Final Program - Omtec

Final Program - Omtec

Final Program - Omtec

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

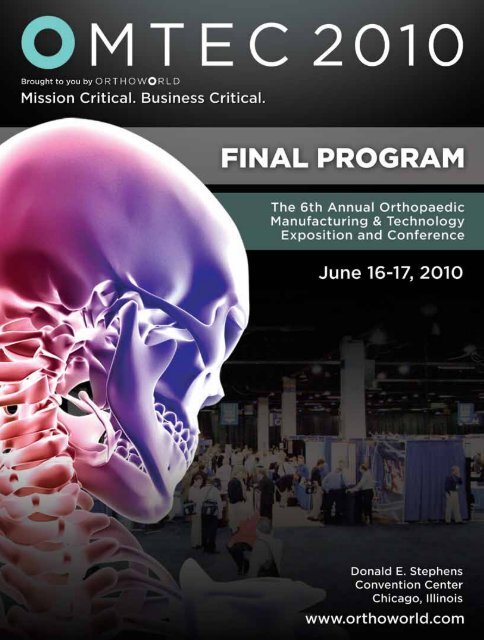

<strong>Final</strong> <strong>Program</strong>Table of ContentsLetter to Attendees.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Advisory Panel .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Schedule of Events. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Attendee Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Addresses, Educational Sessions and Workshops. . . . . . . . . . . . . . . . . . . . . . . . 10Index of Exhibitors by Capability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28Floor Plan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32Sponsors .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34Exhibitor Listing.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35Front Cover: 3D CAD data and imagery provided by Zygote Media Group, Inc. www.3dscience.com2010Page 3

<strong>Final</strong> <strong>Program</strong>WelcomeDear OMTEC Attendee,Thank you for choosing to join us for year six of OMTEC!You are here because you know that investments in brainpower and personal relationshipsyield return. Our mission is to provide access to the intelligence, the expertise, the people andthe companies that will help you overcome your most critical challenges, identify the mostlucrative opportunities and excel. A crucial component of that mission is weeding out thehype and the fluff. OMTEC is serious business. In a nutshell, here’s how it shakes down.Education (experts only; relevant, vital topics only) – Knowledge BuildingReception and Exhibit Floor (superior, “in tune” exhibitors) – Relationship BuildingKnowledge + Relationships = VictoryUse the pages of this program to prioritize your booth visits and educational sessions. Notethat we provide food for fuel to alleviate your having to burn valuable time and dollarstrekking down the street or across town. Do plan to attend the Welcome Reception onWednesday afternoon from 4:00 to 6:00 p.m. in the exhibit hall…previous attendees willaffirm, business gets done.Remember that you can grab any of us during the conference for assistance of any kind. Ourteam is always present in the ORTHOWORLD booth or the registration area. Don’t waste amoment wondering if we might know or be able to help…just ask.Thank you again for choosing OMTEC. On behalf of the entire ORTHOWORLD team, wewish you a productive and enlightening meeting.Best regards,April C. BrightGeneral ManagerORTHOWORLD Inc.Page 42010

<strong>Final</strong> <strong>Program</strong>Schedule Of EventsPage 62010

<strong>Final</strong> <strong>Program</strong>Schedule Of EventsPlease note, presentations and handouts are available for download at www.orthoworld.com. You can make use ofthis resource immediately, or look for an email notification following the event.2010Page 7

<strong>Final</strong> <strong>Program</strong>Attendee ResourcesEXHIBIT FLOOR HOURSThe exhibit floor is open 9:00 am to 6:00 p.m. on Wednesday (the last two hours serving as the Welcome Reception withcomplimentary drinks and hors d’oeuvres) and 9:00 a.m. to 4:00 p.m. on Thursday. No sessions are scheduled during thefollowing times:Wednesday: 9:00 to 9:30 a.m., 12:00 to 1:30 p.m., 4:00 to 6:00 p.m.Thursday: 9:00 to 9:30 a.m., 3:30 to 4:00 p.m.PRESENTATION AVAILABILITYOMTEC speakers have agreed to make their presentations available online at www.orthoworld.com. You may visit thisarea for a limited time and download those presentations of interest to you and your colleagues. We will remind all attendeesof this resource via email following the event.EMAIL KIOSKSTwo email stations are available on the show floor for all attendees to use. The kiosks are located in the northwest andsoutheast corners of the exhibit floor.MEALSAs is customary at OMTEC, a full hot breakfast will be served both mornings and a complete lunch will be served both afternoons,with catered snacks and beverages in between. Adult beverages and hors d’oeuvres will be served at the Welcome Reception heldon the exhibit floor on Wednesday from 4:00 to 6:00 p.m. All meals are included with your full registration.THE ORTHOWORLD TEAMMembers of ORTHOWORLD’s staff will be available in our booth located near the southeast corner of the exhibit floor.Additionally, our conference-planning associates are also wearing staff shirts to ensure they stand out to best serve you.HOTEL INFORMATIONHyatt Regency O’Hare9300 Bryn Mawr AvenueRosemont, IL 60018847-696-1234 (phone)847-698-0139 (fax)Doubletree Hotel O’Hare-Rosemont5460 North River RoadRosemont, IL 60018847-292-9100 (phone)847-292-9295 (fax)ROSEMONT AREA INFORMATIONRosemont Chamber of Commerce, 847-698-1190 or www.rosemontchamber.comPage 82010

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/WorkshopsLecture: Intellectual Property Audits and theCritical Role of R&D Engineers in the ProcessJohn W. Boger, Esq.Associate, Heslin Rothenberg Farley & Mesiti P.C.Wednesday, June 1611:00 a.m. – 12:00 p.m.This session will review the various aspects of and goals forperforming an intellectual property (IP) audit. We will investigatehow to plan, implement, value and evaluate the results, as wellas discuss the pros and cons of various audit deliverables.We will address:• y Business units that should participate in the audit• y Distinct goals for each of these business units• y Different approaches used for the different types ofIP assets• y Planning and implementation• y End-game of the auditAttendees will receive these tools to put to immediate use:• y An outline for planning an IP audit• y How to implement the audit process• y How to design and develop an IP asset valuation grid• y What to do with the deliverables• y How to generate alternative revenue streams fromthe results of the IP auditBIO: John W. Boger is an associate with Heslin RothenbergFarley & Mesiti P.C., a law firm dedicated exclusively to thepractice of Intellectual Property Law. Mr. Boger is a memberof the firm’s Medical Products and Technology practicegroup. His practice focuses on patent prosecution, draftinglegal opinions, conducting due diligence investigations andnegotiating various licensing and technology developmentagreements in the medical device field.Mr. Boger graduated cum laude from Syracuse UniversityCollege of Law. He also received, cum laude, a Bachelor ofScience degree in Bioengineering from Syracuse Universityand a Master of Science degree in Bioengineering from theUniversity of Utah. Prior to joining Heslin Rothenberg Farley& Mesiti P.C., Mr. Boger was in-house in the role of SeniorCounsel to Capital District Physicians’ Health Plan, Inc.Prior to attending law school, Mr. Boger worked for eightyears at a large orthopaedic device company as a productdevelopment engineer and product manager specializing inorthopaedic implant design. He also worked for an advancedbiomaterials joint venture in the role of venture projectmanager, focusing on the development and commercializationof advanced implantable biomaterials. He is admitted topractice in New York and is registered to practice before theUnited States Patent and Trademark Office.Lecture: Preclinical Testing Methodologies forOrthopaedic Spinal ProductsBryan W. Cunningham, MSc.Orthopaedic Spinal Research LaboratoryWednesday, June 161:30 p.m. – 2:45 p.m.This lecture will address the following:In Vitro Biomechanical Cadaveric Models and Testing Strategies- Biomechanical testing methodologies of dynamic spinalstabilization and arthrodesis based spinal devices will bepresented with an emphasis on preclinical strategies - cervicaland lumbar. These will include:• y Total disc arthroplasty• y Posterior dynamic stabilization• y Nucleoplasty• y Annular repair devices• y Anterior and posterior arthrodesis implantsIn Vivo Animal Modeling - Biological and Radiological - Arange of animal models from NZW rabbits through non-humanprimates will be presented as preclinical testing platformsto assess efficacy and safety of new biomaterials, biologictherapies and implantable spinal devices, including:• y Neurotoxicity models• y Total disc arthroplasty — cervical and lumbar spine• y Posterior dynamic stabilization• y Nucleoplasty• y Interbody arthrodesis — cervical and lumbar• y Posterolateral arthrodesis models — lumbar• y Stem cell therapiesResearch centers of excellence (Contract Research Organizationsor CROs) will be included for each topic presented.Attendees will receive these tools to put to immediate use:• y Functional cadaveric modeling and experimentalendpoints• y Functional animal modeling and experimental assaysfor consideration• y Perspectives from Laboratory Testing Facilities and aCRO on what FDA considers to be importantBIO: Bryan Cunningham is Director of Spinal Research atthe Orthopaedic Spinal Research Laboratory. He also holdsthe positions of Associate Professor, Orthopaedic ResearchLaboratories at the Johns Hopkins University School of Medicineand Professor of Orthopaedic Research at the Tianjin MedicalUniversity General Hospital. He has authored numerous articlesin peer-reviewed journals including Spine, the Journal of Bone andJoint Surgery, Foot and Ankle International Journal, The AmericanJournal of Sports Medicine, etc., and has authored numerous bookchapters on the spine. Bryan received his undergraduate degreeat Towson University and completed his graduate work inneuroscience at The Johns Hopkins University.Page 102010

