Insulate Magazine issue 6

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The only independent<br />

insulation industry<br />

trade magazine<br />

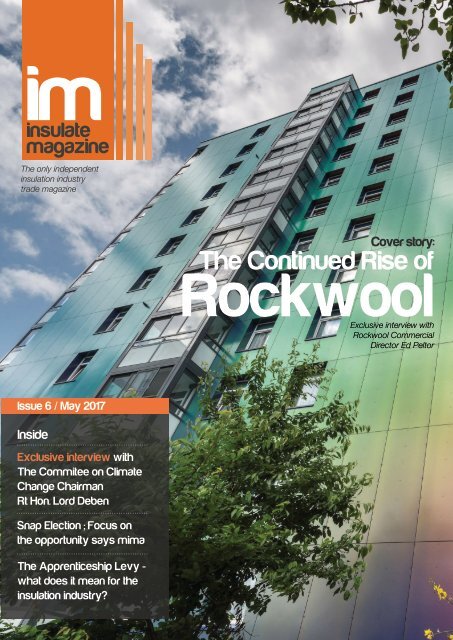

Cover story:<br />

The Continued Rise of<br />

Rockwool<br />

Exclusive interview with<br />

Rockwool Commercial<br />

Director Ed Peltor<br />

Issue 6 / May 2017<br />

Inside<br />

Exclusive interview with<br />

The Commitee on Climate<br />

Change Chairman<br />

Rt Hon. Lord Deben<br />

Snap Election ; Focus on<br />

the opportunity says mima<br />

The Apprenticeship Levy -<br />

what does it mean for the<br />

insulation industry?

SIG360 work with us<br />

on site, to ensure we<br />

not only meet our<br />

client’s needs but<br />

exceed them.<br />

NEIL HARRISON<br />

HARRISON PROJECTS<br />

AN SIG CUSTOMER<br />

BUILD YOUR NAME ON US<br />

Providing impartial<br />

product advice<br />

The SIG360 Technical Centre is a service offering from SIG, that focuses on helping customers<br />

deliver energy efficient buildings.<br />

Through an intimate knowledge of building regulations and product performance, brought<br />

about through more than 50 years specialising in the energy efficiency of the fabric of a<br />

building, the SIG360 Technical Centre is able to make cost effective and impartial product<br />

selection to ensure the best energy performance can be achieved.<br />

The service provided includes energy statements, U value calculations , condensation risk<br />

analysis, thermal modelling and SAP assessments leading to EPC certification.<br />

If you are seeking impartial advice on the fabric energy efficiency of your building contact<br />

SIG360 Technical Centre.<br />

For guidance you can trust call 0844 443 0059<br />

email 360enquiries@sigplc.com or visit www.sig360.co.uk<br />

Talk to the SIG360 Technical<br />

Centre at the start of your project<br />

for a 360 o view of cost effective<br />

and energy efficient home building

www.insulatemagazine.co.uk<br />

Published on a monthly basis by M4 Publications & Events Ltd<br />

Corser House, 17 Geen End, Whitchurch, Shropshire, SY13 1AD<br />

Call 01948 759 351<br />

Outside of the UK +44 1948 759351<br />

Monday - Friday 9am - 5.30pm<br />

Website: www.insulatemagazine.co.uk<br />

Email: sales@insulatemagazine.co.uk<br />

SUBSCRIPTION INFORMATION<br />

Anyone can subscribe for free online at www.powerboatracingworld.com/subscribe<br />

or by phone on 01948 759 351.<br />

Subscriptions are available around the world free in digital format.<br />

Print subscriptions are available around the world, please call us for<br />

a quote or email us on sales@insulatemagazine.co.uk<br />

Our subscriber list is occasionally made available to very carefully<br />

selected companies whose products or services may be of interest<br />

to you. Your privacy is of paramount importance to us and should<br />

you prefer not to be part of these lists then please email your details<br />

and a short message to sales@insulatemagazine.co.uk<br />

CLASSIFIED ADVERTISING<br />

Rate: No photo classified £25 for 20 words, each additional word<br />

costs £1. All classified advertising must be paid in advance. We<br />

must receive your classified advert at least two weeks prior to the<br />

publication date.<br />

WE DO NOT ACCEPT PHONE IN CLASSIFIED ADVERTISING<br />

In the first instance, email your advert to sales@insulatemagazine.<br />

co.uk and await your invoice, once payment is received our design<br />

team will clarify the advert insertion with you directly. CLASSIFIED<br />

ADVERTISING APPEARS IN PRINT AND ONLINE. WE ARE NOT<br />

RESPONSIBLE FOR ERRORS AFTER PROOFING AND INSER-<br />

TION.<br />

DISPLAY ADVERTISING.<br />

Contact one of our sales staff to discuss your requirements on<br />

01948 759 351. Publisher reserves the right to reject any<br />

advertising that in its opinion is misleading, unfair or incompatible<br />

with the character of the magazine.<br />

We adhere to the IPSO code of practice for editors. Further information<br />

can be found at www.ipso.org.uk<br />

BACK ISSUES OR REPRINTS<br />

Digital back <strong>issue</strong>s can be foud online at www.insulatemagazine.<br />

com For printed editions please email contact@insulatemagazine.<br />

co.uk , there will be a postage charge and handling fee of £5+VAT<br />

for each copy requested.<br />

CIRCULATION<br />

The magazine is sent to 23,000 digitial subscribers per month<br />

Contents<br />

The Continued Rise of Rockwool<br />

Achieving Eye Safety Compliance 10-13<br />

Sustainable Moneypenny HQ<br />

6-9<br />

14-15<br />

The Apprenticeship Levy 16-17<br />

Accolade for Belgrade Insulations 18<br />

Reducing costs with full-fill cavity 22-23<br />

Featured CPDs 24-25<br />

Inside story featuring Darren Evans 28-29<br />

The snap election opportunity 31-32<br />

Rockwool goes back to school 34-35<br />

Vision preview 2017 36-37<br />

©M4 PUBLISHING & EVENTS LTD<br />

No part can be reproduced without the express<br />

permission of the publisher<br />

www.facebook.com/insulatemag<br />

www.twitter.com/insulatemag<br />

www.youtube.com/channel/insulatemag<br />

Construction industry post Brexit 38<br />

Rt Hon. Lord Deben on insulation 40-45<br />

The Future of Our Building Stock 46<br />

The UK's only dedicated<br />

trade journal for the insulation industry<br />

3

Cherry Blossom season in Japan - Between 23 rd April and 5 th May<br />

The month of April seemed to pass in a flash here<br />

at <strong>Insulate</strong> HQ. The month began with a fantastic<br />

interview with Committee on Climate Change Chairman,<br />

The RT Hon Lord Deben, an informative interview<br />

with lots of interesting topics covered.<br />

In excess of 100 entries for the inaugural National Insulation<br />

Industry Awards were received with MP Plastering of Cornwall<br />

winning a free table at the event after being nominated by Saint-<br />

Gobain Weber, a pleasing result for a great team, entries have<br />

less than one hundred days to be submitted before the November<br />

ceremony, we look forward to welcoming you all.<br />

Colin Heath<br />

Managing Editor<br />

In this sixth <strong>issue</strong>, our largest to date, an interview with Ed Peltor,<br />

Commercial Director at ROCKWOOL UK gives an insight into<br />

one of the most well-known insulation brands in the UK, a fantastic<br />

column from Sarah Konstense-Winterton, Exec Director at<br />

MIMA in which Sarah suggests that we focus on the opportunity<br />

of the snap election that has dominated the news recently.<br />

Please enjoy!<br />

4<br />

www.insulatemagazine.co.uk

The only independent insulation industry trade magazine<br />

Cover Story<br />

The Continued Rise of<br />

Rockwool<br />

Ed Peltor, Commercial Director of Rockwool - Interview with Colin Heath<br />

Ed Peltor is the commercial director of ROCKWOOL<br />

UK, the stone wool manufacturer. Made from one of<br />

nature’s most abundant resources – volcanic rock,<br />

ROCKWOOL products are not only a naturally renewable<br />

and sustainable material, but they also boasts a unique<br />

combination of acoustic, thermal and fire benefits.<br />

Having previously held positions at Minster and<br />

Sheffield Insulations, as well as MD of FGF, it’s probably<br />

not an overstatement to say that few people can match<br />

Ed’s experience of the insulation market.<br />

<strong>Insulate</strong> <strong>Magazine</strong>’s Colin Heath recently caught up with<br />

