Focus Flexography Brochure - Focus Label Machinery, Ltd

Focus Flexography Brochure - Focus Label Machinery, Ltd

Focus Flexography Brochure - Focus Label Machinery, Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

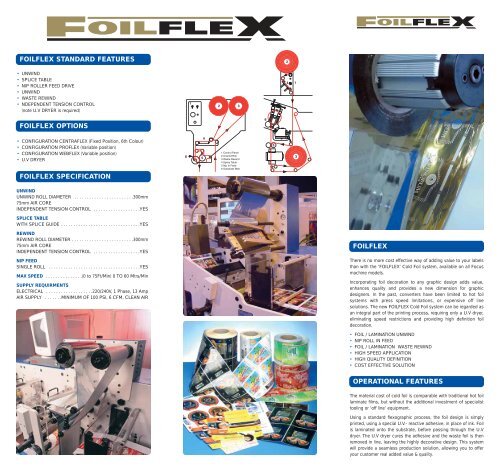

FOILFLEX STANDARD FEATURES<br />

UNWIND<br />

SPLICE TABLE<br />

NIP ROLLER FEED DRIVE<br />

UNWIND<br />

WASTE REWIND<br />

NDEPENDENT TENSION CONTROL<br />

(note U.V DRYER is required)<br />

FOILFLEX OPTIONS<br />

CONFIGURATION CENTRAFLEX (Fixed Position, 6th Colour)<br />

CONFIGURATION PROFLEX (Variable position)<br />

CONFIGURATION WEBFLEX (Variable position)<br />

U.V DRYER<br />

FOILFLEX SPECIFICATION<br />

UNWIND<br />

UNWIND ROLL DIAMETER . . . . . . . . . . . . . . . . . . . . . . . .300mm<br />

75mm AIR CORE<br />

INDEPENDENT TENSION CONTROL . . . . . . . . . . . . . . . . . . .YES<br />

SPLICE TABLE<br />

WITH SPLICE GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES<br />

REWIND<br />

REWIND ROLL DIAMETER . . . . . . . . . . . . . . . . . . . . . . . . .300mm<br />

75mm AIR CORE<br />

INDEPENDENT TENSION CONTROL . . . . . . . . . . . . . . . . . . .YES<br />

NIP FEED<br />

SINGLE ROLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES<br />

MAX SPEED . . . . . . . . . . . . . . .(0 to 75Ft/Min) 0 TO 60 Mtrs/Min<br />

SUPPLY REQUIRMENTS<br />

ELECTRICAL . . . . . . . . . . . . . . . . . . .220/240V, 1 Phase, 13 Amp<br />

AIR SUPPLY . . . . . . .MINIMUM OF 100 PSI, 6 CFM, CLEAN AIR<br />

FOILFLEX<br />

There is no more cost effective way of adding value to your labels<br />

than with the ‘FOILFLEX’ Cold Foil system, available on all <strong>Focus</strong><br />

machine models.<br />

Incorporating foil decoration to any graphic design adds value,<br />

enhances quality and provides a new dimension for graphic<br />

designers. In the past, converters have been limited to hot foil<br />

systems with press speed limitations, or expensive off line<br />

solutions. The new FOILFLEX Cold Foil system can be regarded as<br />

an integral part of the printing process, requiring only a U.V dryer,<br />

eliminating speed restrictions and providing high definition foil<br />

decoration.<br />

FOIL / LAMINATION UNWIND<br />

NIP ROLL IN FEED<br />

FOIL / LAMINATION WASTE REWIND<br />

HIGH SPEED APPLICATION<br />

HIGH QUALITY DEFINITION<br />

COST EFFECTIVE SOLUTION<br />

OPERATIONAL FEATURES<br />

The material cost of cold foil is comparable with traditional hot foil<br />

laminate films, but without the additional investment of specialist<br />

tooling or ‘off line’ equipment.<br />

Using a standard flexographic process, the foil design is simply<br />

printed, using a special U.V.- reactive adhesive, in place of ink. Foil<br />

is laminated onto the substrate, before passing through the U.V<br />

dryer. The U.V dryer cures the adhesive and the waste foil is then<br />

removed in line, leaving the highly decorative design. This system<br />

will provide a seamless production solution, allowing you to offer<br />

your customer real added value & quality.