Focus Flexography Brochure - Focus Label Machinery, Ltd

Focus Flexography Brochure - Focus Label Machinery, Ltd

Focus Flexography Brochure - Focus Label Machinery, Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

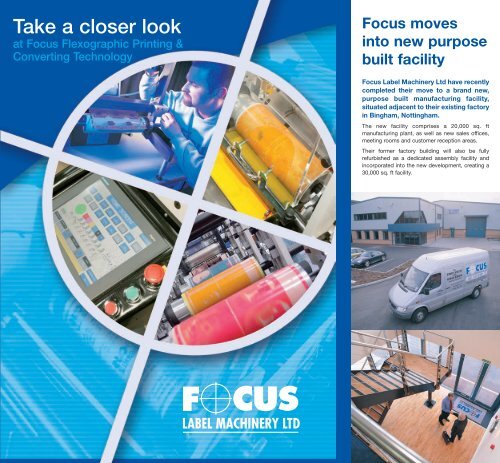

Take a closer look<br />

at <strong>Focus</strong> Flexographic Printing &<br />

Converting Technology<br />

<strong>Focus</strong> moves<br />

into new purpose<br />

built facility<br />

<strong>Focus</strong> <strong>Label</strong> <strong>Machinery</strong> <strong>Ltd</strong> have recently<br />

completed their move to a brand new,<br />

purpose built manufacturing facility,<br />

situated adjacent to their existing factory<br />

in Bingham, Nottingham.<br />

The new facility comprises a 20,000 sq. ft<br />

manufacturing plant, as well as new sales offices,<br />

meeting rooms and customer reception areas.<br />

Their former factory building will also be fully<br />

refurbished as a dedicated assembly facility and<br />

incorporated into the new development, creating a<br />

30,000 sq. ft facility.

Manufacturing review<br />

The £1.5 million investment, which also includes new CNC machining centres, lathes and<br />

cylindrical grinding equipment is designed to further increase manufacturing capacity,<br />

improve work flow and reduce delivery times.<br />

<strong>Focus</strong> Director, David Lee explains "There has been a<br />

steady increase in demand in recent years, as we have<br />

moved into new and expanding export markets. We have<br />

also gained market share in our domestic and European<br />

markets, against strong competition. At the same time, we<br />

have continued to develop and strengthen our ranges of<br />

equipment, with the introduction of new flexo presses and<br />

ancillary machinery.<br />

Obviously, with this growth in machine sales, comes the<br />

increased demand for technical support, tooling and spare<br />

parts. All of this created a real strain on our manufacturing<br />

capacity and we took the decision to expand. The<br />

investment in a new factory and equipment was an essential<br />

step in the development of <strong>Focus</strong> <strong>Label</strong> <strong>Machinery</strong> and will<br />

enable us to continue to improve our manufacturing<br />

operation and technical support for our customers.'<br />

As well as the additional new factory and office space,<br />

<strong>Focus</strong> also have a dedicated Customer Training Centre,<br />

catering for the training requirements of customers from all<br />

over the world. The Centre also provides a full time<br />

demonstration facility for the entire range of printing<br />

presses, platemaking systems and other ancillary<br />

equipment supplied by <strong>Focus</strong>.<br />

The investment in technology is backed by our investment in<br />

quality people. Technical experts who will listen and turn your<br />

ideas into solutions to meet your needs. <strong>Focus</strong> recognises<br />

that we require different approaches and promote flexibility in<br />

our design & manufacturing systems. Importantly, you can<br />

speak directly to our staff in all departments who are happy to<br />

share their expertise and assist our clients.<br />

Innovation comes from listening to our clients and our<br />

continued drive to make improvements and take a leading roll<br />

in our industry.<br />

We have invested heavily in installing the best systems to<br />

link our design, research & development departments with<br />

production. We design all our equipment from mechanical<br />

concepts through to electrical & control systems. We use<br />

the latest in CAD/CAM/CNC manufacturing technology to<br />

ensure every piece of equipment or part that we supply<br />

conforms to its requirements. Inward supply of materials<br />

is controlled through to production, inspection, storage &<br />

despatch of components from our warehouse to you the<br />

client.