Ed and talked to him about his experiences, his insight<br />

into the industry and his views of the future.<br />

It has been almost 4 years since you joined ROCKWOOL. What are<br />

the most significant changes you have seen during that time?<br />

We continue to expand our contractor led approach, pioneered<br />

by our Firestopping and HVAC businesses. Indeed, our<br />

Firestopping business has quadrupled in the last four years.<br />

As well as expanding and upskilling the national sales team, we<br />

6 www.insulatemagazine.co.uk

www.insulatemagazine.co.uk<br />

have also significantly expanded the contractor<br />

support specialist team within the merchant sector<br />

and developed the specification area which<br />

now includes specialists within the EWI, Flat Roof<br />

and Rainscreen sectors.<br />

We have also seen a huge improvement within<br />

technical support, due to the development of<br />

a selection of online support tools. These tools<br />

allow customers to find the information they require<br />

quickly and easily, enabling a more effective<br />

response from the technical support department.<br />

The latest compliance guide that specifiers and<br />

contractors should be aware of, is BR135. Explain a bit<br />

more about this topic, and the support and products<br />

that ROCKWOOL is offering?<br />

Buildings over 18m in height present numerous<br />

challenges when it comes to insulation requirements<br />

and fire safety standards. Given that most<br />

fires occur in domestic dwellings, high-rise residential<br />

buildings over 18m have a high safety risk<br />

in the event of a fire due to the long escape time<br />

for occupants to travel from the top of the building<br />

to safety.<br />

Fire safety standards, embodied in Building<br />

Regulations Part B Fire Safety and associated<br />

Approved Documents, are designed to ensure<br />

that adequate fire safety provisions are incorporated<br />

in tower blocks of any type. Regulation B4<br />

requires the external walls of a building to adequately<br />

“resist the spread of fire” with functional<br />

requirements given in Approved Documents. In<br />

any building, the cladding system and materials<br />

must either conform or exceed the guidance for<br />

limited combustibility as quoted in Part B4,<br />

paragraph 12.7: ‘Insulation Materials/Products’<br />

or, meet the performance criteria given in the<br />

BRE Report: “Fire Performance of External Insulation<br />

for Walls of Multi-Storey Buildings” (BR<br />

135), full scale testing in accordance with BS<br />

8414-1:2002 and BS 8414-2:2005 for its range<br />

of external wall insulation systems.<br />

This testing satisfies building regulations in England<br />

& Wales and Scotland pertaining to fire for<br />

buildings over 18 metres tall.<br />

The BR 135 classification is called for as an alternative<br />

guidance to non-combustibility compliance<br />

for domestic and commercial applications.<br />

With the completion of a number of construction<br />

projects not compliant with Approved Document<br />

B or the guidance under BR135, the Building<br />

Control Alliance in conjunction with its members<br />

looked to readdress misunderstandings within<br />

the market. In June 2014, the BCA published the<br />

first <strong>issue</strong> for guidance note 18, which addressed<br />

the key <strong>issue</strong>s surrounding external wall materials,<br />

including the difference between ‘Surface<br />

Spread of Flame Classification’ (Class 0) and<br />

‘Limited Combustibility’ (Euroclass Classification),<br />

and the various routes for compliance. Following<br />

this revision, the NHBC now include a fourth<br />

option for compliance, published in their<br />

technical bulletin echoing the risk of fire spread<br />

within external wall constructions.<br />

As a publicly available document, Guidance Note<br />

18 is useful to everyone within the construction<br />

process looking to mitigate risk and advises that<br />

“As a guide, insulation of limited combustibility<br />

should be used e.g. Rock mineral fibre type,<br />

stone wool, slag wool or man-made mineral<br />

wool/fibre.”<br />

We have developed a RIBA Accredited CPD,<br />

entitled “Fire safety compliance: Rainscreen<br />

Cladding Systems”. The CPD highlights the<br />

design flexibility and practical benefits that rainscreen<br />

cladding systems can offer both new build<br />

and refurbishment projects. The CPD also explains<br />

how to comply with fire safety performance<br />

within rainscreen systems designed for buildings<br />

above 18 metres.<br />

We have also seen a huge<br />

improvement within technical<br />

support<br />

insulatemag<br />

7

The only independent insulation industry trade magazine<br />

Apart from domestic housing, what sectors of the<br />

built environment will place demands on insulation<br />

manufacturers?<br />

There is a lot of pressure to upgrade schools.<br />

Teaching and learning are acoustically very<br />

demanding activities where it's imperative that<br />

ambient noise is kept as low as possible to<br />

minimise intrusion and distraction.<br />

It's no surprise that studies consistently show<br />

that quieter classrooms achieve better results.<br />

As well as impairing students' reading, comprehension<br />

and verbal interaction, excessive<br />

noise will also compromise behaviour, attention<br />

spans and stress levels.<br />

The existing guidance, Building Bulletin 93<br />

(BB93) "Acoustic Design of Schools", initially<br />

published in 2003 and currently in the process<br />

of revision, offers a clear regulatory framework<br />

for the acoustic design of schools in support<br />

or the Building Regulations.<br />

The revised guidance will support requirement<br />

E4 of the Building Regulations, which applies<br />

to both new schools and schools formed by<br />

change of use of existing buildings. It will also<br />

support the School Premises Regulations<br />

2012, which apply to all state-funded schools<br />

and the Independent Schools Standards,<br />

which apply to all independent schools.<br />

Building Regulations Requirement E4 states<br />

that, "Each room or other space in a school<br />

building shall be designed and constructed<br />

in such a way that it has the acoustic conditions<br />

and the insulation against disturbance<br />

by noise appropriate to its normal use. "The<br />

recently revised School Premises Regulations,<br />

which came into force on the 31 October<br />

2012, require that, "the acoustic conditions<br />

and sound insulation of each room or other<br />

space must be suitable, having regard to the<br />

nature of the activities which normally take<br />

place therein"<br />

8 www.insulatemagazine.co.uk

The Continued Rise of Rockwool<br />

I see that you offer a thermal & sound range. What was<br />

your thinking behind launching this dedicated product?<br />

This range was designed to clarify and simplify<br />

the insulation category by focussing on two<br />

clearly defined applications; Thermal Insulation<br />

and Sound Insulation in the RMI sector, therefore<br />

well served by the builders’ merchants and DIY<br />

channels.<br />

The benefits of Thermal Insulation and its application<br />

are well understood and documented.<br />

Acoustics or Sound, is becoming a more<br />

important consideration in the domestic arena<br />

with ageing housing stock, greater urbanisation,<br />

increasing noise pollution from roads, rail and air<br />

plus the wider adoption of domestic electronics,<br />

TV and surround sound systems in the home.<br />

With its dense, non-directional fibre structure,<br />

our Sound Insulation offering effectively traps<br />

sound waves and dampens vibration to provide<br />

an enhanced noise reducing solution both between<br />

adjacent properties and between rooms<br />

within the same home. The launch of a focussed<br />

Sound range presents clear opportunities for the<br />

contractor to up sell their offer and add value.<br />

We believe our approach brings clarity and opportunity<br />

for the contractor in this category. By<br />

bringing a fresh definition to the category, we<br />

can help contractors find the best insulation for a<br />

particular application. As construction practices<br />

evolve and our lifestyles change, there is a growing<br />

demand for sound insulation and with this<br />

new range and ROCKWOOL’s support we can<br />

help contractors capitalise on that opportunity.<br />

Insulation manufacturers now place greater emphasis<br />

on promoting their solutions to a higher end specification<br />

audience. How successful has Rockwool been in<br />

influencing specifiers?<br />

This is a key sector for us, and one which we<br />

have focussed our attention on recently. We recognised<br />

that this audience requires support when<br />

it comes to specifying insulation, and as such,<br />

we have developed a number of online tools to<br />

support this process.<br />

We recently launched an acoustic calculator,<br />

which provides specifiers with a simple and<br />

effective way of working out the acoustic performance<br />

of insulation installed on walls, floors and<br />

roofs. This calculator enables users to determine<br />

the noise reduction levels that could be achieved<br />

when using ROCKWOOL insulation products.<br />

With over 2,100 acoustic calculations, each with<br />

their own BIM (Building Information Modelling)<br />

objects, this calculator allows users to download<br />

and include BIM objects in their designs quickly<br />

and easily.<br />

The ROCKWOOL acoustic calculator is an extension<br />

of the ROCKWOOL U-value calculator and<br />

complements the ROCKWOOL ROI tool and BIM<br />

solution finder. The calculator provides U-value<br />

results for the calculations, if applicable, as well<br />

as graphical representations of the construction.<br />

We recently launched an acoustic<br />

calculator, which provides<br />

specifiers with a simple and<br />

effective way of working out the<br />

acoustic performance of insulation<br />

installed on walls, floors and roofs<br />

Arguably, ROCKWOOL is one, if not the oldest and<br />

best-known insulation brands. Does this tend to work<br />

in your favour?<br />

Certainly for me, when I started Minster, ROCK-<br />

WOOL was one of the top five suppliers from<br />

whom I needed an account to make the proposition<br />

viable. Their unique history in the UK since<br />

1979 in effect built the specialist insulation distribution<br />

sector. Saying you are from ROCKWOOL<br />

certainly opens a few doors. It’s a fantastic<br />

brand.<br />

insulatemag<br />

9

The only independent insulation industry trade magazine<br />

Health & Safety<br />

Achieving Safety<br />

Eyewear Compliance<br />

George Elliott Technical Service Engineer 3M<br />

Within the insulation industry, eye protection is vital for protecting against a range of<br />

potential hazards, from chemicals and fibres to ultraviolet (UV) sunlight. As a result,<br />

companies are increasingly implementing mandatory eye protection policies,<br />

requiring employees to wear safety spectacles, goggles or full face shields.<br />

However, it is not uncommon to see people<br />

wearing these items on their heads, rather than<br />

on their faces, leaving them potentially exposed.<br />

There are several common reasons for this,<br />

which those responsible for purchasing safety<br />

eyewear should be aware of, in order to improve<br />

compliance rates.<br />

One of the most common reasons for non-compliance<br />

is that workers find their eyewear<br />

uncomfortable, because it fits poorly.<br />

If eyewear is uncomfortably tight, employees may<br />

be less likely to want to wear it for long periods.<br />

Extremely tight eyewear may even force itself off<br />

the wearer’s head over the course of a shift.<br />

Alternatively, if safety eyewear is too loose, the<br />

wearer may need to repeatedly slide it back up<br />

their nose. This can become such an annoyance<br />

that some may opt to remove the eyewear<br />

altogether.<br />

No two head sizes are identical, so to find safety<br />

eyewear that is suitable for an entire worforce,<br />

employees should be involved in the selection<br />

process. As part of this process, staff should be<br />

offered a wide range of safety eyewear options.<br />

However, this can result in employers needing<br />

to stock a number of frame sizes, which can be<br />

a burden in terms of stock management and<br />

storage.<br />

No two head sizes are identical, so to find safety eyewear that is suitable for<br />

an entire worforce, employees should be involved in the selection process.<br />

10<br />

www.insulatemagazine.co.uk

The only independent insulation industry trade magazine<br />

Supplying safety spectacles with adjustable features<br />

or ‘self-adjusting’ features can be one way to<br />

reduce the total number of models that need to be<br />

made available<br />

.<br />

To help employers rationalise their purchasing, 3M<br />

has developed its SecureFit Protective Eyewear<br />

Range.<br />

All models of safety eyewear in this range self-adjust<br />

to fit all head sizes comfortably, without sacrificing<br />

security of fit. This is achieved using 3M’s innovative<br />

Pressure Diffusion Temple Technology, which ensures<br />

that the temple arms apply a similar pressure<br />

for different sized heads.<br />

Another common reason for non-compliance with<br />

safety eyewear requirements is lens fogging.<br />

A study published in Accident Analysis and<br />

Prevention magazine highlighted this <strong>issue</strong> by interviewing<br />

