected the freshwater<br />

aquifers from saltwater intrusion.<br />

Monitor wells proved this out. But more<br />

than one expert told Barry that he could<br />

not grow shrimp on plastic.<br />

• A farm that mechanized as much as<br />

possible. Both feeding and harvesting<br />

activities were mechanized to<br />

reduce the amount of labor<br />

required. Production of 900 mt of<br />

shrimp was accomplished with<br />

three individuals. Typically, farms<br />

would employ many pond feeders<br />

to manually apply feed and clean<br />

screens. This was not the case at<br />

BAL.<br />

• A modular hatchery and maturation<br />

system that operated continuously<br />

for the five years I was present. It<br />

never required the scripted dryouts<br />

that were part of so many hatchery<br />

protocols. By building a modularized<br />

hatchery, the operation could<br />

be operated efficiently 12 months<br />

per year.<br />

The project was not without problems.<br />

But every time a problem developed,<br />

Barry Bowen was steady and<br />

focused. Barry did not allocate blame, it<br />

was R & D. And so we learned and continued<br />

to refine the concept of BAL. The<br />

results spoke for themselves, and further<br />

improvements were made in stocking,<br />

water management and operation of the<br />

settling basins and recycling systems.<br />

Practical Environmentalist<br />

On occasion, Barry Bowen was<br />

attacked for his “environmentalism.”<br />

Barry was a practical environmentalist.<br />

He funded naturalists at his Gallon Jug<br />

Estate and personally loved to hike<br />

though the jungle and watch birds and<br />

other wildlife. He donated 110,000 ha of<br />

jungle land, which became the Rio Bravo<br />

Conservation and Management Area,<br />

ensuring a natural heritage for future<br />

generations of Belizeans.<br />

Barry was consistent in his belief that<br />

shrimp farming could be and should be<br />

done with the environment in mind. And<br />

he made Belize <strong>Aquaculture</strong> a testament<br />

to that belief. But as he told me once: “I<br />

lose patience with those people who<br />

think environmentalism is not to develop<br />

an economy. Developed economies are<br />

required for people to lead better and<br />

happier lives. I bet each of the environmentalists<br />

from the so-called developed<br />

world lives with a yard full of grass that<br />

used to have a virgin forest on it. Their<br />

ancestors did what we in Belize must now<br />

do to develop, and for that we are criticized.”<br />

Father Of Modern Shrimp<br />

Farming<br />

Let me conclude by saying that in my<br />

mind, shrimp farming was changed by<br />

Barry Bowen, changed for the better. He<br />

is my “father of modern shrimp farming.”<br />

He changed ideas that resulted in a more<br />

sustainable model that produces shrimp<br />

with predictability, in quantities never<br />

thought possible and at lower costs that<br />

continually make shrimp more available<br />

to more and more consumers.<br />

Today, shrimp farmers and those<br />

involved in researching shrimp culture<br />

technology routinely talk about biofloc,<br />

limited water exchange, the pedigrees of<br />

shrimp, biosecurity, pushing production<br />

envelopes, developing new markets based<br />

on freshness and green technologies.<br />

Barry Bowen dreamed of these ideas<br />

before any of us, and he had the boldness<br />

to act on his dreams and the skill to make<br />

them happen.<br />

Thank You<br />

I was privileged to work for Barry<br />

Bowen, and for that privilege, I have<br />

become a better shrimp culturist, a culturist<br />

who is no longer bound by limits<br />

set by industrial thinking. Thank you, Sir<br />

Barry Bowen.<br />

A legend is someone about whom<br />

everyone you meet has a story to tell, and<br />

generally a story larger than life itself.<br />

This was Barry Bowen. Anyone in Belize,<br />

on the mention of the name Barry<br />

Bowen, had a story to tell.<br />

