Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

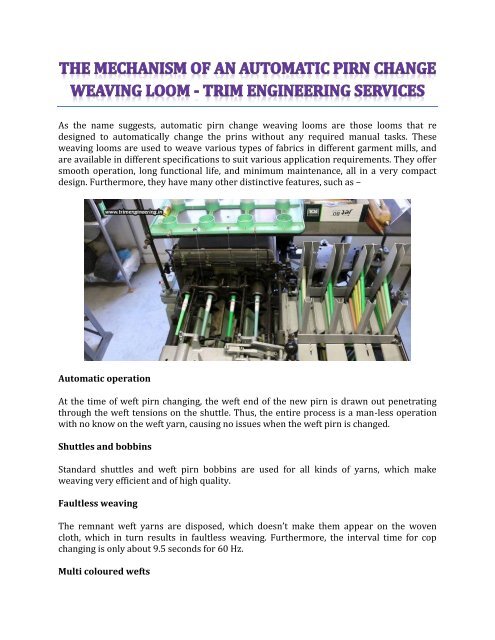

As the name suggests, automatic pirn change weaving looms are those looms that re<br />

designed to automatically change the prins without any required manual tasks. <strong>The</strong>se<br />

weaving looms are used to weave various types of fabrics in different garment mills, and<br />

are available in different specifications to suit various application requirements. <strong>The</strong>y offer<br />

smooth operation, long functional life, and minimum maintenance, all in a very compact<br />

design. Furthermore, they have many other distinctive features, such as –<br />

<strong>Automatic</strong> operation<br />

At the time of weft pirn changing, the weft end of the new pirn is drawn out penetrating<br />

through the weft tensions on the shuttle. Thus, the entire process is a man-less operation<br />

with no know on the weft yarn, causing no issues when the weft pirn is changed.<br />

Shuttles and bobbins<br />

Standard shuttles and weft pirn bobbins are used for all kinds of yarns, which make<br />

weaving very efficient and of high quality.<br />

Faultless weaving<br />

<strong>The</strong> remnant weft yarns are disposed, which doesn’t make them appear on the woven<br />

cloth, which in turn results in faultless weaving. Furthermore, the interval time for cop<br />

changing is only about 9.5 seconds for 60 Hz.<br />

Multi coloured wefts

Certain looms have 1×1, 2×1, and 4×1 shuttle boxes, which enables multicoloured weft<br />

yarns to be woven easily.<br />

Micro-computer control cam mechanism<br />

<strong>The</strong> cam control mechanism in the weaving loom enables effective automation, and is also<br />

easy to operate and maintain.<br />

<strong>The</strong> mechanism of these looms<br />

In an automatic pirn change weaving loom, the yarn extending from the cloth to the shuttle<br />

is cut near the shuttle, and the runout pirn is removed from the shuttle, thus unthreading<br />

the shuttle eye. <strong>The</strong>n, the new pirn is inserted into the shuttle with the end of the yarn held<br />

in a clamp. When the shuttle makes a first stroke with the pirn, the weft yarn is<br />

automatically drawn into the shuttle eye. <strong>The</strong>n, the old and new ends of the yarn are cut off<br />

by selvedge cutters located adjacent to the cloth.<br />

A transfer head is preferably provided for extracting the almost runout pirn from the<br />

shuttle and inserting the full pirn. This transfer head is adapted to move between two<br />

angularly space apart fixed positions, with one positioned for gripping a pirn in the shuttle,<br />

and the second positioned to be stationary beneath the transfer head.<br />

<strong>The</strong> joint comprises of a knotter that is adapted to receive at least a portion of the wire<br />

extending from the almost runout pirn to the shuttle eye, where the pirn is moved by the<br />

transfer head. It is also designed to receive a portion of the wire extending from a full pirn,<br />

when this pirn is moved by the transfer head. <strong>The</strong> stripper draws off the remaining wire<br />

from the runout pirn when the latter has been extracted from the shuttle and placed in the<br />

second position.<br />

To get the best quality pirns for using for fabric weaving, you can approach Trim<br />

Engineering Services, the leading pirn manufacturers in India, who not only supply their<br />

products to India, but also to countries like France, Italy, Spain, Germany, America, Brazil,<br />

Romania, Sri Lanka, Thailand, Malaysia, South Africa, Indonesia, Poland, and Israel; thus<br />

bringing them a global presence.<br />

Stay social with us on: Facebook, Twitter, Google+, LinkedIn