focus groups from a range of industries[1].<br />

Every group interviewed identified fogging as the<br />

main vision-related <strong>issue</strong> they faced, and said it was<br />

a key barrier to compliance. More than 55 per cent<br />

of respondents suggested that an anti-fog solution<br />

would be useful for increasing usage of personal<br />

protective eyewear.<br />

Reducing a worker’s ability to see has obvious<br />

safety implications. However, the bigger risk often<br />

comes when workers are forced to remove their<br />

eyewear in order to wipe away fogging on the lens,<br />

as this can leave them exposed.<br />

To help employes rationalise<br />

their purchasing, 3M has<br />

developed its SecureFit<br />

Protective Eyewear Range<br />

The Scotchgard Anti-Fog Coating Technology,<br />

which works even after repeated washing, is<br />

applied more than 50 per cent thicker than<br />

most coatings on the market, while retaining<br />

optical clarity Class 1.<br />

The coating also provides superior protection<br />

against lens scratching, increasing the eyewear’s<br />

lifespan.<br />

Another consideration when selecting safety<br />

eyewear is lens colour. Insulation work is often<br />

conducted outdoors, which makes UV light<br />

from the sun a potential hazard. UV light can<br />

cause cataracts, corneal damage and blindness.<br />

In addition, glare from bright sunlight can also<br />

be a hazard, as well as an annoyance, as it<br />

can prevent the worker from seeing properly.<br />

For those working outdoors, grey lenses may<br />

be a suitable option to consider as they provide<br />

protection against sun glare. Grey lenses<br />

also provide protection against UV light, as do<br />

all models in the SF600 eyewear range.<br />

Eyewear with a superior anti-fog coating can therefore<br />

be a great asset when encouraging compliance<br />

and increasing worker safety and comfort.<br />

3M recently launched the latest model of safety<br />

spectacles in its SecureFit Protective Eyewear<br />

Range – the 3M Securefit Protective Eyewear 600<br />

Series (SF600) – bringing together its Pressure<br />

Diffusion Temple Technology and Scotchgard<br />

Anti-fog Coating technologies for the first time.<br />

12<br />

insulatemag

The Continued Rise of Rockwool<br />

The SF600 eyewear range<br />

comes in six lens options –<br />

clear, grey, amber, infra-red,<br />

polarised and indoor/outdoor.<br />

When selecting safety eyewear<br />

that is adequate for protecting<br />

against a particular<br />

hazard, one consideration will<br />

be whether to purchase safety<br />

spectacles, goggles or full face<br />

shields.<br />

Safety spectacles can be less<br />

intrusive, as they are typically<br />

lighter and smaller than goggles.<br />

However, in particularly<br />

dusty environments, some<br />

models may not offer enough<br />

protection.<br />

The SF600 eyewear range<br />

comes with the option of<br />

a foam gasket that can be<br />

retro-fitted to the eyewear to<br />

create a tight seal between the<br />

spectacles and the wearer’s<br />

face. This gives the wearer<br />

improved protection without<br />

sacrificing comfort.<br />

For more information on any<br />

of these topics, or for general<br />

information about health and<br />

safety in the workplace, call<br />

the 3M helpline on<br />

0870 608 0060.<br />

The SF600 eyewear<br />

range comes in six<br />

lens options – clear,<br />

grey, amber,<br />

infra-red, polarised<br />

and indoor/outdoor.<br />

www.insulatemagazine.co.uk<br />

13

The only independent insulation industry trade magazine<br />

Case Study<br />

Sweeping Curves<br />

and Glittering Bronze for<br />

Sustainable Moneypenny HQ<br />

Aliva UK created an environmentally-friendly and<br />

visually stunning façade for the award winning<br />

£15m headquarters of Wrexham-based telephone<br />

answering firm Moneypenny<br />

The UK leader in exterior and interior finishes, Aliva<br />

crafted a clean, crisp façade that wraps in unbroken lines<br />

around the curved exterior of the building.<br />

The British Board of Agrement certified render was chosen<br />

for its excellent thermal insulation credentials. The<br />

render’s self-cleaning and anti-algae staining properties<br />

will also ensure the building maintains its pristine finish<br />

for years to come.<br />

Discover more about Aliva here.<br />

Aliva also provided 500sqm<br />

of its Alucovering aluminium<br />

cladding in an anodised<br />

bronze colour matched to<br />

the architect’s specifications.<br />

This was used to create<br />

window detailing which<br />

adds an extra dimension to<br />

the building’s external<br />

appearance.<br />

AEW Architects selected<br />

Aliva to deliver every aspect<br />

of the façade design from<br />

panel layouts and window<br />

details, to the design of a<br />

bespoke façade fixing<br />

system for the building.<br />

14 www.insulatemagazine.co.uk

www.insulatemagazine.co.uk<br />

The new headquarters will be able to accommodate<br />

1,000 staff over three floors, allowing for<br />

Moneypenny’s planned business growth. The<br />

10-acre plot includes nature trails, orchards and<br />

gardens, with the interior of the building featuring<br />

a treehouse meeting room and a ‘village pub’ for<br />

employees.<br />

The building is designed to be as environmentally<br />

sustainable as possible. By using rainwater recycling,<br />

solar energy, ground source heating and<br />

natural ventilation for climate control, the company<br />

aims to be almost entirely self-sufficient. The<br />

thermal efficiency offered by Termok8 insulated<br />

render was therefore a key consideration in the<br />

architects’ selection process.<br />

Phil Hepworth, Associate at AEW Architects said:<br />

“Aliva helped us achieve the effect we wanted for<br />

Moneypenny’s new Headquarters by providing a<br />

high quality self-cleaning insulated render system<br />

that highlighted the smooth curves of the building<br />

and complimented its picturesque setting. The<br />

bronze aluminium cladding was selected to create<br />

window detailing and highlight the stunning<br />

picture windows of the building”.<br />

service and environment in which to answer their<br />

calls, as well as provide our employees with a<br />

world-class space to work. The environmental<br />

credentials of the building were also important to<br />

us and Aliva’s insulated render not only creates<br />

the visually striking finish that we envisaged for<br />

the building’s exterior, but it also lives up to the<br />

energy efficiency standards that we wanted to<br />

reach.”<br />