Barry, you were a living legend in<br />

Belize. And Belize will never see another<br />

like you.<br />

Sir Barry Bowen<br />

Barry Bowen was knighted by<br />

Queen Elizabeth in 2008 for his<br />

many contributions to Belize.<br />

Thereafter he became Sir Barry<br />

Bowen.<br />

Sir Barry Bowen was given an<br />

official state funeral that attracted<br />

thousands of people to pay<br />

respects as the official motorcade<br />

traveled from the funeral service to<br />

his internment in Cayo.<br />

Prime Minister Dean Barrow<br />

said the following about Barry<br />

Bowen during the interment:<br />

“He was obviously one of the<br />

greatest modern-day Belizeans,<br />

one of the greatest Belizeans of his<br />

generation. It’s not just that he<br />

was so immensely successful as a<br />

businessman, it was the fact that<br />

he was always prepared to take<br />

risks, that he was always prepared<br />

to diversify, even when it meant<br />

that he would get into new areas<br />

that were far from certain in terms<br />

of offering the kinds of returns<br />

that businessmen and entrepreneurs<br />

would normally look for.<br />

That is what I found most outstanding<br />

about him – that he had<br />

a mindset that suggested that he<br />

could get anything out of the<br />

Belizean earth.”<br />

8 <strong>May</strong>/<strong>June</strong> <strong>2010</strong> global aquaculture advocate<br />

global aquaculture advocate <strong>May</strong>/<strong>June</strong> <strong>2010</strong> 9

Cli CliCk k or Flip!<br />

DIGITAL ADVOCATE – FREE!<br />

You Can Now View<br />

Or Download The Advocate!<br />

global aquaculture Feeding the World Through<br />

Responsible <strong>Aquaculture</strong> Search the GAA Site<br />

DONATE NOW JOIN GAA<br />

Home About GAA About BAP Get Certified Members Magazine Newsroom Contact Us<br />

View our magazine online!<br />

January / February <strong>2010</strong> Issue<br />

View Online Download<br />

Please note that this digital edition requires flash player 8 or later<br />

If you do not have flash player 8 installed, you can download it from the<br />

following URL: http://getadobe.com/flashplayer<br />

Print/Digital Digital Only<br />

January/February March/April<br />

<strong>May</strong>/<strong>June</strong> July/August<br />

September/October November/December<br />

Enjoy the e-Advocate six times a year. Or join the <strong>Global</strong> <strong>Aquaculture</strong> <strong>Alliance</strong><br />

to also receive three printed issues by first-class mail. Either way, you get<br />

the best of responsible aquaculture – from GAA!<br />

While you’re looking, subscribe to GAA’s Update e-newsletter to receive e-mail notices<br />

when the next informative Advocate is available, as well as other important news<br />

on GAA activities around the world. It’s free, too.<br />

GO<br />

New GAA Directors Consider Integration<br />

At March Board Meeting<br />

During the Boston board meeting, Wally Stevens reviewed<br />

the growing status of the BAP program expressed on the “BAP<br />

at Work” signage displayed at the GAA trade show booth.<br />

The March 14 <strong>Global</strong> <strong>Aquaculture</strong> <strong>Alliance</strong> board of directors<br />

meeting began with a moment of silence in honor of Sir<br />

Barry Bowen, a distinguished founding supporter of GAA who<br />

died in a February plane crash. The meeting in Boston, Massachusets,<br />

USA, was well attended by GAA members from<br />

Europe, South America, Asia and the United States.<br />

New Directors<br />

Two new members have joined the GAA board. The slate of<br />

nominees for the GAA board presented by the Nominating<br />

Committee included replacements for Rick Martin and Erwin<br />

Sutanto, two exiting directors.<br />

The following were elected (or re-elected) to serve on the<br />

GAA board of directors:<br />

Lee Bloom, Eastern Fish Co.<br />

George Chamberlain, <strong>Global</strong> <strong>Aquaculture</strong> <strong>Alliance</strong><br />

