Positech Brochure-new - Ergonomic Partners

Positech Brochure-new - Ergonomic Partners

Positech Brochure-new - Ergonomic Partners

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

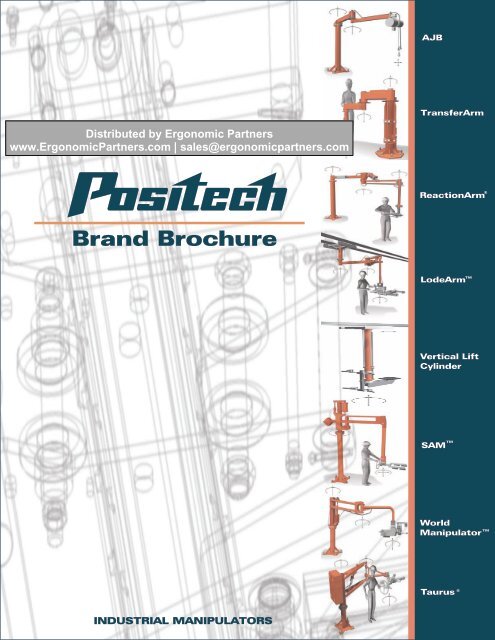

Brand <strong>Brochure</strong><br />

INDUSTRIAL MANIPULATORS<br />

AJB<br />

TransferArm<br />

ReactionArm<br />

LodeArm<br />

Vertical Lift<br />

Cylinder<br />

SAM<br />

TM<br />

World<br />

Manipulator<br />

Taurus<br />

®<br />

TM<br />

®<br />

TM

Solutions<br />

Safe, Efficient, Quality<br />

The Power<br />

“<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

The Manufacturing Challenge<br />

Lifting, rotating, turning, tilting, reaching and<br />

positioning takes physical strength that often<br />

results in strain, injury and decreased production.<br />

The <strong>Ergonomic</strong> Solution<br />

<strong>Positech</strong>’s ergonomically designed, operatorcontrolled<br />

material handling devices lift,<br />

rotate, turn, tilt, reach, and position, enabling<br />

humans to accomplish more while eliminating<br />

physical stress and potential injury<br />

The Bottom Line<br />

By incorporating superior material handling<br />

practices through <strong>Positech</strong> solutions, you can<br />

achieve:<br />

• A safer workplace<br />

• Reduced handling-related injuries<br />

• Enhanced process flow<br />

• Improved product quality<br />

• Increased profitability<br />

Custom Tooling -<br />

An Essential Element<br />

<strong>Positech</strong> designs, manufactures, tests and<br />

integrates tooling to match specific, unique<br />

applications, ensuring you a tool that fits your<br />

application.<br />

At our manufacturing facility, we have one<br />

operator who handles about 400 ceramic<br />

ladle shrouds and stopper rods on a daily<br />

basis. Each one weighs between 50 and<br />

200 pounds. Our <strong>Positech</strong> system provides<br />

the means for easily and safely manipulating<br />

those pieces and preventing physical<br />

injury. It’s a very reliable and lowmaintenance<br />

machine.<br />

Monty Eldridge<br />

Plant Engineer<br />

Vesuvius<br />

Charleston, Illinois<br />

”<br />

2

The Innovator<br />

Strength<br />

The Driving Force<br />

“<br />

<strong>Positech</strong> has evolved since its birth in 1951<br />

as a manufacturer of hydraulic cylinders and<br />

manifolds. since 1975, <strong>Positech</strong>, short for<br />

“positioning technology,” has grown to<br />

become a world leader in the manufacture of<br />

lifting and positioning products designed to<br />

reduce ergonomic-related worker injuries and<br />

improve material handling.<br />

Today, <strong>Positech</strong> occupies 60,000 square feet<br />

of space at its facility in Laurens, Iowa. Our<br />

success stems from a combination of hightech<br />

communications tools, cutting-edge manufacturing<br />

and engineering, and the strong<br />

work ethic of the people of this midwestern<br />

state.<br />

Quality - The Driving Force<br />

Through total quality management principles,<br />

<strong>Positech</strong> is committed to:<br />

• Partnering with customers<br />

• Designing the right solutions to lifting<br />

and positioning challenges<br />

• Assuring complete customer<br />

satisfaction<br />

• Providing service for the life of the<br />

machine<br />

John Deere Harvester Works recently<br />

reached a safety milestone of almost 7<br />

million man-hours without a lost-time<br />

accident. <strong>Positech</strong> manipulators helped<br />

contribute to that milestone by preventing<br />

back strains to our employees. I would<br />

recommend <strong>Positech</strong> Manipulators.<br />

They’re a great system - well-built and<br />

well maintained, easy to use and service.<br />

Ted Zeidler<br />

Plant Engineer<br />

John Deere Harvester Works<br />

East Moline, Illinois<br />

”