<strong>Focus</strong> has a dedicated assembly area, where specialist<br />

technicians work on all aspects of systems & machine<br />

assembly. Many orders are unique to a client and only by<br />

having our own dedicated staff can we ensure that quality<br />

and full flexibility are maintained. Final testing for equipment<br />

is carried by our own Print Technicians prior to despatch.<br />

Contents<br />

Webflex . . . . . . . . . . . . . . . 2-3<br />

Proflex . . . . . . . . . . . . . . . 4-5<br />

Reflex . . . . . . . . . . . . . . . . 6-7<br />

Centraflex . . . . . . . . . . . . 8-9<br />

Foilflex & Screenflex .10-11<br />

Platemate . . . . . . . . . . . . . 12<br />

Platemaking systems . . .13<br />

FLEXOGRAPHIC CONVERTING SYSTEMS

WEBFLEX STANDARD FEATURES WEBFLEX SPECIFICATION<br />

LARGE CAPACITY UNWIND MODULE<br />

AUTOMATIC ROLL LIFT<br />

WEB GUIDE<br />

SPLICE TABLE WITH PNEUMATIC CLAMPS<br />

IN FEED / OUT FEED PACING ROLLS<br />

AUTOMATIC TENSION CONTROL SYSTEM<br />

MODULAR PRINT STATIONS<br />

QUICK CHANGE PRINT CARTRIDGES<br />

AUTOMATIC SELF-CLEAN PLATE SYSTEM<br />

SUPER LIGHT ANILOX ROLLS<br />

DOCTOR BLADE CASSETTE<br />

VARIABLE INFRA-RED & FORCED AIR INTERSTATION<br />

DRYERS<br />

U.V DRYERS (OPTIONAL)<br />

ROTARY DIE STATION MODULES (Heavy Duty)<br />

SLITTING MODULE<br />

WASTE REWIND TURRET<br />

ROTARY DIE SHEETER MODULE (Heavy Duty)<br />

REWIND MODULE<br />

ADVANCE PLC SEQUENCE CONTROL<br />

CENTRAL TRANSMISSION DRIVE MOTOR<br />

WEBFLEX OPTIONS<br />

UNWIND MODULE<br />

CORONA TREATER<br />

WEB CLEANER / ANTI STATIC SYSTEMS<br />

1 to 10 COLOUR CONFIGURATIONS<br />

VIDEO INSPECTION SYSTEM<br />

U.V DRYERS (Full or Part)<br />

CHILL ROLL SYSTEMS<br />

COOLER SYSTEMS<br />

TURN BAR<br />

DELAM/RELAM SYSTEM<br />

COLD FOIL(FOILFLEX)<br />

LAMINATION UNWIND<br />

SILK SCREEN<br />

ADDITIONAL WASTE REWIND TURRETS<br />

ADDITIONAL ROTARY DIE MODULES<br />

ROTARY DIE TOOLING<br />

DIE ADAPTORS<br />

ROTARY DIES<br />

SPROCKET PUNCH<br />

AUTOMATIC STACKER SYSTEMS (Shingle Type or Bottom up)<br />

ADDITIONAL CRUSH SLITTERS<br />

BACK SCORING SYSTEM (Back Slitting)<br />

FAN FOLDER<br />

ADDITIONAL REWIND TURRET<br />

PRINT CYLINDERS & GEARS<br />

TINT ROLLS<br />

SUPER LIGHT CERAMIC ANILOX ROLLS<br />

VIDEO PLATEMOUNTER (see PLATEMATE)<br />

ROTARY DIE LIFTING CRANE<br />

UNWIND MODULE<br />

UNWIND ROLL DIAMETER . . . . . . . . . . . . . . . . . . . . . . . . . .1000mm<br />

75mm AIR CORE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

ROLL LIFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

SPLICE TABLE<br />

REWIND MODULE<br />

REWIND ROLL DIAMETER . . . . . . . . . . . . . . . . . . . . . . . . . . .800mm<br />

75mm AIR CORE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

REWIND TURRETS . . . . . . . . . . . .ONE SUPPLIED, 2nd OPTIONAL<br />

INDEPENDENT DRIVE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . .YES<br />

OPERATOR CONTROLS<br />

PRINTING MODULES<br />

MINIMUM NUMBER OF PRINT MODULES . . . . . . . . . . . . . . . . . . .2<br />

MAXIMUM NUMBER OF PRINT MODULES . . . . . . . . . . . . . . . . .10<br />

MAXIMUM PRINTING WIDTH . . . . . . .13”(330mm) OR 17”(430mm)<br />

PRINT LENGTH RANGE . . . . . . . . . . .6-1/2(165mm) to 24”(609mm)<br />

ON RUN REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .360 Deg<br />

PRINT GEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 /8th C.P<br />

DRYERS . . . .Individual 4Kw Progressive Infra-red with impinged Air<br />

U.V DRYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Optional<br />

TURN BAR/DELAM/RELAM . . . . . . . . . . . . . . . . . . . . . . . . . .Optional<br />

ROTARY SLITTING MODULE<br />

PACING ROLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

SLITTER ANVIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

PNEUMATIC CRUSH SLITTERS . . . . .2 Supplied (more available as<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .option)<br />

ROTARY DIE /SHEETER MODULE<br />

NUMBER OF ROTARY DIE MODULES . . . . . . . . .Two (1 + Sheeter)<br />

ADDITIONAL DIE MODULES . . . . . . . . . . . . . . . . . . . . . . . . .Optional<br />

NUMBER OF DIE STATIONS . . . . . . . . . . . . . . . . . . .One per Module<br />

CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . . . .all Steel Side Frames<br />

PRESSURE BRIDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES<br />

DIE CLAMPING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . .Pneumatic<br />

REMOVABLE ANVIL ROLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES<br />

ON RUN REGISTER ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . .YES<br />

WASTE REWIND TURRET . . . . . .One Supplied, Additional Optional<br />

LAMINATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Optional<br />

DRIVE:<br />

MOTOR SIZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 H.P Minimum<br />

MAX SPEED . . . . . . . . . . . . . . . . .(0 to 320F/Min) 0 TO 150 Mts/Min<br />

SUPPLY REQUIRMENTS<br />

ELECTRICAL . . . . . . . . . . . . . . . . . . . . .380/415V, 3 Phase, 100Amp<br />

AIR SUPPLY . . . . . . . . .MINIMUM OF 100 PSI, 6 CFM, CLEAN AIR<br />

(Additional Volume Air supply is required when using options such<br />

as Turn Bar, Delam- Relam, Silk Screen, and Ink Pumps etc)<br />

Unwind Module<br />

Control Panel<br />

Print Station<br />

Die Station Module<br />

Digital Inkjet Rewind Module

WEBFLEX 330/430<br />

Take a look at the WEBFLEX specification & price ratio and we think you<br />

will want to take a closer look at what <strong>Focus</strong> can provide for your<br />

production requirements<br />

When the <strong>Focus</strong> design team set about developing a new generation of<br />

converting presses, they had a single goal in mind. To produce the ultimate<br />

performance machine, which would meet the demands of the modern<br />

converting & packaging industry. High productivity and consistent quality<br />

are essential in an increasingly demanding market place. In the WEBFLEX,<br />

we have launched a truly modular press, packed with advanced features to<br />

ensure you meet your production quotas head on.<br />

This is a heavy duty converting press, supplied with a unique 3 Zone<br />

Tension Control system, ensuring absolute register stability over a wide<br />

range of substrates from unsupported film through to labels, high density<br />

carton board and packaging materials. The print modules are supplied<br />

with the ultimate, rapid-change cartridge system, which is self-contained<br />

can be removed in seconds and exchanged without the need for tools.<br />

In addition, we have produced a range of ancillary equipment, such as<br />

Cold Foil systems, Silk Screen, Turn-Bar, Delam/Relamination and a host<br />

of other production enhancing facilities that make the WEBFLEX the best<br />

value flexographic press available today.<br />

OPERATION FEATURES<br />

The WEBFLEX is supplied with a large capacity unwind module with<br />

automatic roll lift, splice table & web guide as standard. Each print<br />

module is supplied with an individual infra-red drying system, with<br />

impinged airflow over the substrate, plus waste air extraction. In addition,<br />