Shah Faiez, Blue Archipelago (new nominee)<br />

John Galiher, Preferred Freezer Services<br />

Bill Herzig, Darden Restaurants<br />

Ole Norgaard, Alfesca (new nominee)<br />

Antonio Pino, Promarisco, S.A.<br />

Iain Shone, Lyons Seafoods Ltd.<br />

Bert Bachmann, Rittirong Boonmechote, Ray Jones, Alex<br />

Ko, Jordan Mazzetta, Sergio Nates, John Peppel, John Schramm<br />

and Wally Stevens will continue their terms as GAA directors.<br />

The following officers were approved at the meeting:<br />

Wally Stevens – Executive Director<br />

George Chamberlain – President<br />

Bill Herzig – Vice President<br />

Ole Norgaard – Secretary<br />

Lee Bloom – Treasurer<br />

The Nominating Committee also recommended expansion<br />

of the GAA Executive Committee from four members plus the<br />

executive director to six, plus the executive director. Modification<br />

of the GAA bylaws to accommodate the change was<br />

approved.<br />

Integration<br />

GAA Executive Director Wally Stevens reported that the<br />

success of the Best <strong>Aquaculture</strong> Practices program – as evidenced<br />

by new standards, more certified facilities and further<br />

penetration into the retail arena – is driving changes that will<br />

bring the <strong>Global</strong> <strong>Aquaculture</strong> <strong>Alliance</strong>, <strong>Aquaculture</strong> Certification<br />

Council (ACC) and new Responsible <strong>Aquaculture</strong> Foundation<br />

(RAF) into a tighter trinity.<br />

Since site inspections for Best <strong>Aquaculture</strong> Practices certification<br />

– formerly the responsibility of ACC – have passed to<br />

independent ISO-65-accredited certification bodies, the previously<br />

required definitive separation of GAA and ACC is no longer<br />

necessary. Closer cooperation between the two entities would<br />

make administration of the BAP program more efficient<br />

through the sharing of support services. The pending charitable<br />

status of the RAF can help subsidize the BAP standard-setting<br />

and training activities through foundation funding.<br />

In the integration, which has been approved by the GAA<br />

and ACC boards to phase in later this year, the <strong>Aquaculture</strong><br />

Certification Council will be renamed BAP Certification Management.<br />

As administrative and logistical manager for BAP certification,<br />

it will coordinate inspections, maintain records, monitor<br />

traceability and food safety data, and manage the use of the<br />

BAP mark on retail packaging for companies that participate in<br />

the program.<br />

The Responsible <strong>Aquaculture</strong> Foundation is expecting to<br />

receive charitable tax status – designated 501(c)(3) by the U.S.<br />

Internal Revenue Service – and begin operations soon. It will<br />

house the BAP Standards Oversight Committee that oversees<br />

the standards development process and the technical committees<br />

that develop individual standards. It will also assume primary<br />

responsibility for the training of BAP auditors and educational<br />

outreach to governments, trade associations, companies and<br />

individuals now carried out by ACC.<br />

Budgets<br />

Stevens said the projected budgets for GAA and ACC reflect<br />

the strong growth achieved by both organizations over the last<br />

decade. The current budgets do not adequately cover three areas<br />

tagged for growth in <strong>2010</strong>: Standards Oversight Committee<br />

technical committee work, BAP marketplace expansion and<br />

media coverage.<br />

Further budgets for primary project areas, as well as the need<br />

to establish minimum requirements for contingency funds<br />

retained for emergency reserve, will be reviewed by the GAA<br />

and RAF boards during GOAL <strong>2010</strong> in October.<br />

Strategic Planning<br />

Directors Peppel and Norgaard put forth the need to develop<br />

strategic plans for the next one, two and five years that outline<br />

annual goals for GAA. In examining the aspirations, resources<br />

and risks related to GAA’s execution of its mission, limiting factors<br />

can be identified and plans to address them can more effectively<br />

be formulated. Through strategic planning, the ultimate<br />

question is, how should GAA fit into the global aquaculture seafood<br />

community in five years?<br />

10 <strong>May</strong>/<strong>June</strong> <strong>2010</strong> global aquaculture advocate global aquaculture advocate <strong>May</strong>/<strong>June</strong> <strong>2010</strong> 11