James Ormerod, Managing Director at Aliva<br />

UK, said:<br />

“We were delighted to be selected to design and<br />

supply the façade for this stand-out project. The<br />

crisp, unbroken lines of the render create sweeping<br />

curves that attract the eye, while its thermal<br />

qualities ensure it boosts the building’s environmentally-friendly<br />

credentials.”<br />

A popular choice for energy-conscious building<br />

projects, Aliva’s Termok8 render systems provide<br />

a beautiful, weatherproof and long-lasting finish<br />

that meets the highest modern thermal requirements.<br />

Ed Reeves, co-founder and director of Moneypenny,<br />

who led the ground-breaking project said:<br />

“Since we founded Moneypenny we have strived<br />

to set the industry standard for ‘excellence’. Our<br />

new head office once again raises the bar in<br />

achieving this and will offer clients an unrivalled<br />

insulatemag<br />

15

The only independent insulation industry trade magazine<br />

Employment<br />

The Apprenticeship Levy began last<br />

month - what does it mean for<br />

insulation employers?<br />

UK employers are being encouraged to take on more apprentices following the introduction<br />

of a new levy last month. But which businesses are expected to pay, how much<br />

they have to put in, and on what they can use the funds from it? And why should they<br />

consider taking on apprentices?<br />

Employers with a pay bill over £3 million each<br />

year must pay the new apprenticeship levy, but<br />

they can also use it to fund their own apprenticeship<br />

programmes. Funds in a business’s apprenticeship<br />

service account – and funding provided<br />

by the government through co-investment – can<br />

be used to pay for apprenticeship training and<br />

end point assessment, with a government-approved<br />

training provider and government-approved<br />

assessment organisation. Smaller businesses,<br />

with pay bills under £3 million, will not be<br />

required to pay the levy. These non-levy paying<br />

employers will share the cost of training and assessing<br />

their apprentices with government – this<br />

is called ‘co-investment’.<br />

16 www.insulatemagazine.co.uk

www.insulatemagazine.co.uk<br />

From May 2017, they will pay 10% towards to<br />

the cost of apprenticeship training and the government<br />

will pay the rest (90%), up to the funding<br />

band maximum.<br />

Employers in the insulation and construction<br />

industry could consider technical apprenticeship<br />

programmes – such as thermal insulation engineer,<br />

bricklaying and site carpentry – but there<br />

are also frameworks for other, more ‘back office’<br />

roles that might be useful, such as business administration,<br />

accounting, and human resources.<br />

Apprentices offer a lot to employers: they are<br />

trained in the specific skills and job role required,<br />

and research shows that employers find apprentices<br />

make the most loyal employees. More than<br />

half of apprentice employers say that apprentices<br />

stay in the business longer than other recruits.<br />

Michelle Clark, HR Manager<br />

at Darren Evans Assessments<br />

Ltd – working in energy<br />

efficiency for large commercial<br />

developers through to independent<br />

investors, architects,<br />

house builders and public<br />

sector organisations – is very<br />

positive about the apprentices<br />

the company has taken on, in<br />

business support roles.<br />

“The process was really simple<br />

and we were fully supported by<br />

SGS Filton College, who gave<br />

us help and guidance along the<br />

way,” says Michelle.<br />

“The college shortlisted and<br />

interviewed potential candidates,<br />

carried out basic Maths, English<br />

and IT tests and then sent us a<br />

list of candidates that matched<br />

our business needs. We have<br />

found taking on apprentices really<br />

positive and beneficial to both the<br />

business and our team.”<br />

Michelle says preparation is<br />

key: a good induction, a training<br />

schedule and a buddy<br />

system should all be planned.<br />

“Apprentices could be a school<br />

leaver with limited or no work<br />

experience and new to a work<br />

environment,” says Michelle.<br />

“So time will need to be given<br />

once they join to support them<br />

in their role. We have also given<br />

our apprentices time working<br />

in different departments so that<br />

they can experience working in<br />

varies areas of the business. This<br />

gives our apprentices a feel for<br />

the type of role they enjoy, where<br />

their strengths lie, and may wish<br />

to explore more as their career<br />

progresses, it also helps us to<br />

identify where they may need<br />

additional support in different<br />

business functions.“<br />

Michelle is in no doubt about<br />

the benefits the new recruits<br />

bring to the businesses.<br />

“An apprenticeship scheme has<br />

given Darren Evans Assessments<br />

a chance to play an active role<br />

in moulding our future workforce<br />

and creating the future skills that<br />

we need to help our business<br />

grow,” she says.<br />

“We are so proud to be part of<br />

watching our apprentices grow<br />

into young professionals whilst<br />

gaining a recognised qualification<br />

at college. They have both settled<br />

into the world of work, are enthusiastic<br />

and an asset to our<br />

company already.“<br />

Jack Denton, co-founder<br />

of AllAboutSchoolLeavers.<br />

co.uk – a website dedicated to<br />

informing people about apprenticeship<br />

and school leaver<br />

options – agrees with Michelle<br />

that apprentices bring a lot to<br />

a business.<br />

“They are fresh, eager to learn<br />

and want to get stuck in,” he<br />

says, of the two apprentices the<br />

company took on last year. “It<br />

also gives us a new perspective<br />

on what we’re doing as a business,<br />

as they are also consumers<br />

– young people who have just<br />

left school – and it’s beneficial to<br />

have a variety of points of view.”<br />

For more details on<br />

apprenticeships and<br />

information on the<br />

process of setting up<br />

various programmes,<br />

how much school<br />

leavers of certain ages<br />

should be paid, and<br />

information on training<br />

providers, visit AllAbout-<br />

ShoolLeavers’ dedicated<br />

recruiters pages.<br />

insulatemag 17

The only independent insulation industry trade magazine<br />

News<br />

Belgrade Insulations Featured<br />

in Yorkshire's Fastest 50 Awards<br />

The Management Team and all staff are proud that their business was featured in Yorkshires<br />

