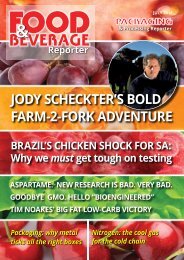

Food & Beverage Reporter August 2018

South Africa's leading B2B magazine for the food & beverage sector and its allied industries in processing/packaging etc

South Africa's leading B2B magazine for the food & beverage sector and its allied industries in processing/packaging etc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INNOVATION<br />

BM FOODS GOES GREEN<br />

WITH CO2 COOLING<br />

In a move that marks a first in South<br />

Africa and which will dramatically<br />

reduce its carbon footprint, BM <strong>Food</strong>s,<br />

manufacturers of Mediterranean<br />

Delicacies, has opted for<br />

environmentally-friendly natural<br />

gas to keep its food cool.<br />

By switching to CO2-driven<br />

refrigeration, the Cape Town<br />

factory reduces any negative<br />

impact on the environment. This<br />

is in line with the Global Warming<br />

Potential (GWP) measure that<br />

allows analysts to calculate<br />

emissions from different gases.<br />

The GWP uses a score-type<br />

system to define what damages<br />

the environment and the lower<br />

the score, the better. In this case,<br />

CO2 has a score of 1 – compared<br />

to traditional refrigeration gases, which<br />

currently have a GWP score of 4922.<br />

Richard Drinkrow, MD of Mainstream<br />

Refrigeration, which supplied the<br />

refrigeration system, advises that CO2 is<br />

a natural gas that is recovered from the<br />

atmosphere and if there are any leaks,<br />

this simply returns to the atmosphere<br />

where it belongs. “CO2 was the original<br />

gas used in the 1930s, which was<br />

Rooftop view of BM <strong>Food</strong>s’ factory showing the<br />

refrigeration system that uses carbon dioxide.<br />

ousted for more modern gases, but the<br />

damage caused by traditional gases and<br />

other pollutants to the ozone layer and<br />

beyond, has resulted in increased global<br />

pressure to protect the environment.”<br />

According to Drinkrow, reverting<br />

to CO2 in refrigeration systems will<br />

assist in making small yet impactful<br />

improvements to our environment<br />

and for manufacturers like BM <strong>Food</strong>s,<br />

returning to natural gases as a<br />

means of refrigeration is taking<br />

a step forward for the food<br />

manufacturing industry.<br />

BM <strong>Food</strong>s CEO, Costas<br />

Vayanos, is more than satisfied<br />

with this innovation as it has<br />

cost-saving advantages. “We are<br />

now using 100% environmentallyfriendly<br />

gas, and as an added<br />

benefit we get free heating for all<br />

of our hot water requirements in<br />

the factory via a heat exchanger.”<br />

The factory no longer<br />

needs electrically-heated hot<br />

water cylinders in the facility, and<br />

combined with its 30% solar power<br />

solution, BM’s carbon footprint has<br />

reduced significantly. “We are highly<br />

motivated to be the South African leader<br />

in environmentally-friendly practices<br />

within the food manufacturing industry,”<br />

says Vayanos.<br />

www.bmfoods.co.za<br />

ID Logistics beefs up tech solutions<br />

ID Logistics South Africa has upped its<br />

game by adopting new technology to<br />

add value to its large FMCG and retail<br />

clients by installing a centralized control<br />

tower at its head office in Boksburg.<br />

Adrien Faye, National Transport<br />

Planning & Execution Tracking Manager<br />

at ID Logistics SA, has been responsible<br />

for rolling out and supporting similar<br />

projects for the global group in France,<br />

Belgium and China. “We started the<br />

planning for the Centralised Control<br />

Tower in South Africa in July 2017 and<br />

by January this year we had established<br />

our centralised transport planning<br />

department at our head office.”<br />

According to Faye, the major<br />

benefits of a centralised facility is<br />

visibility of the clients’ orders through<br />

its entire journey from collection to<br />

delivery, as well real-time track and trace<br />

capabilities, and effective monitoring of<br />

the drivers and vehicles. “This managed<br />

transport service means that we can<br />

orchestrate operations, and receive<br />

real-time analysis which can result in<br />

enhancements and cost savings. In<br />

addition, communication between all<br />

parties, including clients, has improved,”<br />

says Faye.<br />

During 2017, the company implemented<br />

ZENO mobile software, an<br />

online scheduler for same and next day<br />

planning of vehicles and deliveries, with<br />

built-in workflow management. “This<br />

helps to manage both the planning and<br />

execution with real-time events through<br />

the use of alerts, automatic adjustment<br />

of existing schedules following events.<br />

It integrates with the handheld mobile<br />

devices and backend financial system,<br />

which enables our mobile workforce to<br />

receive alerts, downloadable schedules,<br />

signatures-on-line, as well as a lot more<br />

functionality.”<br />

Hand-in-hand with ZENO, is the<br />

company’s optimisation programme,<br />

based on PLATO, which is a suite of<br />

enterprise-level planning software<br />

modules that provides transport<br />

management, route optimisation and<br />

resource utilisation.<br />

www.id-logistics.com/za/southafrica/<br />

32 AUGUST <strong>2018</strong> | FOOD & BEVERAGE REPORTER www.fbreporter.co.za