BANGLADESH<br />

BAP-Certified Plants Species Affiliated Farms<br />

Apex Foods Ltd. 2<br />

Bagerhat Seafood Industries Ltd.<br />

Gemini SeaFood Ltd.<br />

Rupsha Fish & Allied Industries Ltd.<br />

SAR & Co., Ltd.<br />

Best <strong>Aquaculture</strong> Practices At Work<br />

BAP Processing Plants By Country<br />

CHINA<br />

BAP-Certified Plants Species Affiliated Farms<br />

Allied Pacific Aquatic Product (Zhangjiang) Co., Ltd. 1<br />

Allied Pacific Food (Dalian) Co., Ltd.<br />

Asian Seafoods (Zhanjiang) Co., Ltd.<br />

Beihai Beilian Foods Industrial Co., Ltd. 1<br />

Beihai Evergreen Aquatic Product Science<br />

and Technology Co., Ltd.<br />

Foshan City Shunde District Yang Sei<br />

Seafoods Co., Ltd.<br />

Fuqing Yihua Aquatic Food Co., Ltd.<br />

Gallant Ocean (Nanhai) Ltd.<br />

Gaoyao City Evergreen Aquatic Product Science<br />

and Technology Co., Ltd.<br />

Guangdong Jinhang Foods Co., Ltd.<br />

Guangxi Nanning Baiyang Food Co., Ltd.<br />

Guangzhou Luxe Seafood Enterprise, Ltd.<br />

Hainan Allied Pacific Biotech Co., Ltd<br />

Hainan Brich Aquatic Products Co., Ltd.<br />

Hainan Evernew Foods Co.<br />

Hainan Golden Spring Foods Co., Ltd.<br />

Hainan Sky-Blue Ocean Foods Co., Ltd.<br />

Hainan Xiangtai Fishery Co., Ltd.<br />

H.Q. Sustainable Maritime Industries –<br />

Hainan Quebec Ocean Fishing Co., Ltd.<br />

Luye Fisheries Guangzhou Co., Ltd.<br />

Maoming Changxing Foods Co., Ltd. 4<br />

Sanya Dongji Aquatic Products Co., Ltd.<br />

Savvy Seafood Inc.<br />

Shanwei Cathay Food Freezing<br />

and Processing Co., Ltd.<br />

Shenzhen Allied Aquatic Produce Development, Ltd 1<br />

Tongwei Hainan Aquatic Products Co., Ltd.<br />

XIHE Food Co., Ltd.<br />

Yelin Hoitat Quick Frozen Seafood Co., Ltd.<br />

Allied Pacific Aquatic Product (Zhangjiang) Co., Ltd. 1<br />

Zhanjiang Evergreen Aquatic Product Science<br />

and Technology Co., Ltd.<br />

Zhanjiang Go-Harvest Aquatic Products Co., Ltd.<br />

Zhangjiang Guolian Aquatic Products Co., Ltd. 2<br />

Zhangjiang Join Wealth Aquatic Products Co., Ltd.<br />

Zhenye Aquatic (Huilong) Ltd.<br />

Zhong Shan Metro Frozen Food Co., Ltd.<br />

INDIA<br />

BAP-Certified Plants Species Affiliated Farms<br />

Apex Exports<br />

®<br />

Avanti Feeds Ltd.<br />

Devi Sea Foods Ltd.<br />

Devi Sea Foods Ltd.<br />

Falcon Marine Exports, Ltd.<br />

Kader Exports Private Ltd.<br />

Nekkanti Sea Foods Ltd. – Ravulapalem<br />

Sandhya Aqua Exports Pvt. Ltd. 1<br />

Satya Seafood Pvt. Ltd.<br />

Star Agro Marine Exports Pvt. Ltd.<br />

1<br />

1<br />

8<br />

2<br />

1<br />

INDONESIA<br />

BAP-Certified Plants Species Affiliated Farms<br />

P.T. Bumi Menara Internusa 1<br />