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/WorkshopsLuncheon Keynote Address:Orthopaedics in the Post-reform EnvironmentJohn A. Engelhardt, MS, FAIMBEManaging Member, Knowledge Ventures, LLCThursday, June 1712:30 p.m. – 1:15 p.m.The business of orthopaedics will operate under distinctlydifferent conditions in the post-reform environment. Indeed,new success criteria as well as a new set of decisionmakers willhelp dictate the direction of technology and treatment. Successfulcompanies of the future will be those that best understand thesedynamics and adjust their operating systems to address them.This presentation will identify these conditions and describe theimpact, as well as the opportunity that lies within them.This session will address these specific points :• y What effect does reform have on the overall businessmodel and metrics?• y What is the direct impact on R&D and operations?• y How does this impact the R&D/marketing relationship?Attendees will receive these tools to put to immediate use:• y How to identify technologies that will be mostembraced by the system• y How to identify the technology needs of the “new”decisionmakers• y How you can create the most value to yourorganization and best fulfill your company’s goals• y How to identify key new skills your team will need todevelopBIO: John A. Engelhardt is a Managing Member of KnowledgeVentures, LLC, a venture capital firm focused on themusculoskeletal industry, and is the Chief Executive Officerof ORTHOWORLD Inc. A former executive of AcroMedCorporation and DePuy, Mr. Engelhardt is a futurist andrecognized authority on technology trends in orthopaedics.He holds 19 patents covering large and small joints, spine andtrauma.Mr. Engelhardt managed design teams in the early days of discreplacement and ironically, more than a decade later, becamethe first American to receive what is now known as the Prestigecervical disc prior to its release in the U.S.He has published hundreds of articles in the academic andpopular press, is Editor-in-Chief of ORTHOPRENEUR, and is afrequently requested speaker at industry events.Mr. Engelhardt received his Bachelor of Science degree inMechanical Engineering from Virginia Polytechnic Institute andState University, a Masters in Bioengineering from Louisiana TechUniversity and performed post-graduate biomechanics research atLSU Medical Center. Mr. Engelhardt is a Member of the College ofFellows, American Institute for Medical and Biological Engineering.Breakfast Keynote Address:Orthopaedics in the New DecadeShirley A. EngelhardtManaging Member, Knowledge Ventures, LLCWednesday, June 168:00 a.m. – 8:45 a.m.Shirley Engelhardt will discuss the dynamics of the globalorthopaedic marketplace and their impact on the market’s healthin the coming decade. Her presentation will include a discussionof shifts in market growth, competition, delivery and type ofhealthcare, providers and payers, governmental and privateoversight and regulatory and reimbursement environmentsworldwide as well as opportunities and barriers that may arisefor manufacturers, their customers and suppliers.This session will address these specific points:• y Market drivers into the future• y Companies’ potential reactions to healthcare,regulatory and reimbursement initiatives• y How healthcare reform in the U.S. and changes tohealthcare systems outside the U.S. may affect theglobal orthopaedic industry, its players and payersAttendees will receive these tools to put to immediate use:• y An understanding of global market dynamics – sales,demographics, procedures, growth, etc.• y An understanding of key market trends and theirpotential effect on market growth• y An understanding of key players, payers andproviders and how they might work together in achallenging environmentBIO: Shirley A. Engelhardt is President and Founder ofORTHOWORLD Inc. and a Managing Member of KnowledgeVentures, LLC, a venture capital firm solely focused onorthopaedic investments. Mrs. Engelhardt is the world’sforemost authority on the global orthopaedic markets and hasauthored thousands of articles on current and emerging trends,market dynamics and factors affecting the markets. She hasaccurately predicted nearly every major market trend of thepast decade, while developing an international client base ofhundreds of public and private entities.Prior to founding ORTHOWORLD, Mrs. Engelhardt wasDirector of Market Research and Strategic Services for DePuyand Director of Marketing for the technology transfer arm ofCase Western University. She holds a Bachelor of Arts degree inFrench from Virginia Polytechnic Institute and State Universityand a Master of Business Administration from The LouisianaTech School of Management.Page 122010

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/WorkshopsWorkshop: QSR Design Controls: Concept andFeasibility to CommercializationJohn GagliardiPresident, MidWest Process Innovation, LLCWednesday, June 169:30 a.m. – 12:00 p.m.• y Good documentation practices related to design andancillary, supporting processesThe key to this workshop will, of course, be the interactiveparticipation of the attendees with each other and the presenter,i.e. when discussing the benchmarking tool.The goal of this session is to effectivelyenable participants to understandhow medical devices are developedusing design controls and to realizethe appropriately linked processes in aregulated industry.Using an actual example of a simpleorthopaedic instrument, participantswill “process step” a device conceptthrough design controls and post-designcommercialization scenarios. Real-life,after-market issues will be presentedin terms of possibly influencing theoriginal design and addressing the crossfunctional processes that are necessarilyaffected, e.g. production and processcontrol, quality assurance, regulatoryaffairs, purchasing controls, marketingand sales, document control/qualityrecords, risk management, etc.We will address these specific points:• y User needs — design inputs• y Design outputs• y Cross-functional thinkingand team logistics — designreviews• y Design verification —acceptance criteria and relatedactivities• y Design changes• y Design transfer tomanufacturing• y The design history file —dynamic interaction andcomplianceAttendees will receive tools to put toimmediate use; for instance, the processof design that will show how to generate:• y Real-time deliverables using adesign matrix• y Objective evidence relating toregulatory complianceWe Make Orthopedic ImplantsUsing State-of-the-art Technology- Multi-axis milling- Swiss and conventional turning- 6-axis high precision automaticcutter grinding- Laser weldingWe Make Impossible PartsISO 9001:2008 Certified and ISO 13485:2003 Certified2010Page 13