U.V dryers can also be installed, allowing for full U.V or combination<br />

drying techniques for various types of ink. The ink fountains are selfcontained,<br />

quick-change cartridges with ink pan, metering roll, reverse<br />

angle doctor blade & anilox roll. All cartridges are fully interchangeable<br />

and can easily be removed or exchanged, without the need for tools.<br />

<strong>Focus</strong> have also introduced an automatic self-clean plate system, to<br />

remove used ink at press stops, combined with automatic plate throw off<br />

and constant turning anilox rolls.<br />

The unique 3-Zone Tension System ensures register stability is<br />

maintained through any speed variations or changes during the run. The<br />

3-Zone System monitors and adjusts tension at the unwind, print, die<br />

cutting & rewind sections.<br />

Individual die section modules are supplied with quick release pneumatic<br />

locking clamps and on run register adjustments in all directions. The<br />

frames are heavy duty steel construction, designed to cope with carton<br />

cutting & creasing applications. A dedicated slitting module is also<br />

supplied.<br />

One or two rewind turrets can be supplied, with direct torque drives<br />

suitable for film, label, tag & board substrates. Operator controls are<br />

conveniently located at each module for easy & safe machine operation.<br />

HIGH SPEED PRINTING & CONVERTING<br />

IN-LINE PRESS DESIGN<br />

1 to 10 COLOURS, MODULAR CONSTRUCTION<br />

RAPID CHANGE CARTRIDGE TECHNOLOGY<br />

FAST SET UPS & RAPID CHANGEOVERS<br />

CONSTANT ANILOX ROTATION & AUTOMATIC PLATE THROW OFF<br />

AUTO CLEAN PLATE SYSTEM<br />

NFRARED, PART OR FULL U.V DRYING SYSTEMS<br />

ROLL TO ROLL or ROLL TO SHEET CONVERTING NEW WEBFLEX SERVO (Separate information available)<br />

FLEXOGRAPHIC CONVERTING SYSTEMS

2 colour press<br />

6 colour press<br />

PROFLEX STANDARD FEATURES PROFLEX SPECIFICATION<br />

UNWIND<br />

WEB GUIDE<br />

SPLICE TABLE<br />

MODULAR PRINT STATIONS<br />

QUICK CHANGE INK CARTRIDGES & ANILOX ROLLS<br />

INFRA-RED INTERSTATION DRYERS<br />

ROTARY DIE STATION<br />

SLITTING<br />

WASTE REWIND<br />

ROTARY DIE SHEETER STATION<br />

IN FEED / OUT FEED PACING ROLLS<br />

REWIND<br />

PROFLEX OPTIONS<br />

EXTERNAL UNWIND MODULE<br />

CORONA TREATER<br />

WEB CLEANER<br />

2, 4, 6 or 8 COLOUR CONFIGURATION<br />

VIDEO INSPECTION SYSTEM<br />

U.V DRYERS (Full or Part)<br />

CHILL ROLL SYSTEMS<br />

TURN BAR<br />

DELAM/RELAM SYSTEM<br />

COLD FOIL(FOILFLEX)<br />

LAMINATION UNWIND<br />

ADDITIONAL WASTE REWIND<br />

ADDITIONAL ROTARY DIE STATION<br />

DIE ADAPTORS<br />

ROTARY DIES<br />

SPROCKET PUNCH<br />

AUTOMATIC STACKER SYSTEMS (Shingle Type or Bottom up)<br />

ADDITIONAL CRUSH SLITTERS<br />

BACK SCORING SYSTEM (Back Slitting)<br />

FAN FOLDER<br />

ADDITIONAL REWIND TURRET<br />

PRINT CYLINDERS & GEARS<br />

TINT ROLLS<br />

VIDEO PLATEMOUNTER (see PLATEMATE)<br />

CERAMIC ANILOX ROLLS<br />

4 colour press<br />

UNWIND<br />

UNWIND ROLL DIAMETER . . . . . . . . . . . . . . . . . . . . . . . .610mm<br />

75mm AIR CORE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

SPLICE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

WEB GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

EXTERNAL UNWIND MODULE with 1000mm capacity . . .Optional<br />

REWIND<br />

REWIND ROLL DIAMETER . . . . . . . . . . . . . . . . . . . . . . . . .610mm<br />

75mm AIR CORE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

REWIND TURRETS . . . . . . . . . .ONE SUPPLIED, 2nd OPTIONAL<br />

INDEPENDENT DRIVE MOTOR . . . . . . . . . . . . . . . . . . . . . . . .YES<br />

PRINTING MODULES<br />

PRINT STATIONS PER MODULE . . . . . . . . . . . . . . . . . . . . . . . . .2<br />

MINIMUM NUMBER OF PRINT STATIONS . . . . . . . . . . . . . . . . .2<br />

MAXIMUM NUMBER OF PRINT STATIONS . . . . . . . . . . . . . . . . .8<br />

MAXIMUM PRINTING WIDTH . . . . . .10”(254mm) or 13” (330mm)<br />

PRINT LENGTH RANGE . . . . . . . .6 1/2(165mm)” to 20”(510mm)<br />

ON RUN REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES<br />

PRINT GEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/8th C.P<br />

PRINT CARTRIDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES<br />

DRYERS . . . . . . . .Individual progressive infra-red with impinged air<br />

U.V DRYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Optional<br />

TURN BAR/DELAM/RELAM . . . . . . . . . . . . . . . . . . . . . . .Optional<br />

ROTARY SLITTING<br />

PACING ROLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

HARDENED SLITTER ANVIL . . . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

PNEUMATIC CRUSH SLITTERS . . . . . . . . . . . . . . . . . . .2 Supplied<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .(more available as option)<br />

ROTARY DIE /SHEETER MODULE<br />

NUMBER OF ROTARY DIE STATIONS . . . . . . . .Two (1 + Sheeter)<br />

ADDITIONAL DIE STATION . . . . . . . . . . . . . . . . . . . . . . . .Optional<br />

CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . .all steel side frames<br />

PRESSURE BRIDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES<br />

REMOVABLE ANVIL ROLL . . . . . . . . . . . . . . . . . . . . . . . . . . .YES<br />

ON RUN REGISTER ADJUSTMENT . . . . . . . . . . . . . . . . . . . .YES<br />

WASTE REWIND TURRET . . . .One supplied, additional: optional<br />

LAMINATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Optional<br />

DRIVE:<br />

MOTOR SIZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 H.P Minimum<br />

MAX SPEED . . . . . . . . . . . . . . .(0 to 400F/Min) 0 TO 120 Mts/Min<br />

SUPPLY REQUIRMENTS<br />

ELECTRICAL . . . . . . . . . . . . . . . . . . .380/415V, 3 Phase, 35 Amp<br />

AIR SUPPLY . . . . . . .MINIMUM OF 100 PSI, 6 CFM, CLEAN AIR<br />

(Additional volume air supply is required when using options such<br />

as Turn Bar, Delam- Relam, Silk Screen, and Ink Pumps etc)<br />

NEW PROFLEX SERVO<br />

(Separate information available)<br />

Print Station<br />

Die Station<br />

Web Cleaner<br />

Extended Control Box<br />

UV Dryers<br />

Digital Inkjet<br />

Stacker Turnbar-delam/relam unit

Chambered ink<br />

fountain<br />

The longstanding success of <strong>Focus</strong> compact Central Impression<br />