P.T. Bumi Menara Internusa-Surabaya 1<br />

P.T. Centralpertiwi Bahari Process Plant 1<br />

P.T. Centralpertiwi Bahari Process Plant 2<br />

P.T. Central Proteniaprima 2<br />

P.T. Kelola Mina Laut 1<br />

P.T. Mega Marine Pride 1<br />

P.T. Mitra Kartika Sejati<br />

P.T. Panca Mitra Multi Perdana 1<br />

P.T. Royal Fisheries Indonesia<br />

P.T. Surya Alam Tunggal<br />

P.T. Winaros Kawula Bahari<br />

MALAYSIA<br />

BAP-Certified Plants Species Affiliated Farms<br />

Asia <strong>Aquaculture</strong> (M) Sdn. Bhd.<br />

Eastern <strong>Global</strong> (M) Sdn. Bhd. 1<br />

Gropoint Seafood Industries, Sdn. Bhd. 1<br />

SHRIMP<br />

TILAPIA<br />

CATFISH<br />

THAILAND<br />

BAP-Certified Plants Species Affiliated Farms<br />

Andaman Seafood Co., Ltd. 5<br />

Asia Pacific (Thailand) Co. Ltd. 9<br />

Asian Seafoods Coldstorage Public Co. Ltd. 1<br />

Chanthaburi Frozen Food Co., Ltd. 14<br />

Chanthaburi Seafoods Co., Ltd. 14<br />

Charoen Pokphand Foods Public Co., Ltd.<br />

Crystal Frozen Foods Co., Ltd.<br />

Good Fortune Cold Storage Co., Ltd.<br />

Good Luck Product Co., Ltd. 38<br />

Grobest Frozen Foods Co., Ltd.<br />

Inter Pacific Marine Products Co., Ltd. 38<br />

Kingfisher Holdings Ltd.<br />

Kitchens of the Oceans (Thailand) Ltd.<br />

Kongphop Frozen Foods Co., Ltd.<br />

Marine Gold Products, Ltd. 15<br />

<strong>May</strong> Ao Foods Co., Ltd. 2<br />

Narong Seafood Co., Ltd. 38<br />

Okeanos Co. Ltd. 9<br />

Okeanos Food Co., Ltd.<br />

Ongkorn Cold Storage Co., Ltd.<br />

Phatthana Frozen Food Co., Ltd.<br />

Phatthana Seafood Co., Ltd.<br />

Sea Wealth Frozen Food Co., Ltd.<br />

Seafresh Industry Public Co., Ltd. 1<br />

The Siam Union Frozen Foods Co., Ltd.<br />

Tey Seng Cold Storage Co., Ltd.<br />

Thai I-Mei Frozen Foods Co., Ltd. 2<br />

Thai Royal Frozen Food Co., Ltd. 25<br />

Thai Union Frozen Products Public Co., Ltd. 33<br />

Thai Union Seafood Co., Ltd.<br />

Thailand Fisheries Cold Storage Public Co., Ltd.<br />

The Union Frozen Products Co., Ltd. 4<br />

Xian-Ning Seafood Co., Ltd.<br />

VIETNAM<br />

BAP-Certified Plants Species AffiliatedFarms<br />

Amanda Foods 1<br />

Cadovimex – Nam Long Seafood Export<br />

Processing Factory (Dragon Vietnam)<br />

Camau Frozen (Camimex)<br />

Grobest and I-Mei Industrial Co., Ltd.<br />

Investment Commerce Fisheries Corp.<br />

Minh Phu Seafood Corp. 1<br />

Nhatrang Seaproducts Co. 1<br />

Phuong Nam Seafood Factory 1<br />

Saota Foods Joint Stock Co.<br />

Growing Best <strong>Aquaculture</strong> Practices Program<br />

Captures Retailer Attention, Support<br />

Best <strong>Aquaculture</strong> Practices certification continues to drive<br />

