Insulate Magazine Issue 13

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The only independent<br />

insulation industry<br />

trade magazine<br />

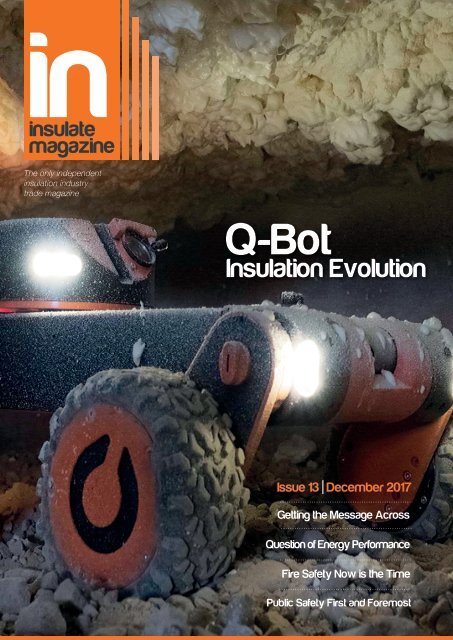

Q-Bot<br />

Insulation Evolution<br />

<strong>Issue</strong> <strong>13</strong> | December 2017<br />

Getting the Message Across<br />

Question of Energy Performance<br />

Fire Safety Now is the Time<br />

Public Safety First and Foremost

Published on a monthly basis by Versanta ltd<br />

Corser House, 17 Geen End, Whitchurch, Shropshire, SY<strong>13</strong> 1AD<br />

Call 01948 759 351<br />

Outside of the UK +44 1948 759351<br />

Monday - Friday 9am - 5.30pm<br />

Website: www.insulatenetwork.com<br />

Email: sales@insulatenetwork.com<br />

Q-Bot Insulation Evolution<br />

www.insulatenetwork.com<br />

Contents<br />

6-9<br />

SUBSCRIPTION INFORMATION<br />

Anyone can subscribe for free online at https://insulatenetwork.<br />

com/insulate-magazine-free-subscription<br />

Subscriptions are available around the world free in digital format.<br />

Print subscriptions are available around the world, please call us for<br />

a quote or email us on sales@insulatenetwork.com<br />

Our subscriber list is occasionally made available to very carefully<br />

selected companies whose products or services may be of interest<br />

to you. Your privacy is of paramount importance to us and should<br />

you prefer not to be part of these lists then please email your details<br />

and a short message to sales@insulatenetwork.com<br />

CLASSIFIED ADVERTISING<br />

Rate: No photo classified £25 for 20 words, each additional word<br />

costs £1. All classified advertising must be paid in advance. We<br />

must receive your classified advert at least two weeks prior to the<br />

publication date.<br />

Getting the Message Across 10-<strong>13</strong><br />

Ensuring Insulation Fits<br />

14-16<br />

New Acoustic Stud System 18<br />

The Effects of Hand Arm Vibration 20-22<br />

WE DO NOT ACCEPT PHONE IN CLASSIFIED ADVERTISING<br />

In the first instance, email your advert to sales@insulatenetwork.<br />

com and await your invoice, once payment is received our design<br />

team will clarify the advert insertion with you directly. CLASSIFIED<br />

ADVERTISING APPEARS IN PRINT AND ONLINE. WE ARE NOT<br />

RESPONSIBLE FOR ERRORS AFTER PROOFING AND INSER-<br />

TION.<br />

DISPLAY ADVERTISING.<br />

Contact one of our sales staff to discuss your requirements on<br />

01948 759 351. Publisher reserves the right to reject any<br />

advertising that in its opinion is misleading, unfair or incompatible<br />

with the character of the magazine.<br />

We adhere to the IPSO code of practice for editors. Further information<br />

can be found at www.ipso.org.uk<br />

BACK ISSUES OR REPRINTS<br />

Digital back issues can be foud online at www.insulatenetworkazine.com<br />

For printed editions please email contact@insulatenetwork.com<br />

, there will be a postage charge and handling fee of<br />

£5+VAT for each copy requested.<br />

CIRCULATION<br />

The magazine is sent to 17,000 digitial subscribers per month<br />

Public Safety First and Foremost 23-25<br />

A Question of Energy Performance 28-31<br />

Fire Protection Specialists<br />

33<br />

Broken Housing Market Been Fixed? 34<br />

Fire Safety Now is the Time<br />

36-37<br />

Insulating our Nation's Homes 38<br />

©VERSANTA LTD<br />

No part can be reproduced without the express<br />

permission of the publisher<br />

www.instagram.com/insulatenetwork<br />

www.twitter.com/insulatenetwork<br />

www.youtube.com/channel/insulatenetwork<br />

The Vase Enters Final Phase 39-40<br />

Ecobuild 2018 Preview 42-43<br />

The UK's only dedicated<br />

trade journal for the insulation industry<br />

3

I<br />

S<br />

Colin Heath<br />

Managing Editor<br />

colin@insulatenetwork.com<br />

@colinversanta<br />

Jamie Street<br />

Creative Director<br />

jamie@insulatenetwork.com<br />

@jamieversanta<br />

It has been a turbulent month for us here at <strong>Insulate</strong> <strong>Magazine</strong>.<br />

Despite exhausting every opportunity and resource to deliver the<br />

Insulation Awards in year one, our plans were thwarted.<br />

We apologise to all for the inconvenience caused. It was the hardest<br />

decision for us to make, given the relentless preparations and the<br />

support from the industry.<br />

We will deal with all of the outstanding issues regarding the awards, learn<br />

from the experience and continue to provide the platform to promote the<br />

Insulation Industry<br />

On a positive note, we are proud to bring you another edition of <strong>Insulate</strong><br />

<strong>Magazine</strong>. Including a great feature on Q-Bot with the BBA, Two articles<br />

written by our new Technical Editor, Paul Forrester and excellent contributions<br />

from our regular insulate columnists. With continued industry support<br />

we are looking forward to taking the publication from strength to strength in<br />

2018.<br />

We wish you and your families a pleasant and rewarding festive period, and<br />

look forward to you joining us in the New Year.<br />

Enjoy<br />

P<br />

p<br />

T<br />

d<br />

T<br />

a<br />

b<br />

s<br />

T<br />

a<br />

4<br />

www.insulatenetwork.com<br />

F<br />

e

SIG360 work with us<br />

on site, to ensure we<br />

not only meet our<br />

client’s needs but<br />

exceed them.<br />

NEIL HARRISON<br />

HARRISON PROJECTS<br />

AN SIG CUSTOMER<br />

BUILD YOUR NAME ON US<br />

Providing impartial<br />

product advice<br />

The SIG360 Technical Centre is a service offering from SIG, that focuses on helping customers<br />

deliver energy efficient buildings.<br />

Through an intimate knowledge of building regulations and product performance, brought<br />

about through more than 50 years specialising in the energy efficiency of the fabric of a<br />

building, the SIG360 Technical Centre is able to make cost effective and impartial product<br />

selection to ensure the best energy performance can be achieved.<br />

The service provided includes energy statements, U value calculations , condensation risk<br />

analysis, thermal modelling and SAP assessments leading to EPC certification.<br />

If you are seeking impartial advice on the fabric energy efficiency of your building contact<br />

SIG360 Technical Centre.<br />

For guidance you can trust call 0844 443 0059<br />

email 360enquiries@sigplc.com or visit www.sig360.co.uk<br />

Talk to the SIG360 Technical<br />

Centre at the start of your project<br />

for a 360 o view of cost effective<br />

and energy efficient home building

Cover Story Exclusive<br />

Q-bot<br />

insulation<br />

evolution<br />

Mathew Holloway from innovators Q-Bot talks about their robot for<br />

insulating under floors - and how BBA Certification will help them gain<br />

prominence in the market place.