The Team Player<br />

<strong>Partners</strong>hip<br />

The <strong>Positech</strong> Approach<br />

<strong>Positech</strong> Project Team<br />

Every <strong>Positech</strong> solution is developed by a dedicated<br />

team of experts, which includes the customer.<br />

Team interaction is key to assuring continuity from<br />

concept through completion. The <strong>Positech</strong> Project<br />

Team consists of:<br />

• The customer<br />

• <strong>Positech</strong> factory trained representative<br />

• <strong>Positech</strong> inside design sales specialist<br />

• <strong>Positech</strong> design engineer<br />

• <strong>Positech</strong> inside project manager<br />

<strong>Positech</strong> <strong>Partners</strong>hip<br />

As a single-source supplier of customized positioning<br />

technology, <strong>Positech</strong> has developed a winning<br />

approach to material handling solutions - <strong>Positech</strong><br />

<strong>Partners</strong>hip is simply how we do business.<br />

Customer input at critical decision points guarantees<br />

a quality material handling solution. Using the<br />

<strong>Positech</strong> approach, team members:<br />

• Gather and analyze detailed facts to<br />

understand customer operations and needs<br />

• Determine the type of material handling<br />

devices best suited for those needs<br />

• Prepare a detailed quotation and tooling<br />

concept rawings. The quote lists each feature,<br />

standard or optional, and a description of each<br />

component and its function.<br />

• Provide a detailed set of assembly drawings<br />

for customer approval<br />

• Engineer, manufacture, assemble and test<br />

manipulator and tooling<br />

• Allow for a variety of product approval options<br />

• Develop a detailed operator/service manual for<br />

the customer’s service team<br />

• Provide long-term service support<br />

<strong>Positech</strong> <strong>Partners</strong>hip Plus<br />

Extend the life and value of your <strong>Positech</strong> material<br />

handling device. <strong>Positech</strong> <strong>Partners</strong>hip Plus gives<br />

customers four cost-effective ways to maximize<br />

return on original investment and keep operations<br />

current:<br />

• Installation supervision<br />

• Provide operator and maintenance training<br />

• Preventive maintenance service plan throughout<br />

the life of the manipulator<br />

• Retooling of the manipulator as<br />

applications change<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

4

Exceeding<br />

Expectations<br />

The Right Choice<br />

• For Safety -<br />

<strong>Positech</strong> product design<br />

promotes ergonomic benefits<br />

and safety in the work<br />

environment.<br />

• For Quality -<br />

World-class quality management,<br />

ISO 9001:94 registration<br />

and employee participation<br />

are driving forces<br />

behind quality processes<br />

and products.<br />

• For Durability -<br />

Long life design provides<br />

strength and durability.<br />

Attention to detail and quality<br />

manufacturing ensure<br />

countless years of service.<br />

• For Convenience -<br />

<strong>Positech</strong> is a single-source<br />

supplier of lifting and positioning<br />

devices. Your personal<br />

project team takes<br />

your project from concept<br />

to completion.<br />

• For Long-Term<br />

Support -<br />

Preventative maintenance<br />

and the <strong>Partners</strong>hip Plus<br />

Program ensure your<br />

machine will be in operation<br />

for countless years of<br />

service. Should you ever<br />

need assistance, our service<br />

department can provide<br />

a quick response.<br />

Exclusive <strong>Positech</strong> Warranty<br />

Expect nothing but the best warranty from the industry<br />

leader<br />

• 12 months - electrical, hydraulic, pneumatic,<br />

magnetic, and vacuum parts<br />

• 18 months - mechanical parts<br />

Industry<br />

Leadership<br />

Integrated Solution, Too<br />

If your product design or manufacturing process has not<br />

yet been defined, <strong>Positech</strong>’s Integrated Solutions Group,<br />

can provide consultative engineering, problem solving and<br />

full project management. This service integrates your<br />

entire material handling operation, by first learning your<br />

process and recommending the correct material handling<br />

solutions for a single work cell or an entire facility. The<br />

Integrated Solutions Group draws on the experience and<br />

expertise of manipulators, overhead light rails, lift tables,<br />

hoists, conveyors, and conveyor systems. Established<br />

partnerships with material handling companies further<br />

ensure the proper solutions are<br />

recommended.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

5

The Custom Source<br />

The Largest Selection<br />

<strong>Positech</strong> builds the largest selection of lifting and positioning equipment in the industry. All models are<br />

available in floor mount or space-saving overhead mount. Each can be hydraulically, electrically or<br />

pneumatically powered. If our standard models don’t meet your needs, customized manipulator can be<br />

