G. Wei 2004)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

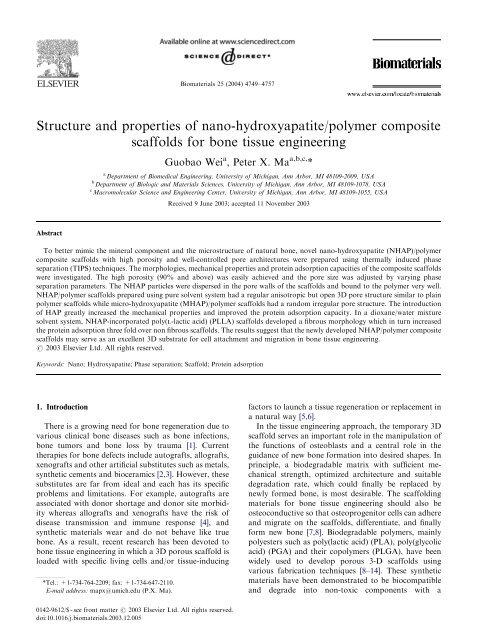

ARTICLE IN PRESS<br />

Biomaterials 25 (<strong>2004</strong>) 4749–4757<br />

Structure and properties of nano-hydroxyapatite/polymer composite<br />

scaffolds for bone tissue engineering<br />

Guobao <strong>Wei</strong> a , Peter X. Ma a,b,c, *<br />

a Department of Biomedical Engineering, University of Michigan, Ann Arbor, MI 48109-2009, USA<br />

b Department of Biologic and Materials Sciences, University of Michigan, Ann Arbor, MI 48109-1078, USA<br />

c Macromolecular Science and Engineering Center, University of Michigan, Ann Arbor, MI 48109-1055, USA<br />

Received 9 June 2003; accepted 11 November 2003<br />

Abstract<br />

To better mimic the mineral component and the microstructure of natural bone, novel nano-hydroxyapatite (NHAP)/polymer<br />

composite scaffolds with high porosity and well-controlled pore architectures were prepared using thermally induced phase<br />

separation (TIPS) techniques. The morphologies, mechanical properties and protein adsorption capacities of the composite scaffolds<br />

were investigated. The high porosity (90% and above) was easily achieved and the pore size was adjusted by varying phase<br />

separation parameters. The NHAP particles were dispersed in the pore walls of the scaffolds and bound to the polymer very well.<br />

NHAP/polymer scaffolds prepared using pure solvent system had a regular anisotropic but open 3D pore structure similar to plain<br />

polymer scaffolds while micro-hydroxyapatite (MHAP)/polymer scaffolds had a random irregular pore structure. The introduction<br />

of HAP greatly increased the mechanical properties and improved the protein adsorption capacity. In a dioxane/water mixture<br />

solvent system, NHAP-incorporated poly(l-lactic acid) (PLLA) scaffolds developed a fibrous morphology which in turn increased<br />

the protein adsorption three fold over non fibrous scaffolds. The results suggest that the newly developed NHAP/polymer composite<br />

scaffolds may serve as an excellent 3D substrate for cell attachment and migration in bone tissue engineering.<br />

r 2003 Elsevier Ltd. All rights reserved.<br />

Keywords: Nano; Hydroxyapatite; Phase separation; Scaffold; Protein adsorption<br />