The only independent insulation industry trade magazine<br />

Q-Bot Insulation Evolution<br />

Mathew Holloway from innovators Q-Bot talks about their robot for insulating under floors<br />

- and how BBA Certification will help them gain prominence in the market place.<br />

Introducing an impressive new product that considerably reduces the cost outlay when people are considering<br />

underfloor insulation. Such an operation traditionally necessitates the complete removal of the<br />

flooring so that insulation materials can be installed and then the floor re- laid afterwards. This can be a<br />

nightmare for Housing Associations commissioning this kind of work as residents often need to be<br />

temporarily rehoused, which amounts to another not inconsiderable cost implication.<br />

Q-Bot Chief Executive Mathew Holloway explains:<br />

“To insulate underfloor space in the UK you need to remove<br />

all carpets and flooring to access the void, then cut<br />

insulation panels by hand between the joists and roll mats<br />

of insulation in between, working to a degree of accuracy<br />

of 1mm, which is really quite difficult. If there are any gaps<br />

left between the insulation and the joists the insulation is<br />

not effective.<br />

“The method is very disruptive and difficult to do well.<br />

And of course, once it’s done you have to put your<br />

home back together and redecorate. It’s usually enough<br />

of a barrier to stop anyone wanting to do it.”<br />

The new procedure takes one or two days at a fraction of<br />

the cost and performs just as well as traditional methods.<br />

This is a particularly welcome innovation for Housing Associations<br />

as it minimises disruption to residents who also<br />

benefit from lower heating bills.<br />

“Specifically, costs are typically half the alternatives and<br />

£150 per year is saved on heating bills. It also reduces the<br />

temperature stratification – the difference from your feet to<br />

your head, creating warm feet, which is a significant factor<br />

in keeping warm.<br />

“An independent case study with the Leeds Beckett University<br />

showed that the heat loss in the building was reduced<br />

by 25% - that’s a huge amount – meaning more<br />

than a quarter of heat loss was from the<br />

floor.”<br />

Another feature of the robot is that it records<br />

the whole process and provides<br />

real time feedback of the thickness of<br />

the insulation, so that the operator can<br />

make sure the job is completed correctly<br />

and the required depth of insulation is<br />

applied. The fact that the process can be<br />

monitored and recorded also incentivises<br />

installers to take pride in their work and<br />

removes the temptation to cut corners.<br />

“Generally, the built environment has got<br />

a problem with accountability and quality<br />

control. The BBA is trying to address this,<br />

and Q-Bot is bringing smarter tools that<br />

8<br />

www.insulatenetwork.com

www.insulatenetwork.com<br />

have quality control built in. Our robot records what<br />

happens using cameras and sensors to build a 3D<br />

map of the void before and after the install. We monitor<br />

the area and depth of insulation, take measurements<br />

during the process, and the installers know<br />

that what they do is being monitored and recorded.<br />

That gives them the motivation to do a better job.<br />

“People can be very negative when it comes to new<br />

technology at first, but eventually they see that this<br />

means they can take pride when working in the built environment.<br />

It allows installers to differentiate themselves<br />

from others and demonstrate they can do a good job.<br />

That philosophy also helped assure the BBA that we<br />

were minimising risk.”<br />

The BBA’s specific focus was to test the polyurethane<br />

foam insulation materials and the spraying process for<br />

efficiency and safety.<br />

“We set up an area in BBA Test Services at Watford to<br />

demonstrate the application process. This was watched<br />

and monitored, with readings taken to see how deep<br />

the insulation was.<br />

“Then the BBA came and visited us to check what<br />

happened onsite. They also came to see our training<br />

and even went and talked to our customers. We went<br />

through a really stringent set of tests.”<br />

BBA Certification is well-known for sealing a new product’s<br />

reputation in the market place, leveraging brands<br />

and providing specifier and consumer confidence.<br />

Mathew explained why the UK’s leading construction<br />

certification body was so important for Q-Bot.<br />

“When you’re a small organisation but one that is rapidly<br />

growing with the potential to change the world and<br />

have a really big impact, you have to make sure you do<br />

everything properly in order to be taken seriously. You<br />

need to punch above your weight. The BBA is a very<br />

well-respected mark and organisation. Audits improve<br />

your control system which gives you a lot of credibility<br />

and helps show customers that there are processes<br />

in place that ensure the quality and scalability of the<br />

service.<br />

“Because this is a relatively new product and solution,<br />

we were unsure as to whether the BBA would even<br />

consider approving something like this as it’s simply<br />

not been done like this before. We are obviously very<br />

pleased that the BBA took it seriously.<br />

“It’s a great relief to finally get our certificate because it<br />

shows the outside world that what we’ve been saying is<br />

true. An independent party is happy to say yes, this is a<br />

process that has quality control built in.”<br />

Q-Bot has been busy all over the south coast, from<br />

Hastings all the way up to the north of Scotland,<br />

through England, Wales and Scotland.<br />

Trials have also been done overseas, in the US and<br />

France. With the blessing of the British Board of Agrément,<br />

this smart little newcomer to the insulation industry<br />

looks set to make its mark in the built environment,<br />

throughout the UK and beyond.<br />

www.insulatenetwork.com<br />

9

Exclusive <strong>Insulate</strong> Column<br />

Getting the<br />

Message Across<br />

In construction marketing, and the marketing of insulation in particular, there’s a popular type of<br />

phrase used in trade press and journal articles. It’s often worded, “ever-increasing building<br />

regulations”, or a close variant on it. But is it the right message to keep shouting? By Paul Forrester.

The only independent insulation industry trade magazine<br />

Exclusive <strong>Insulate</strong> Column<br />

Getting the Message Across<br />

It’s easy to understand the appeal: the wording highlights<br />

the importance of insulation and encourages the reader<br />

to accept manufacturers as the authority on the subject.<br />

There’s an imperative: the reader isn’t as up to date as<br />

they should be, so they should consult the authors to<br />

find out which products can help their current projects<br />

comply.<br />

Looking to the Future<br />

All of which is fine … except that things are fairly static<br />

from a building regulations point of view.<br />

In England and Wales, for example, the U-value targets<br />

for extensions and alterations to existing buildings have<br />

been the same for SEVEN years. Revised standards for<br />

compliance in new-builds were introduced in 20<strong>13</strong> and<br />

2014 respectively, but were still based on a system in<br />

place since 2006.<br />

The biggest change - the introduction of a fabric energy<br />

efficiency standard (FEES) in England - only brought<br />

the country into line with the sort of lower fabric backstops<br />

that had been a hallmark of the Scottish Technical<br />

Handbooks for years.<br />

Updated standards will be introduced across the UK<br />

eventually, but there’s no definitive timetable for revision<br />

- and no reason to make people worry they’re in danger<br />

of not keeping up with something that isn’t here yet.<br />

Known Unknowns<br />

Articles published in the last few editions of <strong>Insulate</strong> have<br />