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/WorkshopsWorkshop: Measurement, Analysis & ChangeControl: The Process Approach to Handling Nonconformances,Feedback, Changes and PossibleHigh-risk ScenariosThursday, June 179:30 a.m. – 12:00 p.m.This session will start by addressing the processes in yourQuality Management System that are used to capture internalas well as external non-conformances and feedback, e.g.complaints, audit findings, adverse events, product failures,process aberrations, etc. Then we will discuss the various waysto handle these results in terms of ensuing changes that couldoccur. Because of this positive and negative feedback, changecontrol must be an integral part of any Quality ManagementSystem. This session is scenario-driven with real life examples,and attendee interaction is the basis for learning what is beingdone when these types of resulting issues are realized.We will address these specific points:• y Installing and implementing a Quality Review Boardas a conduit for further actions• y Using and developing metrics and measurement forManagement Review Sessions• y Controlling change to minimize uncertainties in theQuality Management System• y Listening to customer feedback and understandingwhy complaints are “a gift”• y Implementing the process architecture and linkedrelationships for measuring, analyzing andimproving GMP and ISO-related systems.Attendees will receive these tools to put to immediate use:• y How to develop a Quality Review Board and thelogistics for success• y How to use a risk management file for compliancepurposes• y The corrective and preventive action format forprocess-oriented decisions• y An understanding of process mapping as an asset toyour Quality Management System• y Some approaches to handling this type of sensitiveinformation during FDA inspections and ISO audits• y Management review as a toolBIO: John Gagliardi has had success over the past 40 years inthe medical device and pharmaceutical industries because ofhis practical approach to process-orientation and business. Hisbackground and experience have included active involvementin research and development, quality assurance, operations,process architecture, training and regulatory affairs. John hasspecialized in building systems in these industries that notonly achieve compliance, but are also “business-ready” torealize a profit.Founded in 2000, MidWest Process Innovation, LLC (MPI) helpscompanies develop effective and efficient processes using thearchitecture of ISO 13485:2003, ISO 17025:2005 and the GoodManufacturing Practice/Quality System Regulations.Because process orientation is such an integral part of acompany’s health, MPI has dedicated a segment of its originalcore competencies to transitioncompanies with systems thatrequire a strong regulatory and process-based platform.Workshop: The Toolbox for High Speed Innovationand New Product DevelopmentGregory D. Githens, PMP, NPDPManaging Partner, Catalyst ManagementConsulting, LLCThursday, June 179:30 a.m. – 12:00 p.m.This session will provide useful practices for improving thespeed and effectiveness of innovation programs and strategicinitiatives. Back by popular demand, with new examples!We will address these specific points:• y The large toolbox that can improve the performanceof individuals and organizations• y How to translate vision into results• y The fact that tools help, but don’t replaceorganizational disciplineAttendees will receive these tools to put to immediate use:• y How to construct an elevator pitch that provides acompelling value proposition• y The “what about” tool for surfacing unspokenconcerns and assumptions• y How to clarify roles and responsibilities in theprogram team with the “4 Rs”• y How to turn a marketing spec into a useful technicalspec• y Tips for speeding projects and lowering frustrationBIO: When product development organizations need a “handson” coach who can quickly assess a situation and help getthings moving, they call Greg Githens. Over his twenty-fiveyears of experience in strategic programs and innovation, Greghas developed and acquired practices that address the “crux ofthe matter.” He is skilled at building alignment in people thatenables them to get the tough work done.Greg’s clients have realized the benefits of a more skilledtechnical workforce, improved time-to-market, predictablescheduling, better metrics, better strategic alignment,outstanding design concepts and improved decision making.Page 142010

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/WorkshopsA recognized authority, Greg has spoken to many high-profilegroups and authored over three dozen articles, papers andbooks on the topic. Greg holds advanced degrees in businessand science, and is a certified Project Management Professionaland a certified New Product Development Professional.Workshop: Product Development Metrics forManufacturers: Measuring your ProductivityBradford L. Goldense, NPDP, CMfgE,CPIM, CCPPresident, Goldense Group, Inc.Wednesday, June 169:30 a.m. – 12:00 p.m.Wall Street still values organic innovation over all other forms ofproduct development innovation. Companies with “inventionengines” have highly favorable market capitalizations. This wasthe focus of my OMTEC 2009 session. The world is always movingforward. And, time builds experience. Open Innovation (OI), tosome level for every company, is now inevitable. As a “bodyof knowledge,” OI is maturing. Certain corporate behaviorsnow have patterns, with somewhat consistent approaches, andsome risks are known. Wall Street doesn’t yet know how tovalue everything that is OI, but that will come.We will take a snapshot of the “State of Open Innovation” incorporations. OI is not the major product development trendto pay attention to, however. It is part of a triad that includescontracted-out innovation and product or technology sale orlicensing. These three industry activities all place the “corporatejewels of innovation,” the Intellectual Property (IP), outsideof the owning corporation to some level. Companies arestruggling to protect themselves at these unprecedented levels.As this IP becomes more commoditized, Wall Street will figureout how to value it all. The arms-length sale and exchange ofIP is already in nascent stages in public marketplaces. The firstsix great generations of innovation will be explained to precedea focus on the seventh and next great generation of corporateinnovation, “IP-Based.” This is a quantitative presentation.Many facts, figures and studies will be cited.2010Page 15

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/WorkshopsWe will address these specific points:• y Current corporate trends in OI• y Process maturity levels in OI• y Marketplace valuation of OI• y Current corporate trends in IP• y Process maturity levels in IP• y Marketplace valuation of IPAttendees will receive these tools to put to immediate use:• y Frameworks for creating successful OI relationships• y Emerging lessons learned about the effectiveness ofcertain OI techniques• y Successful management behaviors that foster OI• y Process suggestions for better alignment of allinnovation with IP• y Understanding of future IP impact on companybalance sheets• y Sources of nascent IP exchanges and mutual fundsBIO: Brad Goldense is Founder and Chief Executive Officerof Goldense Group, Inc. (GGI), a 20-year-old consulting andeducation firm concentrating on advanced business andtechnology management practices for line managementfunctions. Mr. Goldense has consulted for over 200 of theFortune 1000 and has worked on productivity improvementand automation projects in over 500 manufacturing locations.He has worked in North America, South America, Europe,Asia and the Middle East. Abbott Laboratories, Bayer, S.C.Johnson, Ford, General Motors, John Deere, Philips, UnitedTechnologies, Carrier, Molex, Monsanto, Bose and Shure areamong GGI’s clients.Mr. Goldense is a member of the faculty at the Gordon Instituteof Tufts University. He holds a Bachelor of Science in CivilEngineering from Brown University and a Master of BusinessAdministration in Cost Accounting and Operations from CornellUniversity. Brad is a certified New Product DevelopmentProfessional by the Product Development and ManagementAssociation, a Certified Manufacturing Engineer by the SME, aCertified Computer Professional by the ICCP, and is Certifiedin Production and Inventory Management by the APICS.He is Worldwide President of Society of Concurrent ProductDevelopment. He is a member of Cornell University’s TechnologyTransfer Committee and recently served a three-year term onCornell’s Advisory Council. Brad is a past member of the Board ofDirectors of the American Society for Engineering Management.Mr. Goldense has been an invited guest on Alexander Haig’sWorld Business Review and has appeared on Public Television,PBS, The Business & Technology Network and CNBC. Brad hasauthored or been quoted in over 150 articles on competitiveproduct development and manufacturing with known industrypublications such as CFO, Design News, Machine Design andPurchasing. He is an internationally recognized expert in rapidproduct development practices and in R&D metrics.Prior to founding GGI in 1986, Mr. Goldense held positionsat Computer Sciences Corporation’s Index Group, PriceWaterhouse, Lester B. Knight & Associates and Texas Instruments.Workshop: The True Cost of OffshoringJohn W. Henke Jr., Ph.D.Planning Perspectives, Inc. and Oakland University,School of Business AdministrationThursday, June 179:30 a.m. – 11:00 a.m.The allure of purchasing goods from Low Cost Countries atlowest piece price is losing its luster as Purchasing organizationsrealize the need to ensure the lowest Total Delivered Cost to thefirm or, as the more enlightened Purchasing organization arepursuing, the Lowest Sustainable Cost. The complexities andrisks of the world’s business environments, however, suggestthat it is time for Purchasing organizations to evolve furtherto the Lowest Risk Assessed Cost model if they are to procuregoods that provide the risk-balanced lowest total cost to the firm.I will address these specific points:• y The evolution from purchasing at the lowest pieceprice to procuring at the Lowest Risk Assessed Cost• y The shortcomings of buying using the Total DeliveredCost and Lowest Sustainable Cost approaches• y The components and benefits of the Lowest RiskAssessed Cost model• y Attendees will receive a Lowest Risk Assessed Costmodel to put to immediate use.BIO: John W. Henke, Jr. serves on the marketing faculty of theSchool of Business Administration at Oakland University inRochester, Michigan. Prior to joining the academic community,he held sales and marketing management positions during a 15-year period with several firms, including the IBM Corporation,Data Processing Division, and the Automotive Division ofGeneral Automation. He has continued his association withthe business world as President of Planning Perspectives, amanagement consulting firm specializing in buyer-supplierworking relations. In this capacity, he has worked withnumerous organizations, including the American PlasticsCouncil, ArvinMeritor, Boeing, BP plc, Chrysler, Cisco Systems,Delphi, Flextronics, Ford, GE Healthcare, General Motors, HiltiCorporation, Holcim, Honda, Lubrizol, Mars, Nissan, PACCAR,PSCU Financial Services, Rolls-Royce plc, Royal Numico N.V.,Toyota, US Air Force Materiel Command and Visteon.Prof. Henke has given numerous presentations in the U.S.,Europe and Japan on business-to-business marketing andsupplier working relations topics. He has been published ina variety of journals, including the Sloan Management Review,Marketing Letters, Industrial Marketing Management, Journal ofPage 162010

