Swiss Report - Medtech Switzerland

Swiss Report - Medtech Switzerland

Swiss Report - Medtech Switzerland

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Friday, June 10, 2011<br />

SPECIAL REPORT<br />

SWITZERLAND COUNTRY<br />

REPORT<br />

INSIDE: 12-PAGE SPONSORED SECTION IN CO-OPERATION WITH DISCOVERY REPORTS<br />

Alpine nation holds the aces<br />

Tennis champ Federer exemplifies<br />

the success of a landlocked country<br />

which punches well above its<br />

weight, writes Ed Peters<br />

Asked to name an<br />

archetypal <strong>Swiss</strong>, most<br />

people would pick tennis<br />

champion Roger Federer,<br />

even though his mother<br />

was born in South Africa. Besides<br />

being at the top of his game,<br />

quadrilingual Federer puts as much<br />

effort into his charity work as he<br />

does on court, and is rich even by<br />

the standards of his homeland.<br />

Estimates vary, but the 29-yearold<br />

is reckoned to be worth at least<br />

US$140 million, having picked up<br />

US$62 million in prize money since<br />

turning professional in 1998.<br />

In fact, 1998 was the 150th<br />

anniversary of the adoption of the<br />

<strong>Swiss</strong> Federal Constitution,<br />

although the country traces its roots<br />

back to the 13th century. In the<br />

intervening years, <strong>Switzerland</strong><br />

has become steadily more<br />

prosperous, keeping itself well<br />

out of European wars – and well out<br />

of the European Union.<br />

Its policies have paid off in<br />

spades. <strong>Switzerland</strong> is one of the<br />

richest countries in the world, with a<br />

nominal per capita gross domestic<br />

product of US$69,838.<br />

Last year, <strong>Switzerland</strong> totted up<br />

the highest wealth per adult of any<br />

country, with US$372,692 for each<br />

man and woman over 18. What’s<br />

more, <strong>Switzerland</strong> has one of the<br />

world’s largest account balances as a<br />

percentage of GDP, only lagging<br />

behind a few oil-producing<br />

countries.<br />

Zurich and Geneva have been<br />

rated second and third respectively<br />

as the cities with the highest quality<br />

of life in the world, while last year,<br />

the World Economic Forum ranked<br />

<strong>Switzerland</strong> as the most competitive<br />

country in the world.<br />

And, just to put the icing on the<br />

cake, the European Union rated<br />

<strong>Switzerland</strong> as Europe’s most<br />

innovative country by far. Not a bad<br />

result for a landlocked nation with a<br />

population of just under 8 million.<br />

As an idea of just how well Brand<br />

<strong>Swiss</strong> does in the international<br />

market place, consider some of its<br />

top companies. Glencore is one of<br />

the foremost mining and<br />

commodities operations, Novartis is<br />

more or less synonymous with<br />

pharmaceuticals, Hoffmann-La<br />

Roche and health care go hand-inhand,<br />

power and automation<br />

technology are the mainstays of<br />

ABB, and Adecco, a human<br />

resources outfit, employs nearly<br />

750,000 professionals.<br />

Adding to this mix are financial<br />

giants UBS, Zurich Financial<br />

Services, Credit Suisse, Clariden Leu,<br />

Credit Agricole and <strong>Swiss</strong> Re. And<br />

where would the world be without<br />

fashionable timepieces produced by<br />

The Swatch Group? Needless to say,<br />

hundreds of similar, if smaller, <strong>Swiss</strong><br />

corporations are performing very<br />

creditably.<br />

If <strong>Switzerland</strong> shines on the<br />

commercial front, it must be in part<br />

due to its excellent education<br />

system. The oldest of its dozen<br />

universities was founded in 1460 in<br />

Basel with a faculty of medicine,<br />

which still maintains a strong<br />

tradition of chemical and medical<br />

research.<br />

The biggest tertiary institution is<br />

the University of Zurich with almost<br />

25,000 students. In business and<br />

management studies, the University<br />

of St Gallen and the International<br />

Institute for Management<br />

Development are the recognised<br />

leaders.<br />

Students flock to <strong>Switzerland</strong>’s<br />

tertiary institutions from around the<br />

world, especially the hotel school in<br />

Lausanne, which has laid the<br />

foundations for many a Hong Kong<br />

hotelier’s career.<br />

Over the years, many Nobel<br />

prizes have been awarded to <strong>Swiss</strong><br />

scientists. The foremost was<br />

physicist Albert Einstein, who<br />

developed his Theory of Relativity<br />

while working in Bern. More<br />

recently, Vladimir Prelog, Heinrich<br />

Rohrer, Richard Ernst, Edmond<br />

Fischer, Rolf Zinkernagel and Kurt<br />

Wuthrich have all been honoured.<br />

Geneva and the nearby French<br />

department of Ain jointly host the<br />

world’s largest laboratory, CERN,<br />

which is dedicated to particle<br />

physics research. The laboratory has<br />

made headlines, thanks to its work<br />

with the Large Hadron Collider, and<br />

it was also the birthplace of the<br />

World Wide Web.<br />

Growing Asian affluence<br />

attracts private banks<br />

......................................................<br />

Chris Davis<br />

Hong Kong’s position as a hub for<br />

the private banking sector continues<br />

to attract <strong>Swiss</strong> institutions, as<br />

wealth grows across the region. By<br />

2013, according to the most recent<br />

Merrill Lynch Capgemini World<br />

Wealth <strong>Report</strong>, the Asia-Pacific is set<br />

to overtake the United States, which<br />

is the world’s leader with about<br />

US$13.5 trillion held by the rich.<br />

Kenneth Toong, Clariden Leu<br />

Asia chairman, says Hong Kong<br />

plays a strategic role in the bank’s<br />

Asia operation.<br />

“Asia has been identified as one<br />

of the key markets for future growth<br />

and expanding our footprint here<br />

will be a priority,” Toong says. “We<br />

strengthened our capabilities in<br />