1. Introduction<br />

There is a growing need for bone regeneration due to<br />

various clinical bone diseases such as bone infections,<br />

bone tumors and bone loss by trauma [1]. Current<br />

therapies for bone defects include autografts, allografts,<br />

xenografts and other artificial substitutes such as metals,<br />

synthetic cements and bioceramics [2,3]. However, these<br />

substitutes are far from ideal and each has its specific<br />

problems and limitations. For example, autografts are<br />

associated with donor shortage and donor site morbidity<br />

whereas allografts and xenografts have the risk of<br />

disease transmission and immune response [4], and<br />

synthetic materials wear and do not behave like true<br />

bone. As a result, recent research has been devoted to<br />

bone tissue engineering in which a 3D porous scaffold is<br />

loaded with specific living cells and/or tissue-inducing<br />

*Tel.: +1-734-764-2209; fax: +1-734-647-2110.<br />

E-mail address: mapx@umich.edu (P.X. Ma).<br />

factors to launch a tissue regeneration or replacement in<br />

a natural way [5,6].<br />

In the tissue engineering approach, the temporary 3D<br />

scaffold serves an important role in the manipulation of<br />

the functions of osteoblasts and a central role in the<br />

guidance of new bone formation into desired shapes. In<br />

principle, a biodegradable matrix with sufficient mechanical<br />

strength, optimized architecture and suitable<br />

degradation rate, which could finally be replaced by<br />

newly formed bone, is most desirable. The scaffolding<br />

materials for bone tissue engineering should also be<br />

osteoconductive so that osteoprogenitor cells can adhere<br />

and migrate on the scaffolds, differentiate, and finally<br />

form new bone [7,8]. Biodegradable polymers, mainly<br />

polyesters such as poly(lactic acid) (PLA), poly(glycolic<br />

acid) (PGA) and their copolymers (PLGA), have been<br />

widely used to develop porous 3-D scaffolds using<br />

various fabrication techniques [8–14]. These synthetic<br />

materials have been demonstrated to be biocompatible<br />

and degrade into non-toxic components with a<br />

0142-9612/$ - see front matter r 2003 Elsevier Ltd. All rights reserved.<br />

doi:10.1016/j.biomaterials.2003.12.005

4750<br />

ARTICLE IN PRESS<br />

G. <strong>Wei</strong>, P.X. Ma / Biomaterials 25 (<strong>2004</strong>) 4749–4757<br />

controllable degradation rate in vivo [15]. Another<br />

major class of biomaterials for bone repair is ceramics<br />

such as hydroxyapatite (HAP) and tricalcium phosphate<br />

(TCP) [16,17]. Being similar to the mineral component<br />

of natural bone, they showed good osteoconductivity<br />

and bone bonding ability [18]. However, the main<br />

limitation for the use of HAP ceramics was their<br />

inherent brittleness and difficulty for processing [19].<br />

To combine the osteoconductivity of calcium phosphates<br />

and good biodegradability of polyesters, polymer/ceramic<br />

composite scaffolds have been developed<br />

for bone tissue engineering either by direct mixing or by<br />

a biomimetic approach [7,8,20]. Compared to plain<br />

polymer scaffolds in which neo tissue matrix was formed<br />

only in the surface layer (o240 mm) [21], the composite<br />

scaffolds supported cells growth and neo tissue formation<br />

throughout the scaffold including in the very center<br />

of the scaffold [6].<br />

Polymer/ceramic composite scaffolds mimic the natural<br />

bone to some extent. Natural bone is composed of<br />

inorganic compound (mainly partially carbonated<br />

HAP on the nanometer scale) and organic compounds<br />

(mainly collagen). The nanometer size of the inorganic<br />

component (mainly bone-like apatite) in natural<br />

bone is considered to be important for the mechanical<br />

properties of the bone [22]. Recent research in this<br />

field also suggested that better osteoconductivity<br />

would be achieved if synthetic HAP could resemble<br />