built to your specifications.<br />

• Taurus -<br />

Designed to emulate the human arm,<br />

<strong>Positech</strong>’s high-capacity Taurus positioning arm<br />

(TPA) handles the heaviest loads with precision<br />

- up to 2,500 pounds.<br />

• SAM (Simple Air Manipulator) -<br />

For jobs that require the compliance and float of<br />

a pneumatic manipulator, this machine gives the<br />

highest level of feel to position the payload.<br />

<strong>Positech</strong>’s SAM uses pneumatic power to<br />

provide quick response and superior<br />

maneuverability with loads up to 940 pounds.<br />

• LodeArm and LodeArm II -<br />

Our LodeArm and LodeArm II lightweight<br />

manipulators provide excellent maneuverability<br />

of payloads up to 225 pounds, increasing<br />

employees’ capacity to perform physically<br />

stressful, repetitive lifting tasks.<br />

• Transfer Arm -<br />

Incorporates the low headroom flexibility of the<br />

Articulated Jib Boom combined with the straight<br />

vertical lift of the Vertical Lift Cylinder.<br />

<strong>Positech</strong>’s low-profile Transfer Arm allows placement<br />

in areas too confined to accommodate<br />

larger material handling equipment and handles<br />

loads up to 500 pounds.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

6

All <strong>Positech</strong> manipulators can be matched to the<br />

various tools shown and many more. Standard<br />

or custom - <strong>Positech</strong> designs and builds tooling<br />

to grip, pitch and rotate your products.<br />

• AJB (Articulated Jib Boom) -<br />

Designed for low headroom operation and to<br />

maneuver around work-area obstructions, our<br />

standard models support up to 2,000 pounds<br />

and allow 360º rotation around the main post.<br />

• Vertical Lift Cylinder -<br />

With up to 6,000-pounds capacity, <strong>Positech</strong>’s<br />

Vertical Lift Cylinder is ideal for straight line<br />

transfer, over-the-assembly line handling and<br />

reach-in operations when combined with overhead<br />

rail system or a <strong>Positech</strong> Articulated Jib<br />

Boom.<br />

• ReactionArm®-<br />

<strong>Positech</strong>’s ReactionArm absorbs shock, torsional<br />

forces, and impact force from power tools;<br />

therefore reducing carpal tunnel injury and<br />

cumulative trauma disorders.<br />

• World Manipulator -<br />

The World Manipulator combines the strength of<br />

the Taurus and the agility of the SAM while<br />

incorporating universally-accepted metric<br />

specifications for easy service and maintenance<br />

anywhere in the world. The World Manipulator is<br />

designed for low headroom applications that<br />

require extended reach and handles loads up to<br />

300 kilograms (660 pounds)<br />

The Custom Source<br />

Selection<br />

To Meet Your Needs<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

7

Taurus <br />

Precise Positioning. Heavy Payloads<br />

Designed to emulate the human<br />

arm, <strong>Positech</strong>’s high-capacity<br />

Taurus Positioning Arm (TPA)<br />

handles the heaviest loads with<br />

precision - up to 2,500 pounds.<br />

The Taurus is the ideal selection<br />

when precision handling and<br />

heavy weight factors come into<br />

play. This manipulator’s parallel<br />

arm is articulated at the shoulder,<br />

elbow and wrist joints. Safe,<br />

low-voltage, variable speed<br />

controls can be hand held,<br />

machine mounted or built into an<br />

ergonomically designed control<br />

station. The operator manually<br />

controls all horizontal movement<br />

and positioning. Vertical<br />

movement is achieved with a<br />

motor-driven hydraulic system<br />

Standard or customized tooling<br />

and controls are available to meet<br />

your requirements.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Performance and Quality<br />

Features<br />

• Direct mount to the floor, on pedestals,<br />

mobile, or portable bases, wall or<br />

flange mounts, fixed overhead<br />

mounts, and dual rail bridge systems.<br />

• Adjustable drag brakes at each vertical<br />

axis of rotation<br />

• Low headroom, no space-consuming<br />

counterweights<br />

• Infinitely variable up/down vertical<br />

speeds; easily adjustable<br />

minimum/maximum speed controls.<br />

• Self-contained, energy-efficient power<br />

unit<br />

• Power/control unit remote mount for<br />

operation in explosives or clean room<br />

environments<br />

• Lifting actuator: single action, ram-type<br />

hydraulic cylinder<br />

• Lowering force: gravity, with full<br />

variable speed control<br />

• Optional electric collector ring<br />

available for continuous main post<br />

rotation.<br />

• Push-button or twist-style up/down<br />

controls<br />

• Precision bearings reduce friction and<br />

wear<br />

• Designed for minimal deflection<br />

• Up to 60,000 inch pounds of end of<br />

arm moment load allowed<br />

• Can be converted from floor to<br />

overhead mount<br />

• Precision bearings and thrust washers<br />

at joints for smooth motion and long<br />

life<br />

8

Safety Features<br />

• 5:1 design factor minimum on all structural components<br />

• Pilot operated lock valve on lift cylinder and gripper cylinders<br />

prevents vertical arm movement and loss of payload if supply<br />

pressure is interrupted<br />

• Gripper Safety Circuitry available. Prevents accidental release<br />

of unsupported parts<br />

• Low-voltage signal on all operator’s controls<br />

• Overload sensors prevent lifting more than machine capacity<br />

• Temperature sensors shut down system automatically to<br />

prevent overheating<br />

Specifications for Standard Models<br />

Model Lifting Vertical Lift Maximum Radial<br />

Capacity (lbs.)* of Paylod (in.) Reach to Center<br />

TPA-5 500 64 114<br />

TPA-10 1,000 64 116<br />

TPA-15 1,500 64 116<br />

TPA-25 2,500 64 136<br />

* Includes payload and tooling<br />

Requires 110-volt AC at 30 amps or 220 at 20 amps or 460 at 15 amps<br />

Options available for extended lift and reach<br />

This magnet tool transfers<br />

irregular steel shapes weighing<br />

up to 720 pounds in a<br />

fabrication process.<br />

This Taurus loads 400-pound<br />

engine blocks onto the final<br />

assembly line.<br />

Tool loads hot billets from a hot<br />

furnace to a forging press.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Quality Profile<br />

Design Integrity & Quality<br />

5:1 design factor minimum<br />

• <strong>Positech</strong> safety standards exceed<br />

those of all competitors<br />

• Stronger pins, bearings structural<br />

members and welds deliver<br />

safety and longer service life<br />

Durability<br />

• Greased and sealed precision<br />

bearings reduce friction and<br />

wear, saving costly replacement<br />

or repair.<br />

• Hard chrome plated shafts and<br />

cases for longer wear, less<br />

friction, resistance to rust and<br />

corrosion<br />

• Expoxy paint available as added<br />

protection in corrosive<br />

environments<br />

• Designed for minimum deflection,<br />

some components have a<br />

structural design factor greater<br />

than 5:1.<br />

Gripper tool grasps the end of a<br />

shaft used in a forging<br />

application.<br />

9

SAM <br />

Superior Maneuverability. Minimal Effort<br />

For jobs that requires the<br />

compliance and float of a<br />

pneumatic manipulator, this<br />

machine give the highest level of<br />

feel and position to the payload.<br />

<strong>Positech</strong>’s SAM uses pneumatic<br />

power to provide quick response<br />

and superior maneuverability with<br />

loads up to 940 pounds.<br />

The Simple Air Manipulator’s lift<br />

cylinder uses compressed air for<br />

vertical lifting positioning.<br />

<strong>Positech</strong> SAMs come equipped<br />

with a standard operator-<br />

controlled up/down metering<br />

valve.<br />

As an option, automatic balancing<br />

control, combined metering and<br />

balancing control, or an<br />

ergonomic twist grip control, is<br />

available. Precision bearings at<br />

every articulated point to minimize<br />

resistance to movement.<br />

Standard or customized tooling<br />

and controls are available to meet<br />

your requirements.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Performance and Quality<br />