shown customers already see insulation manufacturers<br />

as the authority. The issue lies in people knowing they<br />

need advice, and understanding the right time to call on<br />

the available expertise. From personal experience in the<br />

last few months, a couple of examples:<br />

- A property developer wanted to know how best to position<br />

insulation in a flat roof extension, and was surprised<br />

to discover his proposed specification was inadequate -<br />

“Oh, is it 0.18 for a roof now?”<br />

- A conversation with a college brickwork lecturer yielded<br />

its own surprises. He thought the U-value currently required<br />

in walls was 0.35 W/m2K, which is the figure given<br />

in Approved Document L 2002.<br />

Fortunately, it was possible to advise on a better flat roof<br />

specification - but how many other developments are under-insulated<br />

despite the static thermal targets for existing<br />

buildings? And what understanding of insulation are<br />

brickwork students gaining if they’re not familiar with the<br />

solutions they should see on site?<br />

The here and now<br />

It’s not preparing for the future that’s the problem, then,<br />

but getting everybody up to speed on the present!<br />

Communicating via traditional construction media will always<br />

have its place but, arguably, its readers generally<br />

know what they need to do to make a project succeed.<br />

On big contracts, workflows are in place to maximise efficiency<br />

and help things flow as smoothly as possible on<br />

the way to completion.<br />

A roofing contractor, for example, knows the specification<br />

and asks their preferred supplier for a price on insulation<br />

to achieve the required U-value. The distributor prepares<br />

a quote and contacts the manufacturer for a calculation<br />

to back it up. Straightforward, job done, several thousand<br />

square metres of roof ready to go.<br />

Of course, the relative simplicity of larger projects pays<br />

for the advice offered to smaller projects. When a client<br />

or builder needs guiding step-by-step, insulation manufacturers<br />

are almost the front line of defence, identifying<br />

issues in design, specification or installation and steering<br />

them in the right direction.<br />

Another example...<br />

If a chain of correspondence between a housing developer<br />

and an Approved Inspector includes a comment from<br />

the latter - “Not much of a link between wall and floor<br />

insulation, so whoever provides the Energy Performance.<br />

12<br />

www.insulatenetwork.com

www.insulatenetwork.com<br />

So how much should manufacturers police the projects<br />

that cross the desks of their technical teams?<br />

Acknowledgement of the issue was a start, but the<br />

words implied no intent to do anything other than have<br />

an Energy Assessor address it via paperwork. There was<br />

no suggestion of attempting to educate the contractor<br />

or have the work rectified, or of helping the developer<br />

understand why the new properties would benefit from<br />

greater attention to detail.<br />

It’s possible the as-built energy performance calculations<br />

showed a detriment to the predicted performance but,<br />

ultimately, the work was likely signed off and the properties<br />

sold, leaving the buyers to suffer cold draughts and<br />

excessive heat loss - something that was almost certainly<br />

not acknowledged during the purchase.<br />

Fighting the Good Fight...<br />

Reading this, there’s a good chance you have examples<br />

of occasions where you’ve witnessed sub-optimal<br />

building work being the rule rather than the exception.<br />

Skills and training in the construction industry are not<br />

up to scratch, but the magic bullet remains elusive.<br />

The Passivhaus Trust recently released a ‘Good Practice<br />

Guide to Insulation’, and the ‘Builder’s Book’<br />

remains available on the Zero Carbon Hub website, but<br />

these are relatively niche outlets for information, that<br />

most people won’t easily stumble upon.<br />

Insulation manufacturers and their trade associations<br />

do genuinely good work lobbying government and<br />

campaigning for better standards in the built environment.<br />

It’s a long term project though, and people need<br />

advice and guidance now.<br />

Start the Debate<br />

If a chain of correspondence between a housing developer and an Approved Inspector includes a comment from the<br />

latter - “Not much of a link between wall and floor insulation, so whoever provides the Energy Performance Certificate<br />

needs to be aware” - is there anything the manufacturer reading it can do?<br />

1<br />

2<br />

3<br />

4<br />

If traditional media isn’t doing the job, does the answer lie in finding ways to better use social media<br />

to reach people?<br />

Perhaps photographic records of projects, even the smallest extension, need to become part of the<br />

evidence base for compliance so there’s no hiding bad workmanship.<br />

Indeed, more examples of both good and bad work should be put in the public domain as a source<br />

of reference.<br />

Rather than rolling out smart meters, maybe energy companies should be obliged to undertake<br />

thermographic surveys so homeowners can see for themselves where their money is going?<br />

<strong>13</strong>

The only independent insulation industry trade magazine<br />

Insulation News<br />

Ensuring Insulation Fits<br />

for Improved Thermal Performance<br />

Buildings are responsible for nearly 50% of the UK’s energy consumption and carbon emissions.<br />

Well-insulated existing and new-build properties will help improve that figure, but only if the insulation<br />

is correctly fitted in the first place. global leaders in PIR manufacture, Recticel Insulation,<br />

provides a guideline to installation practices and techniques in respect of one of the more innovative insulation<br />