presses has led to the introduction of a new generation of compact inline<br />

flexographic presses, designed to bridge the gap to the larger<br />

WEBFLEX range of machines.<br />

The new PROFLEX 250 is the most affordable modular system on the<br />

market. The PROFLEX is available with 2, 4 , 6 or 8 colour<br />

configurations and will surely appeal to those with space limitations, but<br />

who also have a wide range of printing & converting requirements.<br />

The PROFLEX is a true, modular concept and is fully expandable. The<br />

print modules are supplied with the same quick-change cartridge<br />

system as used for the CENTRAFLEX range, whilst retaining the<br />

versatility of the larger WEBFLEX press to incorporate Cold Foil<br />

systems, Turn-Bar, Delaminating and a host of other production<br />

enhancing facilities. Robust construction techniques ensure stability on<br />

all products, from film through to labels, tags & board.<br />

HIGH SPEED PRINTING & CONVERTING<br />

COMPACT IN-LINE PRESS DESIGN<br />

2, 4, 6 or 8 COLOURS, MODULAR CONSTRUCTION<br />

QUICK CHANGE CARTRIDGE TECHNOLOGY<br />

FAST SET UPS & RAPID CHANGEOVERS<br />

CONSTANT ANILOX ROTATION & AUTOMATIC PLATE THROW OFF<br />

INFRA-RED, PART OR FULL U.V CURING SYSTEMS<br />

ROLL TO ROLL or ROLL TO SHEET CONVERTING<br />

Roll ink fountain<br />

Stage 1<br />

Stage 2<br />

PROFLEX 250/330 OPERATION FEATURES<br />

Stage 3<br />

The PROFLEX is supplied with splice table & web guide as standard.<br />

The unwind can be installed within the main body of the press for those<br />

with space restrictions or supplied with a dedicated unwind module.<br />

Each print module section has 2 colour print stations with individual<br />

drying components. The ink fountains are self-contained, quick-change<br />

cartridges with ink pan, metering roll and reverse angle doctor blade.<br />

No tools are required to remove or exchange them. Anilox rolls can also<br />

be removed within seconds. Automatic plate throw off and constant<br />

turning anilox rolls are standard features, whilst twin nip roll drives<br />

ensure register stability is fully optimized.<br />

The standard drying system uses progressive infra red units, with lamp<br />

intensity matched to press speed. Concentrated impinged air assists<br />

drying on the substrate, with excess air being exhausted away from the<br />

web. Full or partial U.V drying can be added to the machine<br />

specification, giving excellent combination drying opportunities.<br />

The die section module allows up to 3 rotary stations to be supplied,<br />

including a sheeting station for roll to sheet applications. This module<br />

also includes a dedicated slitting station.<br />

One or two rewind turrets can by supplied with direct torque drives<br />

suitable for film, label, tag & board substrates. Both the print and die<br />

stations have full register adjustment in linear & lateral directions.<br />

FLEXOGRAPHIC CONVERTING SYSTEMS

REFLEX STANDARD FEATURES REFLEX SPECIFICATION<br />

UNWIND<br />

WEB GUIDE<br />

SPLICE TABLE<br />

PRINT MODULE<br />

QUICK CHANGE INK CARTRIDGES & ANILOX ROLLS<br />

INFRA-RED INTERSTATION DRYER<br />

ROTARY DIE STATION<br />

SLITTING<br />

WASTE REWIND<br />

ROTARY DIE SHEETER STATION<br />

IN FEED / OUT FEED PACING ROLLS<br />

REWIND<br />

REFLEX OPTIONS<br />

RE-REGISTER SYSTEM<br />

IN LINE INTERFACE FOR DIGITAL SYSTEM<br />

EXTERNAL UNWIND CAPACITY UPGRADE (1000mm Dia)<br />

CORONA TREATER<br />

WEB CLEANER<br />

VIDEO INSPECTION SYSTEM<br />

U.V DRYER (Full or Part)<br />

CHILL ROLL SYSTEM<br />

TURN BAR<br />

LAMINATION UNWIND<br />

ADDITIONAL WASTE REWIND<br />

ADDITIONAL ROTARY DIE STATION<br />

DIE ADAPTORS<br />

ROTARY DIES<br />

SPROCKET PUNCH<br />

AUTOMATIC STACKER SYSTEMS (Shingle Type or Bottom up)<br />

ADDITIONAL CRUSH SLITTERS<br />

BACK SCORING SYSTEM (Back Slitting)<br />

FAN FOLDER<br />

ADDITIONAL REWIND TURRET<br />

PRINT CYLINDERS & GEARS<br />

TINT ROLLS<br />

VIDEO PLATEMOUNTER (see PLATEMATE)<br />

CERAMIC ANILOX ROLLS<br />

APPLICATIONS<br />

LASER SHEETS COMPUTER LABELS BLANK LABELS<br />

COLOUR LABELS & LABEL STOCK THERMAL LABELS<br />

SYNTHETIC LABELS PRINTING & CONVERTING PRE-PRINTED<br />

STOCK VARNISHING VALUABLE DATA FINISHING<br />

Standard Machine With Unwind Module Option & Turn Bar<br />

Stacker Option<br />

UNWIND<br />

UNWIND ROLL DIAMETER . . . . . . . . . . . . . . . . . . . . . . . . 610mm<br />

75mm AIR CORE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Std<br />

SPLICE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Std<br />

WEB GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Std<br />

EXTERNAL UNWIND MODULE with 1000mm capacity . . . Optional<br />

REWIND<br />

REWIND ROLL DIAMETER . . . . . . . . . . . . . . . . . . . . . . . . 610mm<br />

INDEPENDENT DRIVE MOTORS . . . . . . . . . . . . . . . . . . . . . . YES<br />

75mm AIR CORE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Std<br />

REWIND TURRETS . . . . . . . . . .ONE SUPPLIED, 2nd OPTIONAL<br />

PRINTING MODULES<br />

PRINT STATIONS PER MODULE . . . . . . . . . . . . . . . . . . . . . . . . . 1<br />

with No Cost Option of Conventional 2 Roll system or Enclosed Ink<br />

Fountain, with Quick Change Ceramic Anilox Roll, Reverse Angle<br />

Doctor Blades, Auto Plate Throw Off & constant turning Anilox Rolls<br />

MAXIMUM PRINTING WIDTH . . . . . . . . 10”(250mm), 13” (330mm),<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17”(430mm)<br />

