How Are Pirns Wound? - Trim Engineering Services

Pirns perform the same task in weaving, as bobbins perform in stitching and embroidery. Yet, they are so different from bobbins. Not only is the shape and size different, but the way they are wound is also different. Read more @ https://goo.gl/bXNoYb

Pirns perform the same task in weaving, as bobbins perform in stitching and embroidery. Yet, they are so different from bobbins. Not only is the shape and size different, but the way they are wound is also different.

Read more @ https://goo.gl/bXNoYb

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

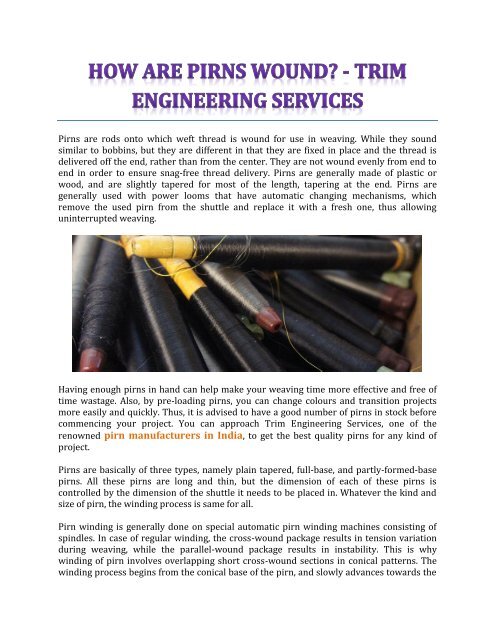

<strong>Pirns</strong> are rods onto which weft thread is wound for use in weaving. While they sound<br />

similar to bobbins, but they are different in that they are fixed in place and the thread is<br />

delivered off the end, rather than from the center. They are not wound evenly from end to<br />

end in order to ensure snag-free thread delivery. <strong>Pirns</strong> are generally made of plastic or<br />

wood, and are slightly tapered for most of the length, tapering at the end. <strong>Pirns</strong> are<br />

generally used with power looms that have automatic changing mechanisms, which<br />

remove the used pirn from the shuttle and replace it with a fresh one, thus allowing<br />

uninterrupted weaving.<br />

Having enough pirns in hand can help make your weaving time more effective and free of<br />

time wastage. Also, by pre-loading pirns, you can change colours and transition projects<br />

more easily and quickly. Thus, it is advised to have a good number of pirns in stock before<br />

commencing your project. You can approach <strong>Trim</strong> <strong>Engineering</strong> <strong>Services</strong>, one of the<br />

renowned pirn manufacturers in India, to get the best quality pirns for any kind of<br />

project.<br />

<strong>Pirns</strong> are basically of three types, namely plain tapered, full-base, and partly-formed-base<br />

pirns. All these pirns are long and thin, but the dimension of each of these pirns is<br />

controlled by the dimension of the shuttle it needs to be placed in. Whatever the kind and<br />

size of pirn, the winding process is same for all.<br />

Pirn winding is generally done on special automatic pirn winding machines consisting of<br />

spindles. In case of regular winding, the cross-wound package results in tension variation<br />

during weaving, while the parallel-wound package results in instability. This is why<br />

winding of pirn involves overlapping short cross-wound sections in conical patterns. The<br />

winding process begins from the conical base of the pirn, and slowly advances towards the

tip. Instead of travelling back and forth along the package, the yarn that is transferred from<br />

the larger package to the smaller pirn is wound on one part of the package at a time. This<br />

mechanism maintains uniform tension of the thread on the pirn and reduces ballooning<br />

effects that are seen in bobbins, which reduces the possibility of slough-off. This winding<br />

mechanism also cleans the pirns from any kinds of slubs or other faults during weaving<br />

itself, which is why no additional yarn cleaning operation is required while winding pirns.<br />

When a pirn is filled, the machine automatically removes it from the spindle and replaces it<br />

with an empty pirn to be filled again, thus allowing uninterrupted weaving. All kinds of silk,<br />

cotton, woolen, synthetic fiber, and terrycot yarns can be wound in this way. When a ready<br />

pirn is used to weave, it is put into a shuttle that travels back and forth across the width of<br />

the shuttle loom. This movement unwinds the yarn from the pirn through the eye or slot of<br />

the shuttle.<br />

This is how simple the winding and weaving mechanism of a pirn is. But, isn’t it interesting<br />

to know how pirns and bobbins are so different from each other, while they perform the<br />

same task!<br />

For more information, visit: http://www.trimengineering.in/