products on the market.<br />

A Green Building Council report released earlier this year<br />

revealed 25 million homes need to be refurbished by<br />

2050 in order to meet insulation standards, and achieve<br />

the UK’s pledge to cut carbon emissions by 80%, by<br />

then in line with the 2008 Climate Change Act. Excess<br />

energy used to heat draughty buildings is a major<br />

contributor to the country’s carbon footprint, hence the<br />

need for quality insulation that is fitted to a high<br />

standard. The onus on providing buildings which deliver<br />

in terms of thermal performance will largely fall on<br />

architects, developers and the building industry as a<br />

whole. However, manufacturers can also play their part<br />

by continuing to refine the properties and performance<br />

of ‘fabric first’ materials which are so vital in putting a<br />

thermal seal on the building envelope.<br />

Innovative Solution<br />

Dedicated to raising the standards of insulation<br />

products in the UK, Eurowall + represents Recticel Insulation’s<br />

commitment to PIR innovation to improve a building’s<br />

thermal performance and enhance the comfort and<br />

wellbeing of its occupants. Eurowall + was the first rigid<br />

insulation board to feature a tongue and groove joint on<br />

all four sides. This interlocking feature ensures boards slot<br />

together easily to provide insulation that is solid and airtight<br />

and minimises heat loss caused by thermal bridging,<br />

as well as offering effective protection against elements<br />

such as wind-driven rain.<br />

In the quest for improved energy efficiency, designers can<br />

be left with little option but to increase the thickness of<br />

insulation in a dwelling’s external walls. This additional<br />

insulation can be added internally, externally or within<br />

the cavity, all of which mean that floorplans need to be<br />

enlarged, which for housebuilders can mean smaller<br />

rooms or fewer houses per plot.<br />

Eurowall +, a premium, full-fill cavity insulation board<br />

manufactured from high performance closed cell polyisocyanurate<br />

(PIR) foam, has been developed to allow<br />

designers and housebuilders to maintain traditional build<br />

techniques, without compromise to thermal performance.<br />

It’s resulted in a board that achieves a U-value of 0.18W/<br />

m2K to enable compliance with Part L1A of the Building<br />

Regulations 20<strong>13</strong> in England and Part L1A of the Building<br />

Regulations 2014 in Wales.<br />

Installation Made Easy<br />

Installing Eurowall + couldn’t be easier. To help the<br />

installer fit the boards the right way, there is a different<br />

gas-tight foil-faced finish on each side: one is distinctive<br />

grey alkali-resistant facing for placing against the inner<br />

leaf; where wet cement can affect the foil facing. The<br />

other is a low emissivity multi-layer aluminum facing<br />

which enhances the thermal resistance of the cavity.<br />

In terms of reveals, wall ties continue to be installed at<br />

every second course of blockwork, rather than every<br />

course, as is common practice. Two ties are positioned<br />

within 225mm of the reveal. Corner details are formed<br />

by cutting the boards squarely and closely butt-jointing.<br />

A vertical 300mm wide DPC covers the corner and runs<br />

the full length of the junction. Cavity trays are fitted by<br />

either cutting the insulation at an angle and running a<br />

DPC over the top of it, or using a partial-fill board behind<br />

the section where the DPC is due to be fitted.<br />

14<br />

www.insulatenetwork.com

Case study: Gerrards Cross, Buckinghamshire<br />

Eurowall + was used by Mentmore<br />

Homes in the construction of two energy-efficient,<br />

detached five-bedroom<br />

homes in Gerrards Cross, Buckinghamshire,<br />

valued at £2.5 million each.<br />

The high-quality, traditionally-constructed<br />

homes feature external walls built<br />

using brick/block cavity construction.<br />

Cavity wall is the UK’s most common<br />

method of wall construction for residential<br />

dwellings. For Mentmore Homes,<br />

a significant challenge was to retain a<br />

standard-sized cavity while complying<br />

with the latest Building Regulations.<br />

To maximise the thermal performance<br />

of the external walls without increasing<br />

the width of the 100mm wide cavity,<br />

Mentmore Homes specified Eurowall<br />

+ full-fill insulation. Using this high-performance<br />

PIR insulation board enabled<br />

the developer to meet the thermal performance<br />

required to achieve Building<br />

Regulation compliance.<br />

A total 500m2 of Eurowall + boards<br />

were used in the wall construction<br />

of the two houses. Nicholas Peck,<br />

contracts manager at Mentmore<br />

Homes was impressed with the performance<br />

of Eurowall +: “We wanted to<br />

make the properties as energy efficient<br />

as possible; to make this happen the<br />

best place to start is the insulation,” he<br />

said. “Specifying Eurowall + meant we<br />

didn’t have to increase the size of the<br />

wall cavity and lose space inside the<br />

properties“.<br />

The panel’s interlocking feature was<br />

another element of the product that<br />

Peck says was beneficial: “Eurowall +,<br />

because it slots together so easily will<br />

remain solid and airtight,” he said. “We<br />

required a high-performance product<br />

for this extremely high-profile project<br />

and Eurowall + didn’t disappoint”.<br />

15

Case study: Hedge End, Southampton;<br />

Ludgershall, Andover<br />

Ease of handling and simplicity of installation were just<br />

two of the reasons Foreman Homes selected Eurowall +<br />

to insulate the walls of the homes on two large housing<br />

developments in the south of England. The schemes at<br />

Hedge End, Southampton, and Ludgershall, Andover, together<br />

contain a mix of over 300 plots of social and private<br />

housing; homes vary in size from two- to five-bedrooms.<br />

Mark Kew, a bricklayer with Foreman Homes, applauded<br />

the benefits of using Eurowall +: “In 35 years’<br />

experience in construction, the insulation developed by<br />

Recticel is easy to cut accurately due to the grid printed<br />

on the foil-facing side which makes it easy to install with<br />

minimal waste. I can honestly say our quality and speed<br />

have excelled as a result of its use.“<br />

In total over 15,000m 2 of Eurowall + insulation was installed.<br />

For Foreman Homes, using Eurowall + meant the<br />

homes’ external walls could be built quicker and easier<br />

resulting in a corresponding saving in construction costs.<br />

And, the full-fill insulation’s excellent thermal performance<br />

will mean that residents on both developments will be able<br />

to enjoy their comfortable, energy-efficient dwellings.<br />

As these case studies demonstrate, innovative PIR<br />

products such as Eurowall + contain a host of benefits to<br />

fit the 21st century need for insulation which improves a<br />

property’s thermal performance and speeds-up the overall<br />

construction process. However, for the performance to<br />

match the quality of the product, its installation has to be<br />

correct – hopefully first time.<br />

16<br />

www.insulatenetwork.com<br />

2802 CI

ecobuild<br />

The future of the built environment is here<br />

06-08 March 2018 / ExCeL, London<br />

Timber<br />

Concrete<br />

Infrastructure<br />

Green & Blue<br />

Infrastructure<br />

Offsite<br />

Energy & HVAC<br />

Building<br />

Performance<br />

District Energy<br />

Presenting the futurebuild districts<br />

The ‘must go’ event<br />

in the construction<br />

industry calendar<br />

for forward thinking<br />

professionals and<br />

influencers.<br />

ecobuild 2018 will<br />

present the latest<br />

technology, the freshest<br />

thinking and materials<br />

to keep you at the<br />

forefront of the industry.<br />

The centrepiece will<br />

be the comprehensive<br />

conference programme<br />

curated by top industry<br />

fi gures. Surrounding<br />

this will be a series of<br />

futurebuild districts, each<br />

exploring a di erent<br />

aspect of the built<br />

environment.<br />

Be part of<br />

something<br />

special<br />

+44 (0)20 3011 2540<br />

info@ecobuild.co.uk<br />

www.ecobuild.co.uk<br />

#ecobuild<br />

#ecobuild<br />

/ecobuildnow<br />

/ecobuildnow<br />

/ecobuild_now<br />

ecobuild-uk<br />

SUPPORTED BY<br />

2802 CIAT ad 210x297mm v5.indd 1 20/10/2017 17:46

Ou<br />

...o<br />

pro<br />

King<br />

and<br />

core<br />

0.018<br />

the u<br />

www<br />

The only independent insulation industry trade magazine<br />

Insulation News<br />

Siniat Targets High Rise Multi-Occupancy<br />

with New Acoustic Stud System<br />

An innovative thin partition system from<br />

leading drywall products manufacturer Siniat<br />

is set to help multi-residential developments<br />

increase floorspace while providing high-specification<br />

acoustic insulation.<br />

Resilient Acoustic Stud (RAS) 90 is the newest addition<br />

to Siniat’s specialist stud range, allowing specifiers and<br />

installers to maximise saleable floorspace for both new<br />

builds and refurbishments without compromising<br />

performance.<br />

RAS 90 is capable of exceeding Part E of Building Regulations<br />

for acoustic performance in residential buildings<br />

at a partition width of only 150mm – up to 50mm thinner<br />

than traditional partitions. It is the first product in the RAS<br />

range to be designed specifically for use in the residential<br />

sector, as well as hotels, student accommodation and<br />

change of use projects.<br />

With value in every square metre of living space, RAS<br />

90 increases net internal areas to have a demonstrable<br />

impact on development value. Most recently, Galliard<br />

Homes’ Great Scotland Yard development – a 95,000 sq<br />

ft hotel refurbishment – gained an additional one square<br />

metre per room by switching from a traditional party wall<br />

and external corridor partition to a RAS system.<br />

The stud’s simple design means that frame installation<br />

can be up to 50 per cent quicker than standard systems.<br />

Unlike traditional metal studs, RAS 90 features an inbuilt<br />

visco-elastic acoustic material which prevents airborne<br />

and impact sound from passing through dividing walls,<br />

removing the need for cavities or an acoustic brace.<br />

Lee Hamilton, product manager for Resilient Acoustic<br />

Stud at Siniat, commented:<br />

“RAS 90 is a simple but game-changing innovation for<br />

creating high-performance acoustic partitions. Its unique<br />

design provides a minimum 45 DnTw +Ctr while only<br />

using half the amount of metal needed for a standard<br />

partition, making it thinner, lighter and faster to install than<br />

traditional equivalents.<br />

“In the context of the housing shortage, the design and<br />

construction sectors need to find new ways to speed up<br />

project delivery and maximise space. RAS 90 reduces<br />

installation time while delivering the high acoustic<br />

performance required for modern homes to ensure quality<br />

of life for residents.”<br />

Reflecting Siniat’s commitment to driving technological<br />

innovation in drywall products, RAS 90 has been developed<br />

by the business’ own acoustic engineering team at<br />

its Innovation and Technology Centre in France, which is<br />

managed by parent company Etex Building Performance.<br />

18

www.insulatenetwork.com<br />

Insulation<br />

Our latest arrivals have landed...<br />

...offering you 4 new lower lambda<br />

products to choose from<br />

Kingspan Kooltherm ® K103 Floorboard, K110 and K110 PLUS Soffit Board,<br />

and K118 <strong>Insulate</strong>d Plasterboard feature an advanced, fibre-free insulation<br />

core, enabling them to achieve an outstanding thermal conductivity of<br />

0.018 W/m . K. As a result, the products can enable buildings to be built to<br />

the upper levels of fabric performance with minimal thickness.<br />

Further information on the Kingspan<br />

range is available on:<br />

+44 (0) 1544 387 384<br />

literature@kingspaninsulation.co.uk<br />

www.kingspaninsulation.co.uk<br />

Pembridge, Leominster, Herefordshire HR6 9LA, UK<br />

www.kingspaninsulation.co.uk/lowerlambda<br />

®<br />

Kingspan, Kooltherm and the Lion Device are Registered Trademarks of<br />

the Kingspan Group plc in the UK and other countries. All rights reserved.<br />

insulatenetwork 19

insulate columnist<br />

The effects of Hand-Arm<br />

Vibration (HAV) in the Workplace<br />

<strong>Insulate</strong> <strong>Magazine</strong> columnist George Elliott, a technical specialist at<br />

science-based technology company 3M, explains ways of controlling<br />

HAV exposure levels in the workplace<br />

The repetitive use of power tools when placing insulation into walls, ceilings and thermal<br />