PRINT LENGTH RANGE . . . . . . . . 6 1/2(165mm)” to 20”(510mm)<br />

ON RUN REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . YES<br />

PRINT GEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/8th C.P<br />

PRINT CARTRIDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . YES<br />

DRYERS . . . . . . Individual progressive infra-red with impinged air<br />

U.V DRYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Optional<br />

TURN BAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Optional<br />

TOOLING (START UP PACK)<br />

RE-REGISTER SYSTEM . .Servo Driven with touch panel control unit<br />

ROTARY SLITTING<br />

PACING ROLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Std<br />

HARDENED SLITTER ANVIL . . . . . . . . . . . . . . . . . . . . . . . . . . Std<br />

PNEUMATIC CRUSH SLITTERS . . . . . . . . . . . . . . . . . 2 Supplied<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (more available as option)<br />

ROTARY DIE /SHEETER MODULE<br />

NUMBER OF ROTARY DIE STATIONS . . . . . . . Two (1 + Sheeter)<br />

ADDITIONAL DIE STATION . . . . . . . . . . . . . . . . . . . . . . . Optional<br />

CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . . all steel side frames<br />

PRESSURE BRIDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . YES<br />

REMOVABLE ANVIL ROLL . . . . . . . . . . . . . . . . . . . . . . . . . . . YES<br />

ON RUN REGISTER ADJUSTMENT . . . . . . . . . . . . . . . . . . . . YES<br />

WASTE REWIND TURRET . . . . One supplied, additional: optional<br />

LAMINATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Optional<br />

STACKER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Optional<br />

DRIVE:<br />

MOTOR SIZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 H.P minimum<br />

MAX SPEED . . . . . . . . . . . . . . (0 to 400F/Min) 0 TO 120 Mts/Min<br />

SUPPLY REQUIREMENTS<br />

ELECTRICAL . . . . . . . . . . . Minimum 380/415V, 3 Phase, 40 Amp<br />

AIR SUPPLY . . . . . . . MINIMUM OF 100 PSI, 6 CFM, CLEAN AIR<br />

(Additional volume air supply is required when using options such<br />

as Turn Bar, Delam- Relam, Silk Screen, and Ink Pumps etc)<br />

Shingle Stacker Register System<br />

Print Station 2 Roll Ink Fountain<br />

Digital Inkjet Slitting Section<br />

Control Panel<br />

Corona Treater &<br />

Web Cleaner<br />

Unwind Module Rotary Die Station

REFLEX 250/330/430 OPERATIONAL FEATURES<br />

REFLEX offers an economic solution to convert and finish any preprinted<br />

web from a Digital or Conventional source. The Servo driven<br />

system controls the web position to ensure perfect register control<br />

across a wide range of substrates for multi pass Printing, Varnishing or<br />

Die Cutting operations.<br />

Every REFLEX is provided with tooling ‘Ready to Go”, for Printing,<br />

Varnishing, Die Cutting, Rewinding or Sheeting.<br />

REFLEX is a compact Converting Tool that has the versatility to be used<br />

as an independent Printing & Converting press if required<br />

IN LINE OR INDEPENDENT OPERATION<br />

ONE TOUCH REGISTER CONTROL (OPTION)<br />

FULL DIGITAL FINISHING & CONVERTING SYSTEM<br />

COMPACT DESIGN & WORK FLOW SOLUTION<br />

FAST, EASY SET UP<br />

QUICK CHANGE CARTRIDGE TECHNOLOGY<br />

INFRA-RED & FULL U.V CURING OPTION<br />

AUTO PLATE THROW OFF & CONSTANT TURNING ANILOX<br />

ROTATION<br />

ROLL TO ROLL AND ROLL TO SHEET FACILITY<br />

The REFLEX system can be used in line with any other Digital<br />

Printing equipment or used as an independent converting tool for<br />

maximum efficiency.<br />

An optional one touch digital register system tracks a pre-printed<br />

Register mark enabling further converting processes such as Printing,<br />

Spot Varnishing, Rotary Die Cutting & Sheeting and finishing of the end<br />

product. The REFLEX is supplied with Automatic web guide & splice<br />

table, a single colour print module with IR drying or U.V Option. Quick<br />

change Ink cartridges are standard for fast changeovers.<br />

The Die Station module allows up to 3 Die Stations including a Sheeter<br />

station for Roll to sheet applications. Various stacking facilities are<br />

available.<br />

One of two Rewind Turrets can be supplied with independent direct<br />

torque drives.<br />

FLEXOGRAPHIC CONVERTING SYSTEMS

CENTRAFLEX STANDARD FEATURES CENTRAFLEX SPECIFICATION<br />

Standard 5+1<br />

Centraflex Press<br />

CENTRAFLEX STANDARD FEATURES<br />

UNWIND<br />

WEB GUIDE<br />

SPLICE TABLE<br />

PRINT STATIONS<br />

QUICK CHANGE INK CARTRIDGES & ANILOX ROLLS<br />

DOCTER BLADE CASSETTES<br />

INFRARED INTERSTATION DRYERS<br />

ROTARY DIE STATIONS<br />

SLITTING<br />

WASTE REWIND<br />

ROTARY DIE SHEETER STATION<br />

REWIND<br />

CENTRAFLEX OPTIONS<br />

EXTERNAL UNWIND MODULE<br />

CORONA TREATER<br />

WEB CLEANER<br />

4,5 or 6 COLOUR CONFIGURATIONS<br />

REVERSE PRINT FACILTY (1 + 5 Colours)<br />

VIDEO INSPECTION SYSTEM<br />

U.V DRYER<br />

ADDITIONAL VARNISH STATION (Allows 6 + 1)<br />

CHILL ROLL SYSTEMS<br />

TURN BAR (2 + 3 Colours max)<br />

COLD FOIL(FOILFLEX)<br />

LAMINATION UNWIND<br />

ADDITIONAL WASTE REWIND<br />

ADDITIONAL ROTARY DIE STATION<br />

DIE ADAPTORS<br />

ROTARY DIES<br />

SPROCKET PUNCH<br />