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/WorkshopsI will address these specific points:• y The price paid for an offshore purchase is not its cost.It is only one of many elements that comprise thecost of an item being purchased.• y Traditional accounting methods obscure therelationships between costs incurred to supportoffshore purchases and the items being purchased.This leads to inappropriate offshoring decisions andundermines a company’s profitability.• y A well-designed, robust cost model can providemanagement with the accurate and relevant costinformation required to make economically soundoffshoring decisions.Attendees will receive these tools to put to immediate use:• y An understanding of how the “price” of a purchaseditem does not equal its “cost” — especially when theitem is manufactured by an offshore supplier.• y A checklist of costs that must be considered if acompany is to understand the true cost of offshorepurchases.• y An outline for creating a valid and robust costmodel that will enable an organization to measurecosts related to offshoring and link them to themanufactured items being purchased.BIO: During his 25 years as a consultant, Doug Hicks haschampioned the development of practical, down-to-earth costmanagement solutions for small and mid-sized organizations.In that time he has helped nearly 200 organizations of all typesand sizes transform their history-oriented accounting data intocustomized, value-enhancing decision support informationthat provides accurate and relevant intelligence needed tothrive and grow in a competitive world. He has shared hisexperience through dozens of seminars conducted throughoutthe U.S. and in dozens of trade and professional periodicals(including Management Accounting, Cost Management,Manufacturing Engineering and Journal of Accountancy) and twobooks, including I May Be Wrong, But I Doubt It: How AccountingInformation Undermines Profitability.Doug is a 1970 graduate of the University of Michigan— Dearborn. In 1997, he was awarded the University’s“Professional Growth and Scholarship Award” for his role asa leader in advancing cost management concepts, and in 1998he was selected as the Institute of Management Accountants’“Instructor of the Year.” He is a member of the Instituteof Management Accountants, Institute of ManagementConsultants and the Michigan Association of CPAs.Workshop: FDA 510(k) 101Floyd G. Larson, MS, MBAPresident, PaxMed International, LLCThursday, June 172:00 p.m. – 3:30 p.m.While there is uncertainty about the future of the 510(k) processfor marketing clearance of medical devices, this has for the past30 years been the dominant pathway by which new medicaldevices have reached the market in the U.S. The 510(k) processhas changed over the years, and may change further, but wedo not expect that it will be abandoned by FDA. Therefore,anyone who works in the field of medical devices, whetherentrepreneur, investor, manager, engineer or regulatoryprofessional, should be familiar with how the process worksand how he or she can contribute to a successful outcome.I will address these specific points:• y History of the 510(k) process, how it has changedfrom its early days and how it fits into FDA’s overallapproval processes• y Strategies for submission and the types of 510(k)s• y The role of FDA guidance documents andinternational standards in facilitating the 510(k)process• y The place of bench testing, in vitro testing, animaltesting and clinical studies in the 510(k) processAttendees will receive these tools to put to immediate use:• y How to determine whether a 510(k), anothersubmission, or even no submission is required• y Examples of classification and guidelines forselection of predicate devices• y Structure of a 510(k) and logistics of submitting it toFDA• y How and when to respond to an FDA request foradditional information• y What to do about a Not Substantially Equivalent(NSE) letterBIO: Floyd G. Larson is a leader in biomaterials technologyand regulatory issues, with extensive experience in productdevelopment, regulatory strategy, marketing clearance andthe translation of ideas to commercial reality. His educationalbackground in chemistry, materials science and businessmanagement prepared him for a career that has includedapplied research, management of R&D, and, as Vice President,Scientific Affairs for a manufacturer of implantable medicaldevices, overall responsibility for R&D, Engineering, ClinicalResearch and New Business Development.Page 182010

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/WorkshopsAs the President of PaxMed International, Floyd leads a teamof industry professionals serving medical device manufacturerclients in directing and implementing market-oriented research,product development, regulatory strategy, manufacturingimplementation and quality system development. He hasserved as the Industry Representative to the Dental ProductsPanel of the FDA Medical Devices Advisory Committee.He currently coordinates programs on calcium phosphatesand other ceramics for the American Society for Testing andMaterials (ASTM) Committee F4 on Medical Devices, andserves as a U.S. delegate to ISO committees on medical devices.Floyd is the convenor of an ISO Working Group responsiblefor developing medical device testing standards. He is alsothe chair of a subcommittee of the U.S.-Accredited StandardsCommittee (recommending and developing U.S. NationalStandards) and of a U.S. Sub-TAG to an ISO committee onmedical device standards. Floyd is a member of the AmericanCeramic Society, Society for Biomaterials, ASM Internationaland the Academy of Osseointegration. He recently was namedone of 100 Notable People in the Medical Device Industry byMedical Device & Diagnostic Industry magazine.Workshop: Partnering and Outsourcing forWin-Win ScenariosWayne MackeyPrincipal, Product Development Consulting, Inc.Wednesday, June 169:30 a.m. – 12:00 p.m.High performance companies have little patience withmeaningless partnering platitudes. If you and your company areready to get serious about taking the steps to build and executea core/non-core business strategy, make partner communicationwork effectively every day and extend your creative reach farbeyond your company’s borders, this practical partneringworkshop is what you have been looking for.I will address these specific points:• y When to partner or outsource, and when not topartner or outsource and why• y What makes a partnership or outsourcing activity“win-win”• y How to set up, execute and maintain an effectiveAM-HalfPageOMTEC<strong>Program</strong>Horiz5-23-10_OdtHalfPageAd.qxd 5/24/10 4:30 PM Page partnership 1 or outsourcing activityISO 9001 and ISO 13485 CertifiedA WORLD OF MANUFACTURING EXPERTISE IN EVERY PART.Visit us at OMTEC – Booth Number 400DRILLS • TAPS •DRIVERS •SCREWS • PLATESTotal engineered solutions for any orthopedic application.Talk to us about becoming your single source forprecision-grade surgical instruments and implantsthat fit right and work together.Michigan • Massachusetts • California877 633 8080www.autocam-medical.com2010Page 19

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/Workshops• y Partnering roles and responsibilities• y Partnership metrics and reviewsAttendees will receive these tools to put to immediate use:• y Core/non-core partnering and outsourcing model• y Matrix of steps to set up, execute and maintain apartnership, sorted by phase and function• y Partnering roles and responsibilities model• y Partnering metrics “dashboard”BIO: Mr. Mackey has been a Principal with ProductDevelopment Consulting, Inc. (PDC) since 1997. Prior to joiningPDC, he worked in industry for 20 years in high tech, aerospaceand automotive fields. He is a natural change agent and leader,having counseled Fortune 500 companies, major universities(Stanford, MIT, Carnegie-Mellon) and government agencies inproduct development, supply chain management and rapidlyimplementing enterprise-wide change. Mr. Mackey has alsoworked as a senior scientist, program manager, engineeringmanager and systems engineering manager.Wayne Mackey’s expertise is grounded in over 20 years ofhands-on leadership of large engineering, manufacturing andprocurement organizations. His management consulting isfocused on product/service development, and he is especiallyeffective in collaborative design, metrics, portfolio managementand business strategy implementation. He is co-author of ValueInnovation Portfolio Management: Achieving Double-Digit GrowthThrough Customer Value (2006), and co-author of the PDMAToolbook for Product Development 3 (2007).Mr. Mackey is an internationally acknowledged expert inmetrics and has been a keynote speaker on achieving rapidorganizational change, partnering and applying the voice ofthe customer to product development. He earned a Bachelor ofScience in electrical engineering and economics from Carnegie-Mellon University in Pittsburgh, Pennsylvania and a Master ofScience in engineering, from Loyola Marymount University inLos Angeles, California.Workshop: Driving Product Portfolio ManagementDecisions with Customer ValueSheila MelloManaging Partner and Principal, ProductDevelopment Consulting Inc.Wednesday, June 161:30 p.m. – 4:00 p.m.Learn how you can help your company select and generateproducts that provide the maximum value to your prospectsand customers, and how to use this information to cancel aproject that won’t create customer value. All cross-functionalorganizations need to be involved in the realization ofinnovative product development. This session will cover howorthopaedic companies can determine how/where they canprovide the greatest customer value and how to remove thepolitical infighting that can send you in the wrong direction.I will address these specific points:• y Driving innovation with market needs, not financialsor political implications• y Positioning your organization to make portfoliodecisions using facts derived from customer value• y Integrating a cross functional team to avoid lengthydiscussions and misinterpretations during productdevelopment• y Using real projects to pilot and roll out a “voice of thecustomer” processAttendees will receive these tools to put to immediate use:• y How to understand what gets in your customer’sway of achieving objectives• y How to create a story of what it is like to be a personwith problems that your product would solve• y How to translate what the customer/consumertold you into measurable requirements that areunderstood and agreed-upon by marketing and newproduct developmentSheila Mello is the author of Customer-Centric Product Definition:The Key to Great Product Development, and co-author of ValueInnovation Portfolio Management: Achieving Double-Digit GrowthThrough Customer Value.Sheila is the managing partner of Product DevelopmentConsulting, Inc. (PDC), and is a widely known, often quoted,well-respected expert in the field of product development.Her clients benefit from her many years of executive andhands-on experience in product development, software andhardware, engineering, marketing, quality, manufacturing,sales and service.Sheila has done extensive research in processes for definingcustomer requirements and is an expert in helping companiesimplement and institutionalize market-driven product definitionprograms and value based portfolio management processes.Sheila has helped scores of companies—Fortune 500 companiesin diverse industries and smaller high growth organizations—to speed time-to-profit and market acceptance, achieve greaterproduct predictability and profitability, identify improvementopportunities and build capabilities that directly impact bottomline results. Sheila helps clients identify their “inch-wide, miledeep”opportunities, build consensus and implement the mosteffective solution. PDC has implemented the Market-DrivenProduct Definition (MDPD) process at over 60 companies.Page 202010