Features<br />

• Substantially greater endjoint side-loading<br />

capability than competitive manipulators<br />

• End of arm rotating axis has: up to<br />

15,000 inch pounds of end of arm<br />

moment loading and 360º full rotation<br />

• Its pantograph design allows for a<br />

rectangular working window<br />

• Tool-mounting surface deflects less than<br />

2º when fully side loaded<br />

• Low SAM models allow for excellent read<br />

in low headroom work areas<br />

• Mounts on a pedestal, overhead spacer,<br />

portable or mobile base, or dual rail<br />

trolley<br />

• Designed for low maintenance and<br />

high productivity<br />

• Special circuitry available to meet<br />

application requirements<br />

• Pneumaticallly operated requires 90 psi<br />

clean dry input pressure<br />

• Precision bearings and thrust washers<br />

at joints for smooth motion and long<br />

life<br />

Safety Features<br />

• 5:1 design factor minimum on structural<br />

components<br />

• Enclosed parallel linkage minimizes<br />

visual obstruction and protects operator<br />

from potential harm at pinch points<br />

• Pilot operated lock valve on lift cylinder<br />

and gripper cylinders prevent vertical arm<br />

movement and loss of payload if supply<br />

pressure is interrupted<br />

• Gripper Safety Circuitry available.<br />

Prevents accidental release of<br />

unsupported parts<br />

• Lost Load Cylinder is a separate, sealed<br />

hydraulic device that protects the<br />

operator from any sudden, uncontrolled<br />

vertical motion of the manipulator’s arm<br />

10

Specifications for Standard Models Quality Profile<br />

Model Lifting Vertical Reach Minimum<br />

Capacity (lbs.)* Lift (in.) (in.) Recommended<br />

Overhead<br />

Clearance (in.)<br />

G 150-390 44.7-87.3 66-126 104-190<br />

K 240-680 44.7-100 66-144 104-215<br />

P 350-940 44.7-100 66-144 104-215<br />

LS-100 515 66 100 96<br />

LS-116 435 77 116 106<br />

Requires 80 psi clean and dry air to operate at rated lift capacity.<br />

*Includes payload and tooling: increasing arm length reduces payload capacity<br />

Specialized poke tool places this<br />

electrical sub assembly into a<br />

power control cabinet.<br />

Tooling provides for the pouring<br />

of a 55-gallon drum in the<br />

chemical industry.<br />

The overhead SAM unit places<br />

a 100-pound seat into a skid<br />

steer.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

More Standard Features<br />

<strong>Positech</strong> Manipulators come with<br />

more standard features than any<br />

competitive product. The<br />

following are just a few of the<br />

standard features on pneumatic<br />

models.<br />

Dual direction lost load system:<br />

Important safety feature; reliably<br />

stops uncontrolled upward or<br />

downward motion of lift arm.<br />

Mounting hardware to attach<br />

Manipulator to support structure<br />

on floor.<br />

Air filter, regulator and<br />

lubricator mounted and<br />

connected to machine.<br />

360º rotating air coupling for air<br />

input.<br />

For easy installation: Each<br />

manipulator is shipped standing<br />

on a pallet the way it will be<br />

installed. The pallet is used as a<br />

lifting platform for installation and<br />

can be disassembled quickly once<br />

the Manipulator is bolted to the<br />

support structure.<br />

Adjustable screw jacks for<br />

mounting bolts eliminate need for<br />

shims to level machine.<br />

Vacuum tool easily maneuvers<br />

an aircraft winsheild in a repair<br />

facility.<br />

11

LodeArm <br />

High Maneuverability. Efficient. Compact<br />

Our LodeArm lightweight<br />

manipulator provides excellent<br />

maneuverability of payloads up to<br />

225 pounds, increasing<br />

employees’ capacity to perform<br />

physically stressful, repetitive<br />

lifting tasks.<br />

Easily adjustable to fit almost any<br />

work cell, <strong>Positech</strong>’s LodeArm is a<br />

high-capacity lift system in a very<br />

compact package. This unit<br />

provides rigid support and<br />

reach-in capability. The LodeArm<br />

4500 functions in low headroom<br />

spaces, with a horizontal lift arm<br />

that swings downward 45 º.<br />

Model 3030’s horizontal lift travels<br />

30º up and down.<br />

Standard or customized tooling<br />

and controls are available to meet<br />

your requirements.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Performance and Quality<br />

Features<br />

• Lightweight and easy to position<br />

• Push-button up/down valve controls lift<br />

and lower for ease of operation<br />

• Up and down speed valves for precise<br />

load control<br />

• Optional balance controls allow operator<br />

to achieve critical load positioning by<br />

hand, without activating up/down valve<br />

• 360º rotation at main post<br />

• Radial reach up to 113 in.<br />

• Vertical travel up to 54 in.<br />

• Parallel link stardard supports loads<br />

beyond end of arm<br />

• Pneumatic is designed to be operated<br />

with clean and dry air<br />

• Precision bearings and thrust washers at<br />

joints for smooth motion and long life<br />

Safety Features<br />

• 5:1 design factor minimum on all structural<br />

components<br />

• Pilot operated lock valve on lift cylinder<br />

and gripper cylinders prevent vertical arm<br />

movement and loss of payload if supply<br />

pressure is interrupted<br />

• Gripper Safety Circuitry available.<br />

Prevents accidental release of<br />

unsupported parts<br />

• Lost Load Cylinder is a separate, sealed<br />

hydraulic device that protects the<br />

operator from any sudden, uncontrolled<br />

vertical motion of the manipulator’s arm<br />

12

Specifications for Standard Models Quality Profile<br />

Model Maximum Lifting Vertical Lift Maximum Reach<br />

Capacity at (in.)** (in.)<br />

77 in. (lbs.)*<br />

LA-3030 225 54 113<br />

LA-4500 225 38 113<br />

LAII-3030 225 54 61<br />

LAII-4500 225 38 61<br />

Requires 80 psi clean and dry air to operate at rated lift capacity<br />

* Maximum capacity at 36” lift arm length. Capacity varies according to arm length.<br />