China with four key appointments.<br />

These appointments are a clear<br />

indication of our commitment to<br />

Asia and the tremendous<br />

opportunities we see.”<br />

Clariden Leu has more than 160<br />

employees in the region, a tenfold<br />

increase since coming to Asia 25<br />

years ago. When hiring relationship<br />

managers, Toong says Clariden Leu<br />

looks for at least 10-15 years of local,<br />

market-specific experience. “Onthe-ground<br />

expertise is important,<br />

as advice will never be taken as<br />

seriously as when you have the<br />

relevant, local experts,” he says.<br />

He says wealthy clients look for<br />

solidarity and safety. “With a 24.6<br />

per cent tier-one capital ratio and a<br />

cost/income ratio of 67 per cent,<br />

Clariden Leu is also one of the best<br />

capitalised financial institutions in<br />

the world,” Toong says.<br />

As the number of high-net-worth<br />

individuals in Asia expands, Toong<br />

says Clariden Leu places an<br />

emphasis on delivering premium<br />

wealth-management solutions that<br />

meet its clients’ needs. “Our<br />

approach is centred on providing<br />

premium service including<br />

discretion, preservation of tradition,<br />

Our experts<br />

based in Hong<br />

Kong offer<br />

tailor-made<br />

products<br />

and services<br />

GEORGES ZECCHIN, CEO, CREDIT AGRICOLE<br />

SUISSE PRIVATE BANKING IN ASIA<br />

confidentiality and deep industry<br />

knowledge,” he says. “Careful<br />

analysis is used to assess each<br />

client’s risk profile.”<br />

He says clients’ needs are met<br />

through innovation and ensuring<br />

core values are never compromised.<br />

Innovation includes state-of-the-art<br />

investment solutions, using an open<br />

architecture product platform and<br />

delivering tailor-made wealthmanagement<br />

solutions.<br />

Clariden Leu has developed<br />

solutions to protect and enhance<br />

hereditary wealth transfer, with<br />

customisation a key strength, Toong<br />

says. “Our relationship managers<br />

have access to products from a<br />

range of providers,” he says. “With<br />

the ability to leverage on the Credit<br />

Suisse platform along with other<br />

third-party providers, we can offer<br />

an attractive proposition.”<br />

Asia is also seen as a rich seam to<br />

be tapped by Credit Agricole Private<br />

Banking, which has received its full<br />

banking licence from the Hong<br />

Kong Monetary Authority. Georges<br />

Zecchin, CEO of Credit Agricole<br />

Suisse Private Banking in Asia, says<br />

clients have access to services<br />

including transactions in yuan.<br />

“Receiving the full banking licence<br />

demonstrates our commitment<br />

towards strengthening our local<br />

presence and our determination<br />

to enhance our products and<br />

services offering for our clients,”<br />

Zecchin says.<br />

He says Hong Kong is one of the<br />

key wealth-management locations<br />

offered to clients. “Our experts<br />

based in Hong Kong offer tailormade<br />

products and services. Either<br />

locally or through our head office,<br />

these services include managing<br />

assets and estate planning,<br />

investment into financial markets,<br />

and alternatives such as physical<br />

gold and real estate,” Zecchin says.<br />

“The internationalisation of the<br />

yuan opens opportunities for our<br />

clients to diversify their assets and<br />

participate in the growth of the<br />

region,” he says. “Both our local and<br />

international clients are increasingly<br />

interested in opening accounts in<br />

Hong Kong, as we are able to offer a<br />

full array of wealth-management<br />

solutions locally. All these quality<br />

services are only possible thanks to<br />

our fully integrated, state-of-the-art<br />

in-house banking logistics centre<br />

located in <strong>Switzerland</strong>.”<br />

Zecchin says clients see value in<br />

straightforward and transparent<br />

products – and this is a key strategy<br />

for the bank. “We are proud of the<br />

way our strict product and service<br />

selection process is designed to<br />

protect our clients, and prevented<br />

exposure to financial harm and toxic<br />

assets during the financial crises.<br />

“Our strict due-diligence and<br />

constant monitoring policies ensure<br />

liquidity and balance risk exposure<br />

with rewards for assets of our<br />

clients,” Zecchin says.<br />

The Paul Scherrer Institute was<br />

responsible for such notable<br />

inventions as lysergic acid<br />

diethylamide, the scanning<br />

tunnelling microscope and the<br />

virtually indispensable Velcro.<br />

Other <strong>Swiss</strong> technologies<br />

enabled the exploration of new<br />

worlds. The pressurised balloon of<br />

Auguste Piccard is the best example,<br />

while the bathyscaphe allowed<br />

Jacques Piccard to reach the deepest<br />

point of the world’s oceans in the<br />

1950s.<br />

Apart from Federer, there’s<br />

another <strong>Swiss</strong> who may not be as<br />

well known but who deserves to be<br />

equally popular. Daniel Peter started<br />

out making candles in the town of<br />

Vevey in the 19th century, but he<br />

found himself out of work due to the<br />

growing popularity of oil lamps. He<br />

decided to switch to the<br />

confectionary business and came up<br />

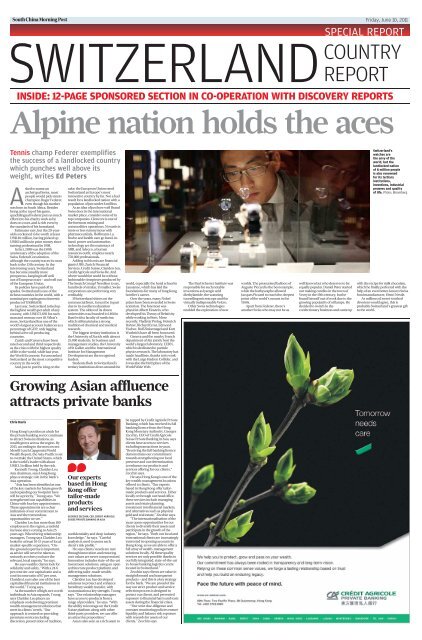

<strong>Switzerland</strong>’s<br />

watches are<br />

the envy of the<br />

world, but the<br />

landlocked nation<br />

of 8 million people<br />

is also renowned<br />

for its tertiary<br />

institutions,<br />

inventions, industrial<br />

prowess and quality<br />

of life. Photo: Bloomberg<br />

with the recipe for milk chocolate,<br />

which he finally perfected with the<br />

help of an even better-known <strong>Swiss</strong><br />

food manufacturer, Henri Nestle.<br />

As millions of sweet-toothed<br />

devotees would agree, this is<br />

probably <strong>Switzerland</strong>’s greatest gift<br />

to the world.