bone minerals more in composition, size and<br />

morphology [23,24]. In addition, nano-sized HAP may<br />

have other special properties due to its small size and<br />

huge specific surface area. Webster et al. [25,26]<br />

have shown significant increase in protein adsorption<br />

and osteoblast adhesion on the nano-sized ceramic<br />

materials compared to traditional micron-sized ceramic<br />

materials.<br />

In previous works, the Ma group has developed a<br />

variety of scaffolds using thermally induced phase<br />

separation (TIPS) [8–10]. Both pore structure and pore<br />

wall morphology can be controlled by phase separation<br />

parameters. They have also demonstrated that the<br />

addition of micron-sized hydroxyapatite (MHAP) increase<br />

the adsorption of proteins and extracellular<br />

matrix (ECM) components [27]. The cell seeding<br />

uniformity into the scaffold was improved substantially<br />

due to the introduction of osteoconductive hydroxyapatite<br />

[6]. The MHAP/PLLA composite scaffolds were<br />

shown to suppress apoptosis of osteoblasts by a possible<br />

mechanism of enhanced adsorption of serum proteins<br />

such as vitronectin and fibronectin onto the scaffolds<br />

[27, 28]. In this paper, we further mimicked the size scale<br />

of hydroxyapatite in natural bone and aim to fabricate<br />

novel and improved composite scaffolds. The pore<br />

structure, pore wall morphology, mechanical properties<br />

and protein adsorption capacity were systematically<br />

investigated.<br />

2. Materials and methods<br />

2.1. Materials<br />

Poly(l-lactic acid) (PLLA) with an inherent viscosity<br />

of 1.4–1.8 dl/g was purchased from Boehringer Ingelheim<br />

(Ingelheim, Germany) and was used as received.<br />

PLGA85 (Medisorb s , LA:GA=85:15) with an inherent<br />

viscosity of 0.6 was obtained from Alkermes Inc.<br />

(Wilmington, OH). NHAP were purchased from Berkeley<br />

Advanced Biomaterials Inc. (San Leandro, CA).<br />

Conventional HAP particles (MHAP, particle size on<br />

the micrometer scale), tetrahydrofuran (THF), dioxane<br />

and benzene were obtained from aldrich chemical<br />

company (Milwaukee, WI).<br />

2.2. Fabrication method<br />

NHAP/PLLA composite scaffolds were fabricated<br />

using a phase separation technique similar to that<br />

reported previously [8]. Briefly, the HAP nanocrystal<br />

powder was dispersed in a solvent by sonication for 30 s<br />

at 15 W (Virsonic 100, Cardiner, NY). After that, PLLA<br />

was dissolved in the NHAP suspended solvent at about<br />

60 C to make homogeneous solutions with desired<br />

concentrations. 2.5 ml polymer/NHAP mixture was<br />

added into a Teflon vial, sonicated again and then<br />

transferred into a freezer at a preset temperature to<br />

induce solid–liquid or liquid–liquid phase separation.<br />

The solidified mixture was maintained at that temperature<br />

overnight and then transferred into a freeze-drying<br />

container which was maintained at a temperature<br />

between 5 C and 10 C by salt–ice bath for freezedrying.<br />

The samples were freeze-dried at 0.5 mmHg for 7<br />

days to remove solvent. The final composition of the<br />

composite foam was determined by the concentration of<br />

the polymer solution and NHAP content in the mixture.<br />

2.3. SEM characterization<br />

The porous morphologies of the scaffold were<br />

examined with scanning electron microscopy (SEM)<br />

(S-3200N, Hitachi, Japan) at 20 or 15 kV. The samples<br />

were cut by a razor blade or fractured after being frozen<br />

in liquid nitrogen for several minutes and then were<br />

coated with gold for 200 s using a sputter coater (Desk-<br />

II, Denton Vacuum Inc.).<br />

2.4. Porosity<br />

The melting behavior of the matrices was characterized<br />

with a differential scanning calorimeter (DSC-7, Perkin-<br />

Elmer, Norwalk, CT) as detailed previously [9]. The<br />

degree of crystallinity, X c , of a sample was calculated as<br />

X c ¼ DH m =DH 0 m ;