FASTEST 50 AWARDS. Positioned midway in the top 50 listings the award<br />

recognises the growth and success since 2010 when Belgrade Insulations was acquired.<br />

Managing Director Alex Khan commented:<br />

This award is a tribute to the hard work of all our staff who have worked together to grow the<br />

company across varied sectors of the Construction Industry. Our commitment to training and<br />

personal development has been fundamental to developing the skills of our people.<br />

We have exciting plans for the future which will see more branches, providing opportunities for<br />

existing staff and new potentials wishing to join a growing business.<br />

Belgrade is a distributor of<br />

Thermal, Acoustic and Fire<br />

Protection Insulation,<br />

together with Drywall Systems<br />

to the Building and Technical<br />

Insulation markets.<br />

The company operates from<br />

branches strategically located<br />

across the UK to provide the<br />

service required by specialist<br />

sub-contractors, merchants<br />

and housing providers.<br />

The company is a member and<br />

supporter of these trade associations;<br />

ASFP, BMF, NFRC,<br />

TICA. Active participation<br />

ensures up to date knowledge<br />

of market trends.<br />

Belgrade develops close relationships<br />

with its manufacturing<br />

suppliers, helping them trial<br />

and introduce new products.<br />

A strong commitment to training<br />

ensures customers receive<br />

latest product and application<br />

detail.<br />

18

Insulation<br />

Our latest arrivals have landed...<br />

...offering you 4 new lower lambda<br />

products to choose from<br />

Kingspan Kooltherm ® K103 Floorboard, K110 and K110 PLUS Soffit Board,<br />

and K118 <strong>Insulate</strong>d Plasterboard feature an advanced, fibre-free insulation<br />

core, enabling them to achieve an outstanding thermal conductivity of<br />

0.018 W/m . K. As a result, the products can enable buildings to be built to<br />

the upper levels of fabric performance with minimal thickness.<br />

Further information on the Kingspan<br />

range is available on:<br />

+44 (0) 1544 387 384<br />

literature@kingspaninsulation.co.uk<br />

www.kingspaninsulation.co.uk<br />

Pembridge, Leominster, Herefordshire HR6 9LA, UK<br />

www.kingspaninsulation.co.uk/lowerlambda<br />

®<br />

Kingspan, Kooltherm and the Lion Device are Registered Trademarks of<br />

the Kingspan Group plc in the UK and other countries. All rights reserved.

Thursday 30 th November 2017<br />

East Midlands Conference Centre & Orchard Hotel<br />

Expert judge panel<br />

22 awards categories<br />

BREEAM Excellent rated venue<br />

Unmissable night of celebration<br />

5 course meal, wine and champagne<br />

Evening hosted by TV personality Nick Knowles<br />

Accepting FREE entries now<br />

www.insulationawards.co.uk | info@insulationawards.co.uk | 01948 759 351

Will you be a winner?<br />

Be a shining star<br />

at the awards event the<br />

insulation industry has been waiting for<br />

Award sponsorship & VIP opportunities available<br />

NiiAwards

The only independent insulation industry trade magazine<br />

Case Study<br />

Using a Full-Fill Cavity<br />

solution to prevent increased<br />

costs in new residential developments<br />

Cavity Wall (brick/block) is the<br />

predominant Build method for<br />

the UK housing industry with<br />

70% of 27.4 million homes<br />

built with cavity walls.<br />

The change to Part L1a in<br />

2013 (which sets the guidelines<br />

for new residential house<br />

builds) brought a second compliance<br />

metric, Fabric Energy<br />

Efficiency Standard (FEES).<br />

As a result of these requirements<br />

the fabric of the building<br />

needed to be more robust,<br />

with better insulation, reduced<br />

air leakage and improved thermal<br />

bridging.<br />

The ultimate goal: the homeowner<br />

to switch the heating on<br />

less.<br />

This ‘whole house’ approach<br />

meant maintaining a strong<br />

fabric performance to comply,<br />

without having to widen<br />

cavities and compromise plot<br />

efficiencies. This, in turn, would<br />

require more land to deliver the<br />

same number of homes.<br />

Increasing wall cavity width<br />

would not only impact space<br />

required for each property. It<br />

would change the products<br />

required in the cavity construction:<br />

longer and stronger<br />

wall ties, thicker cavity closers<br />

and bigger door and window<br />

lintels.<br />

The change in product combined<br />

with the extra land requirements<br />

would bring commercial<br />

challenges; it would<br />

either increase house prices<br />

or reduce house builder profit.<br />

Not a good choice either way.<br />

Performance Vs Cost -<br />

The research<br />

Research carried out across<br />

both Housebuilders and specifiers<br />

identified balancing cost<br />

and performance as a primary<br />

concern.<br />

“Cost is assessed not between<br />

materials, but also on<br />

a whole-cavity or whole-site<br />

basis”<br />

“The impact of increased cavity<br />

width requirements is identified<br />

as a key challenge which<br />

across the whole site can<br />

result in lost m² and impact on<br />

cost significantly”<br />

Source: Celotex PIR Insulation<br />

Research 12th December<br />

2014<br />

22

www.insulatemagazine.co.uk<br />

Product Innovation<br />

To meet the industry needs in response to<br />

changing regulations, Celotex CF5000 was<br />

created; a unique product to solve a technical<br />

problem for housebuilders.<br />

CF5000 is a high thermal performance full-fill<br />

solution for masonry cavity walls that helps to<br />

deliver a U-value within the wall of 0.18 W/m²K<br />

without the need to widen the cavity.<br />

Comprising a rigid polyisocyanurate foam core<br />

adhesively bonded to aluminium foil facings<br />

on both sides, CF5000 is designed with the<br />

installer in mind. Easy to cut and available in<br />

1200x450mm dimensions, it fits with standard<br />

cavity wall tie spacing to provide improved plot<br />

efficiencies on site.<br />

Engineered board edges ship-lap to jigsaw<br />

together, effectively closing the gaps between<br />

the boards; this eliminates the passage of wind<br />

driven rain across the cavity (a requirement of<br />

Approved Document C).<br />

Summary - The impact on the industry<br />

As a company that leads the way in technological<br />

innovations, Celotex filled a huge gap<br />

in the market with the introduction of Celotex<br />

CF5000. Developed with a clear focus on maximising<br />

thermal efficiency with thinner solutions,<br />

the new and innovative CF5000 system gives<br />

architects, designers and specifiers the whole<br />

picture for full fill cavity wall applications.<br />

Instead of choosing commercial value or<br />

performance, housebuilders using CF5000 can<br />

have both.<br />

Find out more about the innovative product<br />

here, or login to our members area for more<br />

valuable product information and specification<br />

tools.<br />

The impact of increased cavity<br />

width resuirements is identified<br />

as a key challenge which across<br />

the whole site can result in lost<br />

m² and impact on cost<br />

significantly<br />

insulatemag 23

The only independent insulation industry trade magazine<br />

Featured CPDs<br />

Recticel CPD provides the ultimate guide to<br />

insulation solution for cavity wall buildings<br />

Leading PIR manufacturer, Recticel Insulation, has<br />

created an informative CPD titled, Toolbox Talk,<br />

which offers a fascinating overview of the insulation<br />

solutions used with masonry cavity wall construction.<br />

The seminar offers an in-depth understanding of a<br />

range of topics. It includes a look at the evolution of<br />

cavity wall construction and how improved thermal<br />

performance requirements have fuelled the development<br />

of insulation products such as low thermal<br />

conductivity rigid pir insulation boards.<br />

Recticel’s presentation, which forms part of the<br />

RIBA core curriculum, also features traditional insulation<br />

solutions as well as analysis on the contrast<br />

between rigid partial-fill and rigid full-fill solutions.<br />

Issues to consider in design, specification and<br />

construction to ensure optimum performance from<br />

rigid full-fill solutions, is another of the seminar’s<br />

highlights.<br />

Recticel is renowned throughout the industry as a<br />

supplier of new-build and refurbishment solutions<br />

through its innovative insulation products which excel<br />

in terms of low thermal conductivity and handling<br />

ability.<br />

For more information on booking a Recticel CPD, visit: www.recticelinsulation.co.uk<br />