S2 Friday, June 10, 2011<br />

SPECIAL REPORT: SWITZERLAND COUNTRY REPORT<br />

East-West partnerships key to<br />

railway development in Asia<br />

Rail transport is essential to sustainable<br />

development in Asia, and Selectron<br />

Systems believes continuing East-West<br />

collaboration is crucial to success.<br />

“Without understanding Asia, no<br />

company can survive 10 years from now,”<br />

says Emmanuel Hannart, president and<br />

CEO of Selectron. “We look at the world<br />

as a village and we can be stronger as<br />

partners working together, than being<br />

only Western or only Chinese.”<br />

Selectron, a leading provider of<br />

automation control and monitoring<br />

solutions for trains, is a recognised name<br />

in Europe with a Safety Integrated Level 2<br />

certification from German railway<br />

authorities. The company designs the<br />

core information system of machines that<br />

makes train systems more reliable,<br />

efficient and safe for passenger service.<br />

It invests 25 per cent of its annual<br />

turnover in research and development to<br />

deliver this level of precision engineering.<br />

The world’s top three train builders<br />

and specialists are among its customers;<br />

<strong>Switzerland</strong>’s Stadler Rail, Germany’s<br />

Emmanuel Hannart,<br />

president and CEO<br />

Vossloh and Austria’s Plasser & Theurer.<br />

Mainland clients include CNR Changchun<br />

Railway Vehicles and CSR Nanjing<br />

Puzhen Rolling Stock. Selectron has<br />

worked with them on major global<br />

projects including the Beijing Airport<br />

Express and Shenzhen Metro.<br />

Selectron opened an office in Beijing<br />

in 2005 to handle sales, after-sales and<br />

training on software engineering<br />

services. Hannart is keen on introducing<br />

better safety features on the mainland’s<br />

railway systems. He is particularly<br />

interested in applying Selectron’s wheelslide<br />

protection technology on the<br />

mainland’s vast rolling stock.<br />

“We have a solution that enables ABS<br />

(automatic block signal) functionality in<br />

the braking system without changing the<br />

hardware or the mechanical brakes,”<br />

Hannart says.<br />

Hannart is confident that a strategic<br />

alliance with an established local player<br />

will lead to cost-effective retrofits on the<br />

mainland. With strong collaboration, the<br />

joint venture can develop more<br />

applications for the mainland’s railway<br />

industry. The company is in talks with<br />

Hong Kong players and is also keen on<br />

forging local partnerships elsewhere in<br />

Southeast Asia.<br />

Basel is strategically located in<br />

<strong>Switzerland</strong>, at the centre of Europe<br />

near the border of southern Germany<br />

and eastern France. The city serves as<br />

an ideal gateway to <strong>Switzerland</strong>,<br />

France and Germany, providing access<br />

to their highways and ensuring ease of<br />

travel to neighbouring countries.<br />

Air Service Basel is a fixed-base<br />

operator (FBO) that offers the<br />

advantages of this strategic position<br />

and provides a full range of services in<br />

Basel airport for aircraft parking,<br />

service and maintenance. It has three<br />

hangars and plans to add a fourth one<br />

next year.<br />

Aside from the usual handling and<br />

catering support, clients’ aircraft and<br />

personal needs are individually<br />

serviced by Air Service Basel as a onestop<br />

shop.<br />

“Our motto is ‘all services under<br />

one roof’. We maintain and manage the<br />

whole aircraft based on client’s<br />

preferences. We even hire crews and<br />

technically and financially manage the<br />

aircraft,” says Air Service Basel CEO<br />

Claudio Lasagni.<br />

Personal service is a top priority for<br />

Air Service Basel. “We try in every<br />

Sponsored section in co-operation with Discovery <strong>Report</strong>s<br />

Zenith: The house that time built<br />

Jean-Frédéric<br />

Dufour,<br />

CEO of Zenith<br />

......................................................<br />

<strong>Report</strong>s by Ea Wederwang,<br />

Jacinta Plucinski and Cassie Lim<br />

Nothing comes close to the<br />

quality and precision of<br />

<strong>Swiss</strong>-made timepieces.<br />

From design to clockwork,<br />

the craftsmanship of <strong>Swiss</strong><br />

watches is a legacy that has been<br />

passed from one generation to the next.<br />

Continuing this tradition of excellence,<br />

Georges Favre-Jacot – the man behind<br />

one of <strong>Switzerland</strong>’s finest watches –<br />

has built an empire to realise his vision<br />

of creating the most accurate and<br />

reliable watches of his era, Zenith.<br />

Favre-Jacot set up shop in Le Locle<br />

in 1865. From the onset of the industrial<br />

revolution until today, Zenith has been<br />

an important contributor in<br />

revolutionising and defining the watch<br />

industry.<br />

Zenith produced its first pocket<br />

chronograph in 1899 – making the<br />

company a pioneer in mechanical<br />

chronography. A Zenith chronograph is<br />

an important timepiece representing<br />

the unwavering dedication to quality<br />

characteristic of the <strong>Swiss</strong>.<br />

The company introduced<br />

innovations such as the world’s most<br />

accurate series-produced movement,<br />

the El Primero, in 1969. While most<br />

precision chronographs beat at eight<br />

vibrations per second, the El Primero<br />

calibre beats at 10 vibrations per<br />

second. The El Primero is the first highfrequency<br />

self-winding chronograph<br />

for the most precise movement ever<br />

produced.<br />

Zenith’s precision watches are<br />

instrumental in marking milestone<br />

achievements. Two Zenith precision<br />

instruments were on board the Blériot<br />

XI when Louis Blériot crossed the<br />

English Channel in 37 minutes in 1909.<br />

More than a century later, Alain<br />

Thébault surpassed Blériot’s feat and<br />

crossed the English Channel three<br />

minutes faster. Commemorating this<br />

accomplishment, Zenith appointed<br />

Thébault the new Zenith brand<br />

ambassador and crafted the limited<br />

edition El Primero Stratos Thébault<br />

watch.<br />

Zenith continues to be part of<br />

history as its special edition El Primero<br />

Stratos joins Johan Ernst Nilson on his<br />

2011 Pole2Pole journey – a North to<br />

South Pole expedition commemorating<br />

the 100th anniversary of Roald<br />

Amundsen’s voyage, where a Zenith<br />

pocket watch was also used.<br />

Zenith makes only 35,000 watches<br />

annually. Respecting the tradition of its<br />

watchmakers, it takes nine painstaking<br />

months for Zenith to produce a watch.<br />

“Our watches stand for exclusivity,<br />

beauty and precision,” says Jean-<br />

Frédéric Dufour, Zenith CEO. “We<br />

produce a beautiful watch not by<br />

focusing solely on appearance but on<br />

details and traditional craftsmanship. A<br />

beautiful watch is a sum of 2,500<br />

operations.”<br />

Zenith produces movement today<br />

the way it did 150 years ago. This is why<br />

Air Service Basel provides clients<br />

with all services under one roof<br />

Claudio Lasagni, CEO<br />

Gautschi boosts aluminium<br />

suppliers’ global plans<br />

With <strong>Swiss</strong> quality and a<br />

90-year legacy as a global<br />

player in the aluminium<br />

industry, Gautschi<br />

Engineering has the<br />

expertise to help the<br />

mainland’s industry players<br />

establish themselves in the<br />

international scene.<br />

Gautschi was involved in<br />

building the world’s most<br />

modern and efficient cast<br />

house for aluminium foil<br />

production in Xiamen.<br />

As a turnkey provider of liquid metal,<br />

casting and heat treatment systems for<br />

aluminium production, Gautschi set its<br />

sights on the mainland 10 years ago. It<br />

opened a unit in Beijing in 2005. With 12<br />

engineers, the Beijing unit enables<br />

Gautschi to provide seamless service on<br />

the mainland and in the rest of Asia.<br />

Gautschi hopes to make its next<br />

impact on the mainland’s transportation<br />

and aerospace industries, leveraging<br />

diverse engineering capabilities at the<br />

<strong>Switzerland</strong> headquarters and research<br />

and development resources available<br />

through its new owner, EED Holding.<br />

“With our Beijing unit and our owner’s<br />

subsidiary in China, which has a sole<br />

focus on fabrication, we have the<br />

Oliver Moos,<br />

managing director<br />

Zenith guarantees service for any<br />

Zenith watch, whether a new model or<br />

the very first one from 1865.<br />

It is important for Zenith to uphold<br />

its age-old watchmaking tradition, but<br />

introducing new technologies to the<br />

craft is crucial as well. Zenith is<br />

exploring the use of new materials<br />