AUTOMATIC STACKER SYSTEMS (Shingle Type or Bottom up)<br />

ADDITIONAL CRUSH SLITTERS<br />

BACK SCORING SYSTEM (Back Slitting)<br />

FAN FOLDER<br />

ADDITIONAL REWIND TURRET<br />

PRINT CYLINDERS & GEARS<br />

TINT ROLLS<br />

VIDEO PLATEMOUNTER (see PLATEMATE)<br />

CERAMIC ANILOX ROLLS<br />

Standard<br />

Machine<br />

Full UV Water Cooled<br />

6 +1 Centraflex Press<br />

250-330<br />

UNWIND<br />

UNWIND ROLL DIAMETER . . . . . . . . . . . . . . . . . . . . . . . . . 610mm<br />

75mm AIR CORE<br />

SPLICE TABLE<br />

WEB GUIDE<br />

EXTERNAL UNWIND MODULE with 1000mm capacity . . . . Optional<br />

REWIND<br />

REWIND ROLL DIAMETER. . . . . . . . . . . . . . . . . . . . . . . . . . 610mm<br />

75mm AIR CORE<br />

REWIND TURRETS . . . . . . . . . . . ONE SUPPLIED, 2nd OPTIONAL<br />

INDEPENDENT DRIVE MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . YES<br />

PRINTING (CENTRAL IMPRESSION)<br />

MINIMUM NUMBER OF PRINT STATIONS . . . . . . . . . . . . . . . . . . 4<br />

MAXIMUM NUMBER OF PRINT STATIONS. . . . . . . . . . . . . . . . . . 6<br />

MAXIMUM PRINTING WIDTH. . . . . . . . . . . . . . . . . . . . 13”(330mm)<br />

PRINT LENGTH RANGE. . . . . . . . . . 6-1/2(165mm) to 20”(510mm)<br />

ON RUN REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . YES<br />

PRINT GEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/8th C.P<br />

PRINT CARTRIDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . YES<br />

DRYERS . . . . . . . Individual progressive infra-red with impinged air<br />

U.V DRYING . . . . . . . . . . . . . . . . . . . . . . After 6th Colour , Optional<br />

REVERSE PRINT (1 + 5 COLOURS) . . . . . . . . . . . . . . . . . . . Option<br />

TURN BAR (2 + 3 COLOURS) . . . . . . . . . . . . . . . . . . . . . . . . Option<br />

ROTARY SLITTING<br />

PACING ROLL<br />

HARDENED SLITTER ANVIL<br />

PNEUMATIC CRUSH SLITTERS . . . 2 Supplied (more available as option)<br />

ROTARY DIE /SHEETER MODULE<br />

NUMBER OF ROTARY DIE STATIONS . . . . . . . Three (2 + Sheeter)<br />

ADDITIONAL DIE STATION . . . . . . . . . . . . . . . . . . . . . . . . . Optional<br />

CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . . . all steel side frames<br />

PRESSURE BRIDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . YES<br />

REMOVABLE ANVIL ROLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . YES<br />

ON RUN REGISTER ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . YES<br />

WASTE REWIND TURRET . . . . One supplied, additional : optional<br />

LAMINATING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Optional<br />

DRIVE:<br />

MOTOR SIZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 H.P Minimum<br />

MAX SPEED. . . . . . . . . . . . . . . . (0 to 400F/Min) 0 TO 120 Mts/Min<br />

SUPPLY REQUIRMENTS<br />

ELECTRICAL . . . . . . . . . . . . . . . . . . . . 380/415V, 3 Phase, 35 Amp<br />

AIR SUPPLY . . . . . . . . MINIMUM OF 100 PSI, 6 CFM, CLEAN AIR<br />

(Additional volume air supply is required when using options such<br />

as Turn Bar, Delam-Relam, Silk Screen, and Ink Pumps etc)<br />

Print Station<br />

Sheeting Station<br />

Video Inspection<br />

NEW CENTRAFLEX<br />

UV/IR 6 + 1 COLOURS<br />

(Separate information available)

CENTRAFLEX 5+1 COLOURS<br />

With Auto Tension Unwind<br />

CENTRAFLEX 250 OPERATIONAL FEATURES<br />

The new generation CENTRAFLEX is possibly the most compact 6 Colour<br />

flexographic press on the market, with unrivalled standard features.<br />

Without modification, the CENTRAFLEX will print and convert<br />

unsupported film substrates through to labels, tags & heavy board. The<br />

Central Impression concept is a proven success for all ranges of materials<br />

and specialist applications. The all-new, highly efficient drying system<br />

allows press speeds comparable with most in-line converting equipment<br />

The print stations are supplied with a quick-change ink cartridge system,<br />

whilst anilox rolls may be changed in seconds, all without the need for<br />

tools. Versatility is also a key feature of the CENTRAFLEX, with Reverse<br />

Print, Rotary Cold Foil, Turn-Bar, Lamination and a host of other<br />

production enhancing facilities available.<br />

HIGH SPEED PRINTING & CONVERTING<br />

COMPACT CENTRAL IMPRESSION PRESS DESIGN<br />

4,5 or 6 COLOUR OPTION<br />

QUICK CHANGE CARTRIDGE TECHNOLOGY<br />

FAST SET UPS & RAPID CHANGEOVERS<br />

CONSTANT ANILOX ROTATION & AUTOMATIC PLATE<br />

THROW OFF<br />

INFRARED & PART U.V CURING SYSTEMS<br />

ROLL TO ROLL or ROLL TO SHEET CONVERTING<br />

The CENTRAFLEX is supplied with splice table & web guide as standard.<br />

The unwind can be installed within the main body of the press for those<br />

with space restrictions, or supplied with a dedicated large capacity<br />

unwind module. The print stations, located around the central drum, each<br />

have a self-contained quick-change ink cartridge, with ink pan, metering<br />

roll and reverse angle doctor blade. No tools are required to remove or<br />

exchange cartridges. Anilox rolls can be removed within seconds .<br />

Automatic plate throw off & constant turning anilox rolls are standard<br />

features, whilst twin nip roll drives ensure print register is fully stable on<br />