Get involved with<br />

insulate magazine<br />

24 www.insulatemagazine.co.uk<br />

sales@insulatemagazine.co.uk | 01948 759 351

www.insulatemagazine.co.uk<br />

Rockwool launches CPD<br />

on acoustic standards in schools<br />

ROCKWOOL has developed a<br />

new CPD for architects entitled<br />

‘Acoustic Standards in Schools’.<br />

The CPD aims to explain the<br />

science behind acoustics, the<br />

latest building regulations, best<br />

practice guidance on acoustics<br />

and explore the most appropriate<br />

sound insulation solutions for<br />

education environments.<br />

A noisier urban environment is<br />

increasing the importance of<br />

good acoustics in schools. In<br />

addition, pressure on space in<br />

our towns and cities is leading to<br />

more buildings being developed<br />

as multi-use, combining residential,<br />

educational and commercial<br />

environments in one unit.<br />

“Excessive and unwanted noise<br />

is known to have a detrimental<br />

effect on academic performance<br />

in the learning environment”,<br />

comments Paul Barrett, Product<br />

Manager at ROCKWOOL<br />

Ltd. “ROCKWOOL has created<br />

this new CPD, focusing on the<br />

increasing <strong>issue</strong>s surrounding<br />

acoustics in school buildings, to<br />

help make sure architects are<br />

aware of the <strong>issue</strong>s and understand<br />

how stone wool insulation<br />

can provide a range of solutions<br />

that will last the lifetime of the<br />

building.”<br />

Over the last 40 years, research<br />

has proved that poor acoustics<br />

can lower pupils’ academic performance,<br />

compromise classroom<br />

control, affect the health of<br />

teachers and classroom assistants<br />

and disadvantage children<br />

with special needs, especially<br />

those with hearing difficulties.<br />

In 2003, the Department of<br />

Education and Skills, introduced<br />

acoustic performance standards<br />

for new schools under the Building<br />

Regulations, Building Bulletin<br />

93 (BB93).<br />

In meeting the acoustic requirements<br />

of BB93, the choice of<br />

insulation material has a major<br />

impact. ROCKWOOL stone<br />

wool insulation is renowned for<br />

its excellent acoustic properties.<br />

Fully tested to meet the rigorous<br />

demands of today’s legislation,<br />

stone wool insulation solutions<br />

are proven to reduce ambient,<br />

impact and reverberation noise<br />

in educational buildings.<br />

ROCKWOOL can provide a<br />

number of different bespoke<br />

acoustic solutions, including<br />

flat roof insulation with<br />

HARDROCK® Multi-Fix, external<br />

wall insulation, using the RE-<br />

DArt® system, internal partitions<br />

with ROCKWOOL FLEXI®,<br />

and internal floor solutions<br />

with ROCKWOOL FLEXI® and<br />

ROCKFLOOR® to combat<br />

impact noise. ROCKWOOL fire<br />

protection products also reduce<br />

flanking transmission, one of the<br />

most prevalent noise concerns<br />

in schools. Flanking transfer<br />

comprises of sound that is<br />

transmitted indirectly via paths<br />

such as external wall cavities,<br />

voids above partitions, ceilings<br />

and internal corridors, or where<br />

there are problems of excessive<br />

reverberation within the rooms<br />

themselves.<br />

To book a place and participate<br />

in ROCKWOOL’s Acoustics<br />

in Schools CPD, please<br />

complete the online enquiry<br />

form www.rockwool.co.uk/<br />

technical-support/CPDS/<br />

cpd-sign-up. For further information,<br />

please visit www.<br />

rockwool.co.uk.<br />

Feature your CPD here:<br />

sales@insulatemagazine.co.uk | 01948 759 351<br />

insulatemag 25

SOUND REDUCTION<br />

Superior sound insulation helps reduce unwanted<br />

noise from both internal and external sources.<br />

THERMAL PERFORMANCE<br />

Stone wool insulation doesn’t just keep buildings warm<br />

today, it maintains its insulating properties for years to come.<br />

© 2016 ROCKWOOL Ltd. All rights reserved.<br />

DIMENSIONAL STABILITY<br />

Density, volume and structural integrity provide<br />

a perfect fit for maintaining performance.

This is ROCK, re-engineered<br />

for a fast, easy and perfect fit.<br />

From volcanic rock to high performance building insulation. See<br />

ROCK re-engineered to provide high performance insulation solutions<br />

for today’s building projects. ROCKWOOL insulation is easy to use,<br />

dense, durable and performs because of its origins in natural stone.<br />

Discover how the transformation happens, and why ROCKWOOL<br />

insulation performs consistently across so many applications.<br />

SEARCH ROCKWOOL INSULATION ORIGINS

The only independent insulation industry trade magazine<br />

Interview<br />

Inside Story<br />

Featuring Darren Evans<br />

Interview with Darren Evans Managing Director, Darren Evans Assessments<br />

Based in Chipping Sodbury near Bristol and with offices in Birmingham, Darren Evans<br />

Assessments Ltd is a busy, fast-growing and dynamic company offering energy saving<br />

assessments, research and consultancy services. Working for large commercial developers<br />

through to independent investors with a small private rental portfolio, architects, housebuilders<br />

and public sector organisations, this leading independent consultant can provide a<br />