such as silicon or alchron for its<br />

watches.<br />

Zenith’s legendary watchmaking<br />

prowess is recognised not only in<br />

Europe but also globally. The company<br />

started expanding internationally as<br />

early as 1890. It ventured to Japan in<br />

1901 and entered the mainland before<br />

the industrial revolution. As Asians<br />

clamour for more high-end<br />

commodities, Zenith finds the Asian<br />

region an integral market for its growth.<br />

Zenith has a very extensive<br />

presence in Asia. Complementing its<br />

more than 38 points of sale in Hong<br />

Kong, the watchmaker will open a<br />

boutique in the territory next month to<br />

offer customers the same experience<br />

<strong>Swiss</strong> Life Network boosts<br />

Asia presence with partners<br />

Strong partnerships are the backbone of<br />

the <strong>Swiss</strong> Life Network’s Asian<br />

operations. This global association of 58<br />

leading life insurance and pension<br />

providers is strengthening its foothold in<br />

Asia, where its partners in 13 countries<br />

deliver world-class employee benefit<br />

solutions to multinational clients.<br />

The <strong>Swiss</strong> Life Network welcomed<br />

China Life Insurance to the club in<br />

January, in addition to existing partner<br />

Ping An Insurance on the mainland,<br />

Prudential Assurance in Singapore and<br />

Apollo Munich Insurance in India to boost<br />

coverage in Asia.<br />

“The partners we work with are all<br />

leading local insurers and they know their<br />

markets inside out,” says Margrit Schmid,<br />

head of the <strong>Swiss</strong> Life Network and a<br />

senior vice-president and chief market<br />

officer for corporate clients at <strong>Swiss</strong> Life,<br />

the network’s <strong>Switzerland</strong>-based parent.<br />

The <strong>Swiss</strong> Life Group, founded in 1857<br />

in Zurich, is one of Europe’s leading<br />

providers of pension and life insurance<br />

solutions. The <strong>Swiss</strong> Life Network is an<br />

important channel for extending the<br />

group’s services worldwide.<br />

Combining unmatched global<br />

expertise and <strong>Swiss</strong> reliability with its<br />

Asian partners’ extensive local market<br />

knowledge, the <strong>Swiss</strong> Life Network lets<br />

Margrit Schmid, head of <strong>Swiss</strong><br />

Life Network, senior vicepresident<br />

and chief market officer<br />

for corporate clients at <strong>Swiss</strong> Life<br />

clients stay focused on their core<br />

businesses. “We take care of employee<br />

benefit solutions around the world so that<br />

companies don’t have to worry about<br />

complexity or differences in each<br />

country,” Schmid says.<br />

The <strong>Swiss</strong> Life Network delivers a full<br />

range of products and services for<br />

corporate clients, including retirement<br />

pensions, life, accident, disability, medical<br />

and captive solutions. It provides<br />

attractive benefits that help employers<br />

attract and retain the best people.<br />

These tailored solutions, alongside the<br />

<strong>Swiss</strong> Life Network’s partnership<br />

programme, are cementing its<br />

commitment to Asia.<br />

necessary capabilities to<br />

serve customers<br />

worldwide from China,”<br />

says Oliver Moos, Gautschi<br />

managing director.<br />

Aside from the price<br />

advantage gained from<br />

Gautschi’s ties with EED<br />

Holding, clients are also<br />

assured of a stable and<br />

efficient operation as<br />

demonstrated by<br />

Gautschi’s track record as<br />

a systems supplier. The<br />

company has comprehensive knowledge<br />

of upstream and downstream<br />

requirements, possibilities and impacts<br />

across a diverse range of industries.<br />

Gautschi offers distinct advantages to<br />

automotive and aerospace<br />

manufacturers with its long-standing<br />

quality certification in these fields.<br />

“Wherever you go in the aluminium<br />

industry, our name is recognised certainly<br />

for the long history but also because the<br />

equipment we supply is long-lasting,<br />

durable and performs very well,” Moos<br />

says.<br />

Gautschi is exploring product<br />

development opportunities with EED<br />

Holding to foster greater innovation in the<br />

aluminium industry.<br />

as walking into the Zenith Manufacture<br />

complex in Le Locle. It will also add 13<br />

more points of sale in Hong Kong.<br />

Present in more than 19 cities on the<br />

mainland, Zenith plans to expand its<br />

sales network by establishing 50 more<br />

points of sale in the country.<br />

The company also has 35 points of<br />

sale in Taiwan, 65 in Japan and 12 in<br />

Singapore. It is also present in Thailand,<br />

the Philippines, Indonesia and Malaysia.<br />

Zenith showcases classic pieces<br />

from the collections in its Le Locle<br />

museum in various Asian locations to<br />

familiarise the market about the brand.<br />

“When people think of<br />

chronographs, I want them to think of<br />

Zenith,” Dufour says. “We have more<br />

than a century of legacy in producing<br />

chronographs. When you buy a Zenith<br />

chronograph, you buy a timeless watch,<br />

a legacy that can be passed from one<br />

generation to the next. It is something<br />

that does not just come from the 21st<br />

century. You also buy a part of the <strong>Swiss</strong><br />

watch industry.”<br />

respect to find a solution to satisfy our<br />

clients’ needs.”<br />

The company services individual<br />

and corporate clients with private and<br />

executive aircrafts. Air Service Basel’s<br />

strategic geographical position,<br />

combined with Basel airport’s slot<br />

availability, longer operational hours<br />

and lower landing, rental and parking<br />

fees, is attracting new clientele<br />

travelling for business and pleasure in<br />

Europe.<br />

With more of Asia’s high-net-worth<br />

individuals and business executives<br />

travelling by private jet, Air Service<br />

Basel is bullish towards the Asian<br />

market, particularly the mainland. The<br />

company hopes to acquire a third of its<br />

client base from Asia.<br />

Lasagni is optimistic about possible<br />

partnerships in the region. The company<br />

would like to work with FBOs or with<br />

airports that have a certain amount of<br />

business flights. “We can assist these<br />

potential partners when they come to<br />

Basel by offering our local services.”<br />

Jossi brings<br />

technologies<br />

to mainland’s<br />

textile industry<br />

Walter Kiechl, managing director<br />

Being at the forefront of technology and<br />

pursuing outstanding design, function<br />

and performance have made Jossi<br />

Systems an unparalleled brand in the<br />

global textile industry. Developing the<br />

highest-quality detecting systems for<br />

spinning mills, the company aims to lead<br />

the market and zoom in on the mainland’s<br />

booming fabrics segment.<br />

Jossi boasts innovative technologies<br />

that respond to yarn manufacturers’<br />

demand for maximum safety and quality<br />

in contamination-free production. The<br />

company invests 10 per cent of its<br />

annual turnover in research and<br />

development, and it is backed by more<br />

than 30 years’ expertise in sensors and<br />

diverters for metal particle and spark<br />

elimination.<br />

“As markets moved, we moved,” says<br />

Walter Kiechl, managing director of Jossi.<br />

“Our main focus now is China.”<br />

Jossi is intensifying its mainland<br />

operations through Jossi Systems China,<br />

which it established in Shanghai last year.<br />

The trading company facilitates incoming<br />

parts from <strong>Switzerland</strong> and final assembly<br />

for the local market. Targeting to sell 50<br />

units annually in the region, Jossi actively<br />

promotes its products at seminars and<br />

trade shows such as ShanghaiTex.<br />

The company launches new products<br />

every three to four years and has more<br />

than 1,500 machines installed worldwide.<br />

Its fourth-generation Vision Shield<br />

Inspect uses four imaging spectroscopes<br />

that can detect the smallest impurities<br />

and a wider range of colours. Its<br />

MagicEye eliminates all kinds of synthetic<br />

materials through multiple detection<br />

principles, which aid in enhanced fibre<br />

processing. It is the only device in the<br />

market that can detect all types of<br />

plastics in fibre.<br />

The company holds free training for<br />

clients’ staff onsite and in <strong>Switzerland</strong>,<br />

and it ensures the availability and fast<br />

delivery of spare parts. Jossi’s overseas<br />

agents in Asia cover Indonesia, Japan,<br />

South Korea, Malaysia, the Philippines,<br />

Taiwan, Thailand and Vietnam.<br />

“Our goal is to be the technological<br />

leader and an important player in the<br />

market,” Kiechl says.