controlled areas exposes personnel to significant levels of Hand-Arm Vibration (HAV), a<br />

health hazard that almost two million people in the UK are exposed to in the<br />

workplace, according to the Health and Safety Executive (HSE).<br />

HAV is the transmission of vibration from a piece of equipment or a tool into the body,<br />

resulting in potential injury and serious health conditions, if used for too long. The most<br />

commonly-associated health risk is hand arm vibration syndrome (HAVS), commonly<br />

manifested in Vibration White Finger, a painful and permanent condition that can<br />

lead to finger numbness, hand tingling and bone cysts.<br />

Users also often complain of a sore sensation and limited movement in the<br />

hands, commonly diagnosed as carpal tunnel syndrome. This<br />

musculoskeletal problem reduces the sufferer’s ability to manipulate<br />

objects.<br />

HAV damage is detrimental and irreversible, yet entirely preventable.<br />

Employers have a duty of care to their workforce, to ensure that<br />

they have adequate protective measures in place to control<br />

excessive HAV exposure.<br />

For this reason, the Control of Vibration at Work Regulations<br />

states a need for HAV-related risk assessments and requires<br />

consequential measures to be put in place to control such exposure.<br />

Continues page 20...<br />

20

21

www.insulatenetwork.com<br />

The importance of risk assessment<br />

According to the HSE, a good power tool supplier<br />

should recommend a range of appropriate tools and<br />

include vibration design information. In addition,<br />

they should provide a clear description of the vibration<br />

risk of each tool and instructions on how to safely use it.<br />

Although all vibrating tool manufacturers are required to<br />

provide figures quantifying each tool’s vibration HAVS<br />

level, a full assessment is still crucial. This is because a<br />

manufacturers’ figures are typically generated using a<br />

standard test carried out on a flat panel with new<br />

machines.<br />

The only way to realistically conclude values for each<br />

working condition is to measure vibration in<br />

the environment that the tool will be used, using the<br />

actual tool, substrate and abrasive.<br />

A competent person within the company should<br />

measure each tool’s vibration level using the HSE’s<br />

purpose-built calculator, available from:<br />

http://www.hse.gov.uk/vibration/hav/information.htm.<br />

However, the testing equipment can be expensive, so<br />

smaller businesses may wish to use an independent<br />

company. Even for larger organisations, this can provide<br />

extra peace of mind. Because the effects of HAV are<br />

cumulative, the calculator gives the total length of time<br />

that a vibrating tool can be safely used for by any single<br />

person over the course of a day, even with breaks.<br />

How much action is required?<br />

The level of activity that employers need to take is<br />

determined by the Control of Vibration at Work Regulations.<br />

This depends on two different values – the<br />

exposure action value (EAV) and the exposure limit value<br />

(ELV). The EAV is 2.5m/s2 (equal to 100 points on the<br />

HSE calculator). The ELV is 5m/s2 (or 400 points).<br />

These figures relate to an eight-hour period during a<br />

single working day. If a tool’s vibration level is less than<br />

the EAV over an eight-hour period, it can theoretically be<br />

used for eight hours a day.<br />

vibration to the lowest level reasonably practicable,<br />

doing likewise for the exposure level if it is above the<br />

EAV. In any workplace where employees are exposed<br />

to HAV, employers must provide access to a competent<br />

occupational physician to receive detailed feedback<br />

about each individual, regularly monitoring and<br />

reporting any confirmed cases HAVS or carpal tunnel<br />

syndrome through the Reporting of Injuries, Diseases<br />

and Dangerous Occurrences Regulations 20<strong>13</strong><br />

(RIDDOR).<br />

Taking Action to Reduce HAV Exposure<br />

Employers can place stickers on tools explaining how<br />

long they can be used for or use tool timers, which<br />

measure how long the tool has been used for and sound<br />

an alert when the limit is reached.<br />

A company can also use alternative, non-vibrating<br />

methods where possible; automating tasks; using jigs,<br />

clamps or rotating work involving vibrating tools between<br />

several workers. Using a tool with a lower vibration<br />

measurement or a smart sensor can also help.<br />

Personnel should be trained to not hold vibrating tools<br />

too tightly; use lower<br />

speed settings; ensure<br />

tools are properly<br />

stored and maintained;<br />

and check<br />

them before use.<br />

HAV exposure is not<br />

limited to the workplace<br />

- DIY tools<br />

used outside of work<br />

can also contribute.<br />

Although out of the<br />

employer’s control,<br />

HAV risk should be<br />

communicated to<br />

employees, nonetheless.<br />

For more information, visit www.3M.co.uk/safety.<br />

Once the EAV is exceeded, employers must demonstrate<br />

that significant health surveillance is being undertaken,<br />

along with measures aimed at reducing exposure<br />

to the lowest possible level.<br />

If the exposure level surpasses the ELV, the operator<br />

must immediately stop using tools likely to cause vibration.<br />

The employer must then reduce the risk from<br />

22 www.insulatenetwork.com

The only independent insulation industry trade magazine<br />

<strong>Insulate</strong> insulate Columnist columnist<br />

Hackitt Review Must Put Maximum<br />

Public Safety First and Foremost<br />

Sarah Kostense-Winterton Executive Director, MIMA<br />

With the Hackitt interim report expected before Christmas, we all have high hopes for<br />

Dame Judith’s independent review. What is clear is that we simply cannot and must not<br />

compromise on public safety.<br />

As the organisation representing the non-combustible insulation manufacturers, MIMA is firmly supportive<br />

of the scope of the Building Regulations review but believes we need to be more stringent, albeit<br />

prescriptive with particular attention being given to all mid- and high-rise, sensitive and high occupancy<br />