broad range of energy efficiency and sustainability services.<br />

How did you become involved<br />

in the industry?<br />

My start in the industry developed<br />

from my interest in<br />

buildings, and an interest in<br />

sustainability. I saw an opportunity<br />

to help and add value<br />

to the construction industry<br />

and the built environment. I<br />

also believed that it would be<br />

difficult for architects, M & E<br />

companies, property developers<br />

and managers etc, to keep<br />

up to date with regulations<br />

as they changed whilst at the<br />

same time follow their passion.<br />

I set up the company in 2007<br />

from my home, with a vision<br />

to have a team of 50 people<br />

with regional offices across<br />

the country. We have come<br />

a long way in ten years and<br />

our client base is testament to<br />

that. We work with large and<br />

small organisations to support<br />

and help them with tenders,<br />

and discover and develop the<br />

‘best’ methods for building.<br />

What is your definition of<br />

'best' when it comes to buildings?<br />

My definition of ‘best’ and<br />

‘sustainable’ is what is acceptable<br />

from an environmental<br />

perspective and also<br />

acceptable from a financial or<br />

business perspective. Things<br />

are not sustainable unless you<br />

are making money and a profit<br />

- an important part of sustainability<br />

that sometimes gets lost<br />

in the mix. I’d add that value<br />

and profitability will only occur<br />

in this market when there is<br />

quality, robustness and trust in<br />

the methodology, the calculation<br />

and the outcome.<br />

What changes have you<br />

seen in the industry over the<br />

years?<br />

There are a lot of good things<br />

going on, however, we struggle<br />

to articulate the<br />

28<br />

www.insulatemagazine.co.uk

www.insulatemagazine.co.uk<br />

sustainability element from a profitability perspective.<br />

We use buzzwords such as “BREEAM,<br />

reducing carbon, responsibility and sustainability”,<br />

but we struggle to define exactly what that<br />

means. One thing to one company means something<br />

else to another company. But the language<br />

every company understands is profit. We are<br />

ultimately trying to define and articulate that. So<br />

when you have a BREEAM assessment done<br />

for example, this is what the pounds and pence<br />

is going to look like. That is where I want to go.<br />

One of the best scenarios is having someone<br />

who understands and has bought into sustainability<br />

within an organisation, and someone who<br />

doesn’t as much, but is open and transparent.<br />

As an industry, we have made huge steps forward<br />

in ensuring that buildings perform better. It<br />

would be great in the marketplace if we continue<br />

to move forward. One way is to look at planning<br />

applications and the expectation of when a building<br />

is going to be completed. Why buy a house<br />

in 2017 which has been built to a 2006 Building<br />

Regulation for example?<br />

What excites you in the world of<br />

sustainability?<br />

Some might say we don’t need another building<br />

standard, but the WELL Building Standard<br />

(WELL), industry’s first benchmark for human<br />

health and wellness is a step in the right direction.<br />

It’s also something Darren Evans Assessments<br />

is going to be adopting and encouraging.<br />

The needs and requirements of people within a<br />

building is something that everybody can identify<br />

with, irrespective of where you are from and what<br />

belief system you have. The health and wellbeing<br />

agenda is looking at the things we connect with,<br />

both purposefully and with an end in mind. This<br />

will help drive and encourage the owners of a<br />

building or company to connect with their staff<br />

better. When you work for a large organisation,<br />

it’s sometimes hard to feel connected with it. By<br />

creating an environment that is better for employees,<br />

there is a greater likelihood of them being<br />

connected to their workplace, from which they<br />

can be productive and flourish. It’s good for us<br />

all to work for organisations that are actually interested<br />

in their people and take employee health<br />

and wellbeing seriously.<br />

What developments in the industry will help<br />

the testing process?<br />

Pulse air pressure testing is a new way of testing<br />

the air pressure within a building and is quite<br />

different to the conventional ‘Blower door’ airtightness<br />

measurement technique. It measures<br />

building airtightness by generating an instant low<br />

pressure rise inside the building envelope. This<br />

new device has potential to deliver a number of<br />

benefits related to on-site testing and will allow<br />

quick and simple measurements to be made at<br />

various points within the build process.<br />

To find out more or for more information<br />

visit: www.darren-evans.co.uk<br />

Darren Evans will be on the esteemed panel of<br />

judges for The Insulation Industry Awards 2017,<br />

taking place at the East Midlands Conference<br />

Centre and Orchard Hotel in Nottingham on 30th<br />

November 2017. For more information visit:<br />

https://www.insulationawards.co.uk/<br />

insulatemag 29

CERTIFICATE 89/2231<br />

It takes bottle to specify<br />

insulation that’s better<br />

for the environment.<br />

TIMBER & RAFTER ROLL 40<br />

Saving energy and saving time on your build project?<br />

Superglass glass mineral wool insulation does both. It cuts<br />

energy bills, of course, and contains 84% recycled glass,<br />

stopping it going to landfill. And with Superglass, you get<br />

service that is second-to-none. Our Teamworks values mean<br />

we’ll work closely with you to deliver your ideal insulation<br />

solution, including same-day order confirmation and next-day<br />

delivery. Which means less time on site and lower costs.<br />

Our Timber & Rafter Roll is a lightweight, flexible option ideal for roofs, walls<br />

and floors with an A+ BRE Green Guide Rating. So for a greener future and great<br />

service, smart specifiers insist on Superglass.<br />

It’s a decision that really doesn’t take too much bottle.<br />

Call 0844 381 4022 or visit www.superglass.co.uk

The only independent insulation industry trade magazine<br />

Interview<br />

The Snap Election:<br />

Let's not get distracted<br />

but focus on the opportunity<br />

Sarah Konstense-Winterton Executive Director, MIMA<br />

It appears that as soon as I write an article the political policy environment changes yet<br />

again; this time it’s to sounds of weary moans and groans to the announcement of yet another<br />

election on 8 June. We all have election/referendum/vote fatigue. However, we must<br />

hold our resolve and grasp this opportunity to communicate our messages to potentially winning<br />

candidates - future and incumbent MPs - and a new government with a fresh intake and<br />

perspective. As industry working together it is vital we continue to position Energy Efficiency<br />

as an Infrastructure (EEI) priority and an integral part of any successful, future energy policy.<br />

The Frontier Economics report<br />

“Affordable Warmth, Clean<br />

Growth” commissioned by the<br />

Energy Efficiency Infrastructure<br />

Group (EEIG), will give the<br />

government the tools for an<br />

achievable, high value for money<br />

energy efficiency infrastructure<br />

programme. The election<br />

will mean a slight delay to<br />

its Westminster launch and<br />

it is now likely to come in the<br />

weeks leading up to summer<br />

recess (when the MPs return<br />

to their constituencies for the<br />

summer break).<br />

Time is of the essence and the<br />

political parties are hurriedly<br />

putting together their election<br />

manifestos and the political<br />

parties have been asking us<br />

for more. This is encouraging<br />

and even better, we have the<br />

research to respond robustly.<br />

In response MIMA, as part of<br />

the EEIG has put together a<br />

mini manifesto to secure “A<br />

commitment to keeping energy<br />

costs in British homes<br />

and buildings down, by delivering<br />

a buildings energy<br />

infrastructure programme to<br />

bring all UK homes up to EPC<br />

Band C by 2035.” and underpinned<br />

by the Frontier Economics<br />

research report and<br />

action plan. Whilst we must<br />

manage our expectations on<br />

successfully securing a slot in<br />

the political parties manifesto<br />

commitments, it helpfully sets<br />

down a marker for our campaign<br />

which is firmly building<br />

momentum. We want a new<br />

government to see the new<br />

Frontier Economics report as<br />

deliverable, fresh and open to<br />

their “ownership”.<br />

Our attentions must then turn<br />

to the prospective candidates<br />

and to help Energy Efficiency<br />

as Infrastructure form part of<br />

election campaigning debate<br />

or, perhaps more realistically,<br />

to ensure that it forms part of<br />

political thinking in the next<br />

parliament.<br />

insulatemag 31

www.insulatemagazine.co.uk<br />

We want to encourage stakeholders in our industry<br />

to targeting constituency candidates and<br />

particularly their local candidates to ask that they<br />

pledge to support Energy Efficiency as an Infrastructure<br />

priority over the coming weeks.<br />

Once 8 June is over and the MPs are back there<br />

will be an intensive period before the summer<br />

break beckons. Some of our supporters on the<br />

backbenches may be lost as a result of this election,<br />

but we may also gain new, fresh-faced ones<br />

and must connect early. We have a strong line up<br />

with the Frontier Economics report launch and a<br />

series of engagement and profile-raising events<br />

over the summer and into the party conference<br />

season. We will be shadowing Ministers, MPs,<br />

special advisors and civil servants to ensure that<br />

our message has clearly reached them and is<br />

resonating. Pre-election our political support was<br />

growing and we need to ensure that this impetus<br />

continues.<br />

Politicians should be left in no doubt that a practical<br />

and cost-effective blue print for UK government<br />

policy making on energy in buildings is a<br />

reality and we can help deliver it. A blue print that<br />

can repair and restore business confidence and<br />

investment in the industry - ensuring a committed,<br />

long-term, sustainable approach for improving<br />

building energy performance. A stable, high<br />

quality programme that will draw on the highest<br />

standards of workmanship and delivery supported<br />

by best practice to inspire consumer confidence.<br />

In turn we can help government deliver on its<br />

targets such as reducing carbon emissions to<br />

ensure it meets its Fourth and Fifth carbon budgets,<br />

and bringing fuel poor homes up to EPC<br />

Band C by 2030. Delivering strong economic<br />

returns, increased productivity, lower energy bills<br />

and significant health benefits, this innovative<br />

approach would be a no brainer for any new (or<br />

not so new) government waking up with a sore<br />

head on 9 June.<br />

What we need is for businesses, organisations<br />

and individuals to come together and join with<br />

our existing 20 plus EEIG members and campaign<br />

with one voice to turn our vision into reality<br />

post election.<br />

Sarah Kostense-Winterton is Executive Director of MIMA, the Mineral Wool Insulation<br />

Manufacturers Association and provides the secretariat to the Energy Efficiency<br />