Sponsored section in co-operation with Discovery <strong>Report</strong>s<br />

To focus on the increasingly important<br />

North Asian markets, LGT is about to<br />

open a second booking platform in Hong<br />

Kong, having been granted a full banking<br />

licence by the Hong Kong Monetary<br />

Authority. With one in every five private<br />

clients of LGT coming from Asia, the<br />

establishment of the second booking<br />

platform enables LGT to offer its clients<br />

an enhanced local platform and an<br />

alternative booking centre.<br />

LGT’s ownership structure gives it an<br />

edge in working with family-owned Asian<br />

companies. “People like the idea of coinvesting,<br />

partnering with a family that is<br />

involved not just as an owner but also in<br />

the management. They value the<br />

alignment of interests and ideas. This has<br />

certainly helped us in attracting clients<br />

and in establishing an extremely<br />

competent and loyal employee base,”<br />

Prince Max says.<br />

As with the other markets it serves,<br />

LGT provides private banking services<br />

to wealthy individuals and their families in<br />

Asia. On the institutional client side,<br />

the majority of LGT’s business is with<br />

pension funds.<br />

Bullish in growing its business<br />

in Asia, LGT targets the mainland, India<br />

and Indonesia. Though regulatory issues<br />

present challenges for LGT’s penetration<br />

strategy in these areas, the company<br />

is constantly thinking about how to<br />

position itself in these markets to help<br />

clients manage their wealth and assets<br />

the right way.<br />

As a strong workforce has been<br />

Friday, June 10, 2011 S3<br />

SPECIAL REPORT: SWITZERLAND COUNTRY REPORT<br />

Family heritage represents financial stability<br />

Aunified set of convictions and<br />

sense of values give family<br />

businesses an edge,<br />

particularly in the highly<br />

regulated and monitored<br />

private banking sector. Lending its<br />

personal touch to an industry, where<br />

ratios and statistics matter, LGT Group<br />

Foundation (LGT) is committed to helping<br />

its clients understand the fundamentals<br />

behind the numbers to ensure that their<br />

needs are addressed appropriately.<br />

LGT is the largest private wealth and<br />

asset management group in Europe that<br />

is a fully-owned family business. Owned<br />

and managed by the Princely House of<br />

Liechtenstein since 1920, LGT hails from<br />

a legacy of excellence built on prudent<br />

decision-making and a future-oriented<br />

approach.<br />

Headquartered in Liechtenstein, LGT<br />

benefits from the stability of the location<br />

as a financial centre. Liechtenstein<br />

boasts a well-educated workforce, liberal<br />

economic policies, a highly-efficient<br />

banking system and the free movement of<br />

services within the European Union.<br />

Having established a strong<br />

foundation in Liechtenstein as early as<br />

the 1970s, LGT has taken an aggressive<br />

strategy to expand internationally. LGT<br />

is present in 29 locations, including Hong<br />

Kong, Singapore, Germany, Austria<br />

and <strong>Switzerland</strong>.<br />

“Coming from a small locale like<br />

Liechtenstein, it is not surprising to have<br />

an international perspective. All<br />

Liechtenstein companies have the benefit<br />

of being forced to develop internationally<br />

from their starting point,” says Prince<br />

Max von und zu Liechtenstein, LGT CEO.<br />

The acquisition of GT Management in<br />

1987 assisted LGT to branch out<br />

internationally. The only truly global<br />

mutual fund business at that time, GT<br />

Management had offices in London, San<br />

Francisco, Hong Kong and Tokyo. Though<br />

LGT later sold GT Management, the<br />

acquisition gave LGT the boost it needed<br />

to compete on an international scale.<br />

LGT has two main areas of business<br />

for private and institutional clients. The<br />

first is private banking and wealth<br />

management, and the second is asset<br />

management. With investment products<br />

geared towards money markets, bonds,<br />

equities, private equity and hedge funds,<br />

LGT ensures the security and growth of<br />

its clients’ assets on a long-term basis.<br />

Building on its strong asset allocation<br />

competencies, LGT counsels high-networth<br />

and institutional clients on<br />

traditional and alternative investments.<br />

Using a client’s investment profile, LGT<br />

determines the opportunities and risks<br />

of a potential outlay.<br />

“We, as a family, have decided to<br />

never sell out. We have a very long-term<br />

perspective as a family that has given us<br />

stability. We are not in the business just<br />

for a quick flip-and-buck. We are<br />

committed to fostering lasting<br />

relationships with our clients,”<br />

Prince Max says.<br />

Under private banking and wealth<br />

management, LGT offers a<br />

comprehensive private banking platform<br />

providing highly efficient and<br />

personalised banking services and full<br />

access to the most professional<br />

independent investment advice and<br />

investment management capabilities.<br />

“The core strength of both private<br />

banking and asset management is a<br />

strong investment management<br />

competence. On the private banking side,<br />

the strong investment management<br />

competence needs to be complemented<br />

by other great service competences that<br />

we have developed in different regions,”<br />

Prince Max says.<br />

LGT’s strong performance as a private<br />

bank is widely recognised in the industry.<br />

The company was ranked by business<br />

magazine Bilanz as the top <strong>Swiss</strong> private<br />

bank for 2011. It has also been ranked by<br />

Handelsblatt Elite <strong>Report</strong> 2011 as one of<br />

the leading private banks in <strong>Switzerland</strong>,<br />

Germany and Austria for 10 years running.<br />

Capital and money markets journal<br />

Euromoney also classified LGT Bank as<br />

the Best Bank in Liechtenstein last year.<br />

LGT Group is one of the few privately<br />

owned banks with a strong credit rating<br />

from Moody’s (Aa3) and Standard &<br />

Poor’s (A+). In addition, LGT has one of<br />

the highest Tier 1 ratios (19.3 per cent)<br />

in the industry, reflecting its conservative<br />

nature and excellent balance sheet<br />

strength.<br />

“On the asset management side, our<br />

investment competence is combined with<br />

the global network that we have built up.<br />

It gives us a lot of know-how across all<br />

asset and key geographic markets in<br />

which we invest. We are, as a family, the<br />

largest client of our own asset<br />

management and that has driven the way<br />

we have built it up,” Prince Max says.<br />

LGT’s asset management activities<br />

are centralised in its New York, London,<br />

<strong>Switzerland</strong>, Hong Kong, Singapore<br />

and Tokyo offices.<br />

To build up its competence in selected<br />

risk areas, LGT also works closely with<br />

the best managers and investment<br />

experts outside the company. Through<br />

close collaboration with professionals<br />

from around the world, an in-depth global<br />

industry perspective complements<br />

LGT’s expertise.<br />

“This manager selection competence<br />

and this asset allocation competence are<br />

two strong points that directly result from<br />

developing the asset management with<br />

family investment perspective, which<br />

enables us to offer our clients core<br />

investment opportunities,” Prince<br />

Max says.<br />

LGT’s alternative investments arm,<br />

LGT Capital Partners, is making waves in<br />

the industry. LGT Capital Partners has<br />

been awarded “Private Equity Fund-of-<br />

Funds Manager of the Year” at the Global<br />

Pensions Awards 2011 and for five years<br />

running. Its Crown Managed Futures<br />

programme is also recognised as the<br />

“best risk adjusted performer” by the<br />

Hedge Fund Intelligence publication<br />

InvestHedge.<br />

Building competence from<br />

the ground up<br />

By working closely with clients, LGT is<br />

able to tailor products according to their<br />

specific needs. The company designates<br />

client advisers who serve as the client’s<br />

permanent link to the company.<br />

LGT’s 1,900-strong workforce goes the<br />

extra mile to deliver unparalleled services<br />

to clients. The company arms its<br />

workforce with keen business acumen,<br />

a passion for service and an<br />

accommodating manner through its<br />

corporate university, the Liechtenstein<br />

Academy.<br />

At the Liechtenstein Academy, LGT<br />

educates its employees about the<br />

dynamics of the industry and the value<br />

of fostering long-term relationships.<br />

This is also where LGT instils the drive for<br />

excellence that has come to define the<br />

LGT brand.<br />

“Our employees understand that all<br />

clients look for stability in the relationship.<br />

They are not only interested in quarterly<br />

returns. They are interested in the longterm<br />

development of their portfolios and<br />

in the long-term development of the<br />

relationship that they have built with us<br />

as an organisation and individuals,”<br />

Prince Max says.<br />

LGT also credits its team of<br />

executives and relationship managers for<br />

building a stable and sustainable<br />

business. From 600 employees<br />