any substrate type, including unsupported films.<br />

The standard drying system uses progressive infra-red units, with lamp<br />

intensity matched to press speed. Concentrated impinged air assists<br />

drying on the substrate, with excess air being exhausted away from the<br />

web. U.V drying can be added for varnish applications.<br />

The Die Section module allows up to 3 Rotary stations to be supplied,<br />

plus a sheeting station for roll to sheet applications. This module also<br />

includes a dedicated slitting station.<br />

One or two rewind turrets can by supplied with direct torque drives,<br />

suitable for film, label, tag and board substrates. Both the print and die<br />

stations have full register adjustment in linear and lateral directions.<br />

PROFESSIONAL CONVERTING SYSTEMS<br />

R O T A R Y S C R E E N S Y S T E M S

FOILFLEX STANDARD FEATURES<br />

UNWIND<br />

SPLICE TABLE<br />

NIP ROLLER FEED DRIVE<br />

UNWIND<br />

WASTE REWIND<br />

NDEPENDENT TENSION CONTROL<br />

(note U.V DRYER is required)<br />

FOILFLEX OPTIONS<br />

CONFIGURATION CENTRAFLEX (Fixed Position, 6th Colour)<br />

CONFIGURATION PROFLEX (Variable position)<br />

CONFIGURATION WEBFLEX (Variable position)<br />

U.V DRYER<br />

FOILFLEX SPECIFICATION<br />

UNWIND<br />

UNWIND ROLL DIAMETER . . . . . . . . . . . . . . . . . . . . . . . .300mm<br />

75mm AIR CORE<br />

INDEPENDENT TENSION CONTROL . . . . . . . . . . . . . . . . . . .YES<br />

SPLICE TABLE<br />

WITH SPLICE GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES<br />

REWIND<br />

REWIND ROLL DIAMETER . . . . . . . . . . . . . . . . . . . . . . . . .300mm<br />

75mm AIR CORE<br />

INDEPENDENT TENSION CONTROL . . . . . . . . . . . . . . . . . . .YES<br />

NIP FEED<br />

SINGLE ROLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES<br />

MAX SPEED . . . . . . . . . . . . . . .(0 to 75Ft/Min) 0 TO 60 Mtrs/Min<br />

SUPPLY REQUIRMENTS<br />

ELECTRICAL . . . . . . . . . . . . . . . . . . .220/240V, 1 Phase, 13 Amp<br />

AIR SUPPLY . . . . . . .MINIMUM OF 100 PSI, 6 CFM, CLEAN AIR<br />

FOILFLEX<br />

There is no more cost effective way of adding value to your labels<br />

than with the ‘FOILFLEX’ Cold Foil system, available on all <strong>Focus</strong><br />

machine models.<br />

Incorporating foil decoration to any graphic design adds value,<br />

enhances quality and provides a new dimension for graphic<br />

designers. In the past, converters have been limited to hot foil<br />

systems with press speed limitations, or expensive off line<br />

solutions. The new FOILFLEX Cold Foil system can be regarded as<br />

an integral part of the printing process, requiring only a U.V dryer,<br />

eliminating speed restrictions and providing high definition foil<br />

decoration.<br />

FOIL / LAMINATION UNWIND<br />

NIP ROLL IN FEED<br />

FOIL / LAMINATION WASTE REWIND<br />

HIGH SPEED APPLICATION<br />

HIGH QUALITY DEFINITION<br />

COST EFFECTIVE SOLUTION<br />

OPERATIONAL FEATURES<br />

The material cost of cold foil is comparable with traditional hot foil<br />

laminate films, but without the additional investment of specialist<br />

tooling or ‘off line’ equipment.<br />

Using a standard flexographic process, the foil design is simply<br />

printed, using a special U.V.- reactive adhesive, in place of ink. Foil<br />

is laminated onto the substrate, before passing through the U.V<br />

dryer. The U.V dryer cures the adhesive and the waste foil is then<br />

removed in line, leaving the highly decorative design. This system<br />

will provide a seamless production solution, allowing you to offer<br />

your customer real added value & quality.

SCREENFLEX<br />

<strong>Focus</strong> has developed a Rotary Screen system specifically for its<br />

range of Flexographic printing presses.<br />

This offers the opportunity to add further value to your <strong>Label</strong><br />

business without the perceived investment of purchasing a<br />

third party system. You will be confident in the knowledge<br />

that this system is designed specifically for your press and<br />

backed by <strong>Focus</strong> service and technical support. Screens<br />

are available from a number of sources and are glued to<br />

<strong>Focus</strong> supplied end rings using the mounting frame<br />

provided. The systems is servo driven with fast set up times<br />

ensured through its auto impression set up. Silk screen<br />

printing can provide various opportunities to add value to<br />

labels and open up brand new markets from Pharmaceuticals<br />

to Beverages.<br />

SCREENFLEX STANDARD FEATURES<br />

COMPACT SYSTEM<br />

QUICK CHANGE<br />

SERVO DRIVEN<br />

VALUE ADDED SOLUTION<br />

UV OR OVEN DRYING OPTIONS AVAILABLE<br />

SCREENFLEX OPTIONS<br />

VARIABLE POS SYSTEM<br />

U.V DRYER (Single Lamp)<br />

U.V DRYER (Twin Lamp).<br />

OVEN TUNNEL DRYER<br />

GRAY MILLS INK PUMP<br />

END RINGS<br />

SCREENS<br />

AUTO REGISTER<br />

SCREENFLEX SPECIFICATIONS<br />

WEB WIDTH . . . . . . . . . . . . . . . . . . . . 250mm, 330mm & 430mm<br />

MACHINE COMPATIBILITY<br />

WEBFLEX, PROFLEX, REFLEX, CENTRAFLEX<br />

SCREEN TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . NICKLEMESH<br />

END RING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FOCUS<br />

MINIMUM PRINT . . . . . . . . . . . . . . . . . . . . . . . 12", 305mm (96T)<br />

MAXIMUM PRINT . . . . . . . 20", 508mm (160T) , 1/8" increments<br />

ACCURACY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +/- 0.5mm<br />

LINEAR REGISTER . . . . . . Auto Servo System, Auto Impression<br />

SIDE RIGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Manual<br />

INK FEED . . . . . . . . .Manual or Ink Pump with auto level control<br />

DRYING SPEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100Mts/min<br />

(depending on applied film weight & drying system)<br />

SET UP TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Minutes<br />

JOB CHANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Minutes<br />

AUTO SCREEN THROW OFF . . . . . . . . . . . . . . . . . . . . . . . . .Yes<br />

(with Constant Rotation at Press stops)<br />

PROFESSIONAL VIDEO PLATE MOUNTING SYSTEMS

PLATEMATE STANDARD FEATURES<br />

HIGH DEFINITION MONITOR WITH SPLIT SCREEN<br />

ADJUSTABLE CAMERA POSITIONS<br />

MATCHED TWIN 1ccd CAMERAS (Professional quality)<br />

MATCHED TWIN HIGH-MAGNIFICATION LENSES<br />

(Professional quality)<br />

TAPE DISPENSER<br />

PLATE HOLDER<br />

MICRO ADJUSTABLE PLATE POSITIONING<br />

CYLINDER SPINDLE<br />

PLATEMATE OPTIONS<br />

WORK STATION<br />

CYLINDER SPINDLES FOR VARIOUS MACHINES<br />

including :- <strong>Focus</strong>, MarkAndy, Nilpeter, Gallus, Aquaflex,<br />

Rotopress, Sanjo, Edale, Allied Gear, Comco, Taiyo, Kopack, KDO<br />

PLATEMATE SPECIFICATION<br />

High Definition B/W (Mono) Monitor . . . . . . . . . . . . . . . . . . . . . . .Std<br />