Infrastructure Group.<br />

For further details of the EEIG and if you would like to join,<br />

please contact Sarah at sarah@mima.info<br />

32 www.insulatemagazine.co.uk

2017<br />

10–12 NEC BIRMINGHAM<br />

10-12 OCTOBER | NEC | BIRMINGHAM<br />

THE UK’S LARGEST<br />

CONSTRUCTION TRADE SHOW<br />

9 SHOWS UNDER 1 ROOF<br />

650+ EXHIBITING COMPANIES<br />

10,000+ INNOVATIVE<br />

PRODUCTS AND SERVICES<br />

OVER 30,000 VISITORS<br />

DEDICATED OFFSITE ZONE<br />

100+ CPD SESSIONS<br />

AND SEMINARS<br />

FOR FREE REGISTRATION AND EXHIBITING ENQUIRIES PLEASE VISIT<br />

Includes access to these events:<br />

UKCONSTRUCTIONWEEK.COM<br />

2017

The only independent insulation industry trade magazine<br />

Rockwool goes back to school<br />

with Hardrock® Multi-Fix (DD) Roof Boards<br />

Thanks to the installation of ROCKWOOL flat roof insulation products, teachers and students<br />

at Stopsley High School are benefitting from a learning environment that has been<br />

acoustically treated to reduce noise disruption.<br />

Located in Luton, Stopsley High School is a mixed Comprehensive and Community College<br />

that educates children from 11 to 16 years old. In 2013, the school received funding from the<br />

Government, via the Priority School Building Programme (PSBP) to demolish and rebuild some<br />

buildings, while others receive upgrades. To support the increase of pupil capacity from 990<br />

to 1,350, a new school building was built to provide 64 classrooms, a four court sports hall,<br />

creative and music spaces and a special needs facility.<br />

Main contractor, Interserve worked with sub-contractor,<br />

Briggs Amasco and Acoustic consultant,<br />

Arup to deliver a modern, purpose-built and<br />

well-insulated school building. The brief for this<br />

project included the following:<br />

To achieve a thermal performance of 0.15 W/<br />

m2K in the school building. To meet the stringent<br />

acoustic performance requirements of BB93,<br />

in order to achieve a target noise reduction of<br />

Rw44Db. To control the noise generated in high<br />

traffic areas of the school, such as the sports hall<br />

and music rooms was desired.<br />

Offering maximum density and exceptional dimensional<br />

stability, approximately 600m2 of the<br />

150mm ROCKWOOL HARDROCK® Multi-Fix<br />

(DD) boards were adhesively applied on the roof<br />

of the building. ROCKWOOL HARDROCK® Multi-Fix<br />

(DD) Underlay was placed across the roof,<br />

followed by the HARDROCK® Multi-Fix (DD) roof<br />

boards providing a non-combustible surface that<br />

was ideal for the application of the torch applied<br />

bitumen waterproofing system.<br />

ROCKWOOL HARDROCK® Multi-Fix (DD) Underlay<br />

was placed across the roof, followed by<br />

the HARDROCK® Multi-Fix (DD) roof boards<br />

providing a non-combustible surface that was<br />

ideal for the application of the torch applied bitumen<br />

waterproofing system.<br />

34

www.insulatemagazine.co.uk<br />

“I have used ROCKWOOL products on several<br />

projects previously, so I was confident that the<br />

ROCKWOOL HARDROCK® Multi-Fix (DD) roof<br />

boards would deliver outstanding results,”<br />

comments Tony Sutton, Contracts Manager at<br />

Briggs Amasco.<br />

“The ROCKWOOL products act as an excellent<br />

sound deadening layer, which helped in controlling<br />

the high level of noise coming from the<br />

sports and the music halls of the school. The<br />

products also deliver optimum levels of thermal<br />

and acoustic performance, which helped us<br />

achieve the set requirements.”<br />

The HARDROCK® Multi-Fix (DD) boards<br />

have helped to deliver a comprehensive thermal,<br />

sound and fire safe solution that is suitable<br />

for this type of multi-purpose application.<br />

HARDROCK® Multi-Fix (DD) products are excellent<br />

sound level controlling products and fully<br />

compatible for use with other flat roofing systems.<br />

Achieving excellent thermal efficiency and sound<br />

insulation was paramount at Stopsley High<br />

School. The thermal, acoustic and fire resistance<br />

properties of ROCKWOOL products have<br />

helped Stopsley High School to provide effective<br />

teaching and learning environment. Additionally,<br />

the excellent fire resistance properties of the<br />

ROCKWOOL products provide a high level of fire<br />

protection that will last the lifetime of the school<br />

building.<br />

www.rockwool.co.uk<br />

Get involved with<br />

insulate magazine<br />

sales@insulatemagazine.co.uk | 01948 759 351<br />

insulatemag 35

The only independent insulation industry trade magazine<br />

Industry Event<br />

All-star line up revealed for Vision 2017<br />

UNStudio, Zaha Hadid Architects, Gensler,<br />

Foster & Partners and more<br />

Vision 2017 has announced its programme, including some of the biggest names and<br />

world-renowned experts from across the built environment industry. The programme<br />

will address the main <strong>issue</strong>s facing the profession, both in the UK and in a global context<br />

and new technologies, materials, products and approaches will be explored across five<br />

lecture theatres on the 6-7 June. The event is also affiliated to major industry partners, such<br />

as the RIBA, the London Festival of Architecture, New London Architecture, the Museum of<br />

Architecture and BRE.<br />

Alongside the extensive<br />

programme, this year Vision<br />

has also partnered with various<br />

international trade authorities,<br />

including Belgium, France, Italy,<br />

Luxembourg, Latvia and the<br />

Czech Republic, represented<br />

at the event through a number<br />

of pavilions. Live demonstrations<br />

and networking will<br />

provide opportunities to meet<br />

and exchange ideas with our<br />

continental counterparts.<br />

As always, the exhibitors at<br />

Vision cover a range of products<br />

and services, including<br />

research and development into<br />

the latest software, bringing<br />

elegant solutions to everyday<br />

challenges in the built environment.<br />

This year’s programme is<br />

split into four main categories:<br />

Architectural & Design<br />

Evolution; Building Health &<br />

Wellness; Offsite & Modular<br />

Construction; and Materials &<br />

Systems Innovation. Highlights<br />

in the former include keynote<br />

lectures from Caroline Bos<br />

of UNStudio, who will unveil<br />

brand-new research into the<br />

circular economy, as well as<br />

Stefano Paiocchi from Zaha<br />

Hadid Architects explaining a<br />

groundbreaking CodeStructed<br />

Skin project that fuses architecture<br />

with fashion. On the<br />

second day, this theatre will<br />

see a major debate, chaired<br />

by the NLA’s Peter Murray,<br />

that will tackle housing as part<br />

of our complex urban future.<br />

The RIBA President Elect Ben<br />

Derbyshire will take a leading<br />

role in this debate, outlining<br />

his vision for solutions to the<br />

ongoing crisis. This theatre is<br />

sponsored by ACO.<br />

Academics, designers and innovators<br />

will gather in Building<br />

Health & Wellness theatre to<br />

discuss the ways which light,<br />

air, heat and space can be<br />

controlled for cities of the next<br />

generation, from the likes of<br />

the Mack, the Bartlett, Buro-<br />

Happold, Hoare Lea and the<br />

RIBA Ambassador on Climate<br />

Change: Lynne Sullivan OBE.<br />

The debate gets technical in<br />

the Offsite & Modular<br />

36<br />

www.insulatemagazine.co.uk

www.insulatemagazine.co.uk<br />

Construction theatre, with<br />

Aukett Swanke outlining how<br />

they are using the disruptive<br />

technology of offsite manufacture<br />

techniques to reshape<br />

projects for the future and<br />

Hawkins\Brown will explain<br />

the prefabricated construction<br />

methods that were essential<br />

for Crossrail.<br />

Sponsored by Nudura, the<br />

Materials & Systems Innovation<br />

theatre will explore future materials,<br />

such as bio-responsive<br />

stone, a material that absorbs<br />

water and grows moss; mushroom<br />

mycelium structures; urban<br />

balcony farms; and interactive<br />

coastal monitoring and<br />

management systems. BIG will<br />

reveal their unique approach to<br />

architectural conundrums, the<br />

first such talk from the London<br />

studio, and the Soane Museum<br />

will team up once again<br />

with ScanLAB to explore one<br />

of London’s greatest architectural<br />

masterpieces through the<br />

lens of virtual reality.<br />

BRE will also be running their<br />

thought leadership conference,<br />

BIM Prospects, exploring the<br />

approaches that educators<br />

and training providers are<br />

taking to provide the knowledge<br />

and skills needed to take<br />

forward BIM in the world of design<br />

and construction, as well<br />

as showing how BIM can help<br />

architects better engage with<br />

construction suppliers and<br />