10 years ago, LGT now has nearly<br />

2,000 employees.<br />

Aside from a world-class workforce,<br />

LGT believes that diversification is<br />

important for establishing stability in the<br />

financial business environment. Just as<br />

LGT diversifies its services portfolio, it<br />

also diversifies the risks in asset<br />

categories and geographic markets.<br />

LGT’s stability has been key to the<br />

company’s strong financial performance<br />

through the years. Its group profit of<br />

HK$932 million in 2009 increased to<br />

HK$1.3 billion last year.<br />

Prince Max attributes this 40-per cent<br />

growth to strategic business<br />

developments, such as the integration of<br />

the Dresdner Bank in <strong>Switzerland</strong> into the<br />

organisation, and the promising growth<br />

coming from the Asian region. A new<br />

Frankfurt office specialising in traditional<br />

investments has also contributed to LGT’s<br />

institutional sales boost.<br />

Given its forward-thinking strategy,<br />

LGT is always on the lookout for<br />

innovations and strategies that will<br />

enhance its service delivery and create<br />

lasting asset value for its clients.<br />

Longevity in the Asian sphere<br />

LGT started operations in Hong Kong<br />

25 years ago. But it was not until after the<br />

Asian financial crisis in 1997 that LGT<br />

emphasised the development of its<br />

Asian franchise.<br />

The company has two main offices in<br />

Singapore and Hong Kong. LGT is<br />

represented in these areas by private<br />

banks but also by its asset management<br />

brands LGT Capital Management and LGT<br />

Capital Partners. LGT also has a<br />

Japanese office, which is primarily<br />

focused on asset management.<br />

Henri Leimer,<br />

CEO Wealth<br />

Management<br />

Asia<br />

instrumental in LGT’s success in other<br />

geographical markets, LGT aims<br />

to replicate this strategy in Asia. The<br />

company seeks to work with the<br />

right people who will be groomed to<br />

become experts in different wealth<br />

and asset segments.<br />

LGT is also open to developing more<br />

partnerships in the region to help the<br />

company boost its growth. “We see an<br />

opportunity in establishing partnerships.<br />

We think we can be a fantastic partner<br />

for Asian financial institutions because<br />

we have significant strengths in<br />

international investment management<br />

and global investment management<br />

which local and national players do not<br />

have,” Prince Max says.<br />

The company is looking for business<br />

partners that can complement its<br />

strengths. The ideal partners should have<br />

strong national distribution in areas LGT<br />

does not cover. They should also have the<br />

same commitment to quality that LGT<br />

possesses to uphold the company’s<br />

legacy of excellence.<br />

“We like entrepreneurs who want to<br />

work with us with the same long-term<br />

perspective that we have. We believe<br />

in building long-term partnerships.<br />

Those are generally the ties that we like,”<br />

Prince Max says. “For wealthy families<br />

and individuals interested in growing<br />

their wealth with a long-term perspective,<br />

for those who are looking for individual<br />

solutions and personalised service,<br />

LGT would be the right company to<br />

bank with.”<br />

H.S.H. Prince Max von und zu Liechtenstein, CEO

S4 Friday, June 10, 2011<br />

SPECIAL REPORT: SWITZERLAND COUNTRY REPORT<br />

André Maeder, CEO of Charles Vögele<br />

In the clothing industry, it takes more<br />

than a sharp fashion sense to be<br />

successful longer than last<br />

season’s collection. No other<br />

company exemplifies this better<br />

than major retailer Charles Vögele,<br />

whose success spans 56 years, 10<br />

countries, 840 stores – and is still<br />

growing.<br />

Voted one of “Reader’s Digest<br />

European Trusted Brands 2010” by more<br />

than 32,000 consumers in 16 countries,<br />

Charles Vögele proves its commitment to<br />

its legacy. Dating back to 1955, Charles<br />

and Agnes Vögele founded the company<br />

in Zurich as a specialty clothing store for<br />

motor scooter drivers.<br />

“Staying close to our roots of goodquality<br />

fashion for a reasonable price<br />

has enabled us to achieve a longstanding<br />

history,” says CEO André<br />

Maeder. “We now have a gross annual<br />

turnover reaching approximately HK$12<br />

billion, 8,000 employees worldwide and<br />

an output of 70 million pieces a year.”<br />

The company has expanded into<br />

Pfiffner delivers <strong>Swiss</strong> precision<br />

machinery to automotive sector<br />

Combining <strong>Swiss</strong> precision with costeffective<br />

production is a key element in<br />

K.R. Pfiffner’s rise as a leader in Europe’s<br />

rotary transfer systems market. Based<br />

in Zurich, the 40-year-old machine tools<br />

manufacturer provides customised<br />

solutions that meet the stringent<br />

demands of various industries. It<br />

mainly serves central Europe and<br />

the United States.<br />

“More than selling machines, we<br />

offer customers solutions to their<br />

problems,” says Pfiffner CEO Martin<br />

Folini. “We produce special machines<br />

to meet the manufacturing goals of<br />

our customers.”<br />

Pfiffner accomplishes this<br />

challenging task by being actively<br />

involved in the development process<br />

of its target sectors. “We listen not only<br />

to our own customers but also to<br />

the customers of our customers,”<br />

Folini says.<br />

With the expansion of<br />

manufacturing centres on the mainland,<br />

many factories are embracing<br />

automation technology. This is where<br />

Pfiffner comes in with its wide array<br />

of easy-to-operate rotary transfer<br />

systems, comprised of modules that<br />

can be tailor-fitted to customers’<br />

requirements. By providing advanced<br />

machining technology at sensible price<br />

points, Pfiffner offers potential mainland<br />

clients the capability to reduce their<br />

production costs and to ensure tight<br />

quality demands.<br />

The automotive sector is the<br />

company’s key target on the mainland,<br />

where more than 40 Pfiffner machines<br />

comprehensive apparel lines, with<br />

women’s, men’s and children’s wear<br />

accounting for 60, 30 and 10 per cent of<br />

total sales respectively. It has also<br />

broadened its geographical scope<br />

throughout <strong>Switzerland</strong>, Liechtenstein,<br />

Germany, Austria, Belgium, the<br />

Netherlands, Slovenia, Hungary, the<br />

Czech Republic and Poland.<br />

“Our friendly and customer-minded<br />

people on the floor are also a significant<br />

success factor in our growth,” says vicepresident<br />

for group marketing Rudolf<br />

Scheben. “Charles Vögele’s customer<br />

service is always rated as one of the<br />

best, and far above industry standards.”<br />

With a strong foundation and history<br />

in quality fashion and service, the<br />

company is poised for continuing<br />

growth. Listed on the SIX <strong>Swiss</strong><br />

Exchange, Charles Vögele seeks to<br />

strengthen its foothold in Europe through<br />

a three-pillar strategy focused on<br />

processes, fascination and growth.<br />

Charles Vögele is sharpening its<br />

profile by modernising store designs and<br />

creating targeted advertisements.<br />

Among its recent initiatives is the launch<br />

of testimonial campaigns featuring<br />

celebrity icons Penélope and Mónica<br />

Cruz and Til Schweiger, who embody<br />

Charles Vögele’s glamorous yet practical<br />

style. Through these ambassadors, the<br />

company aims to appeal to a mature<br />

customer base.<br />

Charles Vögele is also centralising<br />

and simplifying processes to<br />

complement its optimised expansion and<br />

productivity plans. It expects potential<br />

growth to come from its online shop<br />

launched in February. Through its online<br />

presence, the company is initially<br />

offering its Casa Blanca brand and<br />

lingerie and underwear collections.<br />

The company highlights its tight<br />

procurement and logistics operations as<br />

key drivers to its growing business. It<br />

sources most of its products directly<br />

from more than 200 external suppliers in<br />

Asia and Europe through its centralised<br />

purchasing headquarters in <strong>Switzerland</strong>.<br />

By eliminating intermediate trade, the<br />

company ensures quality control through<br />

its in-house staff, and reduces cost.<br />

With 90 per cent of its products<br />

coming from Asia, the company invests a<br />

large proportion of its resources in<br />

facilitating smooth transitions, from<br />

sourcing in factories to branch<br />

deliveries. It has offices in Hong Kong,<br />

Shanghai and Bangladesh, and three<br />

offices in India. It plans to open a new<br />

office in northern China by early next<br />

year.<br />

“We have been buying from Asia for<br />

40 years and have been able to build a<br />

vast merchandise division that checks<br />

quality at all levels,” Maeder says. “We<br />

have 200 local employees who also<br />

maintain quality assurance and supplier<br />

connections, which are necessary for a<br />

vertical group.”<br />

The company has worked closely<br />

with TexLine in Singapore as its partner<br />

and values its long-term relationships<br />

with suppliers. It is interested in<br />