Includes payload and tooling<br />

** Vertical lift varies according to lift-arm length<br />

Manually-operated tool picks up<br />

125-pound starters and transfers<br />

to the engine during final<br />

assembly of a tractor engine.<br />

Tool positions engine heads for<br />

placement into a 5-axes<br />

machining center.<br />

Vacuum tool handles picture<br />

tube funnels during the<br />

manufacturing process.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Detailed Price Quotations<br />

Following a strategy unique to<br />

<strong>Positech</strong>, we emphasizes the<br />

importance of specifics in our pro<br />

posal process, with communications<br />

going both ways. We start<br />

by gathering detailed facts about<br />

your operation and your needs,<br />

then prepare an equally detailed<br />

quotation, including drawings.<br />

Quotations list each feature,<br />

standard or optional, and a<br />

description of that component and<br />

its function. This way, you under<br />

stand exactly what you’re pur<br />

chasing and can make a better<br />

informed decision.<br />

Tool manipulates disk brake<br />

hubs through the various<br />

manufacturing and machining<br />

operations.<br />

13

Transfer Arm <br />

Low Profile. Compact.<br />

Incorporates the low headroom<br />

flexibility of the Articulated Jib<br />

Boom combined with the straight<br />

vertical lift of the Vertical Lift<br />

Cylinder. <strong>Positech</strong>’s low-<br />

profile Transfer Arm allows<br />

placement in areas too confined to<br />

accommodate larger material<br />

handling equipment and handles<br />

loads up to 500 pounds.<br />

<strong>Positech</strong>’s low-profile Transfer<br />

Arm allows placement in areas too<br />

confined to accommodate larger<br />

material handling equipment.<br />

Specifically designed for minimum<br />

vertical travel and to fit<br />

limited-access work cells, this<br />

machine is well-suited for loading<br />

and unloading machining centers<br />

and for positioning in assembly.<br />

Mounting options include<br />

pedestal, portable base and<br />

overhead fixed or on trolleys.<br />

Standard or customized tooling<br />

and controls are available to meet<br />

your requirements.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Performance and Quality<br />

Features<br />

• Fits into work cells too small for larger<br />

material handling equipment.<br />

• Hydraulic and pneumatic models<br />

• Push-button metering valve or balance<br />

controls lift/lower for ease of operation<br />

• Hardened lift-section components for<br />

extended service life<br />

• Drag Brakes on 3 axes for personalized<br />

adjustment<br />

• End of arm rotating axis has: up to 12,000<br />

inch pounds of end of arm moment<br />

loading<br />

• Mounting options include pedestal,<br />

portable base and overhead mixed or on<br />

trolleys<br />

• Power/control unit remote mount for<br />

operation in explosive or clean room<br />

environments<br />

• Pneumatic is designed to be operated<br />

with clean and dry air<br />

• Precision bearing and thrust washers at<br />

joint for smooth motion and long life<br />

Safety Features<br />

• 5:1 design factor minimum on all structural<br />

components<br />

• Pilot operated lock valve on lift cylinder<br />

and gripper cylinders prevents vertical arm<br />

movement and loss of payload if supply<br />

pressure is interrupted<br />

• Gripper Safety Circuitry available.<br />

Prevents accidental release of<br />

unsupported parts<br />

14

Specifications for Standard Models Quality Profile<br />

Model Lifting Vertical Reach<br />

Capacity (lbs.)* Lift (in.) (in.)<br />

ATA-3** 300 24 72<br />

ATA-5** 500 24 72<br />

TTA-3*** 300 24 72<br />

TTA-5*** 500 24 72<br />

* Includes payload and tooling<br />

** Requires 90 psi air to operate at rated lift capacity<br />

*** Standard 110-volt AC at 20 amps<br />

Options available for extended lift and reach<br />

Tool allows for the automated<br />

transfer of tables and desktops<br />

with specially designed vacuum<br />

tool that allows product to be<br />

placed on a conveyor.<br />

A nickel alloy tool positions parts<br />

into a furnace during the heat<br />

treat process.<br />

Special gripper handles solid<br />

fuel rockets during test and<br />

assembly for defense project.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

The best positioning<br />

device package in the<br />

industry...only from<br />

<strong>Positech</strong><br />

<strong>Positech</strong> Manipulators perform<br />

functions no other equipment can<br />

handle. But the advantages of<br />

working with us extend far beyond<br />

the capabilities of the machines<br />

themselves. To assure quality and<br />

total customer satisfaction, we<br />

survey our customers frequently<br />

for input, always seeking to<br />

improve both our product and the<br />

way we do business. We believe<br />

that only by fully understanding<br />

our customers’ needs can we<br />

provide complete solutions for<br />

their material handling problems.<br />

Tool grips and manually rotates<br />

a handling basket used for<br />

plating 250 pound parts<br />

15

Articulated Jib Boom <br />

Maneuverability. Low Headroom<br />

Designed for low headroom<br />

operations and to maneuver<br />

around work-area obstructions,<br />

our standard models support up to<br />

2,000 pounds and allow 360º<br />

rotation around the main post.<br />

When low headroom prohibits<br />

space, the <strong>Positech</strong> Articulated Jib<br />

Boom could be the ideal solution.<br />

Maneuver around obstructions<br />

with a radial reach of 10 feet and<br />

360º rotation around the main<br />

post. Engineered to fit easily into<br />

any facility. The Articulated Jib<br />

Boom is an ergonomic<br />

replacement for the standard<br />

stiff-arm jibs. It mounts on<br />

pedestals, overhead spacers, wall<br />

or column flanges and portable<br />

bases. Extended reaches are<br />

available.<br />

Standard or customized tooling<br />

and controls are available to meet<br />

your requirements.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Performance and Quality<br />

