The 2006 Supplier Directory - Orthoworld

The 2006 Supplier Directory - Orthoworld

The 2006 Supplier Directory - Orthoworld

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

LOGISTICS<br />

RFID Technology, continued from page 21<br />

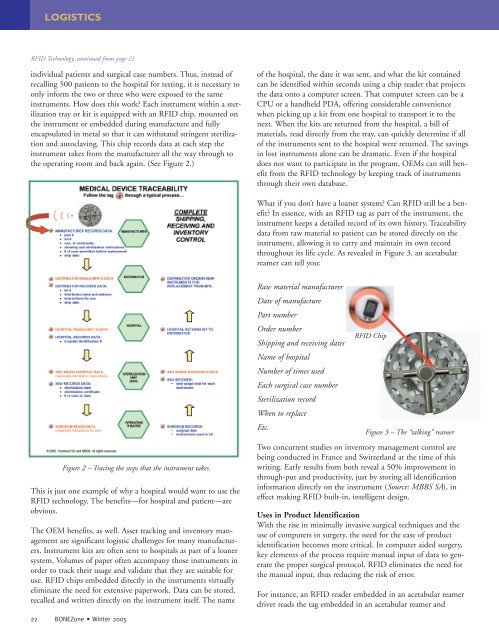

individual patients and surgical case numbers. Thus, instead of<br />

recalling 500 patients to the hospital for testing, it is necessary to<br />

only inform the two or three who were exposed to the same<br />

instruments. How does this work? Each instrument within a sterilization<br />

tray or kit is equipped with an RFID chip, mounted on<br />

the instrument or embedded during manufacture and fully<br />

encapsulated in metal so that it can withstand stringent sterilization<br />

and autoclaving. This chip records data at each step the<br />

instrument takes from the manufacturer all the way through to<br />

the operating room and back again. (See Figure 2.)<br />

Figure 2 – Tracing the steps that the instrument takes.<br />

This is just one example of why a hospital would want to use the<br />

RFID technology. <strong>The</strong> benefits—for hospital and patient—are<br />

obvious.<br />

<strong>The</strong> OEM benefits, as well. Asset tracking and inventory management<br />

are significant logistic challenges for many manufacturers.<br />

Instrument kits are often sent to hospitals as part of a loaner<br />

system. Volumes of paper often accompany those instruments in<br />

order to track their usage and validate that they are suitable for<br />

use. RFID chips embedded directly in the instruments virtually<br />

eliminate the need for extensive paperwork. Data can be stored,<br />

recalled and written directly on the instrument itself. <strong>The</strong> name<br />

22 BONEZone • Winter 2005<br />

of the hospital, the date it was sent, and what the kit contained<br />

can be identified within seconds using a chip reader that projects<br />

the data onto a computer screen. That computer screen can be a<br />

CPU or a handheld PDA, offering considerable convenience<br />

when picking up a kit from one hospital to transport it to the<br />

next. When the kits are returned from the hospital, a bill of<br />

materials, read directly from the tray, can quickly determine if all<br />

of the instruments sent to the hospital were returned. <strong>The</strong> savings<br />

in lost instruments alone can be dramatic. Even if the hospital<br />

does not want to participate in the program, OEMs can still benefit<br />

from the RFID technology by keeping track of instruments<br />

through their own database.<br />

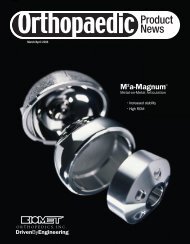

What if you don’t have a loaner system? Can RFID still be a benefit?<br />

In essence, with an RFID tag as part of the instrument, the<br />

instrument keeps a detailed record of its own history. Traceability<br />

data from raw material to patient can be stored directly on the<br />

instrument, allowing it to carry and maintain its own record<br />

throughout its life cycle. As revealed in Figure 3, an acetabular<br />

reamer can tell you:<br />

Raw material manufacturer<br />

Date of manufacture<br />

Part number<br />

Order number<br />

Shipping and receiving dates<br />

Name of hospital<br />

Number of times used<br />

Each surgical case number<br />

Sterilization record<br />

When to replace<br />

Etc.<br />

RFID Chip<br />

Figure 3 – <strong>The</strong> “talking” reamer<br />

Two concurrent studies on inventory management control are<br />

being conducted in France and Switzerland at the time of this<br />

writing. Early results from both reveal a 50% improvement in<br />

through-put and productivity, just by storing all identification<br />

information directly on the instrument (Source: MBBS SA), in<br />

effect making RFID built-in, intelligent design.<br />

Uses in Product Identification<br />

With the rise in minimally invasive surgical techniques and the<br />

use of computers in surgery, the need for the ease of product<br />

identification becomes more critical. In computer aided surgery,<br />

key elements of the process require manual input of data to generate<br />

the proper surgical protocol. RFID eliminates the need for<br />

the manual input, thus reducing the risk of error.<br />

For instance, an RFID reader embedded in an acetabular reamer<br />

driver reads the tag embedded in an acetabular reamer and