attracting additional suppliers, especially<br />

as it crosses into new product lines such<br />

Sponsored section in co-operation with Discovery <strong>Report</strong>s<br />

Charles Vögele emerges as one<br />

of Europe’s most trusted brands<br />

are already running in different<br />

industries. Catering mainly to key<br />

suppliers of domestic and international<br />

original equipment manufacturers,<br />

Pfiffner is proud that its customers<br />

attest to the reliability and productivity<br />

of its machines.<br />

The company has three lead agents<br />

on the mainland, but aims to be closer<br />

to the domestic market. It is setting<br />

up a subsidiary to grow its sales<br />

and service network through local<br />

engineers.<br />

Pfiffner anticipates future turnover<br />

from the mainland to represent 20 per<br />

cent of total revenue. “China is more<br />

open to new technologies nowadays,”<br />

Folini says. “That is why I see that we<br />

have a distinct advantage in the<br />

Chinese market.”<br />

Martin Folini, CEO<br />

C-CIT unveils chemical<br />

sensors for the region<br />

The health care industry is on the brink<br />

of groundbreaking transformation, as<br />

the Centre for Chemical Information<br />

Technology (C-CIT) unveils the first and<br />

only online sensor system for disposable<br />

reactors that facilitates improved cell<br />

culture growth and vaccine production,<br />

CITSens Bio.<br />

Spinning off from ETH Zurich’s<br />

Centre for Chemical Sensor (CCS) nearly<br />

10 years ago, C-CIT has developed indepth<br />

know-how on chemicals and<br />

biosensors through strong connections<br />

with the biotechnology, medical<br />

technology, and environment and food<br />

technology industries.<br />

CITSens Bio measures glucose,<br />

glutamate and lactate in cell cultures in<br />

situ. Instead of examining cultures<br />

manually, CITSens Bio captures relevant<br />

data and sends it to a computer through<br />

a radio transmitter, enabling continuous<br />

monitoring. It also reduces labour time<br />

and contamination risks and promotes<br />

long-term culture stability.<br />

Recognising the potential of CITSens<br />

Bio, well-known multinational<br />

Known for their high level of<br />

craftsmanship, <strong>Swiss</strong> companies are<br />

constantly raising the bar in<br />

manufacturing technology. Willemin-<br />

Macodel epitomises the <strong>Swiss</strong><br />

dedication to perfection with more than<br />

35 years’ experience in developing<br />

high-precision machine tools.<br />

The leading toolmaker started as a<br />

family-owned engineering company in<br />

1974. It initially catered to the watch<br />

industry, but has expanded to offer<br />

machining solutions for other sectors<br />

such as aviation, aerospace and<br />

defence, medical, dental and jewellery.<br />

“We bring not only the machines<br />

but also our technology and high-end<br />

solutions,” says Patrick Haegeli,<br />

Willemin-Macodel sales and marketing<br />

head and board member. “We are<br />

flexible with our machines and that is<br />

one of our strengths. Our customers<br />

come to us not to get a machine, but to<br />

get a solution.”<br />

Powered by more than 200 skilled<br />

personnel, the company has expanded<br />

its know-how to manufacturing<br />

Stefan Spichiger, CEO<br />

corporations are exploring partnership<br />

opportunities with C-CIT.<br />

C-CIT also develops sensor systems<br />

for different measurement applications<br />

– CAPSens 5000 for food oil, CITSens Ion<br />

for ions, and CITSens Gas for gas.<br />

customers worldwide with subsidiaries<br />

in Germany, Russia, the United States,<br />

Canada and the mainland. It has also<br />

established an extensive sales and<br />

support network in western and<br />

as underwear and fashion accessories.<br />

It is also open to creating a design team<br />

closer to its sourcing markets in fashion<br />

hubs such as Shanghai.<br />

With a diverse supplier base, the<br />

company enforces standards that<br />

safeguard the rights of employees who<br />

work in factories manufacturing its<br />

products. As a founding member of the<br />

Business Social Compliance Initiative,<br />

Charles Vögele guarantees that its<br />

suppliers adhere to applicable laws and<br />

regulations covering environmental,<br />

working condition, wage and other<br />

sustainability and social responsibility<br />

concerns.<br />

“We look forward to forming longterm<br />

direct relationships with specialised<br />

suppliers to provide the best high-quality<br />

products to end consumers,” Maeder<br />

says. “Finding suppliers that have the<br />

standards, right machines and ability to<br />

deliver to Europe is crucial, but gaining<br />

partners that possess the creativity and<br />

philosophy behind the products is<br />

equally important to us.”<br />

<strong>Swiss</strong> toolmaker brings<br />

high-precision technology<br />

Art and science come together in the<br />

intricate process of packaging. Not only<br />

should packaging be attractive enough to<br />

attract consumers, it should also function<br />

to protect and preserve product quality.<br />

Paper producer turned plastic film<br />

manufacturer Pavag Folien has built an<br />

unparalleled expertise in flexible film<br />

extrusion, printing and conversion,<br />

successfully harnessing its properties<br />

for use in different industries.<br />

Pavag Folien has been producing and<br />

converting flexible films since 1975, but<br />

has been in the business since 1926 as<br />

Pavag, the first <strong>Swiss</strong> paper factory.<br />

Investing in the development of patented<br />

machinery, Pavag Folien is equipped to<br />

develop solutions based on specific client<br />

requirements. The company’s product<br />

range and flexibility make it an ideal<br />

partner for clients.<br />

The company works closely with<br />

customers in managing the supply chain.<br />

“By end-to-end supply chain<br />

implementation, we help clients minimise<br />

costs and stock levels. We provide top<br />

Blaise Haegeli,<br />

president and CEO<br />

service with the shortest lead time,” says<br />

Erich Steiner, Pavag Folien CEO.<br />

Food segment applications make up<br />

60 per cent of Pavag Folien’s business.<br />

CAPSens 5000, in particular, has<br />

been attracting attention in Asia. The<br />

National University of Singapore (NUS)<br />

has endorsed CAPSens 5000 for<br />

boosting food quality following positive<br />

test results. It also reduces health risks<br />

since oil replacement is determined<br />

automatically.<br />

The importance of oil in Asia’s<br />

culinary cultures makes it a significant<br />

market for CAPSens 5000. The<br />

company wants to establish a<br />

production facility in Singapore or<br />

Malaysia technoparks to cater to the<br />

Asian market.<br />

C-CIT works with distributors from<br />

Japan, Singapore, Malaysia and the<br />

mainland to capitalise on growth<br />

opportunities. The company angles<br />

towards the biotechnology sector on<br />

the mainland to address this growing<br />

segment.<br />

“We want to demonstrate our<br />

commitment to health in Asia. We are<br />

open to research collaborations to<br />

raise awareness about our sensors,”<br />

says Stefan Spichiger, CEO of C-CIT.<br />

Introducing film applications to the<br />

mainland’s construction industry<br />

Erich Steiner, CEO<br />

eastern Europe, the Middle East, Asia<br />

and South America to ensure that<br />

it is able to meet the requirements<br />

of its customers.<br />

With offices in Xian and Shanghai,<br />

Willemin-Macodel aims to strengthen<br />

its presence in Southeast Asia and the<br />

mainland. The company is a leading<br />

provider in the aerospace industry on<br />

the mainland and is looking for<br />

manufacturing partners to satisfy a<br />

growing demand for high-precision<br />

tools in other industries.<br />

Haegeli says a long-term plan to<br />

enhance expertise in cutting-edge<br />

technology is essential. The company<br />

is tapping universities and research<br />

institutes on the mainland for technical<br />

collaboration. It is already working with<br />

a research institute in Beijing.<br />

Willemin-Macodel designs its<br />

machine tools and works with<br />

manufacturers in key locations<br />

worldwide. Soon, partner<br />

manufacturers on the mainland could<br />

be making these world-class<br />

machines.<br />

The remaining 40 per cent comprises<br />

industrial, technical, and non-food<br />

applications.<br />

Pavag Folien’s multilayer films<br />

possess superior oxygen barrier and<br />

optical properties. The company’s<br />

products, such as Rolamit, can be used<br />

in construction. It can be used in<br />

waterproofing floors, roofs and walls and<br />

in repairing and sealing windows and<br />

doors. Rolamit protects wood and steel<br />

against the elements.<br />

Pavag Folien aims to market Rolamit<br />

and a new product called Pavacross on<br />

the mainland over the next couple of<br />

months. Pavacross is similar to Rolamit,<br />

but with much higher mechanical and<br />

stretching properties. Its surface is also<br />

smoother, ideal for prints.<br />

“We are looking for an agent to<br />

help us creatively develop new film<br />

applications on the mainland. We are<br />

looking for partners with experiences<br />

in packaging and industrial and an<br />

existing network of at least 10 years,”<br />

Steiner says.