Matched Twin 1 ccd cameras (Professional quality) . . . . . . . . . .Std<br />

Matched high Magnification Lens . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

Tape Dispenser With 75mm Cone Core adaptor . . . . . . . . . . . . .Std<br />

Plate Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

Micro Adjustable Plate Positioning . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

Max Cylinder Width . . . . . . . . .17”, 430mm (other sizes on request)<br />

Max Cylinder Diameter . . . . . . . . . . . . . . . . . .24”, 610mm Diameter<br />

Dimensions L x W X h . . . . . .650 x 780 x 1000mm (Standard Unit)<br />

Supply… . . . . . . . . . . . . . . . . . . . .220.240V , single phase, 13 amp<br />

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 Kgs<br />

PLATEMATE<br />

PLATEMATE is simply the most effective system for mounting all types<br />

of flexible photopolymer printing plates. Guaranteed to be pin<br />

accurate every time, the PLATEMATE is quick & simple to operate and<br />

has an integral adhesive tape dispenser as standard.<br />

No more valuable production time due to mislaid plates - or costly<br />

down time waiting for plates to be mounted. A complete set of printing<br />

plates can be pre-mounted, before going to press, with full confidence<br />

they will be square and accurate. Available for all <strong>Focus</strong> machine<br />

models, the PLATEMATE system is compatible with printing cylinders<br />

from almost every type narrow web press, ensuring the full production<br />

press shop can enjoy the benefits of the system.<br />

COMPACT, HEAVY DUTY FRAME<br />

TWIN HIGH-MAGNIFICATION CAMERAS<br />

SPLIT VIDEO SCREEN<br />

FINE ADJUSTMENT OF PRINT PLATE<br />

ADHESIVE TAPE DISPENSER<br />

REDUCED SET UP TIMES<br />

COST EFFECTIVE SOLUTION<br />

COMPATIBLE WITH ALL CYLINDER TYPES<br />

OPERATIONAL FEATURES<br />

The systems utilize 2 pre-applied register marks at each edge of the<br />

printing plates, aligned perpendicular to the printing direction. The<br />

print cylinder is loaded onto a spindle, directly under the high<br />

magnification cameras. Double sided mounting tape is applied to the<br />

printing cylinder. The printing plate is then positioned and clamped<br />

under the two cameras and each camera is focused onto a different<br />

half of each register mark. The combined image is displayed on the<br />

high definition monitor. The position of the printing plate to the<br />

cylinder can be infinitely adjusted until the two half images make a<br />

perfect full display. At this point, the printing plate can be firmly<br />

applied to the printing cylinder & released from the plate clamp. The<br />

plate is now mounted and ready to go to press.<br />

This procedure takes les than 30 seconds and is repeated for each<br />

printing plate cylinder.

PROFILE RANGE<br />

- Solvent Washout Flexo Platemakers<br />

A complete range of compact combination units for flexographic<br />

platemaking.<br />

This ‘ all in one’ version combines all the platemaking process steps<br />

and is designed for all types of plates and solvents (chlorinated or<br />

unchlorinated). Although compact and economic to run, these<br />

systems are of excellent build quality and will easily produce flexo<br />

plates of the highest quality, with smooth even floors, crisp detail<br />

and fine, clean reversals.<br />

PROFILE FLW<br />

- Water Washout Flexo Platemakers<br />

A complete range of compact combination units for water washable<br />

flexographic plates. This ‘all in one’ version combines all the<br />

platemaking process steps and is designed for use with the leading<br />

brands of water washable plates. Ideally suited to the smaller plate<br />

making operation where space is limited and value for money is<br />

paramount, this line is perfectly adapted for customers using limited<br />

thickness of plate.<br />

Optional filter device for low production OR For higher production,<br />

the external filter unit is recommended.<br />

MODEL Processing Max plate size Max plate size<br />

(cm) (inches)<br />

PROFILE FLEXO A4 Solvent 27 cm x 37 cm 10.5” x 14.5”<br />

PROFILE FLEXO A3 Solvent 37 cm x 52 cm 14.5” x 20.5”<br />

PROFILE FLEXO A2 Solvent 55 cm x 76 cm 21.5” x 30”<br />

PROFILE FLEXO A1 Solvent 60 cm x 80 cm 23.5” x 31.5”<br />

PROFILE FLW A3 Water 37 cm x 52 cm 14.5” x 20.5”<br />

PROFILE FLW A2 Water 55 cm x 76 cm 21.5” x 30”<br />

Washout section: The plate is fixed face down on the<br />

plate holder. Relief washout is obtained by orbital<br />

movement of the plate over a brush frame ( An exhaust<br />

device is incorporated for solvent fumes on solvent<br />

version ).<br />

Exposure: Pull out vacuum drawer with draw down<br />

sheet to hold plate during exposure.<br />

Light finisher: Pull out drawer for UVC anti-tack<br />

exposure (profile models only).<br />

Dryer: Three dryer drawers with temperature control<br />

and exhaust blower.<br />

Exposure Drawer Digital Control Panel<br />

Vacuum Frame Multi Function Control<br />

Plate Drying Plate Wash Out

Q U A L I T Y P R O D U C T I O N T E C H N I Q U E<br />

<strong>Focus</strong> <strong>Label</strong> <strong>Machinery</strong> <strong>Ltd</strong> reserve the right to change the specification without prior notice.<br />

CD Rom & Video available on request<br />

<strong>Focus</strong> <strong>Label</strong> <strong>Machinery</strong> <strong>Ltd</strong><br />

Kendryl Park Chapel Lane Bingham Nottingham NG13 8GF England<br />

Telephone: +44 (0) 1949 836223 Fax: +44 (0) 1949 836542<br />

Web: www.focuslabel.com E-mail: admin@focuslabel.com<br />

Printed in England † Trademark Pending UKPO/1M 9/05