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/WorkshopsIn addition to her consulting experience, Sheila is a frequentspeaker at seminars and conferences on product development andis a recognized speaker on industry topics ranging from improvingbusiness performance and value-based portfolio management, toteam management and organizational structure.PDC focuses exclusively on product development, helping clientsto optimize the process of developing products and services.PDC’s unique approach in providing collaborative productdevelopment solutions that speed time-to-market and increasecustomer acceptance enables their clients to stay competitive andrun efficiently.Before joining PDC, Sheila held director and vice presidentpositions at Bolt, Beranek & Newman, Wang Laboratories,Palladian Software and Distribution Management Systems, andwas a principal consultant with Arthur D. Little, Inc.Sheila earned a Bachelor of Science degree, magna cum laude, inmathematics from Tufts University. She is a member of TheInstitute of Electrical and Electronics Engineers (IEEE), the ProductDevelopment and Management Association (PDMA), and theAmerican Marketing Association.Where Ideas andIngenuity ConvergeWorkshop: Demand ForecastingMark A. Moon, Ph.D.Associate Prof. of Marketing, University of TennesseeWednesday, June 161:30 p.m. – 4:00 p.m.Through a series of studies involving over 400 companies over 20years, the University of Tennessee Sales Forecasting Research Teamhas developed a vision of world-class forecasting, demand planningand demand/supply integration. This presentation will articulatethat vision, and will position demand forecasting in an overallcorporate process of Demand/Supply Integration. Participants willleave with a framework for benchmarking their own forecastingprocesses, and with ideas about how to improve forecasting in thecontext of a corporate strategy for integrating demand with supply.I will address these specific points:• y What forecasting excellence comprises, across the criticaldimensions of functional integration, approach, systems andperformance measurement.• y How to benchmark forecasting practices and processesagainst that vision of world-class forecasting.• y How to develop successful strategies for forecastingprocess improvement.• y How to integrate demand forecasting processes intoa broader corporate process of Demand/SupplyIntegration.Onyx is your world-classmanufacturing partner, offeringvertically integrated solutionsfrom concept design throughdock- to-stock inventory fororthopedic cutting, nailing,navigation and fixation devices.Onyx is committed to deliveringon your specifications andexceeding expectations—always.Visit us at OMTEC booth #313800-238-6981Memphis, TNonyxmedical.netISO 13485:2003 / FDA 10436532010ONX_AD_Vert_02.indd 15/10/10 4:26 PMPage 21

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/WorkshopsAttendees will receive these tools to put to immediate use:• y A checklist of the forecasting dimensions,documenting worst-in-class and best-in-classpractice.• y A case study of a large manufacturing company andits approach to demand forecasting and demand/supply integration.• y A set of arguments to present to senior executives asto why forecasting process improvement should be acorporate imperative.BIO: Dr. Mark A. Moon is an Associate Professor of Marketingat the University of Tennessee, Knoxville. Prior to joining theuniversity faculty in 1993, Dr. Moon earned his Doctor ofPhilosophy from the University of North Carolina at ChapelHill. He also earned his Bachelor of Arts (BA) and Master ofBusiness Administration (MBA) degrees from the Universityof Michigan in Ann Arbor. Dr. Moon’s professional experienceincludes positions in sales and marketing with IBM andXerox. He teaches at the undergraduate, MBA and ExecutiveMBA levels, and addresses Demand Planning, Forecastingand Marketing Strategy in numerous Executive <strong>Program</strong>soffered at the University of Tennessee’s Center for ExecutiveEducation. Dr. Moon’s primary research interests lie in Salesand Operations Planning (S&OP), demand management, salesforecasting and buyer/seller relationships. He is the author,along with Dr. John T. (Tom) Mentzer of Sales ForecastingManagement: A Demand Management Approach. Mark hasconsulted with numerous companies including, Cooper Tire,Lockheed-Martin, Nissan North America, Johnson & Johnsonand Winn-Dixie. Dr. Moon has also delivered custom executiveprograms to a variety of companies, including Honeywell,Sony, Union-Pacific Railroad and Corning.Workshop: Supply Management Issues: IntegratingStrategic and Tactical ActivitiesRussell Morey, Ph.D.President, Morey and AssociatesThursday, June 179:30 a.m. – 12:00 p.m.This presentation will identify the importance of integratingstrategic and tactical professionals in managing the supplychain. Organizations need to support this effort in order toproject a common image to maximize supplier performance. Alltoo often, corporations ask people to be strategic and yet expectthe same individuals to be involved in day-to-day tactical issues.We will address these specific points:• y Think globally and manage locally• y Major strategic and tactical activities• y Recognizing and meeting major supplier needs• y Training to be consistent — strategically and tacticallyAttendees will receive these tools to put to immediate use:• y Useful elements of supply management leadership• y How to respond to supplier questions• y Websites for the Strategic Supply Managementprofessional• y Tactical indicators of a financially troubled supplierBIO: Dr. Russell Morey is Professor Emeritus of Supply ChainManagement at Western Illinois University. He received hisDoctor of Philosophy from the University of Nebraska in 1973,his C.P.M. in 1976 and has had a 44-year career in business andhigher education.Dr. Morey is currently the President of Morey and Associatesand has conducted training programs for more than 35 Fortune500 corporations in Brazil, Canada, China, England, Germany,Mexico and the United States.He has published numerous articles and cases, and has givenpresentations at various regional, national, and internationalconferences. Dr. Morey has received more than 100 awards andcertificates of achievement for his contributions to educationand supply management purchasing and has been listed innumerous Who’s Who publications throughout his career.He specializes in cost negotiations and professional certificationtraining and has served on numerous local, regional andnational professional committees throughout his career.Workshop: A Supply Chain Manager’s Guide toStrategic Purchasing or, How to Be On Top ofThings Instead of Having Things On Top of YouRebecca A. MorganPresident, Fulcrum ConsultingWorks, Inc.Wednesday, June 161:30 p.m. – 4:00 p.m.This interactive workshop will address the role of strategyin effective procurement, internal and external factors thatimpact success, techniques, tools, metrics and other relatedconsiderations.I will address these specific points:• y The relationship of business, operations andprocurement strategy• y Supplier relationships• y What others are doing to increase the effectiveness ofprocurement• y Making process changes workAttendees will receive these tools to put to immediate use:• y Evaluation and improvement of current metricsPage 222010