ARTICLE IN PRESS<br />

G. <strong>Wei</strong>, P.X. Ma / Biomaterials 25 (<strong>2004</strong>) 4749–4757 4751<br />

where DH m was the measured enthalpy of melting and<br />

DHm 0 was the enthalpy of melting for 100% crystalline<br />

polymer. For PLLA, DHm 0 ¼ 203:4 J=g: The estimated<br />

density and porosity of the matrix were obtained as<br />

follows. The diameter and height of the matrix were<br />

measured to calculate the volume. The mass of the matrix<br />

was measured with an analytical balance. The density was<br />

calculated from the volume and mass. The porosity, e;<br />

was calculated from the measured overall densities D m of<br />

the matrix and the skeletal density D s . For a composite<br />

scaffold, the skeletal density was determined using the<br />

densities of the polymer and HAP powder. The porosity<br />

was given by<br />

e ¼ D s D m<br />

;<br />

D s<br />

where D s was calculated from the following formula:<br />

1<br />

D s ¼<br />

;<br />

ð1 X h Þ=D p þ X h =D h<br />

where D h is the density of the HAP powder with a value<br />

of 3.16 g/ml and X h is the percentage of HAP in the<br />

composite while D p is the density of the polymer. D p was<br />

calculated from<br />

1<br />

D p ¼<br />

;<br />

ð1 X c Þ=D a þ X c =D c<br />

where X c was the degree of crystallinity of the polymer.<br />

The density of amorphous PLLA (D a ) is 1.248 g/ml and<br />

the density of 100% crystalline PLLA (D c ) is 1.290 g/ml.<br />

2.5. Mechanical properties<br />

The compressive mechanical properties of the scaffolds<br />

were tested using a MTS Synergie 200 mechanical<br />

tester (MTS systems Co. Eden Prairie, Minnesota). The<br />

scaffolds have dimensions of about 16 mm in diameter<br />

and 3 mm in thickness. A crosshead speed of 0.5 mm/<br />

min was used. The compressive modulus was defined as<br />

the initial linear modulus. At least five specimens were<br />

tested for each sample. The averages and standard<br />

deviations were graphed. A two-tail Student’s t-test<br />

(assuming equal variances) was performed to determine<br />

the statistical significance (po0.05) of the differences in<br />

mechanical properties.<br />

2.6. Protein adsorption<br />

Protein adsorption was performed by incubating the<br />

scaffolds in phosphate buffered saline (PBS, 0.1 m,<br />

pH=7.4) containing 2.5% or 5% fetal bovine serum<br />

(FBS). The disk-like specimens with dimensions of 15.5–<br />

16.5 mm in diameter and 370.1 mm in thickness were<br />

used. Before incubation in the medium containing<br />

proteins, the specimens were pretreated by ethanol for<br />

30 min and then washed by PBS three times overnight<br />

under gentle shaking. Specimens were then put into 24-<br />

well culture plates (one specimen for each well) and<br />

1.5 ml FBS/PBS solution was added into each well. The<br />

scaffolds were incubated at 37 C for a chosen incubation<br />

time. The concentration of the protein in the FBS/<br />

PBS solution was then quantified with a commercial<br />

protein assay kit, BCA (Pierce, Rockford, IL), using<br />

bovine serum albumin (BSA) standards. The amount of<br />

absorbed proteins was determined by subtracting the<br />

amount of proteins left in the FBS/PBS solution after<br />

adsorption from the amount of proteins in control FBS/<br />

PBS solution (without specimen) under the same<br />

incubation conditions.<br />

3. Results<br />

3.1. Porosity<br />

NHAP/polymer composite scaffolds with high porosity<br />

have been fabricated using thermally induced phase<br />

separation techniques (Tables 1 and 2). Two solvent<br />

systems were used to obtain composite scaffolds with<br />

different pore structures. One is a mono-solvent system<br />

of pure dioxane or benzene and the other, a solvent/nonsolvent<br />

mixture system of dioxane and water in different<br />

proportions. The densities and porosities of scaffolds are<br />

listed in Tables 1 and 2. Incorporation of nano-sized<br />

HAP only decreased the porosity slightly. This was<br />

especially true when NHAP content was low. Regardless<br />

of detailed morphology and composition, all scaffolds<br />

have a high porosity of at least 89%, which was<br />

considered to be beneficial for cell ingrowth and<br />

survival. The solvent system did not have much<br />

effect on the density and porosity. The quenching<br />

temperature did not affect the porosity significantly<br />

either (p=0.12).<br />

3.2. Morphology<br />

The morphology and microstructure of the scaffolds<br />

were examined using SEM (Fig. 1): micrographs of<br />

PLLA scaffolds (a,b), MHAP/PLLA (c,d) and NHAP/<br />

PLLA (e–h) composite scaffolds fabricated with pure<br />

Table 1<br />

Densities and porosities of NHAP/PLLA composite scaffolds prepared<br />

from dioxane solutions, phase separated at 18 C<br />

Scaffolds<br />

PLLA:HAP<br />

(w/w)<br />

D p<br />

(g/cm 3 )<br />

D s<br />

(g/cm 3 )<br />

Porosity<br />

(%)<br />

PLLA 100:0 1.2577 0.08812 93.0<br />

PLLA–NHAP 90:10 1.3383 0.09708 92.8<br />

PLLA–NHAP 70:30 1.5394 0.1176 92.3<br />

PLLA–NHAP 50:50 1.7993 0.1475 91.8<br />

PLLA–NHAP 30:70 2.1737 0.2304 89.4<br />

PLLA–MHAP 50:50 1.7993 0.1505 91.6

4752<br />

ARTICLE IN PRESS<br />

G. <strong>Wei</strong>, P.X. Ma / Biomaterials 25 (<strong>2004</strong>) 4749–4757<br />

Table 2<br />

Porosities of NHAP/PLLA scaffolds fabricated using dioxane/water mixture solvent system and phase separated at various temperatures<br />

Scaffolds PLLA:HAP (w/w) Dioxane:H 2 O (v/v) Quenching temp. ( C) Porosity (%)<br />