Features<br />

• Highest standard capacity in the industry<br />

- up to 2,000 pounds<br />

• Angle-adjustable middle axis for better<br />

control of jib movement<br />

• Mounting options are available for Electric<br />

and Air Hoists, Pneumatic Balance Hoists<br />

and the Vertical Lift Cylinders<br />

• All joints are roller bearing mounted to<br />

minimize resistance to movement<br />

• Optional electric collector rings available<br />

to allow 360º continuous rotation when<br />

using an electric hoist<br />

• Precision bearings and thrust washers at<br />

joints for smooth motion and long life<br />

Safety Features<br />

• 5:1 design factor minimum on structural<br />

components<br />

16

Specifications for Standard Models<br />

Model** Maximum Moment Loading Example*<br />

(Reach x Total Payload)<br />

Allowed at Main Axes (in.-lbs.)<br />

AJB-40 24,000 200 lbs. @ 120 in.<br />

AJB-60 48,000 400 lbs. @ 120 in.<br />

AJB-90 72,000 600 lbs. @ 120 in.<br />

AJB-150 126,000 1,050 lbs. @ 120 in.<br />

AJB-200 156,000 1,300 lbs. @ 120 in.<br />

AJB-300 240,000 2,000 lbs. @ 120 in.<br />

* Reaches beyond 120 in. available<br />

** Custom jibs also available<br />

Hook mounted tool handling V-<br />

10 engine blocks through its<br />

various machining stages.<br />

Hook mounted tool grips and<br />

maneuvers large, engine wrist<br />

pins in the manufacturing<br />

process<br />

An AJB with an attached vertical<br />

lift cylinder.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Quality Profile<br />

Superior Service Manual<br />

<strong>Positech</strong> provides the most<br />

complete service manual in the<br />

industry. Compiled specifically for<br />

your machine and tooling, it<br />

contains full details on installation<br />

and start up, maintenance and<br />

trouble-shooting, plus operation<br />

and safety instructions. It also<br />

includes technical information for<br />

all major components and a<br />

complete list of parts with number<br />

for re-ordering convenience.<br />

Manufacturer’s name and part<br />

number are given for purchased<br />

components.<br />

AJB with hook mounted joist has<br />

the ability to handle a 1/4 ton<br />

weight capacity.<br />

17

Vertical Lift Cylinder<br />

Smooth. Flexible. Reach-In Capability<br />

With up to 6,000-pound capacity,<br />

<strong>Positech</strong>’s Vertical Lift Cylinder is<br />

ideal for straight line transfer,<br />

over-the-assembly line handling<br />

and reach-in operations when<br />

combined with overhead rail<br />

system or a <strong>Positech</strong> Articulated<br />

Jib Boom.<br />

The <strong>Positech</strong> V-Lift system is<br />

uniquely designed with a<br />

pneumatic of hydraulic lift cylinder.<br />

This lift cylinder provides smooth,<br />

controlled lift with the flexibility of<br />

off-center loading. Control<br />

circuits and auxiliary/optional<br />

components mount on the cylinder<br />

case, keeping the tooling and<br />

operator sight lines free of<br />

obstructions. The V-Lift can be<br />

mounted on a monorail trolley, a<br />

dual rail bridge, or on the <strong>Positech</strong><br />

Articulated Jib Boom.<br />

Standard or customized tooling<br />

and controls are available to meet<br />

your requirements.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Performance and Quality<br />

Features<br />

• Monorail, dual bridge system and<br />

<strong>Positech</strong> Articulated Jib mount options<br />

• Up to 400,000 inch pounds of off-center<br />

loading allows side uploading and reach in<br />

• Optional 360º continuous rotation around<br />

its vertical axis<br />

• Push button or twist-style up/down<br />

controls<br />

• Pneumatic includes air filter/regulator<br />

system. Does not require line lubrication<br />

• Standard flange plate bottom mounting for<br />

adaptability to a variety of special tooling<br />

• Pneumatic units require 90 psi clean dry<br />

input pressure. Hydraulic unit requires<br />

240/460 VAC single or three-phase power<br />

• Precision bearings and thrust washers at<br />

jonts for smooth motion and long life<br />

Safety Features<br />

• 5:1 design factor minimum on structural<br />

components<br />

• Pilot operated lock valved on lift cylinder<br />

and gripper cylinders prevent vertical arm<br />

movement and loss of payload in the<br />

event of a power loss<br />

• Gripper Safety Circuitry available.<br />

Prevents accidental release of<br />

unsupported parts<br />

• Narrow design lift assemblies minimize<br />

obstructions in the operator’s line of sight<br />

18

Specifications for Standard Models<br />

Model Lifting Maximum Moment Vertical<br />

Capacity (lbs.)* Load (in.-lbs.) Lift (in.)<br />

Lite Lift 400 0 24-48<br />

Pneumatic 2,500 24,000 12-72<br />

Hydraulic 6,000 400,000 12-72<br />

* Includes payload and tooling<br />

Power requirement: 90 psi clean, dry air or 220/440 VAC.<br />

Tool transfers packaged 150<br />

pound furniture products off end<br />

of assembly line.<br />

This Lite V-Lift with vacuum tool<br />

offers an economic solution for<br />

simple straight-line transfer.<br />

This specialized tool allows for<br />

the installation of 2,800 pound<br />

tires onto a tractor.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Quality Profile<br />