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/Workshops• y Evaluation and improvement of Supply ChainManager job descriptions, personnel evaluations andreward systems• y Identification of gaps in strategy and executionBIO: Rebecca A. Morgan, President of Fulcrum ConsultingWorks,is a manufacturing strategy consultant skilled at clarifyingcomplex ideas, finding creative solutions to problems anddeveloping and leveraging operational strengths. She works withmanufacturers to develop and execute an operations strategythat enables them to leverage resources and deliver profitablecompetitive advantage to their markets. Her ability to work aseffectively with off-shift workers as with owners and C-levelexecutives and her 30 years professional experience combine tosupport both strategic vision and daily execution. She served insenior management positions for Stouffers, TRW (subsequentlyPrecision Castparts Corp.) and others prior to founding heroperations consulting business in 1990. Her strategic thinkingand operational expertise have helped manufacturers large andsmall. Ms. Morgan has served as the Operations content expertfor INC.com, the online home of INC Magazine. In addition, herexpertise has been tapped by numerous national and industrypublications including Fortune Magazine, Business Week, Dow-Jones Newswires and Industry Week on topics ranging from LeanManufacturing to Steel Tariffs to B2B relationships.Morgan’s experience spans Operations, Supply ChainManagement, Accounting Systems, Information Systems,Strategic Planning, Consulting and Academe. She has beendirectly responsible for cost and revenue centers in single andmulti-plant situations.Ms. Morgan has B.A. and M.S. degrees in Economics andcompleted post-graduate work in Business Administration. Sheis Board Approved in Operations Management by the Societyfor Advancement of Consulting and is certified as a Fellow byThe Association for Operations Management. She is also one ofthe few authorized facilitators nationwide to deliver the jointAME/SME/Shingo Lean Certification Review <strong>Program</strong>.We Help Bone GrowCam Bioceramics is one of the pioneers in bioceramic bone growth, tissue augmentationand coatings. Our core activity is the development and production of calcium phosphatepowders as precursor for granules, blocks and coating of prostheses. Cam Bioceramics'strength lies in its diverse product range and strong customer focus. We support even thelargest orthopaedic companies in their R&D efforts and are extremely flexible in thedevelopment and production of custom-made products.As a committed partner Cam Bioceramics:· Produces premium bioceramic calcium phosphate powders, granules and blocks· Supplies custom-made CE marked bone substitutes for your private label sales· Partners with clients in research & development of calcium phosphate applications· Applies bioceramic coatings on orthopaedic prostheses, spinal and dental implants· Offers a full packaging, labelling and sterilization serviceVisit us atOMTECBooth 330Leiden Bio Science Park Zernikedreef 6 2333 CL Leiden The Netherlands31 (0) 71 5240600 (phone) 31 (0) 71 5240650 (fax) www.cambioceramics.com2010Page 23

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/WorkshopsWorkshop: QSR Purchasing Controls: GHTFGuidance on the Control of Products and ServicesObtained from SuppliersChristine NelsonIndependent ConsultantWednesday, June 161:30 p.m. – 4:00 p.m.The Food and Drug Administration (FDA) holds medical devicemanufacturers responsible for evaluating and controllingsuppliers of products and services. Manufacturers can finduseful guidance on effectively carrying out their responsibilitiesin the Global Harmonization Task Force’s (GHTF) guidancedocument, Quality Management System — Medical Devices —Guidance on the Control of Products and Services Obtained fromSuppliers, issued in December 2008. This session will addressthe GHTF guidance and purchasing control tools.My co-presenter, John Gagliardi, and I will address thesespecific points:• y Planning for selection of suppliers of products andservices• y Selection of potential supplier(s), supplier evaluationand acceptance• y <strong>Final</strong>ization of controls• y Delivery, measurement and monitoring• y Feedback and communication, including CorrectiveAction and Preventive Action processAttendees will receive these tools to put to immediate use:• y Use of risk analysis in supplier selection, evaluationand monitoring• y How to monitor supplier performance• y How to cope with less-than-perfect suppliersBIO: Chris Nelson worked for FDA’s Center for Devices andRadiological Health from 1990 to 2006. She provided supportfor legal actions; spoke on the Quality System Regulation atindustry conferences; provided training on quality systemsand FDA enforcement of medical device requirements to FDAinvestigators, reviewers, industry and foreign governments;and participated in the Global Harmonization Task Force’sauditing study group.In 2006, Chris retired from FDA. Currently, she providestraining and consultation to the medical device industry onquality systems issues.Chris has a Bachelor of Science from Northern IllinoisUniversity and a Master of Science from the Universityof Illinois. She is a member of the Association for theAdvancement of Medical Instrumentation and the AmericanSociety for Quality.Lecture: Pursuing Growth Strategies in theReal WorldMark Siders, Ph.D.Associate Prof. of Marketing, Southern OregonUniversityThursday, June 172:00 p.m. – 3:00 p.m.This session explores a set of growth strategies that has beenshown to succeed, even in tough times. The four strategiesof market penetration, market development, productdevelopment and market diversification can be employed tosatisfy an organization’s quest for continued growth. Eachstrategy will be discussed in depth in a fast paced interactivelearning environment. Learn why lower sales volume might bemore profitable, explore product strategies that avoid productcannibalization and consider strategies that maximize capacityand take advantage of organizational strengths.I will address these specific points:• y Market Penetration Strategies• y Market Development Strategies• y Product Development Strategies• y Market Diversification StrategiesAttendees will receive these tools to put to immediate use:• y Using Ansoff’s Generic Growth Opportunities Matrix• y Computing the trade off between idle capacity andsales volume• y Defining the Competitive SetBIO: Mark Siders is Associate Professor of Marketing atSouthern Oregon University. He received his Doctorateof Philosophy in Management/Marketing from VirginiaCommonwealth University in 1998. Prior to entering academia,he spent over 20 years in the orthopaedic industry, holdingpositions including Product Manager, Director of Marketing,Senior Market Analyst and Project Leader - Sales Operations.Dr. Siders continues to provide consulting services to a varietyof industries.Lecture: An Introduction to ComparativeEffectiveness ResearchIsabella Sledge, M.D., MPHFounder & CEO, Strata LLCThursday, June 172:00 p.m. – 3:00 p.m.Bringing products to market in the age of comparativeeffectiveness: understanding the changing landscape. Thepresentation will last 40 minutes with a 20-minute questionperiod. Covered topics will include: a brief history of newPage 242010

your vision should never be lost in translationWORLD-CLASS CONTRACTMANUFACTURERSEXPERTISE:IMPLANTSINSTRUMENTATIONCOMPONENTSGRAPHIC CASESSTERILE PACKAGINGLaunch your breakthrough products without the compromises. BranchMedical Group’s superior capabilities ensure your innovations arecreated true to specifications. And because we believe a deadline issomeone’s lifeline, you’ll find that our speed of response is second tonone in the business. From ‘Design for manufacturing’ methods toleading edge pro-active quality systems, we are geared for whateverchallenge you can throw at us. Call us. We speak excellence, fluently.• Visit us at OMTEC 2010 Booth #614 •CAPABILITIES:EIGHT-AXIS MILL TURNSSEVEN-AXIS SWISS LATHESFIVE-AXIS BAR FED MILLSPRECISION LASER QCEDMLASER MARKINGAND MOREwe do it for lifeBRANCHMEDICALGROUP.COM AN IS0 13485 CERTIFIED COMPANY200 SCHELL LANE, PHOENIXVILLE, PA 19460 1-877-99-BRANCH

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/Workshopstechnology adoption in orthopaedics; the nuts and boltsof technology assessment, comparative effectiveness andeconomic analysis; how comparative effectiveness analysesare influencing coverage decisions in the U.S. and abroad; thehealthcare policy landscape in the U.S. and those changes thatare anticipated in the next five years.I will address these specific points:• y How new products were approved and adopted inthe past, and how this process has changed over thepast five years• y Terminology and definitions for technologyassessment and economic analysis• y A worldview of how comparative effectiveness isinfluencing decisionmaking• y Understanding the impact of the health policylandscape in the U.S. on decisions regarding newproducts• y How best to prepare for the coming comparativeeffectiveness studies in orthopaedicsAttendees will receive these tools to put to immediate use:• y How to interpret a technology assessment/comparative effectiveness review• y How to position a product in anticipation of acomparative review• y How to know what outcomes will be important forfuture coverage and reimbursement decisionsBIO: Isabella Sledge, M.D., MPH is Founder and ChiefExecutive Officer of Strata LLC and former Medical Directorat United BioSource Corporation (UBC). Dr. Sledge is a boardcertified internist who has dedicated much of her careerto various evidence-based medical initiatives designed forphysician and patient consumption. Dr. Sledge has publishednumerous systematic reviews, meta-analyses and technologyassessments for pharmaceutical, medical device, non-profitand government clients. She is the senior author of two recentmeta-analyses in atrial fibrillation published in 2009. She haspublished and presented on many evidence-based topics, witha particular emphasis on the application of evidence to thedevelopment of medical devices and emerging technologiesand the translation of outcomes research into healthcare policy.Dr. Sledge is a founder of Strata, a medical informatics companythat offers software solutions to collect, analyze and disseminateevidence about established and emerging technologies. Stratahas over 12 years of experience with patient data registries anddecision support tools. Strata has now launched HealthLink,a web networking portal for patients that both providesevidence-based information and collects health outcome data.Dr. Sledge received her medical degree from University ofMaryland School of Medicine and holds a Masters in PublicHealth degree from the Harvard School of Public Health.Breakfast Keynote: Vested Outsourcing: Five RulesThat Will Transform Your Supplier RelationshipsKate VitasekUniversity of TennesseeThursday, June 178:00 a.m. – 8:45 a.m.Many outsourcing deals are structured with fundamentalflaws in the business model that prevent transformationalresults through outsourcing. The University of Tennesseehas been researching leading companies that are challengingconventional outsourcing and has identified a next generationapproach in the book, Vested Outsourcing: Five Rules that WillTransform Outsourcing.Kate will share her research and insights, including:• y What Vested Outsourcing is, and why the approachworks• y Ten “perverse incentives” you might have if you areusing conventional outsourcing arrangements• y Five Rules that will transform how you outsourceAttendees will receive these tools to put to immediate use:• y A w eblink to a free eBook to learn more• y A weblink to an “assessment framework” forgauging the health of your outsourcing agreement• y A weblink to download the implementation modeland other tools to implement Vested OutsourcingWorkshop: Vested OutsourcingThursday, June 179:30 a.m. – 12:00 p.m.The keynote provided a high level overview of VestedOutsourcing and a look at how applying the concepts willtransform outsourcing and your existing supplier relationships.This session will provide an interactive workshop setting todig in and see how the Vested Outsourcing methodology canhelp your company.We will address these specific points:• y What game theory is and how it can be used toimprove how companies approach outsourcing• y A overview of each of the ten ailments ofconventional outsourcing• y An overview of the five steps of implementingVested OutsourcingAttendees will receive these tools to put to immediate use:• y An interactive session to help them better understandgame theory• y An interactive session in which they “grade” theiroutsourcing efforts against the ten ailmentsPage 262010