PLLA–NHAP 70:30 100:0 18 92.3<br />

PLLA–NHAP 70:30 95:5 18 91.6<br />

PLLA–NHAP 70:30 90:10 18 93.1<br />

PLLA–NHAP 70:30 87:13 4 94.5<br />

PLLA–NHAP 70:30 87:13 18 93.1<br />

PLLA–NHAP 70:30 87:13 70 92.8<br />

PLLA–NHAP 70:30 87:13 196 (LN 2 ) 92.5<br />

dioxane or benzene. NHAP/PLLA composite scaffolds<br />

maintained a regular internal ladder-like pore structure<br />

similar to plain PLLA scaffolds, a typical morphology<br />

formed by solid–liquid phase separation [8,10]. By<br />

controlling the heat transfer direction, NHAP/PLLA<br />

scaffolds with tubular pore architecture were also<br />

obtained using benzene as a solvent. Nano-sized HAP<br />

particles were distributed within the pore walls of the<br />

scaffolds and no large aggregates appeared in pores. In<br />

MHAP/PLLA scaffolds, the HAP platelets with size<br />

ranging from 10 to 50 mm were found randomly<br />

distributed in the PLLA matrix. Some were embedded<br />

in the pore wall and some others were piled together<br />

between pores or in the pores. The pore size of all these<br />

scaffolds ranged from 50 to 100 mm. NHAP/PLGA85<br />

composite scaffolds prepared with pure dioxane had<br />

leaf-like morphology and well-interconnected pore<br />

structures (Fig. 2).<br />

Very different morphologies appeared in composite<br />

scaffolds fabricated with dioxane and water mixture<br />

solvent system (Fig. 3). The proportion of water in the<br />

solvent systems had a significant effect on the pore size<br />

and overall morphology of the scaffold. Even a small<br />

amount of water (less than 5%) in the solvent system<br />

significantly reduced the pore size from 100 mm to about<br />

10 mm and random pore structure replaced the regular<br />

ladder-like pore structure (Figs. 3a, band c). Another<br />

obvious change was the pore wall surface texture.<br />

Unlike relative solid and smooth pore wall in NHAP/<br />

PLLA scaffold prepared from mono-solvent system,<br />

fibrous and loose network became the characteristics of<br />

the pore structure of the scaffolds prepared from the<br />

mixed solvent system. When the water volume was 13%<br />

in the mixture solvent, the scaffolds consisted of three<br />

ranges of pore sizes. Large macropores were developed<br />

in a range of 200–500 mm while much smaller micropores<br />

(tens of microns) between the pore walls of the<br />

large pores. The pore wall surface was not smooth, and<br />

appeared as loose fibrous structure with several microns<br />

in between. NHAP particles were entrapped in the<br />

fibrous network of the porous structures and had little<br />

effect on the changes in morphology with different water<br />

proportions since plain PLLA scaffolds had the same<br />

morphological changes (data not shown).<br />

3.3. Mechanical properties<br />

The compressive modulus of NHAP/PLLA scaffolds<br />

increased with NHAP content (Fig. 4). The plain PLLA<br />

scaffolds prepared using solid–liquid phase separation<br />

techniques had a compressive modulus of 4.3 MPa. The<br />

addition of NHAP into the scaffold improved the<br />

mechanical properties. The modulus increased significantly<br />

when the NHAP proportion reached 30% of the<br />

composite and reached 8.3 MPa when the ratio of<br />

NHAP to PLLA was 50:50. The solvent system had a<br />

large effect on the mechanical properties of the porous<br />

scaffolds (Fig. 5). The introduction of a non-solvent<br />

component (in this case, water) in the polymer/HAP/<br />

solvent mixture likely induced liquid–liquid phase<br />

separation instead of solid–liquid phase separation.<br />

Since regular and orientated pore architectures were<br />

replaced by random pore structures in scaffolds<br />

fabricated using mixed solvent system, the compressive<br />

modulus decreased significantly. However, the modulus<br />

recovered substantially when dioxane/water (87:13, v/v)<br />

system was used. This might have resulted from the<br />

uniform structure of the scaffolds (Figs. 3 d–f).<br />

3.4. Protein adsorption<br />

NHAP/PLLA composite scaffolds with different<br />

amounts of NHAP were incubated in FBS/PBS solution<br />

to investigate protein adsorption. For all NHAP/PLLA<br />

composite scaffolds, the protein adsorption reached<br />

equilibrium in 25 h and there was no significant increase<br />

of protein adsorption during further incubation<br />

(Fig. 6a). The addition of NHAP increased the protein<br />

adsorption. NHAP/PLLA 50:50 and NHAP/PLLA<br />

70:30 composite scaffolds absorbed 2.4- and 3.2-fold,<br />

respectively, more serum proteins than plain PLLA<br />

scaffold (Fig. 6b). The size of HAP particles also<br />

affected protein adsorption onto the scaffolds containing<br />

a high percentage of HAP. Serum protein adsorption<br />

was significantly greater on NHAP/PLLA scaffolds<br />

than on MHAP/PLLA scaffolds when the HAP/PLLA<br />

was 50:50 or higher (po0.05, Fig. 6c). However, when<br />

the ratio of HAP in the composite was lower than 50%,<br />

the differences in the protein adsorption between NHAP

ARTICLE IN PRESS<br />

G. <strong>Wei</strong>, P.X. Ma / Biomaterials 25 (<strong>2004</strong>) 4749–4757 4753<br />

Fig. 1. SEM micrographs of plain PLLA, NHAP/PLLA and MHAP/PLLA scaffolds fabricated from 5% dioxane (a–e) and benzene (f,g) solution.<br />

(a,b) Pure PLLA scaffold, 50, 400; (c,d) MHAP/PLLA 50:50 scaffold, 100, 500; (e,f) NHAP/PLLA 50:50 scaffold, 100, 1000;<br />

(g) Tubular NHAP/PLLA scaffold, cross-section, 200; (h) Tubular NHAP/PLLA scaffold, longitudinal section, 100.