industry improvements via high standards that deliver significant<br />

benefits through responsible facility management. Hundreds<br />

of aquaculture facilities certified to the BAP standards<br />

in Asia, Latin America and other parts of the world are positively<br />

addressing biodiversity protection, effluent limits,<br />

worker safety, controls on chemical use and many other issues.<br />

They are truly making a difference.<br />

See the “Best <strong>Aquaculture</strong> Practices At Work” listings of<br />

certified processing plants to left and above. These, as well as<br />

BAP-certified tilapia, shrimp and channel catfish farms, are<br />

also listed online.<br />

The Best <strong>Aquaculture</strong> Practices program is also making<br />

Ahold USA<br />

Asda<br />

Busch Gardens<br />

Channel Processing Co. Inc.<br />

COOP<br />

Cumbrian Seafoods Ltd.<br />

Darden Restaurants<br />

Disney<br />

Eastern Fish Co.<br />

Empress International, Ltd.<br />

Expack Seafood, Inc.<br />

Export Packers Company Ltd.<br />

Foodvest<br />

Gorton’s Seafood<br />

Great American Seafood Imports Co.<br />

H & N Foods International<br />

Hai Yang International, Inc.<br />

HighLiner Foods USA Inc.<br />

International Marketing Specialists, Inc.<br />

Lyons Seafoods, Ltd.<br />

Maloney Seafood Corp.<br />

Mazzetta Company, LLC<br />

Meridian Products<br />

Morrisons<br />

National Fish & Seafood Inc.<br />

Odyssey Enterprises, Inc.<br />

OFI Markesa International<br />

Ore-Cal Corp.<br />

Orion Seafood International, Inc.<br />

Pacific Supreme Co.<br />

further inroads into the global<br />

seafood marketplace. BAP certification<br />

has been adopted by<br />

major companies at both the<br />

®<br />

wholesale and retail levels. Walmart<br />

Stores, Darden Restaurants<br />

and Lyons Seafoods, for example, have specified Best<br />

<strong>Aquaculture</strong> Practices certification for their shrimp suppliers.<br />

Additional companies in the United States, Canada and<br />

other countries support BAP in various ways. These BAP<br />

market endorsers source their seafood from processing plants<br />

that have been certified to BAP standards.<br />

PanaPesca USA Corp.<br />

Quirch Foods<br />

Rubicon Resources<br />

Sam’s Club<br />

SeaPak Shrimp Co.<br />

Sea Port Products Corp.<br />

Slade Gorton & Co. Inc.<br />

Sobeys<br />

Sodexo<br />

Tampa Bay Fisheries<br />

Target<br />

Topco Associates, LLC<br />

U.S. Foodservice<br />

Walmart<br />

Walmart Canada<br />

12 <strong>May</strong>/<strong>June</strong> <strong>2010</strong> global aquaculture advocate global aquaculture advocate <strong>May</strong>/<strong>June</strong> <strong>2010</strong> 13<br />

Seaprodex Minh Hai<br />

Stapimex Joint Stock Co. – Tan Long-Phat Dat 1<br />

Tac Cau Shrimp Processing Plant –<br />

BIM Seafood Joint Stock Co.<br />

Truc An Co., Ltd.<br />

Vietnam Fish One Co., Ltd.<br />

EUROPE<br />

BAP-Certified Plants Species Affiliated Farms<br />

Italy<br />

Friulittica, Societa Cooperativa Agricola*<br />

United Kingdom<br />

Cumbrian Seafoods Ltd. Seaham*<br />

Lyons Seafoods Ltd.*<br />

* Reprocessing Plant<br />

1<br />

WESTERN HEMISPHERE<br />

BAP-Certified Plants Species Affiliated Farms<br />

Ecuador<br />

Aquamar, S.A. 1<br />

Negocios Industriales Real, S.A.<br />

Omarsa S.A. 2<br />

Produmar, S.A. 1<br />

Promarisco, S.A. 2<br />

El Salvador<br />

Aquacorporacion de El Salvador, S.A. de C.V. 1<br />

Guatemala<br />

Novaguatemala, S.A.<br />

Honduras<br />

Empacadora Deli, S.A. 3<br />

Nicaragua<br />

Camarones de Nicaragua, S.A. 6<br />

United States<br />

Beaver Street Fisheries, Inc.*<br />

Consolidated Catfish Producers, LLC 2<br />

Consolidated Catfish Producers, LLC*<br />

Harvest Select Catfish 3<br />

High Liner Foods (USA) Inc.*<br />

King and Prince Seafood Corp.*<br />

SouthFresh Catfish Processors of Alabama<br />

Tampa Bay Fisheries, Inc.*<br />

*Reprocessing Plant<br />

BAP Market Endorsers

Nandeesha Joins BAP Standards Oversight Committee<br />

Dr. Mudnakudu Nandeesha<br />

has recently joined the<br />

Best <strong>Aquaculture</strong> Practices<br />

Standards Oversight Committee.<br />

He replaces Dr.<br />

Claude Boyd, who will continue<br />

to assist the BAP<br />

techincal committees.<br />

Nandeesha currently serves<br />

as an advisor to the Centre for<br />

<strong>Aquaculture</strong> Research and<br />

Development being established<br />

Dr. Mudnakudu Nandee- under the St. Xavier’s Bishramsha<br />

has more than 25 years ganj in Tripura, India. He has<br />

experience in teaching and more than 25 years of experi-<br />

research on aquaculture. ence in teaching and researching<br />

aquaculture in India, Cambodia<br />

and Bangladesh.<br />

He is a former professor of aquaculture at the College of<br />

Fisheries under the Central Agricultural University in Tripura<br />

and worked for a decade in the Department of <strong>Aquaculture</strong> at<br />