<strong>Final</strong> <strong>Program</strong>Addresses, Educational Sessions/Workshops• y Hard copy printout of a Vested Outsourcingimplemention project plan to help them implementVested Outsourcing. They will also receive a weblinkto download the softcopy project plan, as well as aweblink for additional tools they can use.BIO: Author, educator and business consultant, Kate Vitasekis a nationally recognized innovator in the practice of supplychain management and outsourcing. Vitasek’s approaches andinsights have been widely published in respected academic andtrade journals. She is the co-author of the Council of SupplyChain Management Professionals’ best selling book, SupplyChain Process Standards, and has contributed to over 75 articlesand five books, including her latest book, Vested Outsourcing:Five Rules That Will Transform Outsourcing.Vitasek is a faculty member at the University of Tennessee’sCenter for Executive Education and is the Founder of SupplyChain Visions, a boutique consulting firm recognized byARC Advisory Group as a Top 10 Boutique Consulting firmspecializing in Supply Chain Management.She’s been recognized as a “Woman on the Move in Trade andTransportation” for her leadership in the profession, and wasrecently honored as a “Woman of International Influence”by Global Executive Women. She has served on the Boardof Directors for the Council of Supply Chain ManagementProfessionals and has been called a “Rainmaker” for hertireless effort in educating the supply chain profession. In 2009,she was honored as finalist for a Stevie Award for womanentrepreneurs of the year.Workshop: Sales & Operations PlanningThomas WallaceT.F. Wallace & CompanyWednesday, June 169:30 a.m. – 12:00 p.m.This session focuses on Sales & Operations Planning (S&OP),primarily its top management component: Executive S&OP.This process helps companies balance demand and supply;integrate financial planning with operational planning; developalternative scenarios — what-if analyses — that are financiallyand operationally valid; meet monthly, quarterly and annualfinancial targets more effectively; launch new products morequickly and more “sure-footedly;” build teamwork andimprove internal communications. All of these functions willbe discussed with examples given from actual companies.We will address these specific points:• y Part 1 will be an overview of the process, describingwhat it is and how it works.• y In Part 2, we’ll cover benefits that companies haverealized from using the process successfully.• y Part 3 will focus on implementation: how to make theprocess work.Ample time will be provided for Q&A and group discussion.Attendees will receive these tools to put to immediate use:• y An understanding of how the process works: itsinternal logic and structure• y A framework to evaluate their own S&OP-typeprocesses in terms of effectiveness• y An understanding of the right way to implement theprocess — or to re-implement if necessary• y Knowledge of their likely role in Executive S&OPBIO: Tom Wallace is an author and teacher specializing in Sales& Operations Planning. He is a Distinguished Fellow of theOhio State University’s Center for Operational Excellence, andteaches in conjunction with the Institute of Business Forecastingand Planning. He has taught well over 10,000 business peoplein Australia, Belgium, Canada, China, France, Great Britain,Mexico, New Zealand and the U.S.Tom has written twelve books, including Sales & OperationsPlanning: the How-To Handbook, 3rd Edition (2007), Sales &Operations Planning: the Executive’s Guide (2006) and Sales &Operations Planning: the Self-Audit Workbook (2005). His bookshave been translated into Chinese, Italian, Korean, Portuguese,Russian, Thai and, in process, French. Tom has also produceda number of videos, most recently, The Education Kit for Sales& Operations Planning (2009), a multi-media teaching resourcefor delivering S&OP education.Download Presentationsand Handoutsonline atwww.orthoworld.com2010Page 27

<strong>Final</strong> <strong>Program</strong>Index of Exhibitors by CapabilityBusiness DevelopmentCastingComponent PartsDelivery SystemsDevice TestingEquipment/MachineryFinancial AffairsForgingHuman ResourcesInsurance/Risk ManagementLegal Affairs/Intellectual Prop.Laser ProcessingMarket Data/ResearchImplant/Instrument MachiningManufacturer RepsProduct Design/Dev/IncubPackaging/SterilizationReg/Clin Affairs/Tech WritingRaw MaterialsSupply Chain ManagementSales/MarketingSoftware SolutionsSurface Prep/TreatmentsPage 282010

<strong>Final</strong> <strong>Program</strong>Index of Exhibitors by CapabilityBusiness DevelopmentCastingComponent PartsDelivery SystemsDevice TestingEquipment/MachineryFinancial AffairsForgingHuman ResourcesInsurance/Risk ManagementLegal Affairs/Intellectual Prop.Laser ProcessingMarket Data/ResearchImplant/Instrument MachiningManufacturer RepsProduct Design/Dev/IncubPackaging/SterilizationReg/Clin Affairs/Tech WritingRaw MaterialsSupply Chain ManagementSales/MarketingSoftware SolutionsSurface Prep/TreatmentsPage 302010

CURBELL PLASTICSPlastics for Orthopedic and Medical ApplicationsHOW CURBELL PLASTICS CAN BENEFITYOUR BUSINESS:• ISO 9001:2008 quality management system• Lot and batch traceability• Providing paperwork and certifications• Material selection assistance• Technical supportAVAILABLE MEDICAL-GRADE MATERIALS:• Polypropylene(Polystone ® P MG)• Acetal (Celcon ® )(Sustarin ® C MG)• Radel ® R(Sustason PPSU MG)• PEEK(SustaPEEK MG)• Polysulfone(Sustason PSU MG)• Noryl ®(Susta PPO MG)• Ultem ®(SustaPEI MG)Medical-grade materials complywith agency standards includingUSP Class VI, ISO 10993-5, andFDA, call your Curbell Plasticssales rep for more informationPut us to work – for you! TMCurbell Plastics has been supplying plastic sheet, rod, tube, films, adhesives, sealants, tapes, prototyping and tooling materials, and fabricated parts for over 65 yearsOur medical-grade partnerNATIONWIDE1.888.CURBELLwww.curbellplastics.com©2010 Curbell Plastics, Inc. All other trademarks and service marks are propertyof their respective manufacturers. MAP1010A 0510

<strong>Final</strong> <strong>Program</strong>Floor PlanPage 322010

<strong>Final</strong> <strong>Program</strong>2010Page 33

<strong>Final</strong> <strong>Program</strong>Show SponsorsPremierPlatinum and SupportingGoldGoldGoldGoldGoldSilver Silver SilverBronzeSupportingPage 342010