4754<br />

ARTICLE IN PRESS<br />

G. <strong>Wei</strong>, P.X. Ma / Biomaterials 25 (<strong>2004</strong>) 4749–4757<br />

Fig. 2. SEM micrographs of NHAP/PLGA85 (30:70) scaffolds fabricated from 10% dioxane solution quenched at 70 C. (a) 150 and (b) 500.<br />

and MHAP incorporated scaffolds were not statistically<br />

significant. With the dramatic changes in morphology of<br />

scaffolds prepared using different solvent systems, the<br />

protein adsorption also changed greatly. Scaffolds with<br />

fibrous texture absorbed about four times greater<br />

amount of protein than those with smooth pore wall<br />

surface. These results suggested that the protein<br />

adsorption on the scaffolds could be regulated by the<br />

content of HAP, its size scale, and the pore wall<br />

morphology of the scaffolds.<br />

4. Discussion<br />

The present studies described a phase separation<br />

technique to fabricate polymer/NHAP-composite scaffolds<br />

with high porosity and controlled pore architecture.<br />

Different solvent systems were used to obtain<br />

scaffolds with different microarchitectures and properties.<br />

When dioxane was used alone, the porous structure<br />

resulted from a solid–liquid phase separation of the<br />

polymer solution. During quenching, the solvent crystallized<br />

and the polymer was expelled from the solvent<br />

crystallization front. Solvent crystals became pores after<br />

subsequent sublimation. The characteristics of the pores<br />

were determined by the morphologies of solvent crystals<br />

under such quenching conditions. The temperature<br />

gradient along the solvent crystallization direction led<br />

to anisotropic structure. The introduction of HAP<br />

particles into the polymer solution perturbed the solvent<br />

crystallization to some extent and thereby made the pore<br />

structure more irregular and isotropic. As expected,<br />

MHAP/PLLA composite scaffold exhibited an isotropic<br />

and irregular pore structure. The perturbation by<br />

NHAP particles, however, was small even in high<br />

proportion up to 50% due to their nanometer size scale<br />

and uniform distribution. As a result, NHAP/PLLA<br />

composite scaffolds maintained the main characteristic<br />

pore architecture of solid–liquid phase separation which<br />

was anisotropic and regular. In contrast to NHAP/<br />

PLLA, the regular anisotropic pore structure was<br />

obtained only when the HAP content was very low in<br />

MHAP/PLLA scaffolds, e.g., MHAP/PLLAo10/90<br />

(images not shown). In this case, low content of HAP<br />

did not affect the solvent crystallization significantly<br />

enough to alter the pore structure.<br />

When mixed solvent (dioxane/water) was used to<br />

prepare 5% PLLA solutions, a liquid–liquid phase<br />

separation was induced and this process dominated the<br />

final pore structure of the system [29], resulting in<br />

random and interconnected pore architecture. The pore<br />

size was also much smaller. With the increase of water<br />

content in the system, larger quench depth allowed the<br />

system to continue on a coarsening process to further<br />

reduce the interfacial free energy between two phases<br />

separated in earlier stage [30]. The coarsening effect<br />

might have resulted in the formation of macropores in<br />

addition to the micropores (Figs. 3d–f). It is therefore<br />

possible to optimize various phase separation parameters<br />

to achieve a macroporous structure in composite<br />

scaffold. The mechanism of fibrous texture formation is<br />

not fully understood. Since PLLA is a semicrystalline<br />

polymer, the crystallization in the polymer-rich phase<br />

may present a possible explanation for the formation of<br />

the fibrous structure [9].<br />

Most mammalian cells are anchorage-dependent cells<br />

and they need a biocompatible substrate for attachment,<br />

migration and differentiation to form new tissues.<br />

Recent research demonstrated that cell adhesion and<br />

survival could be modulated by protein pre-adsorption<br />

on the substrate [25–28]. Therefore, protein adsorption<br />

is of importance in evaluating a scaffold for tissue<br />

engineering. In this paper, we have shown that the<br />

addition of hydroxyapatite particles into the composite<br />

scaffolds greatly increased protein adsorption. In addition<br />

to the high affinity of hydroxyapatite itself for

ARTICLE IN PRESS<br />

G. <strong>Wei</strong>, P.X. Ma / Biomaterials 25 (<strong>2004</strong>) 4749–4757 4755<br />

Fig. 3. SEM micrographs of NHAP/PLLA (30:70) scaffolds fabricated using dioxane/water mixture solvents. (a) Dioxane:water=95:5, 500. (b,c)<br />