buildings such as schools, hospitals and care homes.<br />

Fit for purpose?<br />

We need to go wider with a review that fully considers<br />

the implications for fire safety in technology advances.<br />

Current developments in technology mean it is perfectly<br />

practical to track a product from factory to installation<br />

while keeping a digital record of what the product characteristics<br />

are. A record for current and future building<br />

occupants.<br />

We should consider whether wider testing methodologies<br />

are fit for purpose. Specifically focusing on whether the<br />

testing regimes applying in all buildings are only testing a<br />

perfect installation rather than a ‘real world’ one.<br />

Current regulations are ambitious<br />

Currently ‘guidance’ for facades in buildings over 18m<br />

high sits in multiple documents with Approved Document<br />

B referencing a variety of supporting documents which<br />

don’t lead to clear guidance on what is or isn’t permitted.<br />

To offer maximum public safety, the approved document<br />

should offer the only point of reference and the only permissible<br />

routes to compliance should be the use of Euroclass<br />

A1 or A2 rated products on facades which should<br />

be clearly set out in a redrafted Approved Document B.<br />

That redrafting should also clearly set out that Approved<br />

Document B is the only acceptable route to compliance<br />

Routes to compliance<br />

Approved Document B is not the only means to<br />

compliance with the Building Regulations – other bodies<br />

are permitted to publish their own guidance on how the<br />

regulations can be met. This has led to industry bodies<br />

publishing their own guidance on BR<strong>13</strong>5 – these guides<br />

both contained four routes to compliance including<br />

desktop studies, which allow for combustible materials to<br />

be used without even being tested.<br />

There is substantial confusion within the industry and even<br />

amongst fire experts about what the official regulations do<br />

and do not state – many are under the false impression<br />

that the oft-quoted ‘four routes to compliance’ are in ADB<br />

or BR<strong>13</strong>5, when they are not.<br />

Only specifying either A1 or A2 Euroclass products / systems<br />

can ever offer certainty to occupants that the façade<br />

will offer the maximum protection against fire. All other<br />

routes permit human error or judgement in to the system.<br />

Classification<br />

References in Approved Document B to national fire<br />

classifications such as “Class O” alongside Euroclasses<br />

than is actually the case. Similarly, marketing terms such<br />

as “fire retarded”, “fire safe” and “non-flammable” are<br />

www.insulatenetwork.com<br />

23

www.insulatenetwork.com<br />

frequently used to describe the reaction to fire properties<br />

of materials which are classified as combustible.<br />

The difference between combustible and non-combustible<br />

materials is an extremely significant distinction which<br />

must not be blurred. Combustible materials contain considerable<br />

fuel loads which contribute to the spread of fire.<br />

Non-combustible products cannot contain significant<br />

quantities of combustible materials, including any glues<br />

and binders, as this would prevent them from achieving a<br />

non-combustible classification. Fact.<br />

Building regulations must offer greater assurance of fire<br />

safe performance for occupants of both residential and<br />

non-residential buildings over 18m. With the health of<br />

building occupants, a priority, the smoke toxicity of construction<br />

products must be tested, classified and labelled<br />

to provide important information to consumers and made<br />

a key component within Approved Document B.<br />

The Euroclass system should be the only classification<br />

system referenced in a redrafted Approved Document B.<br />

All reference to the British Standard (BS) ‘Class O’ should<br />

be removed as this adds ambiguity and uncertainty of interpretation.<br />

Testing Methods<br />

No modelling available can ever genuinely replicate the<br />

behaviour of a fire in a complex building in the real world<br />

while no fire test on a perfect installation can ever replicate<br />

fire behaviour in buildings that have received real world<br />

installation practices.<br />

Desktop Studies<br />

There are serious concerns about the validity and accuracy<br />

of probability-based calculations for both desktop<br />

studies and fire safety engineering and little to no experience<br />

is available today to show that buildings assessed<br />

using Fire Safety Engineering have performed as predicted<br />

during a fire.<br />

Desktop studies do not produce a reliable indication of fire<br />

performance. These generalised assessments can do little<br />

more than guess at how combustible materials might behave<br />

in a fire on an unspecified building. The acceptance<br />

of these studies has promoted a light-touch approach.<br />

24

The only independent insulation industry trade magazine<br />

BS8414 Test<br />

Even passing a full BS8414 test does not necessarily indicate<br />

that a system would provide adequate resistance<br />

to a real-life fire and do not reflect common installation<br />

issues in the market, as recognised in the Each Home<br />

Counts Review.<br />

Testing regimes must be continually reviewed to keep<br />

pace with construction practices as well as to ensure the<br />

process is sufficiently robust. The BS8414 test should be<br />

updated to reflect real life construction features such as<br />

windows and vents and the communication of test results<br />

based on perfect laboratory conditions must highlight<br />

the limitations of these tests in terms of predicting<br />

real life performance as highlighted by the Fire Protection<br />

Association.<br />

Given the fatal danger of toxic smoke, material testing<br />

and classification should be introduced for toxicity. These<br />

products must then be labelled and regulated accordingly.<br />

new guidance will tackle policing and sanction should<br />

also be clearly set out. No one can disagree that sanctions<br />

must be meaningful, tough and properly enforced.<br />

MIMA believes that public safety is paramount and we<br />

can be instrumental in developing a comprehensive fire<br />

risk analysis for both existing and new buildings. However<br />

Dame Judith must recommend the right framework<br />

to ensure we can deliver maximum safety for the general<br />

public across the UK.<br />

MIMA’s submission to the Hackitt Review can be found<br />

here at http://mima.info<br />

Sarah Kostense-Winterton is Executive Director of MIMA,<br />

the Mineral Wool Insulation Manufacturers Association and provides<br />

the secretariat to the Energy Efficiency Infrastructure Group<br />

(EEIG). For further details of the EEIG or if you would like to<br />

join, please contact Sarah at sarah@mima.info<br />

Enforcement<br />

Finally, compliance clearly needs to be policed while sanctions<br />

for non-compliance robust. Approaches on how any<br />

25

IMPROVEMENTS<br />

IN SAP* FROM<br />

USING THE<br />

HYBRID SYSTEM<br />

RESULTED IN<br />

LOWER PROJECT<br />

COSTS<br />

Peter Dawson, Housebuilder<br />

HYBRID INSULATION - TOGETHER FOR THE FUTURE<br />

HCONTROL HYBRID<br />

HYBRIS<br />

BOOST’ R HYBRID<br />

We know that making SAP improvements is<br />

high on your agenda. We also understand<br />

that minimal insulation thickness can help you<br />

to reduce overall project costs. So we have<br />

good news. The reduction in thermal bridging<br />

achieved by our Hybrid range is producing<br />

up to 15% SAP improvement*, proving that<br />

savings can be made on the DER vs TER<br />

without compromising on space.<br />

All Hybrid products can be used in walls and<br />

roofs, separately or together, to provide a high<br />

performance, total insulation system. They are<br />

certified to harmonised standards by accredited<br />

bodies, are CE marked and have LABC and<br />

NHBC acceptance acceptance when used in<br />

accordance with the certification.<br />

Each Hybrid product combines both insulation<br />

and airtightness properties:<br />

<br />

<br />

<br />

HControl Hybrid, a thin multifoil insulation<br />

product with a built-in vapour control function<br />

and an unrivalled thermal performance.<br />

, an innovative reflective insulation<br />

product providing an excellent thermal<br />

performance.<br />

R Hybrid, a thin multifoil insulation<br />

product with a built-in breather membrane<br />

function and an exceptional thermal<br />

performance.<br />

*as calculated over a standard house using Hybrid model<br />

junctions compared with default junction heat losses

The UK's Only Exhibition<br />

Dedicated to the Insulation Industry<br />

Showcasing the latest insulation innovations, perspectives & expertise<br />

18th & 19th June 2018 | EMCC Nottingham<br />

Register for your free visitor ticket<br />

Book your exhibitor space<br />

www.insulationexpo.co.uk<br />

@insulationexpo

Exclusive <strong>Insulate</strong> Column<br />

A Question<br />

of Energy Performance<br />

Insulation manufacturers sell quality products designed to make people more comfortable in<br />

their homes and reduce their energy bills - but is the message getting through? And what will<br />

it take for home buyers and tenants to ask different questions? by Paul Forrester.