Acknowledging his ongoing<br />

work to advance the Best<br />

<strong>Aquaculture</strong> Practices (BAP)<br />

certification program,<br />

IntraFish Media named<br />

<strong>Global</strong> <strong>Aquaculture</strong> <strong>Alliance</strong><br />

President George Chamberlain<br />

one of six nominees for<br />

<strong>2010</strong> Person of the Year.<br />

“Chamberlain has made<br />

the right moves to put GAA<br />

George Chamberlain: and its BAP ecocertification<br />

“Mr. <strong>Aquaculture</strong>”<br />

into the forefront of the aquaculture<br />

sustainability arena,”<br />

IntraFish said.<br />

After a strong 2009, IntraFish said, GAA “solidified its spot at the<br />

top of the aquaculture ecocertification world, moving forward in both<br />

the expansion of certification standards and the development of an<br />

infrastructure within GAA to further grow its ecolabeling program.”<br />

Hundreds of aquaculture facilities in Asia, Central America,<br />

Europe and the United States are certified to GAA’s Best <strong>Aquaculture</strong><br />

Practices standards. Adding to the current standards for<br />

processing plants and tilapia, channel catfish and shrimp farms,<br />

BAP certification will extend to feed mills and Pangasius farms<br />

later this year.<br />

GAA Vice President of Development Peter Redmond has<br />

successfully carried the BAP message to top retailers. Dozens of<br />

major grocers, retailers and foodservice companies around the<br />

world have joined Walmart Stores in support of BAP certification.<br />

IntraFish called Chamberlain “Mr. <strong>Aquaculture</strong>.” He has served<br />

as GAA president since the organization’s founding over a decade<br />

ago. Chamberlain said his nomination symbolizes the strides the<br />

organization has made in advocating responsible aquaculture.<br />

The IntraFish Person of the Year award goes to a seafood<br />

industry leader who clearly influences the direction of the global<br />

the University of Agricultural Sciences in Kartaka, India.<br />

Nandeesha also spent nearly a decade on grass-roots aquaculture<br />

projects supported by Oxfam International, the Food and Agriculture<br />

Organization of the United Nations, World Bank and<br />

Network of <strong>Aquaculture</strong> Centres in Asia-Pacific.<br />

Nandeesha has a doctorate degree in aquaculture nutrition.<br />

Through the publication of two books and over 100 papers and<br />

articles, he had contributed to the fields of fish nutrition, fish<br />

reproduction, developing aquaculture technologies for small<br />

farmers, gender issues in aquaculture and fisheries education.<br />

He served on the World <strong>Aquaculture</strong> Society board of directors<br />

from 2006 to 2009. He is also a co-chairman of <strong>Aquaculture</strong><br />

without Frontiers.<br />

Nandeesha has been recognized through a number of awards,<br />

including the Sahameitrei Award from the government of Cambodia<br />

for his contributions to the aquaculture and human<br />

resource development of that country. He also received the Professor<br />

H. P. C. Shetty and Gold Medal Awards from the Asian<br />

Fisheries Society. The International Research Foundation, Sweden,<br />

presented Nandeesha the Jubilee Award in 2002 for his<br />

efforts in the field of fish nutrition.<br />

Chamberlain Nominated For IntraFish Person Of Year<br />

industry. The recipient of the award is decided by the votes of<br />

IntraFish readers. The winner was to be announced at the European<br />

Seafood Exposition in Brussels, Belgium, in late April.<br />

Advocate Goes Green(er)<br />

The <strong>Global</strong> <strong>Aquaculture</strong> Advocate is getting greener. After<br />