Dioxane:water=90:10, 500, 8000. (d,e,f) Dioxane:water=87:13, 45, 500, 10000.<br />

proteins, incorporation of HAP also altered the pore<br />

surface morphology of the composite scaffolds and may<br />

have made them more suitable for protein adsorption.<br />

Furthermore, NHAP/PLLA scaffold absorbed significantly<br />

more proteins than MHAP/PLLA at high HAP<br />

content but not at low HAP content. It was likely that<br />

most particles were embedded in the polymer pore walls<br />

and the effect of HAP size was not evident when the<br />

HAP content was low in the composite. With the<br />

increase of HAP content, more and more particles were<br />

exposed on the surfaces of the pore walls. This<br />

phenomenon was most evident when the scaffold<br />

exhibited fibrous morphology. Fibrous scaffolds had<br />

much greater surface to volume ratio than scaffolds with<br />

solid pore walls, which might have further increased the<br />

protein adsorption capacity.<br />

5. Conclusion<br />

The present study investigated new NHAP/polymer<br />

composite scaffolds developed using thermally induced<br />

phase separation techniques. Nano-sized HAP particles<br />

were successfully incorporated into the PLLA porous

4756<br />

ARTICLE IN PRESS<br />

G. <strong>Wei</strong>, P.X. Ma / Biomaterials 25 (<strong>2004</strong>) 4749–4757<br />

scaffolds. The incorporation of NHAP improved the<br />

mechanical properties and protein adsorption of the<br />

composite scaffolds while maintaining high porosity and<br />

suitable microarchitecture. These results suggest that the<br />

newly developed NHAP/polymer composite scaffolds<br />

may be superior for bone tissue engineering.<br />

Fig. 4. Effects of NHAP content on the compressive modulus of<br />

NHAP/PLLA scaffolds fabricated from 5% dioxane solutions<br />

% po0.05, w p=0.29, n=5.<br />

Fig. 5. Effects of mixture solvent composition and quenching<br />

temperature on the compressive moduli of NHAP/PLLA scaffolds<br />

fabricated from 5% dioxane/water solvent systems.<br />

Fig. 6. Protein adsorption on porous composite scaffolds incubated in<br />

FBS/PBS solution. (a) as a function of time, 2.5% FBS/PBS, labels<br />

indicate the w/w ratios of NHAP to PLLA; (b) as a function of NHAP<br />

content, 2.5% FBS; (c) Comparison of MHAP and NHAP, 5.0% %<br />

FBS/PBS. po0.05, w p=0.71, n=3. (d) Comparison of NHAP/PLLA<br />

(30:70) scaffolds prepared using different solvent systems, 2.5% %<br />

FBS/PBS. po0.05, n=3.