The only independent insulation industry trade magazine<br />

A Question of<br />

Energy Performance<br />

A friend and I recently went walking<br />

in the Peak District. It was bright and<br />

sunny - a perfect November day for<br />

exploring the Pennine Way - albeit<br />

cold, particularly in the wind. Our<br />

route took us through the village of<br />

Edale, passing picture-perfect stone<br />

cottages. Outside one home, a man<br />

in overalls was attacking a<br />

rigid insulation board with a saw.<br />

Not in a frenzied sort of way, I should<br />

make clear! In fact, he was being very<br />

precise about it. He’d already cut a<br />

couple of letterbox-sized holes right<br />

through the board, and was setting<br />

about removing further sections of<br />

insulation to around half the depth of<br />

the board.<br />

“I want to know how that insulation’s<br />

going to be used!” I muttered, fighting<br />

the temptation to go over and<br />

make a polite enquiry.<br />

Most likely, it needed to accommodate<br />

some service penetrations and<br />

a few lumps and bumps in whatever<br />

bit of the structure it was going to be<br />

fixed to. Trouble is, the holes would<br />

introduce significant cold bridges,<br />

and the half-cut sections would<br />

worsen the insulation’s thermal conductivity.<br />

Other software will display it<br />

differently, but the important thing is<br />

knowing what to look for.<br />

The Heating’s On<br />

I reconciled my lack of investigative skills with an awareness<br />

that I might have started ‘preaching’ to the guy<br />

about how he was ruining the product’s performance,<br />

and so we continued walking.<br />

Inspired by this turn of events, a new topic of conversation<br />

arose: “These last few weeks, I’ve had to have the<br />

heating on,” my friend bemoaned. He’d only been in his<br />

new flat for a couple of months - his first taste of home<br />

ownership - and was encountering low temperatures for<br />

the first time. “I can’t not have the heating on.”<br />

“To feel comfortable?” I added, to confirm my<br />

understanding that he isn’t a Dickensian miser who’d<br />

huddle around a single candle if it was an option.<br />

At which point he asked a question that too few<br />

people consider when looking at property: “Why don’t<br />

they give more information about the energy efficiency of<br />

properties?”<br />

“Who’s ‘they’? Who do you wish you’d had more<br />

information from?” I asked with genuine interest.<br />

“The sellers? The estate agents?” he suggested,<br />

launching us into a wide-ranging conversation about the<br />

cost of energy and fuel poverty, among other topics.<br />

Property performing properly<br />

It brought to mind the fact that, since early 20<strong>13</strong>,<br />

advertisements for property being sold or let have been<br />

required to include the energy rating of the property. It<br />

also brought to mind the time I was told, anecdotally, that<br />

many estate agents advise customers, “nobody takes<br />

any notice of EPCs anyway”.<br />

Encountering apathy on that scale is dispiriting, but what’s<br />

even more dispiriting is accepting there might be logic<br />

behind it. For existing properties, an EPC is based on a<br />

visual survey and records of work carried out to improve<br />

the property. It doesn’t allow for the quality of the work<br />

being undertaken.<br />

If the cottage we walked past is put up for sale or rent,<br />

an Energy Assessor will compile the specification and<br />

include for insulation of a particular thickness and<br />

performance, installed to an assumed standard.<br />

30<br />

www.insulatenetwork.com

The assessment isn’t sophisticated enough to reflect the<br />

impact of insulation boards being modified to accommodate<br />

services or irregular building fabric.<br />

Where improvements are suggested, they’re not always<br />

feasible, leading the authority of EPCs to be questioned.<br />

An ex-colleague was once advised to consider ground<br />

floor insulation to improve the energy rating of his home.<br />

He’d have had to dig up the floor of every room, since<br />

there wasn’t enough height to accommodate insulation<br />

over the existing structure.<br />

Hardly a practical suggestion, and indicative of the issues<br />

many properties will face when trying to improve<br />

occupant comfort.<br />

Short-term thinking<br />

SAP calculations, for example.<br />

On a more optimistic note,<br />

if the new requirement is<br />

communicated well then<br />

it might encourage more<br />

tenants to ask the same<br />

question my friend did. If that<br />

gives television producers reason<br />

to change what they put on our<br />

screens, or estate agents to offer<br />

more informative advertisements, then<br />

we could start to find ourselves on<br />

the righttrack.<br />

As property prices have ballooned and escaped the<br />

grasp of more and more first-time buyers, estate agent<br />

adverts seem increasingly targeted at those who can<br />

afford to add to an existing property portfolio. Seeing<br />

property as an investment is nothing new, of course,<br />

but the effective retrofit of properties is becoming an<br />

urgent consideration - and one that is not effectively<br />

communicated to buyers or renters.<br />

Television programmes like Homes Under the Hammer<br />

only encourage this trend, focussing on quick turnarounds,<br />

rental yields, and aesthetics and surface sheen.<br />

On one episode, the person renovating a house decided<br />

to keep it for their daughter to live in. “We’ve taken a<br />

bit more time over it than normal,” he said, admitting he<br />

only aimed for a better standard of work after deciding<br />

his family would enjoy the benefit of it.<br />

While it might be idealistic to expect everybody to buy<br />

in to relatively distant aims like carbon reduction targets<br />

in 2050, the casual acceptance of such complacency<br />

on a popular daytime programme only makes the<br />

retrofit challenge harder, not easier.<br />

A New Direction?<br />

Between now and 2020, new legislation will make<br />

landlords more responsible for better comfort and lower<br />

energy bills for tenants. Rental properties will have to<br />

meet a minimum EPC rating of E, and it will be interesting<br />

to see what impact such a requirement has.<br />

demonstrate compliance, or risk losing work to those<br />

who will - especially when other anecdotal evidence<br />

suggests this has been known to happen with as-built<br />

31

Spray Foam’s<br />

Biggest Event is Back<br />

… with Keynote Speaker, Jeff Havens!<br />

2018 CONVENTION & EXPO<br />

January 29 – February 1<br />

Mobile, Alabama<br />

Uncrapify Your Life!<br />

With all the entertainment of a comedy show, Jeff Havens will<br />

lead us in the most hilarious communication and teambuilding<br />

keynote. Prepare to learn and laugh in equal measure!<br />

Join the Who’s Who in Spray Foam for:<br />

• Four Days of Educational Sessions<br />

• The Industry Excellence Awards<br />

• Annual Golf Tournament<br />

• Professional Certification Programs and Testing<br />

• A 50,000 Square Foot Exhibit Hall<br />

• VIP Events<br />

• And More!<br />

Network with the Best in the Business.<br />

Don’t miss it!<br />

thesprayfoamshow.com • sprayfoam.org/expo

The only independent insulation industry trade magazine<br />

Insulation News<br />

SIG Fire Protection Specialists Increase<br />

Client Service Capabilities Across UK<br />

SIG Fire Protection Specialists attain FSIDip<br />

status to increase client service capabilities across UK<br />

The specialist SIG fire protection service has<br />

been developed; with six members of the<br />

national team receiving an industry<br />

accredited Fire Stopping Inspection Diploma. The<br />

SIG team receiving the qualification is the largest<br />

and most experienced dedicated Fire Protection<br />

team working across the UK.<br />

The SIG Fire Protection Specialists offer expert advice to<br />

customers installing fire protection materials, in what is<br />

a complex and challenging area, especially as now it is<br />

under increased scrutiny.<br />

SIG’s dedicated team of Fire Protection Specialists provides<br />

customers with early engagement and advice on<br />

Fire Protection and Fire Stopping for a range of new build<br />

and refurbishment projects. Six members of the team,<br />

Shaun Hugill, Lee Bentley, Aaron Gardiner, Jon Scott, and<br />

Dave Steel, as well as National Manager Nigel Gillingham,<br />

have all studied and received the Fire Stopping Inspection<br />

Diploma, recognised and accredited by The Institute of<br />

Fire Safety Managers and Institution of Fire Engineers.<br />

Due to the complexity of fire protection, detailed<br />

information such as scope of application, fire tests and<br />

assessment reports are needed, as they allow robust<br />

product selection to complement all the other<br />

construction systems and interfaces in each application.<br />

This diploma provides each member of the SIG Fire<br />

Protection Specialist team with knowledge of material<br />

technical documents, and the latest methods of best<br />

practice.<br />

Nigel Gillingham, National Manager, comments:<br />

“SIG is committed to investing in our people to raise<br />

knowledge and consistently improve skills and available<br />

expertise. This has given us a proven level of competency,<br />

and we are the go-to people for all fire stopping and<br />

protection, with representation in every region of the UK.<br />

“This diploma applies a different perspective for the Fire<br />

Stopping activities we undertake; on our responsibilities;<br />

the responsibilities others have for Fire Stopping; our responsibilities<br />

to be accurate in our understanding and our<br />

knowledge, and our communication in the high risk, high<br />

liability Fire Stopping arena.<br />

“I am extremely proud of the team’s enthusiasm whilst<br />

undertaking this course, and proud that each member of<br />

the team passed with flying colours.”<br />

L-R: Nigel Gillingham, Shaun Hugill, Jon Scott,<br />

Aaron Gardiner, Dave Steel and Lee Bentley<br />

33

The only independent insulation industry trade magazine<br />

<strong>Insulate</strong> Columnist<br />

Has the Broken Housing<br />

Market Been Fixed?<br />

Simon Storer, Chief Executive of Insulation Manufacturers Association (IMA)<br />

The announcement in the budget last week of a package of housing measures totalling around £44bn<br />

was welcome news for everyone in the construction industry. But will this really deliver on the<br />