reducing the number of annual print issues while maintaining<br />

six issues via digital delivery, GAA’s bimonthly magazine is<br />

making further changes to lessen its environmental impacts.<br />

Beginning with this <strong>May</strong>/<strong>June</strong> issue, the Advocate will be<br />

printed on paper stock with at least 10% post-consumer<br />

recycled content. The masthead will also bear the logo of the<br />

Sustainable Forestry Initiative (SFI) chain-of-custody certification<br />

system for responsible forestry practices.<br />

GAA’s publication printing partner – St. Louis, Missouri,<br />

USA-based Mulligan Printing – is handling the transition<br />

to the greener Advocate.<br />

After working with GAA in the move to fewer printed<br />

issues, Mulligan proposed the current changes as additional<br />

ways to decrease the magazine’s overall footprint. Mulligan<br />

Printing also participates in AmerenUE’s PurePower clean<br />

air program utilizing renewable energy.<br />

“This is definitely a case where less is more,” GAA<br />

Assistant Director Sally Krueger said. “We appreciate the<br />

input we receive from Mulligan and will consider further<br />

changes in the future.”<br />

The non-profit Sustainable Forestry Initiative maintains<br />

the largest single forest standard in the world. SFI addresses<br />

such issues as worker health and safety, fair labor practices,<br />

civil rights, anti-discrimination and fair wages. Although the<br />

SFI program certifies lands only in the United States and<br />

Canada, program participants must show that paper fiber<br />

they buy offshore is from responsible and legal sources.<br />

BAP Standards Oversight Committee Approves Feed Standards,<br />

Considers IOMs For Small Farms<br />

Wally Stevens said market demand is driving an increase<br />

in farm certifications.<br />

Continued progress in standards development and market<br />

reach was reported at the Best <strong>Aquaculture</strong> Practices (BAP)<br />

Standards Oversight Committee (SOC) meeting held March 14<br />

in Boston, Massachusetts, USA.<br />

In his introduction, GAA Executive Director Stevens summarized<br />

the overall progress of the BAP program. He referred to<br />

large posters and said market demand for “two-star” product<br />

from BAP-certified farms and processing plants is driving an<br />

increase in farm certification, particularly at tilapia facilities.<br />

Additional processors are becoming engaged in anticipation of<br />

the BAP salmon farm standards.<br />

Stevens also described the proposed new organizational<br />

structure that would integrate the <strong>Aquaculture</strong> Certification<br />

Council (ACC) with GAA to manage the BAP certification<br />

process using ISO-accredited inspection bodies to conduct facility<br />

audits. Under the plan, the SOC would become part of the<br />

Responsible <strong>Aquaculture</strong> Foundation, a new body with charitable<br />

status. Within the foundation, Jeffrey Peterson would direct<br />

BAP’s education and training program.<br />

Integrated Operating Modules<br />

ACC President Jim Heerin joined Vice President Bill More<br />

and Peterson in providing an update on the Integrated Operating<br />

Module (IOM) program for multiple small shrimp farms.<br />

In IOMs, a number of farms with similar production methods<br />

and combined total annual production not exceeding 4,000<br />

mt can be grouped together. All undergo full inspections and<br />

participate in traceability, but modified administrative arrangements<br />

allow the farms to save on certification costs. Each IOM<br />

must have a written quality management system defining how<br />

the group is managed to meet BAP standards criteria.<br />

Feed Standards<br />

The BAP feed mill standards were approved for release<br />

pending final changes and review. Requested changes included a<br />

requirement that sources for all fishmeal and fish oil be certified<br />

to the International Fishmeal and Fish Oil Organisation (IFFO)<br />

<strong>Global</strong> Standard for Responsible Supply or Marine Stewardship<br />

Council program within three years. Until that time, feed mills<br />

are required to develop a plan for transition to sustainable fishmeal<br />

sources.<br />

Tilapia, Salmon Standards<br />

Review of the BAP standards for tilapia farms saw a request<br />

to begin collecting fuel and energy use data so figures for direct<br />

energy use can be calculated. The SOC recommended the establishment<br />

of a minimum mean annual survival rate as an indicator<br />