ARTICLE IN PRESS<br />

G. <strong>Wei</strong>, P.X. Ma / Biomaterials 25 (<strong>2004</strong>) 4749–4757 4757<br />

References<br />

[1] Braddock M, Houston P, Campbell C, Ashcroft P. Born again<br />

bone: tissue engineering for bone repair. News Physiol Sci<br />

2001;16:208–13.<br />

[2] Goldberg VM, Stevenson S. Natural history of autografts and<br />

allografts. Clin Orthop 1987;225:7–16.<br />

[3] Costantino PD, Friedman CD. Synthetic bone graft substitutes.<br />

Otolaryngol Clin North Am 1994;27:1037–74.<br />

[4] Bonfiglio M, Jeter WS. Immunological responses to bone. Clin<br />

Orthop 1972;87:19–27.<br />

[5] Langer R, Vacanti JP. Tissue engineering. Science 1993;260:920–6.<br />

[6] Ma PX, Zhang R, Xiao G, Franceschi R. Engineering new bone<br />

tissue in vitro on highly porous poly(alpha-hydroxyl acids)/<br />

hydroxyapatite composite scaffolds. J Biomed Mater Res<br />

2001;54:284–93.<br />

[7] Zhang R, Ma PX. Porous poly(l-lactic acid)/apatite composites<br />

created by biomimetic process. J Biomed Mater Res 1999;45:285–93.<br />

[8] Zhang R, Ma PX. Poly(alpha-hydroxyl acids)/hydroxyapatite<br />

porous composites for bone tissue engineering. I. Preparation and<br />

morphology. J Biomed Mater Res 1999;44:446–55.<br />

[9] Ma PX, Zhang R. Synthetic nano-scale fibrous extracellular<br />

matrix. J Biomed Mater Res 1999;46:60–72.<br />

[10] Ma PX, Zhang R. Micro-tubular architecture of biodegradable<br />

polymer scaffolds. J Biomed Mater Res 2001;56:469–77.<br />

[11] Mikos AG, Thorsen AJ, Czerwonka LA, Bao Y, Langer R,<br />

Winslow DN, Vacanti JP. Preparation and characterization of<br />

poly(l-lactic acid) foams. Polymer 1994;35:1068–77.<br />

[12] Whang K, Thomas CH, Healy KE, Nuber G. A novel method to<br />

fabricate bioabsorbable scaffolds. Polymer 1995;36:837–42.<br />

[13] Mooney DJ, Baldwin DF, Suh NP, Vacanti JP, Langer R. Novel<br />

approach to fabricate porous sponges of poly(d,l-lactic-coglycolic<br />

acid) without the use of organic solvents. Biomaterials<br />

1996;17:1417–22.<br />

[14] Borden M, Attawia M, Laurencin CT. The sintered microsphere<br />

matrix for bone tissue engineering: in vitro osteoconductivity<br />

studies. J Biomed Mater Res 2002;61:421–9.<br />

[15] Visscher GE, Robison RL, Maulding HV, Fong JW, Pearson JE,<br />

Argentieri GJ. Biodegradation of and tissue reaction to 50:50<br />

poly(DL-lactide-co-glycolide) microcapsules. J Biomed Mater Res<br />

1985;19:349–65.<br />

[16] Li SH, De Wijn JR, Layrolle P, de Groot K. Synthesis of<br />

macroporous hydroxyapatite scaffolds for bone tissue engineering.<br />

J Biomed Mater Res 2002;61:109–20.<br />

[17] Flautre B, Descamps M, Delecourt C, Blary MC, Hardouin P.<br />

Porous HA ceramic for bone replacement: role of the pores and<br />

interconnections—experimental study in the rabbit. J Mater Sci-<br />

Mater Med 2001;12:679–82.<br />

[18] LeGeros RZ. Properties of osteoconductive biomaterials: calcium<br />

phosphates. Clin Orthop 2002;395:81–98.<br />

[19] Cooke FW. Ceramics in orthopedic surgery. Clin Orthop<br />

1992;276:135–46.<br />

[20] Thomson RC, Yaszemski MJ, Powers JM, Mikos AG. Hydroxyapatite<br />

fiber reinforced poly(alpha-hydroxy ester) foams for<br />

bone regeneration. Biomaterials 1998;19:1935–43.<br />

[21] Ishaug SL, Crane GM, Miller MJ, Yasko AW, Yaszemski MJ,<br />

Mikos AG. Bone formation by three-dimensional stromal<br />

osteoblast culture in biodegradable polymer scaffolds. J Biomed<br />

Mater Res 1997;36:17–28.<br />

[22] Rho JY, Kuhn-Spearing L, Zioupos P. Mechanical properties<br />

and the hierarchical structure of bone. Med Eng Phys 1998;20:<br />

92–102.<br />

[23] Du C, Cui FZ, Zhu XD, de Groot K. Three-dimensional nano-<br />

HAp/collagen matrix loading with osteogenic cells in organ<br />

culture. J Biomed Mater Res 1999;44:407–15.<br />

[24] Du C, Cui FZ, Feng QL, Zhu XD, de Groot K. Tissue response<br />

to nano-hydroxyapatite/collagen composite implants in marrow<br />

cavity. J Biomed Mater Res 1998;42:540–8.<br />

[25] Webster TJ, Ergun C, Doremus RH, Siegel RW, Bizios R.<br />

Specific proteins mediate enhanced osteoblast adhesion on<br />

nanophase ceramics. J Biomed Mater Res 2000;51:475–83.<br />

[26] Webster TJ, Siegel RW, Bizios R. Osteoblast adhesion on<br />

nanophase ceramics. Biomaterials 1999;20:1221–7.<br />

[27] Woo KM, Zhang R, Deng H, Ma PX. Protein-mediated<br />

osteoblast survival and migration on biodegradable<br />

polymer/hydroxyapatite composite scaffolds. Transaction of the<br />

28th Annual Meeting of the Society for Biomaterial, vol. 605,<br />

2002.<br />

[28] Woo KM, <strong>Wei</strong> G, Ma PX. Enhancement of fibronectin- and<br />

vitronectin-adsorption to polymer/hydroxyapatite scaffolds suppresses<br />

the apoptosis of osteoblasts. J Bone Miner Res<br />

2002;17(Suppl 1):M49.<br />

[29] Zhang R, Ma PX. Processing of polymer scaffolds: phase<br />

separation. In: Atala A, Lanza R, editors. Methods of tissue<br />

engineering. San Diego, CA: Academic Press; 2001. p. 715–24.<br />

[30] Nam YS, Park TG. Porous biodegradable polymeric scaffolds<br />

prepared by thermally induced phase separation. J Biomed Mater<br />

Res 1999;47:8–17.