Government’s promise to fix our broken housing market?<br />

Certainly scrapping stamp duty for properties under the £300,000 threshold for first time buyers is good news for the<br />

consumer but we need to be sure that when they invest in their new home that they are getting a property that is fit<br />

for purpose. This means being able to buy a home with confidence that has been properly built by a skilled workforce<br />

and that lives up to current energy efficiency regulations, otherwise any cost savings on stamp duty will be negated by<br />

higher running costs for the building over its lifetime.<br />

It is also good to see that there will be a review on the<br />

controversial topic of ‘land banking’. With claims from<br />

large builders on the one hand that planning issues are<br />

the real cause of the problem and claims from others that<br />

speed of build is being deliberately slowed down to push<br />

up house prices, it will be good to get some clarity from<br />

Oliver Letwin on this so that building can proceed at the<br />

ambitious rate demanded. The announcement that<br />

support to unlock smaller sites and identify brownfield sites<br />

to allow SME builders to build 40,000 new homes is great<br />

news for the construction industry but again we need a<br />

skilled workforce to deliver on this.<br />

With around £34 million promised to develop construction<br />

skills across the country, we need to be sure that we get<br />

the skills training in place ahead delivery of the ambitious<br />

target of 300,000 new homes a year, otherwise the<br />

construction industry is setting itself up for failure and<br />

consumers will lose confidence.<br />

Building 300,000 new homes a year is certainly an<br />

ambitious target and a pledge that we have heard numerous<br />

times before but we need to ensure that all new<br />

homes can live up to the expectations of those living in<br />

them or aspiring to live in them. Will that happen? Let’s<br />

wait and see.<br />

For more information about<br />

Insulation Manufacturers Association please visit:<br />

www.insulationmanufacturers.org.uk<br />

34<br />

www.insulatenetwork.com

The only independent insulation industry trade magazine<br />

<strong>Insulate</strong> Columnist<br />

Fire Safety: Now is the Time<br />

for Architects to Take Back Ownership<br />

Duncan Voice, Store Manager, Insulation Superstore, outlines why architects need to learn a valuable lesson from<br />

the Grenfell Tower tragedy and take back control of specification.<br />

In the wake of the Grenfell tower tragedy, there has been a dramatic shift in attitudes towards the role<br />

of architects within construction. The avoidable disaster has forced the industry to take design quality<br />

more seriously, whilst also demonstrating how high-quality build specifications can not only protect<br />

occupants, but save lives.<br />

A post-Grenfell review is currently underway, spearheaded<br />

by the Department for Communities and Local Government<br />

(DCLG), with RIBA also calling for a comprehensive<br />

reappraisal of Approved Document B and related fire<br />

standards. Although the official outcome is still yet to be<br />

determined, there will undoubtedly be a focus on the fact<br />

that components such as cladding, insulation and fixing<br />

methods must be considered holistically as part of a robust<br />

fire safety build strategy.<br />

Traditionally, architects have always played a significant<br />

role in the specification of materials; however, the rise of<br />

complex ‘design build’ contracts is increasingly leaving<br />

them powerless within the construction supply chain -<br />

with no say or input on budget cuts or the substitution of<br />

cheaper alternative products.<br />

Following Grenfell, it is crucial that architects become<br />

leaders on fire safety, as well as taking responsibility for<br />

their specifications, considering the impact of individual<br />

components across an entire build while future proofing<br />

their designs by using non-combustible materials. This is<br />

an issue focused on care, protection and long-term build<br />

performance, working to ensure tragedies like Grenfell do<br />

not happen again.<br />

Vital Lesson<br />

A critical factor in the failure of Grenfell was the cost saving<br />

substitution of an FR grade aluminium composite material<br />

cladding for an unrated grade with a polyethylene<br />

core, which has since proved combustible in Government<br />

tests. In addition, the synthetic insulation used on<br />

the building was made from polyisocyanurate, which is<br />

known to burn when exposed to heat. Initial reports from<br />

the disaster also revealed that the insulation chosen for<br />

the £10m tower refit was acceptable for use on tall buildings,<br />

but only when combined with incombustible cement<br />

panels.<br />

Individually, both the cladding and insulation materials can<br />

prove problematic, but when used together, they can be,<br />

and were, catastrophic. Detailed analysis of public documents<br />

has also revealed a complex chain of contractors<br />

and sub-contractors, which has raised the question of<br />

who was ultimately responsible for fire safety during the<br />

refurbishment.<br />

95% of buildings screened and covered by the recent<br />

Government BS8414 testing program failed to meet current<br />

fire safety standards, indicating that ambiguity and<br />

confusion is still prominent across the industry. There are<br />

two major fire components of fire safety to consider; stopping<br />

fire ignition and intensity, as well as preventing it from<br />

spreading. These are essential factors when focusing on<br />

a building’s exterior envelope, with all components of a<br />

wall contributing to its fire performance.<br />

A New way Forward<br />

In the past, architects have been able to ensure that<br />

specified materials were used as part of a unified design<br />

strategy. However, facing increasing industry pressure<br />

to cut costs, this isn’t the reality with performance<br />

specifications enabling alternative materials to be used -<br />

often selected by the developer, contractor or sub-contractors.<br />

This shift in build processes has meant that<br />

during construction there is no longer a single appointed<br />

36<br />

www.insulatenetwork.com

www.insulatenetwork.com<br />

professional who is responsible for ensuring that the<br />

specified materials perform when placed under pressure<br />

from potential risks such as fire, heat and smoke.<br />

Designers now need to take responsibility for any<br />

non-standard build slip ups. This includes understanding<br />

how materials work together in a more holistic way, as well<br />

as their influence on key build factors such as fire safety,<br />

attention to detail, environmental impact and workmanship.<br />

Informed specification decisions should be based<br />

on not just budget requirements or their performance in<br />

isolation, but on how components interact across the entire<br />

build and with each other.<br />

Getting Serious<br />

Architects play a vital role in ensuring tragedies like Grenfell<br />

do not happen again, making fire safety not just an<br />

extra consideration but instead a vital component in the<br />

early design stages. This is essential when protecting<br />

a building’s exterior, evaluating and selecting products<br />

based on their behaviour with other structural elements,<br />

the surrounding environment and its occupants.<br />

For example, if a non-combustible insulation product cannot<br />

be applied uniformly across a façade, it is the architect’s<br />

responsibility to ensure the implementation of cavity<br />

barriers to stop, or at least slow fire spreading. Non-combustible<br />

insulation can also provide an element of building<br />

preservation during fires, offering an extra opportunity to<br />

protect its inhabitants.<br />

This is supported by recommendations from RIBA, which<br />

has advised that architects should act as a single point<br />

of responsibility from project conception to completion,<br />

as this would prevent key specification decisions (such<br />

as the use of fire-retardant cladding) being transferred to<br />

contractors during the build process. It would also mean<br />

that the materials specified not only work together cohesively<br />

as part of a wider fire safety strategy, but that they<br />

are also correctly installed and maintained to regulatory<br />

standards.<br />

Whilst reviews and investigations are still ongoing, there<br />

is no doubt that fire safety regulations and standards will<br />

become more stringent, and undoubtedly architects will<br />

be expected to play a greater role within not just design,<br />

but also construction. Designers now have the opportunity<br />

to educate developers and contractors on the importance<br />

of incorporating high quality specifications and<br />

fire protection measures into building design at an early<br />

stage. Whilst budget cuts are unlikely to be eradicated<br />

overnight, Grenfell serves as a lesson to all those within<br />

the industry on how cost cutting can potentially cost lives.<br />

www.insulatenetwork.com<br />

37

The only independent insulation industry trade magazine<br />

<strong>Insulate</strong> Columnist<br />

Insulating Our Nation's Homes<br />

Neil Marshall, Chief Executive, National Insulation Association (NIA)<br />

Household Energy Efficiency Statistics published by Government last week identified that whilst there<br />

has been considerable progress in insulating homes across Great Britain there is<br />

still allot more to be done.<br />

The figures identified that nearly 16 million homes in the<br />

UK have only 125mm or less of existing loft insulation<br />

compared to the current standard of 270mm. These<br />

properties would certainly benefit from topping up.<br />

There are still over 5 million homes with cavity walls that<br />

are not insulated andvonly 718,000 which equates to just<br />

8% of the 8.5 million homes with solid walls have been<br />