Focus Flexography Brochure - Focus Label Machinery, Ltd

Focus Flexography Brochure - Focus Label Machinery, Ltd

Focus Flexography Brochure - Focus Label Machinery, Ltd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

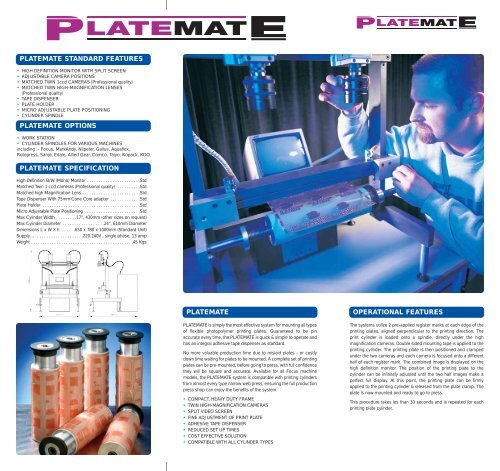

PLATEMATE STANDARD FEATURES<br />

HIGH DEFINITION MONITOR WITH SPLIT SCREEN<br />

ADJUSTABLE CAMERA POSITIONS<br />

MATCHED TWIN 1ccd CAMERAS (Professional quality)<br />

MATCHED TWIN HIGH-MAGNIFICATION LENSES<br />

(Professional quality)<br />

TAPE DISPENSER<br />

PLATE HOLDER<br />

MICRO ADJUSTABLE PLATE POSITIONING<br />

CYLINDER SPINDLE<br />

PLATEMATE OPTIONS<br />

WORK STATION<br />

CYLINDER SPINDLES FOR VARIOUS MACHINES<br />

including :- <strong>Focus</strong>, MarkAndy, Nilpeter, Gallus, Aquaflex,<br />

Rotopress, Sanjo, Edale, Allied Gear, Comco, Taiyo, Kopack, KDO<br />

PLATEMATE SPECIFICATION<br />

High Definition B/W (Mono) Monitor . . . . . . . . . . . . . . . . . . . . . . .Std<br />

Matched Twin 1 ccd cameras (Professional quality) . . . . . . . . . .Std<br />

Matched high Magnification Lens . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

Tape Dispenser With 75mm Cone Core adaptor . . . . . . . . . . . . .Std<br />

Plate Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

Micro Adjustable Plate Positioning . . . . . . . . . . . . . . . . . . . . . . . .Std<br />

Max Cylinder Width . . . . . . . . .17”, 430mm (other sizes on request)<br />

Max Cylinder Diameter . . . . . . . . . . . . . . . . . .24”, 610mm Diameter<br />

Dimensions L x W X h . . . . . .650 x 780 x 1000mm (Standard Unit)<br />

Supply… . . . . . . . . . . . . . . . . . . . .220.240V , single phase, 13 amp<br />

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 Kgs<br />

PLATEMATE<br />

PLATEMATE is simply the most effective system for mounting all types<br />

of flexible photopolymer printing plates. Guaranteed to be pin<br />

accurate every time, the PLATEMATE is quick & simple to operate and<br />

has an integral adhesive tape dispenser as standard.<br />

No more valuable production time due to mislaid plates - or costly<br />

down time waiting for plates to be mounted. A complete set of printing<br />

plates can be pre-mounted, before going to press, with full confidence<br />

they will be square and accurate. Available for all <strong>Focus</strong> machine<br />

models, the PLATEMATE system is compatible with printing cylinders<br />

from almost every type narrow web press, ensuring the full production<br />

press shop can enjoy the benefits of the system.<br />

COMPACT, HEAVY DUTY FRAME<br />

TWIN HIGH-MAGNIFICATION CAMERAS<br />

SPLIT VIDEO SCREEN<br />

FINE ADJUSTMENT OF PRINT PLATE<br />

ADHESIVE TAPE DISPENSER<br />

REDUCED SET UP TIMES<br />

COST EFFECTIVE SOLUTION<br />

COMPATIBLE WITH ALL CYLINDER TYPES<br />

OPERATIONAL FEATURES<br />

The systems utilize 2 pre-applied register marks at each edge of the<br />

printing plates, aligned perpendicular to the printing direction. The<br />

print cylinder is loaded onto a spindle, directly under the high<br />

magnification cameras. Double sided mounting tape is applied to the<br />

printing cylinder. The printing plate is then positioned and clamped<br />

under the two cameras and each camera is focused onto a different<br />

half of each register mark. The combined image is displayed on the<br />

high definition monitor. The position of the printing plate to the<br />

cylinder can be infinitely adjusted until the two half images make a<br />

perfect full display. At this point, the printing plate can be firmly<br />

applied to the printing cylinder & released from the plate clamp. The<br />

plate is now mounted and ready to go to press.<br />

This procedure takes les than 30 seconds and is repeated for each<br />

printing plate cylinder.