<strong>Final</strong> <strong>Program</strong>Exhibitor Listing1sourcesupplies, Inc.3310 Commercial ParkwayMemphis, TN 38116USA901-345-6011 (phone)901-345-5383 (fax)www.1sourcesupplies.comProvider of web based off-site automated inventory management andreplenishment solutions for all organizations that need to inventory,manage, consume and replenish any item or product. Inventory can bemanaged from any location via the internet. Whether you need a product/supply vending machine at the “point of use” or a system for a VendorManaged Inventory program, our solutions strategically deliver lowest totalcost to all customers within the supply chain.Silver SponsorAcme Manufacturing Company4240 North Atlantic BoulevardAuburn Hills, MI 48326USA248-393-4200 (phone)248-393-4060 (fax)www.acmemfg.comIntegrated Robotic Polishing, Grinding & Buffing Systems forOrthopaedic Components. Largest global manufacturer of robotic gategrinding and finishing systems. We focus on providing a complete, fullydeveloped, risk-free finishing system to support the global medicalimplant industry. In-house technical support staff of engineers forapplications, product and electrical controls, off-line programming andtraining. ISO 9001:2008 certified.3M AbrasivesIndustrial BusinessCustomer Response CenterBuilding 225St. Paul, MN 55106USA800-362-3550 (phone)www.3M.com/AbrasivesComplete solutions. For precision finishing orthopaedic instrumentsand implants, 3M offers the right choices of our Trizact, Cubitron, andScotch-Brite high-performance abrasive products to help improve yourproductivity. For 100+ years, we have led in the development of advancedabrasives designed to help customers in virtually every industrial sectorimprove productivity and achieve consistent high-quality finishes.Advantage ManufacturingTechnologies, Inc.14298 169th Drive SEMonroe, WA 98272USA425-485-3980 (phone)425-483-1608 (fax)www.teamamt.comWe work with various metals, moving with you, incorporating every stepfrom engineering design assistance through assembly and final packaging,performing work to your exact specifications. With consistency, ourproduction and quality systems provide parts that meet your tight toleranceand specifications time after time. AMT’s exceptional team works as yoursilent partner towards the mutual success of each of our companies.AceCo Precision Manufacturing4095 South Gekeler LaneBoise, ID 83716USA208-387-0466 (phone)208-343-1237 (fax)www.aceco.comAn ISO 9001 and ISO 13485 certified manufacturing facility. For 20+ yearswe have machined precision components for the Semiconductor, TFT-LCDand Solar Industries. Our engineering and design capabilities, coupledwith our machining and quality disciplines, provide a perfect fit for thestringent requirements of the medical industry. Our Engineers, TechnicalStaff and Machinists collaborate with clients to create solutions to improvefunctionality, reduce costs and extend component lifetime.AeroMed, Inc.2342 North Penn RoadHatfield, PA 19440USA215-997-2900 (phone)215-997-0165 (fax)www.aerom.comPrecision Medical Components. AeroMed specializes in multi-axis CNCmachining including Swiss turning and High Speed milling of componentsand assemblies. We manufacture medical devices such as orthopaedicimplants and screws, ortho-fixation and implantable devices used inmicro- and minimally invasive surgery. AeroMed provides full project andinventory management and is FDA compliant. Certified to ISO 9001:2000FM514233 and ISO 13485:2003 FM507091.Ackermann MedicalEisenbahnstr 65-67DE-78604 Rietheim-WeilheimGermany49-7461-966170 (phone)49-7461-9661770 (fax)www.ackermannsurgical.deFrom its modest beginnings over 50 years ago, Ackermann company hasgrown into an instrument and implant company well placed to become amarket leader in its product fields. The medical equipment manufactured byAckermann results from a close collaboration between practising surgeonsand specialists, working together in concert, to establish the most effectivedirections for the company’s continual process of development.AIP724 Fentress BoulevardDaytona Beach, FL 32114USA386-274-5335 (phone)386-274-4746 (fax)www.aipdaytona.comAIP has 30+ years of experience machining ultra high precision complexplastic components from polymer materials such as PEEK, PEEK-OPTIMA,CF-PEEK-OPTIMA, PTFE, RADEL-PPSU, TECANYL-MT, UHMW-PE,TECAPRO-MT, ULTEM, etc. AIP boasts an impressive customer list in eachof the industries we serve, while maintaining a small, hungry companymentality to assure top notch service to all our potential and existingcustomers. ISO 9001:2008 and ISO 13485:2003 certified.2010Page 35

<strong>Final</strong> <strong>Program</strong>Exhibitor ListingAlliance Global Technology Company2F, No 92, Luke 5th RoadLushu, Kachisung 82151Taiwan886-7-695-6688 (phone)886-7-695-5329 (fax)www.alliance-gt.comProfessional OEM for orthopaedic implants and tools such as plates, screwsand instruments. ALLIANCE is the first company of engaging in Class IIImedical devices in Taiwan. Equipped with precise CNC manufacturingskills and surface treatment of advanced medical devices, we integrate stateof the art developing ability into an existing production line. Our qualitysystem is certified to ISO 13485 and Taiwan GMP.ASTRO Medical Devices7124 Industrial Park BoulevardMentor, OH 44060USA440-269-6984 (phone)440-602-6091 (fax)www.astromedical.comThe Fine Art of Precision Machining. ASTRO Medical Devices specializesin implant production: spinal, orthopaedic, fixation and deformity, as wellas instrumentation. ASTRO Medical Devices offers tight tolerance Swissand 5 Axis CNC Machining capabilities, industry expertise and exceptionalcustomer service. From prototypes to production, we make your parts looklike “fine art” for the medical device industry. ISO 13485 certified.Alliant Insurance – Life Sciences & Medical Products Solutions2415 East Camelback Road, Suite 420Phoenix, AZ 85016USA602-707-1917 (phone)866-878-9932 x7071917 (toll free)480-333-6974 (fax)www.alliantinsurance.comAlliant Insurance is the 11th largest insurance brokerage firm in the U.S.With a proven record in your industry and an extensive global portfolio oforthopaedic manufacturer and distributor clients, we deliver cost-effectivesolutions that optimize coverage and meet your specific insurance, riskmanagement, and employee benefit needs. Contact us now and truly benefitfrom our specialized products, programs, resources, and intellectual capital.Autocam MedicalGlobal Headquarters4436 Broadmoor SEKentwood, MI 49512USA616-541-8080 (phone)877-633-8080 (toll free)616-698-6876 (fax)www.autocam-medical.comHigh-precision machining and manufacturing CNC precision milling andturning are specialties. IMPLANTS: spine, trauma/reconstructive surgery,hip, shoulder, knee and extremities; INSTRUMENTS: reconstructive, spine,sports medicine, trauma, arthroscopic and endoscopic. Drills, drill guides,bone taps and reamers are our expertise, among others. HAND PIECES/COMPONENTS/SUBASSEMBLIES: Orthopaedic, Vitrectomy, etc. ISO9000/13485.Premier SponsorAPS Materials4011 Riverside DrDayton, OH 45405USA937-278-6547 (phone)937-278-4352 (fax)www.apsmaterials.comAPS Materials has been providing biomedical implant coatings since 1983.We produces titanium and hydroxyapatite (HA) coatings for seven of theten largest medical manufacturers in the world. Contact Mark Snider at 937-278-4352, ext. 226.Avalign Technologies272 East Deerpath RoadSuite 208Lake Forest, IL 60045USA800-996-2121 (toll free)260-480-5223 (fax)www.avaligntech.comPremier, full-service supplier of implants, instruments and delivery systems.Our expert engineering, diverse manufacturing capabilities and completededication to your project ensure success from start to finish. We comprisethree innovative companies: Nemcomed (Implants and Instruments);NGInstruments (Premium Cutting Instruments) and Advantis Medical(Cases and Trays). As a whole, Avalign Technologies brings the highestquality standard and custom products to our OEM customers acrossmultiple surgical specialties.Arcam ABKroslatts Fabriker 30Molndal 431 37Sweden31-7103200 (phone)31-7103201 (fax)www.arcam.comAdditive Manufacturing of Orthopaedic Implants. Arcam’s Electron BeamMelting technology offers unique route to cost effective production ofstandard and custom implants designed with your trademark TrabecularStructure. Arcam offers a complete portfolio of equipment, software, metalpowder, service and training.BioMedGPS LLC3943 Irvine Blvd #150Irvine, CA 92602USA949-559-5511 (phone)www.biomedgps.comFounded by Sharon O’Reilly, Founder/former CEO of Medtech Insight,BioMedGPS provides online business intelligence and dynamic decisionmakingtools specifically designed for life science executives. Offeringsinclude the SmartTRAK Online Business Intelligence database, StrategicPartnering & Investment Conferences, and an expert Consulting Group.Page 362010