Your Own Personal<br />

Project Team<br />

All <strong>Positech</strong> Manipulators are<br />

designed, engineered and manu<br />

factured to your exact specifications.<br />

To assure continuity from<br />

concept to completion, your<br />

project is handled by a team<br />

including a field representative,<br />

sales engineer, design engineer,<br />

project coordinator and assembly<br />

technicians. Once your<br />

machinery is shipped, the team’s<br />

complete file - including a<br />

comprehensive history, all<br />

technical information and a<br />

duplicate manual - is turned over<br />

to the service team. Should you<br />

ever need assis tance, our service<br />

department can provide a rapid,<br />

well researched response.<br />

Simple hook tool transfers<br />

engine heads during the<br />

machining process.<br />

19

Reaction Arm ®<br />

Absorbs Shock. Decreases Injury.<br />

<strong>Positech</strong>’s ReactionArm absorbs<br />

shock, torsional forces, and<br />

impact force from power tools;<br />

therefore reducing carpal<br />

tunnel injury and cumulative<br />

trauma disorders.<br />

Cumulative trauma injuries cost<br />

the U.S. economy billions each<br />

year. The ReactionArm reduces<br />

injuries to workers’ wrists, arms<br />

and upper bodies by absorbing<br />

the shock of the attached power<br />

tool. A power tool mounted on a<br />

ReactionArm can be easily moved<br />

and positioned throughout the<br />

work cell. A variety of styles,<br />

capacities and mounting options<br />

provide versatility.<br />

Standard or customized tooling<br />

and controls are available to meet<br />

your requirements.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Performance and Quality<br />

Features<br />

• Balance configuration for “zero gravity”<br />

control<br />

• Variety of tool-holder designs and end<br />

joints available or special designs<br />

provided.<br />

• Three standards styles with various torque<br />

capacities, vertical working ranges and<br />

reach capacities, including tabletop and<br />

pit mount units<br />

• Incorporated into a work cell, <strong>Positech</strong> can<br />

provide appropriate work tools and stands<br />

• Vertical axis brakes available<br />

• Pilot-operated lock valves ensure arms<br />

will not drop the part<br />

• Can be used as a lightweight manipulator<br />

• Pneumatically operated requires 90 psi<br />

clean dry input pressure<br />

• Precision bearings and thrust washers at<br />

joints for smooth motion and long life<br />

Safety Features<br />

• 5:1 design factor minimum on allstructural<br />

components<br />

• Pilot operated lock valve on lift cylinder<br />

and gripper cylinders prevents vertical arm<br />

movement and loss of payload if supply<br />

pressure is interrupted<br />

• Gripper Safety Circuitry available when<br />

used as a lightweight manipulator.<br />

Prevents accidental release of<br />

unsupported parts<br />

20

Tabletop Unit - 50 Ft-Lbs Maximum Torque<br />

Lift Arm Lift Lift<br />

Length Height Capacity<br />

(inches) (inches) (pounds)<br />

21.5 21.5 60<br />

Standard main arm lengths available: 18 in. and 24 in.<br />

Requires 90 psi clean and dry air to operate at rated lift capacity<br />

Pit Mount Unit - 80 Ft-Lbs Maximum<br />

Torque<br />

Lift Arm Lift Lift<br />

Length Height Capacity<br />

(inches) (inches) (pounds)<br />

24.0 24.0 40.0<br />

30.0 30.0 30.0<br />

36.0 36.0 20.0<br />

Requires 90 psi clean and dry air to operate at rated lift capacity<br />

ReactionArm® - 850 Ft-Lbs Maximum Torque<br />

Lift Arm Lift RA-3P<br />

Length Height Lift Capacity<br />

(inches) (inches) (lbs.)<br />

36.0 20.4 235<br />

42.0 23.8 200<br />

48.0 27.3 165<br />

54.0 30.7 140<br />

60.0 34.1 120<br />

Standard main arm lengths available are 24 in., 30 in., 36 in.,<br />

42 in., 48 in., and 54 in.<br />

Requires 90 psi clean and dry air to operate at rated lift capacity<br />

Nut runner oriented UP to<br />

tighten fasteners on the under<br />

side of a vehicle.<br />

Tool positions and loads<br />

aluminum heads into a 5-axes<br />

machining center.<br />

Nut runner oriented DOWN to<br />

tighten fasters on an engine<br />

block.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

This seat handler allows<br />

worker’s easier handling of this<br />

70-pound seat into the final<br />

assembly of a car.<br />

21

World Manipulator <br />

Durable. Extended Reach<br />

The World Manipulator combines<br />

the strength of the Taurus and the<br />

agility of the SAM while incorpo-<br />

rating universally-accepted metric<br />

specifications for easy service and<br />

maintenance anywhere in the<br />

world. The World Manipulator is<br />

designed for low headroom<br />

applications that require extended<br />

reach and handles loads up to<br />

300 kilograms (660 lbs.)<br />

The World Manipulator is a strong,<br />

handy extension of the operator’s<br />

arm. It protects expensive<br />

payloads, speeds up handling and<br />

can reach long distances in<br />

headroom-restricted areas. The<br />

device’s side-loading feature<br />

allows the user to extend the<br />

tooling and payload well beyond<br />

the end of the arm while rotating<br />

360º around the arm.<br />

Standard or customized tooling<br />

and controls are available to meet<br />

your requirements.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Performance and Quality<br />