Sponsored section in co-operation with Discovery <strong>Report</strong>s<br />

Few names in history have<br />

successfully preserved their<br />

legacy of excellence across so<br />

many generations. Spanning<br />

more than 2 1 ⁄2 centuries, the<br />

legendary Rothschild clan remains one<br />

of the most powerful and influential<br />

families in Europe, particularly in the<br />

field of banking and finance.<br />

Geneva-based Banque Privée<br />

Edmond de Rothschild (BPER) has<br />

honed its expertise in private banking<br />

and asset management while<br />

husbanding the Rothschild family’s own<br />

intergenerational wealth over decades.<br />

The bank delivers the same family brand<br />

of service to clients worldwide,<br />

including to the growing affluent<br />

population in Asia.<br />

“We are privileged in preserving a<br />

name that is almost a myth,” says<br />

Bernard Schaub, a BPER senior vicepresident<br />

and member of the executive<br />

committee. “It is a benchmark for<br />

excellence in finance.”<br />

Seasoned financier Baron Edmond<br />

de Rothschild, who bought out the then<br />

tiny Banque Privée in 1953, founded<br />

BPER. A visionary who dared to rise to<br />

new challenges, Edmond de Rothschild<br />

strengthened his family’s wealth and<br />

asset management business and<br />

ventured into uncharted territories in<br />

modern finance.<br />

The family’s values and traditions<br />

are now in the hands of his son,<br />

Benjamin de Rothschild, who<br />

represents the seventh generation of<br />

the elite dynasty. Following his father’s<br />

footsteps, he continues to lead the<br />

family-controlled business to steady<br />

growth.<br />

The BPER Group’s net profit rose 9.6<br />

per cent last year to the equivalent of<br />

HK$1.3 billion. Despite economic and<br />

regulatory hurdles in <strong>Switzerland</strong> and<br />

worldwide, BPER managed to attract a<br />

net inflow of HK$56.3 billion in fresh<br />

funds. Assets under management at the<br />

end of 2010 totalled HK$802.8 billion.<br />

“To this day, we continue to<br />

specialise in managing families’ money<br />

across their various members and<br />

generations,” Schaub says. “That has<br />

been a major focus of our business for<br />

generations and is still what we know<br />

and do best. We are here to take care of<br />

our clients’ assets. We make sure these<br />

are properly managed in order to<br />

provide the returns that the families are<br />

expecting.” BPER is the publicly traded<br />

parent company of the Edmond de<br />

Rothschild Group. As a full-service bank<br />

geared towards finance, it caters to<br />

private and institutional clients. It does<br />

not engage in commercial or investment<br />

banking, so clients can rest assured that<br />

there are no underlying conflicts of<br />

interest and that BPER stays focused<br />

entirely on the growth and preservation<br />

of their assets.<br />

Headquartered in the international<br />

wealth management capital of the<br />

world, BPER has established its<br />

presence in major financial centres with<br />

a workforce of 1,600.<br />

The bank has affiliates, branches<br />

and offices in nearly 20 countries,<br />

including the Bahamas, Belgium,<br />

Britain, China, Israel, Italy, Japan,<br />

Luxembourg, Monaco, Poland, Portugal,<br />

Slovakia, Spain, Taiwan and Uruguay.<br />

Long-standing presence in Asia<br />

Asia is a highly valued market for BPER,<br />

which has been in the region for more<br />

than 20 years. The bank’s presence in<br />

Hong Kong dates back to 1987 when it<br />

launched a joint venture with First<br />

Interstate Bank, a United States-based<br />

institution with operations in Asia and<br />

Latin America. After collaborating with<br />

First Interstate for a few years, BPER<br />

bought its Asian clients and established<br />

a proprietary representative office in<br />

Hong Kong in 1992.<br />

BPER recognises the region’s<br />

potential for strong wealth creation, and<br />

thus aims to strengthen its operations in<br />

Asia further by elevating the Hong Kong<br />

office into a fully-fledged branch upon<br />

obtaining its banking licence. Hong<br />

Kong will serve as the booking centre<br />

for the bank’s Asian clients.<br />

“Basically, we chose Hong Kong<br />

because we know the place very well.<br />

We feel comfortable here,” Schaub<br />

says. “By setting up a bank in Hong<br />

Kong, we can move closer to our clients<br />

and they can keep in touch with us on a<br />

daily basis. We will be able to provide<br />

them with much more personalised<br />

service.”<br />

Schaub points out that having a<br />

stronger Asian presence will also foster<br />

a deeper understanding of economic<br />

and political developments throughout<br />

the region and enable the bank to gain<br />

greater insights on investment<br />

opportunities that can be offered to<br />

clients.<br />

BPER’s Paris-based sister company,<br />

La Compagnie Financière Edmond de<br />

Rothschild Banque, also has<br />

representative offices in Shanghai and<br />

Hong Kong.<br />

“We have been in Asia for a long<br />

time and we are here to stay,”<br />

Schaub says.<br />

The bank boasts a team of<br />

dedicated financial experts who are<br />

veterans in the Asian market. Bruce Von<br />

Cannon, the chief representative in<br />

Hong Kong, is a prominent banker and<br />

wealth management specialist. The<br />

team has an extensive network among<br />

the region’s high-net-worth individuals<br />

(HNWIs).<br />

“The new branch gives us closer<br />

access to these people and allows us to<br />

appraise what kinds of service we can<br />

provide them with,” Schaub says.<br />

BPER is committed to educating<br />

entrepreneurs in the region about the<br />

value of investing, even outside their<br />

own companies. The big challenge,<br />

Schaub says, lies in convincing them<br />

Friday, June 10, 2011 S5<br />

SPECIAL REPORT: SWITZERLAND COUNTRY REPORT<br />

New generation carries the Rothschild flame<br />

Bernard Schaub, senior vice-president and member of the executive committee<br />

that they need to preserve part of their<br />

wealth for their families’<br />

intergenerational benefit.<br />

The surge in the number of<br />

millionaires and billionaires on the<br />

mainland gives wealth management<br />

specialists, such as BPER, a broad<br />

platform for growth. Bain & Company, a<br />

global consultant, forecasts that the<br />

number of Chinese HNWIs will reach<br />

585,000 this year, nearly double the 2008<br />

figure. This new elite has individual<br />

investable assets exceeding HK$12<br />

million.<br />

Referring to a study published in<br />

April, Bain notes that the new breed of<br />

HNWIs is becoming more<br />

discriminating when it comes to<br />

managing their fortunes and new<br />

investments.<br />

The same study revealed that while<br />

wealth creation is still a top priority for<br />

well-to-do Chinese, they also put greater<br />

value on safety and on providing for their<br />

children’s education and inheritance.<br />

Asset allocation among the<br />

mainland’s super-rich is also changing,<br />

the study showed, with growing<br />

openness to alternative investments.<br />

The old mainstays – cash, deposits and<br />

property – are giving way to bonds,<br />

equities and more sophisticated<br />

products.<br />

Protecting and growing wealth<br />

for generations<br />

Asian clients will surely appreciate the<br />

strong family-oriented values of the new<br />

Rothschild-owned branch. Preserving<br />

wealth across generations has always<br />

been the centrepiece of BPER’s<br />

mandate.<br />

Through prudent investments and<br />

sound management of financial risk, the<br />

bank maintains a balanced portfolio that<br />

has kept it healthy and profitable over<br />

the years.<br />

Clients benefit from this same<br />

capability, thanks to the highly talented<br />

financial experts in BPER’s wealth<br />

engineering department. They have<br />

expertise ranging from legal and tax<br />

matters to trusts and foundations. The<br />

bank also provides reliable assistance in<br />

estate planning and asset structuring.<br />

“What clients find most valuable in<br />

these services is the personalised<br />

approach that we can give,” Schaub<br />

says. After careful analysis of the needs<br />

and risk profile of each client, the bank’s<br />

experts design a tailor-fit wealth<br />

management solution that serves his<br />

best interests. The service provided is<br />

enhanced with state-of-the-art<br />

investment techniques.<br />

Customised wealth management is<br />

the hallmark of BPER’s long-standing<br />

relationship with highly valued clients.<br />

The bank tracks clients’ changing<br />

circumstances over time and adjusts<br />

their portfolios accordingly.<br />

“We have decades of experience in<br />

making sure that our clients’ assets are<br />

safe and well allocated on a diversified<br />

basis, not only in terms of asset class but<br />

also across currencies, countries and<br />

regions,” Schaub says.<br />

As family businesses in Asia become<br />

more global, they need to brace for<br />

certain implications in taxes and other<br />

matters. “When you make money that’s<br />

international, at a certain point you will<br />

need a private bank to help you,”<br />

Schaub says. “We make sure that<br />

people know that we’re there.”<br />

BPER’s management of client<br />

portfolios provides scope for future<br />

changes in the tax system and<br />

legislation of the countries concerned. It<br />

also makes sure that the next generation<br />

will have the money that was saved for<br />

them.<br />

Having a loyal team of relationship<br />

managers who have been with the bank<br />

for many years is a big advantage,<br />

enabling BPER to deal more effectively<br />

with different family generations. “Our<br />