Features<br />

• Fits well in areas with low headroom<br />

• End of arm rotating axis is: up to 1130<br />

<strong>new</strong>ton-meters (10,000 inch-pounds) of<br />

end of arm moment loading and 360º<br />

full rotation<br />

• Drag brakes on 3 axes for personalized<br />

adjustment<br />

• Lubrication-free cylinders<br />

• Leveling jacks provided for ease of<br />

installation and leveling<br />

• For payload and tooling capacity of 100-<br />

200 kg (220-440 lbs.)<br />

• Pneumatic is designed to be operated<br />

with clean and dry air<br />

• Precision bearings and thrust washers at<br />

joints for smooth motion and long life<br />

Safety Features<br />

• 5:1 design factor minimum on all structural<br />

components<br />

• Pilot operated lock valve on lift cylinder<br />

and gripper cylinders prevents vertical arm<br />

movement and loss of payload if supply<br />

pressure is interrupted<br />

• Gripper Safety Circuitry available.<br />

Prevents accidental release of<br />

unsupported parts<br />

• Lost Load Cylinder is a separate, sealed<br />

hydraulic device that protects the<br />

operator from any sudden, uncontrolled<br />

vertical motion of the manipulator’s arm<br />

22

Specifications for Standard Models<br />

Lifting Vertical Minimum<br />

Model Capacity Lift Reach Overhead<br />

(kg. / lbs.) (mm. / in.) (mm. / in.) (mm. / in.)<br />

WM 200 200 / 440 1397 / 55 2921 / 115 2185 / 86<br />

WM 300 300 / 660 1397 / 55 2921 / 115 2185 / 86<br />

Requires 6.2 BAR (90 psi) clean and dry air to operate at rated lift capacity.<br />

This core gripper on a World<br />

Manipulator allow for easy<br />

handling of bulky rolls of paper,<br />

plastic and film in doffing, palletizing,<br />

and crating operations<br />

Tool grips transmission<br />

assemblies to place these<br />

assemblies into shipping crates.<br />

Tool grips porcelain insulators<br />

and positions these parts into a<br />

high voltage switchgear cabinet.<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Tool handles a 150-pound wheel<br />

hub assembly by gripping the<br />

inside diameter of the hub and<br />

orienting the hub to a tire rim<br />

23

Custom<br />

Engineered Tooling<br />

At <strong>Positech</strong>, we consider the<br />

tooling an essential element of<br />

every material handling solution.<br />

We realize the uniqueness of<br />

each application and strive to<br />

design our tooling accordingly.<br />

We do not try to fit your material<br />

handling problem into a pre-<br />

designed or standard tool. You<br />

work together with <strong>Positech</strong><br />

project team to design,<br />

manufacture, and integrate the<br />

tooling to a base manipulator.<br />

This procedure guarantees that<br />

the tooling is matched to the<br />

manipulator and that both operate<br />

to their fullest potential. The<br />

following pages show a small<br />

representation of the types of<br />

tooling we have already designed<br />

to solve a variety of material<br />

handling problems.<br />

Adjustable width fork tool Fork type tool, non-adjustable<br />

O.D. grip, 90º gripper rotation O.D. grip for high temperature applications<br />

O.D. cradle with pitch & tire roll Roll handler with 90º pitch<br />

Vacuum tool horizontal grip with reach in<br />

Multi-cup multi-box vacuum gripper<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

Vacuum tool vertical grip with rotation<br />

Flat and non-flat vacuum grippers for glass<br />

24

Manual scissors too<br />

Special purpose O.D. gripping<br />

Large range O.D. grip with jaw roll & tool roll<br />

Cabinet gripper with 90º pitch<br />

Highly specialized multi-cup grippers<br />

Trap tool<br />

Special purpose dual gripper tools<br />

Adjustable range I.D. and O.D. gripper<br />

Vacuum grippers for cylindrical shapes<br />

Vacuum head bag handler<br />

Trap tool with mechanical clamps<br />

Manual barrel handler for steel drums<br />

Small range O.D. grip for odd shaped parts<br />

Grippers for odd shapes with top to bottom rotation<br />

Vacuum head box handler<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

25

Magnet tools on a spreader bar<br />

Powered barrel handling for fiber, plastic, and steel<br />

Special O.D. gripping and positioning for assembly<br />

Special hook hung vacuum tools<br />

Specialized vacuum plates<br />

O.D. gripping, parallel jaw movement<br />

O.D. gripping, non-cylindrical shapes<br />

Fixed O.D. grip with pitch for positioning paint dryers<br />

Single vacuum cup box gripper<br />

Roll handler I.D. grip with pitching<br />

O.D. grip with adjustable grip range<br />

Vacuum plate box handler<br />

C-frame gripping with gripper rotation<br />

Multi-cup vacuum box gripper with rotation<br />

Hoist hung I.D. grip roll handler<br />

www.positech.com • 800-831-6026 • sales@positech.com<br />

26

191 North Rush Lake Road<br />

Laurens, IA 50554<br />

1-800-831-6026<br />

Fax: 712-841-4765<br />

E-mail: sales@positech.com<br />

Website: www.positech.com<br />

©2005 <strong>Positech</strong> Corporation<br />

All Rights Reserved<br />

WARNING! ARNING!<br />

TO AVOID INJURY:<br />

• All mechanical equipment must be<br />

installed, operated, and maintained<br />

properly.<br />

• Installation, maintenance and operation<br />

must be carried out as instructed in the<br />

manual provided with the equipment.<br />

• Do not use any <strong>Positech</strong> product for lifting<br />

people; special equipment is required for<br />

this purpose. Refer to ASME/ANSI A-17<br />

Series and applicable state and local<br />

codes for specific requirements.